-

Instruction manual AutoChief C20

AA-00391-A

AutoChief C20

Instruction Manual

MAN B&W ME Engines

Controllable Pitch Propeller installation

-

Instruction manual AutoChief C20

AA-00391-A

-

Instruction manual AutoChief C20

AA-00391-A

Revisions

Written by Checked by Approved by Rev. Date Sign. Date Sign.

Date Sign.A 06.10.2004 T 31.01.2005 SM 31.01.2005 SM B C D

Document history

Issue No. ECO No. Paragraph No. Paragraph Heading / Description

of changeA AAE-000164 First Issue

The information contained in this document is subject to change

without prior notice. Kongsberg Maritime AS shall not be liable for

errors contained herein or for incidental or consequential damages

in connection with the furnishing, performance, or use of this

document. 2005 Kongsberg Maritime AS. All rights reserved. No part

of this work covered by the copyright hereon may be reproduced or

otherwise copied without prior permission from Kongsberg Maritime

AS.Bekkajordet P.O.Box 1009N-3194 Horten,Norway

Kongsberg Maritime AS

Telephone: +47 33 03 20 00Telefax: +47 85 02 80

28www.kongsberg.com -

Instruction manual AutoChief C20

AA-00391-A i

Table of contents

1 INTRODUCTION

…………………………………………………………………………………………………………….12 FUNCTIONAL

DESCRIPTION………………………………………………………………………………………..22.1 REMOTE CONTROL SYSTEM FUNCTIONAL

DESCRIPTION……………………………………………………2

2.2 AUTOCHIEF CONTROL PANEL

(ACP)…………………………………………………………………………..52.2.1 LCD

Display………………………………………………………………………………………………………….6

2.2.2 Cancel functions

…………………………………………………………………………………………………….7

2.2.3 Alarm Acknowledge and in command

functions………………………………………………………….7

2.2.4 Multifunctional

knob……………………………………………………………………………………………….82.3 AUTOCHIEF COMBINED LEVER AND TELEGRAPH UNIT (LTU)

…………………………………………9 2.3.1 Emergency

Stop

……………………………………………………………………………………………………..9

2.3.2 Command Transfer functions

…………………………………………………………………………………10

2.3.3 Sub-Telegraph

functions………………………………………………………………………………………..11

2.3.4 Lever

function………………………………………………………………………………………………………122.4 AUTOCHIEF BRIDGE WING CONTROL UNIT

BWU…………………………………………………………13

2.4.1 Emergency Stop

……………………………………………………………………………………………………13

2.4.2 Transfer

functions…………………………………………………………………………………………………14

2.4.3 Safety

functions…………………………………………………………………………………………………….15

2.4.4 Panel Dimming and lamp

test…………………………………………………………………………………16

2.4.5 Lever

function………………………………………………………………………………………………………17

2.4.6

Indicators…………………………………………………………………………………………………………….172.5 AUTOCHIEF PUSH-BUTTON TELEGRAPH (PBT)

…………………………………………………………..18

2.5.1 Command Transfer functions

…………………………………………………………………………………19

2.5.2 Sub-Telegraph

functions………………………………………………………………………………………..202.6 EMERGENCY PITCH CONTROL

PANEL…………………………………………………………………………….21

2.7 SAFETY SWITCH PANEL

………………………………………………………………………………………………222.7.1 Safety

functions…………………………………………………………………………………………………….22

2.8 PBT IN CABINET FOR ME ENGINE

………………………………………………………………………………..242.8.1 function and

indicators………………………………………………………………………………………….24

2.9 PBT IN CABINET FOR

CPP…………………………………………………………………………………………..252.9.1 function and

indicators………………………………………………………………………………………….25

2.10 DISTRIBUTED PROCESSING UNITS

…………………………………………………………………………………262.10.1 General

…………………………………………………………………………………………………………..26

2.10.2 Dual Process Segment Controller

(dPSC)……………………………………………………………28

2.10.3 RPMD Unit (RPMD)

………………………………………………………………………………………..29

2.10.4 Remote Analogue Input

(RAi-16)………………………………………………………………………..30

2.10.5 Remote Digital Input (RDi-32 and

RDi-32a)………………………………………………………..31

2.10.6 Remote Analogue Output (RAo-8)

………………………………………………………………………31

2.10.7 Remote Digital Output

(RDo-16)………………………………………………………………………..32

2.10.8 Process Segment Starcoupler (PSS)

……………………………………………………………………322.11 REMOTE CONTROL SYSTEM FUNCTIONS

………………………………………………………………………..33

2.11.1 Start fail/block

…………………………………………………………………………………………………33 -

Instruction manual AutoChief C20

ii AA-00391-A

2.11.1.1 Start

failed……………………………………………………………………………………………………………….

33 2.11.1.2 Start air pressure

low…………………………………………………………………………………………………

33 2.11.1.3 Engine tripped

………………………………………………………………………………………………………….

33 2.11.1.4 Start blocked

……………………………………………………………………………………………………………

33 2.11.1.5 Engine

blocked…………………………………………………………………………………………………………

342.11.2 Engine/CPP Not

ready………………………………………………………………………………………34

2.11.2.1 Start air distributor

blocked………………………………………………………………………………………..

34 2.11.2.2 Main Start air valve blocked

………………………………………………………………………………………

34 2.11.2.3 Turning gear

engaged………………………………………………………………………………………………..

34 2.11.2.4 Control air

vented……………………………………………………………………………………………………..

34 2.11.2.5 Engine not

ready/ready………………………………………………………………………………………………

35 2.11.2.6 CPP Hydraulic Pressure

…………………………………………………………………………………………….

35 2.11.2.7 CPP Not Zero

…………………………………………………………………………………………………………..

352.11.3 Starting the main engine

……………………………………………………………………………………36

2.11.3.1 Delayed start

……………………………………………………………………………………………………………

36 2.11.3.2 Prepare Start.

……………………………………………………………………………………………………………

36 2.11.3.3

Starting……………………………………………………………………………………………………………………

36 2.11.3.4 Repeated start

…………………………………………………………………………………………………………..

36 2.11.3.5

Running…………………………………………………………………………………………………………………..

362.11.4 RPM

limiters……………………………………………………………………………………………………37

2.11.4.1 Load

Limitation………………………………………………………………………………………………………..

372.11.5 QPT, Quick pass through barred speed range

function………………………………………….37

2.11.5.1 Load reduction

…………………………………………………………………………………………………………

382.11.6 Operation

modes………………………………………………………………………………………………38

2.11.6.1 Emission

mode…………………………………………………………………………………………………………

38 2.11.6.2 Economy mode

………………………………………………………………………………………………………..

39 2.11.6.3 Fixed RPM mode 1

…………………………………………………………………………………………………..

39 2.11.6.4 Fixed RPM Mode

2…………………………………………………………………………………………………..

39 2.11.6.5 Separate RPM

mode………………………………………………………………………………………………….

40 2.11.6.6 Combinator

mode……………………………………………………………………………………………………..

402.11.7 Stopping the main

engine…………………………………………………………………………………..41

2.12 SAFETY SYSTEM FUNCTIONS

……………………………………………………………………………………….412.12.1 Safety function Shut

down………………………………………………………………………………….41

2.12.1.1 Shut Down Function (1 6)

……………………………………………………………………………………….

41 2.12.1.2 Cancellable Shut

Down……………………………………………………………………………………………..

42 2.12.1.3 Emergency Stop function

…………………………………………………………………………………………..

43 2.12.1.4 Over-speed Shut Down

……………………………………………………………………………………………..

432.12.2 Safety function Slow Down

………………………………………………………………………………..44

2.12.2.1 Slow Down Function (1 20)

…………………………………………………………………………………….

44 2.12.2.2 Cancellable Slow

Down…………………………………………………………………………………………….

452.13 RPM MEASUREMENT

FUNCTIONS…………………………………………………………………………………46

2.13.1 Dual engine speed detector system for MAN B&W ME

Engines……………………………..46 2.13.2 RPM detector

failure

………………………………………………………………………………………..463 OPERATING

INFORMATION……………………………………………………………………………………….473.1 INTRODUCTION

…………………………………………………………………………………………………………47 -

Instruction manual AutoChief C20

AA-00391-A iii

3.2 OPERATION FROM BRIDGE

………………………………………………………………………………………….48

3.2.1 Preparing engine for start in

ECR…………………………………………………………………………..48

3.2.2 Transfer control from ECR to Bridge

………………………………………………………………………50

3.2.3 Start Auxilliary

blowers…………………………………………………………………………………………51

3.2.4 Start

engine………………………………………………………………………………………………………….52

3.2.5 Change propulsion

mode……………………………………………………………………………………….53

3.2.6 Select ahead

thrust………………………………………………………………………………………………..54

3.2.7 Select Zero

thrust………………………………………………………………………………………………….56

3.2.8 Select astern thrust

……………………………………………………………………………………………….56

3.2.9 Normal operations from

Bridge………………………………………………………………………………573.2.9.1 Cancel

SHD……………………………………………………………………………………………………………..

57 3.2.9.2 Cancel

SLD……………………………………………………………………………………………………………..

58 3.2.9.3 Cancel Limits

…………………………………………………………………………………………………………..

59 3.2.9.4 Sound

off…………………………………………………………………………………………………………………

59 3.2.9.5 Alarm

ack………………………………………………………………………………………………………………..

603.3 OPERATION FROM THE BRIDGE

WING……………………………………………………………………………61

3.3.1 Transfer from bridge to bridge wing

……………………………………………………………………….61

3.3.2 Manoeuvring from the bridge wing

…………………………………………………………………………62

3.3.3 Transfer from Bridge Wing to

Bridge………………………………………………………………………643.4 EMERGENCY CONTROL FROM BRIDGE OR

ECR………………………………………………………………65

3.4.1 Introduction

…………………………………………………………………………………………………………653.5 OPERATION FROM

ECR………………………………………………………………………………………………66

3.5.1 Transfer control from bridge to ECR

………………………………………………………………………66

3.5.2 Select ahead

thrust………………………………………………………………………………………………..67

3.5.3 Select Zero

thrust………………………………………………………………………………………………….68

3.5.4 Select astern thrust

……………………………………………………………………………………………….68

3.5.5 Change propulsion

mode……………………………………………………………………………………….69

3.5.6 Operation in separate RPM mode

…………………………………………………………………………..70

3.5.7 Normal operations from

ECR…………………………………………………………………………………713.5.7.1 Cancel

SHD……………………………………………………………………………………………………………..

71 3.5.7.2 Cancel

SLD……………………………………………………………………………………………………………..

72 3.5.7.3 Cancel Limits

…………………………………………………………………………………………………………..

73 3.5.7.4 Sound

off…………………………………………………………………………………………………………………

73 3.5.7.5 Alarm

ack………………………………………………………………………………………………………………..

74 3.5.7.6 Cancel Shut Down from SSP

……………………………………………………………………………………..

75 3.5.7.7 Cancel Slow Down from SSP

…………………………………………………………………………………….

76 3.5.7.8 Cancel Limiter from SSP

…………………………………………………………………………………………..

773.5.8 General operation from Local Stand, ME Engine

……………………………………………………..78

3.5.8.1 Transfer control from ECR to Local stand

……………………………………………………………………

78 3.5.8.2 Start/RPM control from Local

Stand……………………………………………………………………………

79 3.5.8.3 Local Pitch Control

…………………………………………………………………………………………………..

80 3.5.8.4 Cancel Shut down from local

stand……………………………………………………………………………..

81 3.5.8.5 Select astern thrust from Local

Stand…………………………………………………………………………..

82 3.5.8.6 Select zero Thrust and stop

engine………………………………………………………………………………

833.6 ADVANCED OPERATION BRIDGE AND ECR.

…………………………………………………………………..84

3.6.1 Guide to the Graphic

pages……………………………………………………………………………………84 -

Instruction manual AutoChief C20

iv AA-00391-A

3.6.2 Dynamic indications Home

………………………………………………………………………………..85

3.6.3 Fine

tuning…………………………………………………………………………………………………………..86

3.6.4 Control position transfer.

………………………………………………………………………………………87

3.6.5 Misc.

menu…………………………………………………………………………………………………………..88

3.6.6 Safety System

……………………………………………………………………………………………………….953.6.6.1 B&W Modes

………………………………………………………………………………………………………….

1014

MAINTENANCE…………………………………………………………………………………………………………..1034.1 INTRODUCTION

……………………………………………………………………………………………………….103

4.2 OVERVIEW

……………………………………………………………………………………………………………..103

4.3 UNIT

REPLACEMENT…………………………………………………………………………………………………1044.3.1 Recommended tools

…………………………………………………………………………………………….104

4.4 PREVENTIVE

MAINTENANCE………………………………………………………………………………………1044.4.1 General

……………………………………………………………………………………………………………..104

4.4.2 Weekly maintenance

……………………………………………………………………………………………1054.4.2.1 Distributed Processing Units

…………………………………………………………………………………….

105 4.4.3 3-monthly

maintenance………………………………………………………………………………………..106

4.4.4 6-monthly

maintenance………………………………………………………………………………………..106

4.4.5 Yearly maintenance

…………………………………………………………………………………………….1064.5 TROUBLESHOOTING

…………………………………………………………………………………………………107

4.5.1 Troubleshooting Distributed Processing Units

……………………………………………………….1074.5.1.1 How to handle Distributed Processing Units error codes

……………………………………………… 107 4.5.1.2

How to handle Distributed Processing Units communication errors

………………………………. 1084.5.2 Additional Troubleshooting for AutoChief Control Panel

(ACP),………………………………111 4.6 REPLACEMENT OF

UNITS

………………………………………………………………………………………….1124.6.1 How to replace the HMI units of the Autochief Propulsion

Control System ………………..112 4.6.2 How to replace

Distributed Processing Units, MEI, DGU, ESU, RPMU

……………………113 4.6.3 How to replace

printers……………………………………………………………………………………….1155 AS BUILT CONFIGURATION FROM SEAMATE

……………………………………………………….116 -

Instruction manual AutoChief C20

AA-00391-A 1

1 INTRODUCTION This manual is generated through the

configuration tool called Seamate. The manual is therefore

customised for each system delivery.The intention with this manual is to explain the functionality

for each mayor component and the total system as its configured for

each delivery.How to operate the system is described in a manner where we

assume that the system is in operation and that normal operations

shall be carried out. This manual is not made for advanced

troubleshooting.The manual contains five chapters

Introduction Functional Description Operation Maintenance As

Built Configuration From Seamate. -

Instruction manual AutoChief C20

2 AA-00391-A

2 FUNCTIONAL DESCRIPTION

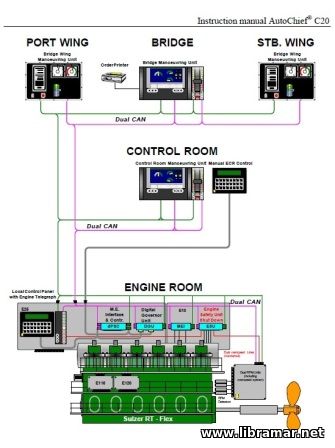

2.1 Remote Control System Functional Description

The Kongsberg Maritime C20 Marine Automation system consists of,

among others the AutoChief C20 Propulsion Control System. Modular

design allows flexibility in configuring the system to individual

requirements, covering the whole range from standard propulsion

configurations to highly advanced twin or quadruple engine

installations with high, medium or low speed engines connected to

reduction, reversing gear or variable pitch propellers. This system

may be a part of a total integrated ship control system consisting

of other sub. Systems such as:Alarm and monitoring system. Auxiliary control system. Power

management system. Ballast automation system. HVAC (air

conditioning). Management support The system is based on Kongsberg

Maritime unified automation concept, where each individual ship

configuration is built up using standard modules communicating on

CAN- and local area networks. The C20 system is configurable for

all ship types. The AutoChief C20 Propulsion Control System is

designed for remote control of the main engine from the combined

telegraph and manoeuvring lever in the wheelhouse. By moving this

lever, the system will control the controllable pitch propeller and

provide forward or reverse thrust as requested -

Instruction manual AutoChief C20

AA-00391-A 3

BRIDGE

CONTROL ROOM

ENGINE ROOM

PORT WING

Bridge WingManoeuvring Unit

Bridge WingManoeuvring Unit

Bridge Manoeuvring Unit

STB. WINGOrder Printer

Control Room Manoeuvring Unit

Local Control Panelwith Engine Telegraph

Dual overspeed Lines(Hardwired)

RPMDetectors

Em.stop line(Hardwired)

Dual CAN

Telegraph Lines

Dual CAN

LocalControl Line(Hardwired)

SSPPanel

Engine Safety UnitSlow Down

Engine Safety UnitShut Down

Hard wired 2x 4-20 mA and 2x stop.

ASTERN

AHEAD

DPU ESU

EICUA&B

ASTERN

AHEAD

Dual RPM Units(Includingoverspeedsystem)

OD BOX

Controllable PitchPropeller

EmergencyPitch

Control

C2MEI

Speed setlever

EmergencyPitch

Control

Pitch controlunits

LocalTelegraph Unitfor local pitch

control

MAN B&W ME

ECUA&B

-

Instruction manual AutoChief C20

4 AA-00391-A

The main components of the AutoChief C20 Propulsion Control

System are:Control panel Remote control system Engine telegraph system

Engine safety system Emergency pitch control system Manoeuvring

recorder Distributed processing units AutoChief C20 complies with

the requirements of IMO, local maritime authorities, IACS, and

eleven classification societies. It is designed to meet the

classification societies requirements for periodically unmanned

engine room operation. The system conforms to all rules and

regulations, and all modules are type approved. The system

incorporates the latest advances in hardware and software

technology. AutoChiefC20 is developed to strict military QA

standards -

Instruction manual AutoChief C20

AA-00391-A 5

2.2 AutoChief Control Panel (ACP)

CancelSHD

CancelSLD

Cancellimits

Incommand

Soundoff

Alarmackn.

35 %46 % 46 %

50

1000

25 75

100806040200

-100-80-60-40-20

HOMEME/CPP MainB&W ModesSafetySystem

Fine TuningMisc MenuControl Pos.LimitersAlarms

At Sea Emmis.mode Bridge Eng Ready System Ready

FUEL INDEX

LEVERSETP

Engine State

46 %100-100

-50 500

PITCH ANGLE

48 rpm1200

30 9060

FIXED RPM 1

The control panel is designed for ease of operation. An advanced

yet simple to use multifunction controller gives access to all

system functions. Information is provided only when needed to keep

operation simple. A colour display presents key information

graphically for easy understanding. Custom designed mimic pictures

are available for each engine type, and all main variables such as

RPM, pitch, start air and scavenging air pressure, engine state

etc. are always available. The control panel can be installed into

any standard console. To distinguish between user groups several

levels of control are available.functions

Bump-less control transfer

Cancel shutdown/slowdown

Alarm ackn./sound off Cancelling of limiters Changing of

parameters General alarm ind.Indications

Analogue Pitch command and set-point

Engine RPM Actual pitch Engine load Current main engine state

Start blockings Shutdown/slowdown Control position -

Instruction manual AutoChief C20

6 AA-00391-A

2.2.1 LCD Display

35 %

46 % 46 %

50

1000

25 75

100806040200

-100-80-60-40-20

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

At Sea Emmis.mode Bridge Eng Ready System Ready

FUEL INDEX

LEVERSETP

Engine State

46 %100-100

-50 500

PITCH ANGLE

48 rpm1200

30 9060

FIXED RPM 1

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

At Sea Eng Ready System Ready

Engine State

PITCH ANGLE

0 rpm

0 %

-100

-50 500Propulsion Modes

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

Bridge

CPP Pump Start

CPP Pump Stop

CPP Pump 1Running

CPP Pump 2Running

Show CPP Lim.CPP L. CurvesSet Pitch curves

HOME

Bridge Eng Ready System ReadyAt Sea

46 % 46 %

100806040200

-100-80-60-40-20

SETPManual pitch limiterQPT Active

Pitch LimitersLoad Limitation

Limiters

Limitation IncreasedSlowdown

LEVER

The ACP LCD display is used for the mayor interface between the

operator and the system to be monitored. All interaction such as

monitoring of propeller pitch, main engines RPM and load,

adjustment of operational parameters and displaying of safety

related and conventional alarms are carried out with the aids of

this display.The information is selected from menus via soft-keys. When a

menu is chosen a corresponding mimic picture will appear.The mimic pictures may consist of textual information, analogue

indicators, bar graphs or soft-keys making the operator able to

navigate into other related mimics.However, functions which require direct access, such as,

emergency stop, cancel functions and alarm acknowledge / sound off

is accessible via push-buttons on the front of the ACP. -

Instruction manual AutoChief C20

AA-00391-A 7

2.2.2 Cancel functions

CancelSHD

CancelSLD

Cancellimits

The cancel functions available on the AutoChief control panel

are:Cancel SHD, only cancellable Shut Downs will respond to this

function.Cancel SLD, only cancellable Slow Downs will respond to this

function. Slow down is normally a load reduction by reducing the

main propellers pitch to a predefined levelCancel limits, used to raise RPM, pitch, fuel and load limiters

which are active in the remote control system. The default value is

10 %.2.2.3 Alarm Acknowledge and in command functions

Incommand

Soundoff

Alarmackn.

The alarm and command functions available on the AutoChief

control panel are:In Command, indicates with a green LED that the actual ACP is in

commandSound off, used for silencing buzzer when an alarm is

active.Alarm Ackn., used for accepting alarm indications. When the

alarm condition has returned to normal state the alarm text will

disappear from the display -

Instruction manual AutoChief C20

8 AA-00391-A

2.2.4 Multifunctional knob

The multifunctional knob (Rotary Knob):

For navigating through mimic pictures and objects in in the

mimic pictures.To be turned clockwise or counter clockwise, until required

field is high-lighted, push the wheel for entering into a new mimic

picture or field to be operated.Change value, move graphic levers or handles or scroll through

roll-up menus, press knob for activating required function.The multifunctional knob has no stop in turning either way, it

will navigate the operator through available fields in each

picture. -

Instruction manual AutoChief C20

AA-00391-A 9

2.3 AutoChief Combined Lever and telegraph unit (LTU)

Bridge

ECR

Local

At sea

Stand by

FWE

D.Slow AST

EmergencyStop

Essentially, an Engine Telegraph System is designed to control

the engine and comprises an AutoChiefC20 Lever Telegraph Unit (LTU)

at the following locations:Bridge Control room

The AutoChiefC20 Lever Telegraph Unit (LTU) is a combined

telegraph & manoeuvring lever with telegraph handle and

emergency stop switch2.3.1 Emergency Stop

Bridge

ECR

Local

At sea

Stand by

FWE

D.Slow AST

EmergencyStop

Bridge

ECR

Local

At sea

Stand by

FWE

STOP

The emergency stop button in the bridge console is located in

the LTU. At the lower part of the lever, a cover marked with

emergency stop can be opened. The emergency stop button is located

below this cover The emergency stop function activates the

emergency stop system in the main engine safety system.

Additionally the conventional stop system is activated and the

speed order to the rpm control system is set to zero rpm.Functions Push-button pressed once for emergency stop

Push-button pressed twice for resetIndications The push-button illumination is red. When active the

illumination is enhanced. The cover has a translucent section, so

if its closedthe light will show through

-

Instruction manual AutoChief C20

10 AA-00391-A

2.3.2 Command Transfer functions

Bridge

ECR

Local

The command transfer section is used for selecting the location

for controlling the main engine Bridge The operator on the bridge

is controlling the engine via the automatic Remote Control System.

The Engine Telegraph System is disabled. ECR The control room

personnel have control of the engine. Communication is established

between the bridge and engine control room via the telegraph system

Local The engine room personnel have control of the engine from the

local control system. Communication is established between the

bridge and engine room via the telegraph system.Functions Push-button pressed once for request of command

Push-button pressed twice for accept of commandIndications The push-button LED indicator is lit to confirm

control position The push-button LED indicator is flickering

when acontrol position is requested but not accepted.

-

Instruction manual AutoChief C20

AA-00391-A 11

2.3.3 Sub-Telegraph functions

At sea

Stand by

FWE

The sub-telegraph functions are included for informing the

engine crew about the subsequent need for propulsive and electric

power. At Sea The operator on the bridge is informing that all

systems has to be prepared and set-up for seagoing. Stand by The

operator on the bridge is informing that all systems has to be

prepared for stand by. Engine to be prepared for start. It may also

inform the crew that the vessel is entering channel or harbours

where special attention has to be made to the machinery or steering

plant. FWE ( Finished with engine) The operator on the bridge is

informing that there will be no need for propulsive power. The crew

will block main start valve and drain the line, Start air

distributor will be locked and control air drained. For the MAN

B&W engines this lamp will flicker until all actions is made to

inhibit the engine to start unintentionally. This function is

called FWE Loop abnormal.Functions Push-button pressed for request of mode

Indications The push-button LED indicator is lit to confirm

sub-telegraph mode

-

Instruction manual AutoChief C20

12 AA-00391-A

2.3.4 Lever function

Bridge

ECR

Local

At sea

Stand by

FWE

SLOW

EmergencyStop

SLOW

SLOW

The telegraph handle enables an operator on the bridge to be in

direct command of the ship by controlling engines RPM and

propellers thrust direction The lever operates in eleven fixed

steps, where each step represents an Pitch and or a rpm command in

ahead or astern direction. The steps will provide pitch commands as

long as Fixed RPM mode 1 or 2 are selected. If combinator mode is

selected the steps will represent both a rpm command and a pitch

command The steps are the following: Ahead: D.Slow, Slow, Half,

Full, Navigation Full, Stop Astern: D.Slow, Slow, Half, Full,

Emergency Astern The lever can be moved between the steps as for

adjusting the rpm/pitch order. Additionally its possible to use a

fine tuning parameter available on the ACP mimic.Functions Lever set to required position.

Indications A corresponding led is lit on each side of the

lever. Above the cover for emergency stop button there area digital display which shows textual information, which

telegraph position which is selected.On each side of the lever there are a digital display which

shows textual information and a arrow indicating the direction of

rotation -

Instruction manual AutoChief C20

AA-00391-A 13

2.4 AutoChief Bridge wing control unit BWU

ASTERN AHEAD

BWU C20BRIDGE WING UNIT

STOP

D.SLOW

SLOW

HALFFULL

NAV.FULL

D.SLOW

SLOW

HALF

FULL

EM.AST.

rpm

0

60

120PITCH

-100

0

100

ASTERN AHEAD

Command Transfer

Alarm

SHDNONE

CANCEL

SHDCANCEL-

ABLE

SHDACTIVE

OVER-SPEED

PANELDIM

+

SOUNDOFF

CANCELSHD

SLDNONE

CANCEL

SLDCANCEL-

ABLE

SLDACTIVE

EMERG.STOP

CANCELSLD

INCOMMAND

ALARMACK.

CancelSafety

function

LAMPTEST

PANELDIM

—

EMERGENCY STOP

2.4.1 Emergency Stop

EMERGENCY STOP

EMERGENCY STOP

EMERGENCY STOP

The emergency stop button in the bridge wing console is located

in the BWU C20. At the lower part of the panel, a cover marked with

emergency stop can be opened. The emergency stop button is located

below this cover The emergency stop function activates the

emergency stop system in the main engine safety system.

Additionally the conventional stop system is activated and the

speed order to the rpm control system is set to zero rpm.Functions Push-button pressed once for emergency stop

Push-button pressed twice for resetIndications The push-button illumination is red. When active the

illumination is enhanced. The cover has a translucent section, so

if its closedthe light will show through

-

Instruction manual AutoChief C20

14 AA-00391-A

2.4.2 Transfer functions

Command Transfer

Alarm

SHDNONE

CANCEL

SHDCANCEL-

ABLE

SHDACTIVE

OVER-SPEED

PANELDIM

+

SOUNDOFF

CANCELSHD

SLDNONE

CANCEL

SLDCANCEL-

ABLE

SLDACTIVE

EMERG.STOP

CANCELSLD

INCOMMAND

ALARMACK.

CancelSafety

function

LAMPTEST

PANELDIM

—

Command Transfer INCOMMAND

The command transfer function is solved by functions in the

push-button panel at the left side of the BWU (bridge wing unit

Port or starboard. Wing control is selected from the ACP in the

centre bridge console. When the request is done the indicator lamp

In Command on the bridge wing will flicker. The system is equipped

with an electric shaft system between the levers, which makes a

bump-less transfer possible. The pushbutton In command will, when

pressed, transfer the control from bridge to requested bridge

wings.Functions Push-button pressed once for activation

Indications The push-button LED indicator is green.

-

Instruction manual AutoChief C20

AA-00391-A 15

2.4.3 Safety functions The Safety functions in the BWU are

divided in two section, cancellable and not cancellable. The safety

functions which are cancellable will be announced on the following

indicators:SHDNONE

CANCEL

SHDCANCEL-

ABLE

SHDACTIVE

CANCELSHD

SLDNONE

CANCEL

SLDCANCEL-

ABLE

SLDACTIVE

CANCELSLD

Shut Down Warning Whether its a cancellable or not cancellable

shut down individual indicator Leds will be illuminated. A

cancellable function is provided with a pre-warning time, while a

not cancellable will activate immediately. Cancel Shut Down The

pushbutton, will when activated, cancel shut downs which are

predefined as cancellable. Shut Down Active. The Led is lit when

the shut down is active. Slow Down Warning Whether its a

cancellable or not cancellable slow down individual indicator Leds

will be illuminated. A cancellable function is provided with a

pre-warning time, while a not cancellable will activate

immediately. Cancel Slow Down The pushbutton, will when activated,

cancel slow downs which are predefined as cancellable. Slow Down

Active. The Led is lit when the slow down is active.Functions Push-button pressed once for activation Push-button

pressed twice de-activationIndications If the push-button is pressed and the cancel

functionis activated the LED indicator gets fixed red light. If the

push-button is pressed again the cancelfunction is switched off and the LED indicator starts flickering

if the Safety function is still active but extinguishes if the

safety function is not active. -

Instruction manual AutoChief C20

16 AA-00391-A

OVER-SPEED

EMERG.STOP

Over-speed A separate indicator for over-speed shut down is

provided. If the engine is over-speeding the safety system will

stop the engine. The lever has to be set to stop and the engine has

to be re-started. Emergency Stop A separate indicator for emergency

stop shut down is provided. It indicates that one of the emergency

stop switches is active. The manoeuvre lever has to be set to stop,

the emergency stop switch active has to be reset and the engine has

to be re-started.Indications The LED indicator is red and illuminated when

thesafety function is active.

2.4.4 Panel Dimming and lamp test

PANELDIM

+

PANELDIM

+

LAMPTEST

The BWU instrumentation and lever do all include background

illumination. The intensity can be adjusted by dedicated

pushbuttons on the push-button panel.This pushbutton is for increasing background light intensity for

the BWU panelThis pushbutton is for decreasing background light intensity for

the BWU panelThis button is for checking all indicator lights and Leds in the

BWU panel.Functions By pressing + button intensity will be enhanced By

pressing — button intensity will be reduced By pressing Lamp Test

the lamp test will run untillamp test is pressed once more.

Indications LED indicator is lit as long as pushbutton is

pressed. -

Instruction manual AutoChief C20

AA-00391-A 17

2.4.5 Lever function

STOP

D.SLOW

SLOW

HALFFULL

NAV.FULL

D.SLOW

SLOW

HALF

FULL

EM.AST.

The manoeuvre lever on the bridge wing unit has the same

divisions as the bridge lever. Each division has a step.Functions Lever to be moved to required step The electric shaft

function will move lever in centrebridge and the other bridge wing accordingly.

Indications Illuminated scale showing each lever position.

2.4.6 Indicators

PITCH-100

0

100

ASTERN AHEAD

rpm

0

60

120

The BWU C20 includes indicators for engine rpm and engine pitch,

The indicators are operative whether the wing control station is in

command or not.Indications

Propeller pitch indicates the propellers actual pitch in

astern or ahead direction. Astern is indicated with negative (-)

pitch value and red scale. Ahead is positive and green scale.Engine rpm, indicates the engines actual rpm

-

Instruction manual AutoChief C20

18 AA-00391-A

2.5 AutoChief Push-Button Telegraph (PBT)

Bridge

ECR

Local

At sea

Stand by

FWE

Nav.full

Full

Half

Slow

DeadSlow

Stop

DeadSlow

Slow

Half

Full

Emerg.Astern

EmergencyStop

Wrong way

LampTest

In addition to the Lever Telegraph Unit, another unit provides a

simple sub telegraph system for the engine room. The Push Button

Telegraph (PBT) enables an operator to transmit/receive messages

between the bridge, control room and engine room. The following

standard functions are available as explained above:Engine Telegraph Modes: Engine Telegraph Control Location Engine

Telegraph Status Emergency StopThe following telegraph divisions are provided by push buttons

with indicators: Ahead: D.Slow, Slow, Half, Full, Navigation Full,

Stop Astern: D.Slow, Slow, Half, Full, Emergency AsternFunctions Push-buttons activated for accepting and

confirmingorder received from the bridge Emergency Stop pushbutton pressed

once foractivation and pressed again for reset. Lamp test pushbutton for

testing all indicators andbackground illumination.

Indications A corresponding led is lit on each pushbutton

whenactivated Emergency Stop pushbutton, illumination is red.

When active the illumination is enhanced. Wrong way alarm. The

cover has a translucent section, so if its closedthe light will show through

-

Instruction manual AutoChief C20

AA-00391-A 19

2.5.1 Command Transfer functions

Bridge

ECR

Local

The command transfer section is used for selecting the location

for controlling the main engine Bridge The operator on the bridge

is controlling the engine via the automatic Remote Control System.

The Engine Telegraph System is disabled. ECR The control room

personnel have control of the engine. Communication is established

between the bridge and engine control room via the telegraph system

Local The engine room personnel have control of the engine from the

local control system. Communication is established between the

bridge and engine room via the telegraph system.Functions Push-button pressed once for request of command

Push-button pressed twice for accept of commandIndications The push-button LED indicator is lit to confirm

control position The push-button LED indicator is flickering

when acontrol position is requested but not accepted.

-

Instruction manual AutoChief C20

20 AA-00391-A

2.5.2 Sub-Telegraph functions

At sea

Stand by

FWE

The sub-telegraph functions are included for informing the

engine crew about the subsequent need for propulsive and electric

power. At Sea The operator on the bridge is informing that all

systems has to be prepared and set-up for seagoing. Stand by The

operator on the bridge is informing that all systems has to be

prepared for stand by. Engine to be prepared for start. It may also

inform the crew that the vessel is entering channel or harbours

where special attention has to be made to the machinery or steering

plant. FWE ( Finished with engine) The operator on the bridge is

informing that there will be no need for propulsive power. The crew

will block main start valve and drain the line, Start air

distributor will be locked and control air drained. For the MAN

B&W engines this lamp will flicker until all actions is made to

inhibit the engine to start unintentionally. This function is

called FWE Loop abnormal.Functions Push-button pressed for request of mode

Indications The push-button LED indicator is lit to confirm

sub-telegraph mode

-

Instruction manual AutoChief C20

AA-00391-A 21

2.6 Emergency pitch control panel

CPPEMERGENCY

CONTROL

CPPINCREASE

AHEAD

LAMPTEST

CPPINCREASEASTERN

The emergency pitch control panel is located on the bridge and

in control room. The purpose of the panel is to make the operator

able to perform direct pitch control. The panel is hardwired direct

to the propeller systems solenoid valves in the oil distribution

box, or to the outputs of the pitch control units MEI and C2.CPPEMERGENCY

CONTROL

This pushbutton is for activating CPP Emergency control.

Press once for activation

Press once more for deactivation

CPPINCREASEASTERN

This pushbutton is for moving the pitch for astern thrust. As

long as the pushbutton is pressed the pitch will move.CPPINCREASE

AHEAD

This pushbutton is for moving the pitch for ahead thrust. As

long as the pushbutton is pressed the pitch will move.LAMPTEST

This pushbutton is for performing lamp test for the Emergency

pitch control panel. -

Instruction manual AutoChief C20

22 AA-00391-A

2.7 Safety switch panel

SHUTDOWN

SLOWDOWN

CANCELSHUTDOWN

CANCELSLOWDOWN

NORMALFORCED ECR

CONTROL NORMALINCREASE

LIMIT

SSP

LAMPTEST

RESETSLOWDOWN

The safety switch panel is located in the engine control

room2.7.1 Safety functions

SHUTDOWN

Indicates that shut down is activated.

CANCELSHUTDOWN

Pushbutton for cancelling shut down.

-

Instruction manual AutoChief C20

AA-00391-A 23

SLOWDOWN

Indicates that slow down is activated.

CANCELSLOWDOWN

Pushbutton for cancelling slow down.

NORMALINCREASE

LIMIT

Selector switch for increasing limiters in the remote control

system.NORMALFORCED ECR

CONTROL

Selector switch for forced control take-over, from remote to

Engine Control room control.LAMPTEST

Pushbutton for testing all lamps in the Safety switch panel.

RESETSLOWDOWN

Pushbutton for reset slow down.

-

Instruction manual AutoChief C20

24 AA-00391-A

2.8 PBT in cabinet for ME engine

Bridge

ECR

Local

At sea

Stand by

FWE

Nav.full

Full

Half

Slow

DeadSlow

Stop

DeadSlow

Slow

Half

Full

Emerg.Astern

EmergencyStop

Wrong way

LampTest

0 1020

30

40

607080

90

100

50

For the MAN B&W ME engine the pushbutton telegraph is

mounted in a cabinet together with a control dial for local control

of the ME engine2.8.1 function and indicators

0 1020

30

40

607080

90

100

50

The control dial is used for local speed control of the main

engine. The dial is directly connected to the MAN B&W ECU

A&B units. The control dial has a scale from 0-100 % Fuel

index..There is also a buzzer mounted in the cabinet for announcing new

telegraph commands given from the bridge to the local

telegraph.See separate description of the pushbutton Telegraph

-

Instruction manual AutoChief C20

AA-00391-A 25

2.9 PBT in cabinet for CPP

Bridge

ECR

Local

At sea

Stand by

FWE

Nav.full

Full

Half

Slow

DeadSlow

Stop

DeadSlow

Slow

Half

Full

Emerg.Astern

EmergencyStop

Wrong way

LampTest

For the local CPP control station the pushbutton telegraph is

mounted in a cabinet together with a buzzer for telegraph command

announcement.2.9.1 function and indicators

The telegraph includes the same functionality as described for

the pushbutton telegraph earlier in the document.For the CCP configurations there are two telegraph panels in the

engine room, one for by the main engines local control stand and

one by the CPP local control stand. When a new manoeuvring order is

activated from the bridge an accept of this command may be given

either from the main engine or from the local CPP standThe buzzer will activate as long as a new command is not

accepted.See separate description of the pushbutton Telegraph

-

Instruction manual AutoChief C20

26 AA-00391-A

2.10 Distributed processing units

2.10.1 General A number of different Distributed Processing

Units are available for different tasks. The main functions of the

Distributed Processing Units are to monitor analogue or digital

sensors and to provide analogue and digital output to different

devices. All units have the same mechanical construction and are

built using the same electronic design principles. The main

characteristics of the Distributed Processing Units are:Distributed Processing Units (DPU) LED indicators on the housing

for Watch-dog, Run, Generalinformation, unit initialised and power polarity. Three-way

isolation between: — I/O and power. — I/O and process-bus. — Power

and process-bus. Single printed circuit board design. Easy service

replacement without setting trimmers, dip switches,jumpers or sockets. No additional EMC protection required (only

IP).Time synchronisation. Non-volatile memory. Remote alarms

function. Dual CAN-bus interfaces. -

Instruction manual AutoChief C20

AA-00391-A 27

Software can be downloaded into the unit. Built In Self-Test

(BIST) monitoring temperature, powerand sensor excitation overload. All parameters are stored in

each unit. Each unit is remotely configurable. No serviceable parts

inside. All connections are pluggable.Each Distributed Process Unit contains its own microprocessor.

These are programmed for a number of different tasks such as

detecting when a monitored signal move outside set limits. Unwanted

alarms are inhibited during start-up and shut-down of the

machinery. Status information is continuously monitored by the

AutoChiefC20 AMSs Remote Operator Stations through the system

network. When an unacceptable condition is detected, the

Distributed Process Unit and AutoChiefC20 AMS generates an alarm

signal, identifies the responsible sensor, and provides information

about the condition. The following gives a short description of

each Distributed Processing Unit type: -

Instruction manual AutoChief C20

28 AA-00391-A

2.10.2 Dual Process Segment Controller (dPSC)

The dual Process Segment Controller (dPSC) is a dual two channel

CAN gateway. Its main task is to process messages from the local

CAN segment and send them on the global process bus, where they are

available for other dPSCs and the Remote Operator Stations. In most

cases the two channels are working in parallel on redundant CAN

lines. Commands and downloading of parameters and software from any

Remote Operator Station to the Distributed Processing Units

connected to the local process bus is handled as well. The main

features are:Redundant routing of messages between local and global CAN

segments.Application mastership with active running backup. PLC algorithm

for controlling I/O-signals connected to thelocal DPUs.

Self checking Remote configurable No serviceable parts All

connections pluggable All parameters stored in module Dual

redundant 24VDC input (power) -

Instruction manual AutoChief C20

AA-00391-A 29

2.10.3 RPMD Unit (RPMD) The RPMD module is a module with pickup

inputs and digital outputs, two relay output and two solenoid

driver output. The value from the pickups can be used to activate

the outputs and will be reported on CAN. The main features are: 4

pickup inputs, 2 or 3 wire (NPN or PNP pickup required). 2 Relay

output, one changeover contact 2 channels for Solenoid driverScaled in technical units. Limit check. Alarm and monitoring for

all channels. Trend. Time stamp of alarms and events (0.001

seconds). Self checking. Sensor excitation power overload. CAN net

status, error handling.RPMD C20

-

Instruction manual AutoChief C20

30 AA-00391-A

2.10.4 Remote Analogue Input (RAi-16) This unit has 16 analogue

input channels. Each channel is selectable as voltage, current and

resistance input in different ranges and has free technical units

scaling. It also incorporates a 5-500Hz counter channel. The main

features are:16 analogue or digital input channels. Scaled in technical

units. 1 Counter 5 — 500 Hz. Limit check. Alarm and monitoring for

all channels. Trend. Time stamp of alarms and events (0.001

seconds). Self checking. Sensor excitation power overload. CAN net

status, error handling. -

Instruction manual AutoChief C20

AA-00391-A 31

2.10.5 Remote Digital Input (RDi-32 and RDi-32a)

These units have 32 digital input channels/dry contacts and

includes LED status indicators. The main features are:32 digital input channels with LED status indicators. Input dry

contacts. Alarm and monitoring for all channels. Trend. Time stamp

of alarms and events. Self checking. Sensor excitation power

overload. CAN net status, error handling.2.10.6 Remote Analogue Output (RAo-8) This unit has 8 analogue

output channels. Each channel is selectable for voltage or current

output in different ranges and almost free technical units scaling.

This module is suited to drive analogue indicators. By placing the

module close to instruments long cables can be avoided. The main

features are:8 analogue output channels. 10VDC / 20 mA. CAN net status, error

handling. -

Instruction manual AutoChief C20

32 AA-00391-A

2.10.7 Remote Digital Output (RDo-16) This unit has 16 digital

output channels and includes LED status indicators. The maximum

output current for each channel is 3 Amperes (resistive load).

Maximum voltage is 230 VAC. The main features are: 16 digital

output channels with LED status indicator. The main features

are:Change over, brake before make relay-contacts. Pulse on output.

Pulse off output. CAN net status, error handling.2.10.8 Process Segment Starcoupler (PSS)

CAN lines are vulnerable against short circuit and un-terminated

lines. A short-circuit or a broken line will disable the entire CAN

segment. The PSS will protect two sections of a CAN segment from

each other. A typical application is to protect CAN segments

running across fire- or flood-zones.Protection of sections in a single CAN segment Extension of bus

topology No configuration No serviceable parts All connections

pluggable -

Instruction manual AutoChief C20

AA-00391-A 33

2.11 Remote control system functions

2.11.1 Start fail/block As long as any of the below mentioned

conditions is active the engine is inhibited for starting.2.11.1.1 Start failed Starting failure is announced from the MAN

B&W ECS when one of the following conditions occurs, and is

indicated on ECR and Bridge ACP.3 failed starts Slow turning failure

2.11.1.2 Start air pressure low

To secure a safe starting of the main engine a minimum starting

air pressure is required. The value for minimum starting air

pressure allowed is preset in parameters in the remote control

system. If the pressure is below this preset level Start Block is

activated.2.11.1.3 Engine tripped

Engine has tripped because of a shut down detected and created

by the safety system.Details to be found in the alarm list on the Safety system mimic

pages.2.11.1.4 Start blocked

If one or more of the following conditions are present the ECS

will block the start:Shut down Main starting valve blocked Starting air distribution

system blocked Control air vented Turning gear engaged Starting air

pressure low and bridge control active Auxiliary blowers not

operational and bridge control active -

Instruction manual AutoChief C20

34 AA-00391-A

When the start is blocked the ECS will release an alarm and

route Start Blocked signal to the RCS via the serial connection.

The ECS will automatically reset the start blocking when the

condition has returned to normal and stop command is released.2.11.1.5 Engine blocked

This is a signal from the Electronic Control System to the

remote control system via serial line informing that the engine is

blocked for operation. Its active if one or all of the following

conditions is active:Main starting valve blocked Starting air distribution system

blocked Control air vented2.11.2 Engine/CPP Not ready

2.11.2.1 Start air distributor blocked

For safety reasons, when the main engine is not in use, the

start air distributor is blocked. To be able to start the engine

the start air distributor has to be unblocked.2.11.2.2 Main Start air valve blocked

For safety reasons, when the main engine is not in use, the main

start air valve is mechanically blocked. To be able to start the

engine the main start air valve has to be unblocked.2.11.2.3 Turning gear engaged

The turning gear is mechanically engaged to the flywheel. The

main engine is therefore inhibited from starting.2.11.2.4 Control air vented

The control air valve is closed and the line is pressure

released with a ventilation valve. -

Instruction manual AutoChief C20

AA-00391-A 35

2.11.2.5 Engine not ready/ready

Engine Not Ready is used for an indication at the bridge, ECR

and LOP. The purpose of the Engine Not Ready indication is to

inform the navigator/engine staff that the engine is not fully

capable of functioning. For example it may not be possible to start

the engine again if it has been stopped.It is allowed to perform a start attempt if the Engine Not Ready

indication is on. However, the normal procedure is to wait until

Engine Not Ready deactivates before a start attempt is carried out

e.g. after black-out.The ECS will route Engine Not Ready to the remote control system

via serial connection. The Engine Not Ready signal is set active if

the condition for engine ready is not fulfilled Engine Not Ready is

thus the inverse of the following signals:Main starting valve in service position Starting air

distribution system in service position Turning gear disengaged

Control air pressure OK Hydraulic supply system OK Auxiliary

blowers operational ECS OK2.11.2.6 CPP Hydraulic Pressure

This function monitors the actual control oil pressure for the

controllable pitch propeller. If the CPP pumps is not running (At

least one) or the pressure is to low this message will appear. It

means that we have no control of the propeller pith and therefore

the CPP is not ready.2.11.2.7 CPP Not Zero

Prior to start of the engine the propellers pitch has to be

neutral (Zero), meaning that no ahead or astern thrust is

initiated. If the CPP is not in zero CPP is not ready an engine

cannot be started. -

Instruction manual AutoChief C20

36 AA-00391-A

2.11.3 Starting the main engine The engine is started

automatically in ahead (or astern) direction from bridge (if the

engine is prepared for start), simply by setting the bridge handle

from stop to any position in ahead (or astern) direction.2.11.3.1 Delayed start

This function indicates that the Prepare Start sequence has to

be activated before the engine is Ready for start.2.11.3.2 Prepare Start.

This function is activated from the ACP mimic pages, its

activated for starting the auxiliary blowers prior to the normal

start of the engine. As long as this sequence is not performed the

engine will be in the state Delayed Start. When the sequence is

ready the engine state will be Ready for Start.2.11.3.3 Starting Starting of the main engine is performed by

selecting the picture ME/CPP main on the ACP. On this picture is

possible to select a soft-key named ME Start. When the engine is

ready for start the start signal will be sent to the MAN B&W

electronic control system.2.11.3.4 Repeated start If the engine fails to start (run on

fuel) after the starting air is switched off, the system will

automatically try to restart the engine. Indication for «repeated

starts» will show on bridge and ECR. If the second start also

fails, the system will try once more. After 3 starting attempts,

start failed alarm will be activated.2.11.3.5 Running The signal Running is transferred to the RCS

from the ECS when the engine is running on fuel. -

Instruction manual AutoChief C20

AA-00391-A 37

2.11.4 RPM limiters For protecting the engine against thermal

stress and destruction some fixed RPM Limiters are included in the

ECS.2.11.4.1 Load Limitation

This function is including the operational limiters:

Chief rpm limit Torque Limiter Scavenging air Limiter

The limiter functions is adjustable only in the MAN B&W

ECS.2.11.5 QPT, Quick pass through barred speed range function

The QPT function is an optional feature to help the main engine

passing through the critical RPM range. In some cases its difficult

to pull the engine through the critical RPM range as the fuel

limiters may activate and restricting the engine to increase in

speed. This problem is avoided as the RPM control system detects

the critical RPM lower level and sends a zero pitch signal to the

AC-C20 pitch control system. The AC-C20 will then take the pitch to

zero and the speed control system will be able to increase the

pump-index with the effect that the engines RPM will increase and

reach the critical RPM upper level. When this RPM is reached the

zero pitch signal is turned of and the AC-C20 take the propellers

pitch angle up to the level which is matching the manoeuvre lever

position. -

Instruction manual AutoChief C20

38 AA-00391-A

2.11.5.1 Load reduction A slow down is caused by a input signal

detected by the slow down module. If such a signal is detected, the

safety system will send a load reduction request to the pitch

control system. The pitch set-point will after a pre-warning time

be reduced to the predefined load reduction level.Time

Pitc

h

SLD loadLevel

SLD Active During pre-warning time an alarm «slow down

cancellable» or «slow down none cancellable» will be displayed on

the ACP.2.11.6 Operation modes

2.11.6.1 Emission mode

This mode is selectable from the ACP mimic. Emission mode is a

special feature controlled by the MAN B&W Electronic Control

System. It secures operation of the main engine with the lowest

emissions for the actual engine type. -

Instruction manual AutoChief C20

AA-00391-A 39

2.11.6.2 Economy mode

This mode is selectable from the ACP mimic. Economy mode is a

special feature controlled by the MAN B&W Electronic Control

System. It secures the operation of the main engine with the lowest

consumption and thereby in the most economic way.2.11.6.3 Fixed RPM mode 1

This mode will be selected automatically after SEPARATE RPM or

as default after power up. Fixed RPM mode means pitch control from

bridge, bridge-wing or control room by the AutoChief C20 control

levers with a fixed engine speed. Fixed RPM 1 mode can be manually

selected by operating the ACPs mimic mode select section on the

bridge or in control room (the one in control). The RPM level for

this mode is adjustable but is normally set to 85% of MCR. Fixed

RPM can not be selected if the remote control system is not in

charge of RPM control. (which means that the ACC20system have lost

control of the engine speed (separate RPM), in such a case, the RPM

must be set manually to the fixed RPM position by use of the manual

lever.2.11.6.4 Fixed RPM Mode 2

Fixed RPM mode 2 is selected manually but the functionality is

the same as for Fixed RPM 1. The fixed RPM 2 rpm level is normally

set to 100% of MCR but is adjustable from the engine control room

panel. In the case were the ship has a dynamic positioning control

system the operation mode in DP-mode is Fixed RPM mode. In this

case the dynamic positioning system gets information whether Fixed

Rpm mode 1 or 2 is selected. -

Instruction manual AutoChief C20

40 AA-00391-A

2.11.6.5 Separate RPM mode

Separate RPM mode means pitch control from bridge, bridge-wing

or the control room by the AutoChief C20 control levers (Local

control of the CPP is also possible in this mode). RPM are in this

mode controlled separately, from the speed-setting lever provided

in the control room or from the control lever provided on the local

engine side control station. The system will go automatically into

separate RPM mode if the pneumatic /electric change over

valve/switch located in the control room (and in the engine side

control console) are set out of remote (which means that the ACC20

system have lost control of the engine speed). An alarm Separate

RPM mode will be announced on bridge and in control room.2.11.6.6 Combinator mode

Combinatory mode means combined control of RPM and pitch from

bridge, bridge-wing or control room by the AutoChief C20 control

levers according to a pre-programmed combinatory curves. Combinator

mode can be manually selected by operating the ACPs mimic mode

select section on the bridge or in control room (the one in

control).Combinatory mode can not be selected if the pneumatic

/electric change over valve/switch is set to manual which means

that the ACC20 system have lost control of the engine speed

(separate RPM)). Combinator mode is blocked if DP-panel is in

control.Manoeuvring lever position in %

Rpm

AheadAstern Stop

0 %- 100 % 100 %

Combinator curve for Rpm.

P1

P2P3 P4

P5

P6

Lever position in %

AheadAstern Stop

0 %- 100 % 100 %

Pitch%Ahead

P3

Pitch%Astern

P6

P5

P7

P2

P1

-

Instruction manual AutoChief C20

AA-00391-A 41

2.11.7 Stopping the main engine The engine is stopped

automatically by first selecting the picture ME/CPP main on the

ACP. On this picture its possible to select a soft-key for stopping

the engine. The stop solenoid valve is activated, and stop signal

is given to the MAN B&W Electronic Control System.2.12 Safety system functions

2.12.1 Safety function Shut down

2.12.1.1 Shut Down Function (1 6) Then engine will automatically

shut down (stop), if any of the shut down sensors is activated. The

emergency stop solenoid valve will be activated, and the fuel rack

to zero order is given to the governor. The engine will then stop.

The following inputs for shut down sensors are provided: Shut down

1: (Fixed as over speed) Shut down 2-6: (To be project specified

for the actualproject) Custom Shut down 1-5 (To be project specified for the

actualproject) The input sensors may be of digital (on/off) or

analogue type. The shut downs may be configured as cancellable or

non cancellable type. Non cancellable types will stop the engine

immediately. Shut down is reset (after the sensor is de-activated)

by setting the manoeuvring lever at the control stand in control to

stop position. The engine may then be restarted. -

Instruction manual AutoChief C20

42 AA-00391-A

2.12.1.2 Cancellable Shut Down It will be possible, during the

time delay, to cancel the shut down by pressing the «Cancel SHD»

pushbutton on the ACP unit. There will be time delay on the

cancellable shut downs. The delay time may be adjusted individually

for each sensor. The cancellable shut-downs may be cancelled

individually from the ACP in control room, regardless of control

position, it will additionally be possible to cancel all shut-downs

from bridge while in bridge control, control room in control room

control and from engine side while in emergency control. The

indications mentioned will be shown on the LCD display of the ACP

unit. -

Instruction manual AutoChief C20

AA-00391-A 43

2.12.1.3 Emergency Stop function Safety System has possibility

for total 5 emergency stop push buttons Normally 3 emergency stop

pushbuttons will be used:Bridge Pushbutton with light with integrated in bridge LTU.

Control Room Pushbutton with light with cover integrated in the

ECR LTULocal Control: Pushbutton with light with cover integrated in

emergency control PBT.Emergency stop solenoid valve is directly activated through the

ESU when one of the pushbuttons is activated. Stop signal is sent

to the RCS and fuel rack to zero order is given to the governor.

The engine will stop, and an alarm «emergency stop», emergency stop

valve activated», and information of which of the emergency stop

pushbutton is activated will be shown on the ACP. Emergency stop

may be activated from all control stands at all time, regardless of

the control position. Emergency stop is simply deactivated when the

pushbutton are pressed once more.2.12.1.4 Over-speed Shut Down Over speed is detected by the RPM

detection system, from tacho pick-ups which are mounted towards

engine fly-wheel, when the engine revolution exceeds the over speed

level (107% of MCR, adjustable). A hardwired signal from the RPM

detection system is connected to a shut down input on the ESU for

direct activation of emergency stop solenoid valve. And the RPM

detection system will by dual redundant CAN order shut down of

engine to RCS, Safety System and Governor System. This will cause

the emergency stop solenoid valve to be activated and the fuel rack

position moved to zero. The engine will stop and the alarm «over

speed» will be shown on the ACP. Over speed is reset by setting the

manoeuvring lever at the control stand to stop position. The engine

may then be restarted. -

Instruction manual AutoChief C20

44 AA-00391-A

2.12.2 Safety function Slow Down

2.12.2.1 Slow Down Function (1 20) The engine will automatically

get a load reduction by a pitch reduction signal. The load is

corresponding to the telegraph order slow (adjustable) if any of

the slow down sensors is activated. Slow down signal will be sent

to the remote control system and/or the speed control system, which

takes action. Slow down is indicated on the ACP. The inputs for

slow down sensors are as follows: Slow down 1-20: (To be project

specified for the actualproject) The input sensors may be of digital (on/off) or

analogue type. The slow downs may be configured as cancellable or

non cancellable type. Non cancellable types will reduce the engine

speed immediately; while there will be time delay on the

cancellable ones. The delay time may be adjusted individually for

each sensor. The cancellable slow-downs may be cancelled

individually from the ACP in control room, regardless of control

position, it will additionally be possible to cancel all slow-downs

from bridge while in bridge control, control room in control room

control and from engine side while in emergency control. Slow down

is automatically reset after the sensor is de-activated,

alternatively it is reset when the sensor is de-activated, and the

bridge handle is set below the slow down level. A none cancellable

slowdown will activate speed reduction immediately after the time

delay has run out. Slow down action is performed as follows: Bridge

Control Automatically by the remote controlsystem.

Control Room Contr. Automatically by the governor or manually by

the operatorLocal Control: Manually by the local speed device.

-

Instruction manual AutoChief C20

AA-00391-A 45

2.12.2.2 Cancellable Slow Down It will be possible during the

time delay to cancel the slowdown by pressing the «Cancel SLD»

pushbutton on the ACP unit. If not cancelled, the slow down will be

activated and be indicated as «slow down activated» and the speed

set-point will be reduced to the slow down level, normally

corresponding to dead slow (adjustable). It will be possible to

adjust main engine speed in the area between minimum run and slow

down level. Slow down is reset automatically, when the slow down

signal goes off. The indications mentioned will be shown on the LCD

display of the ACP unit. -

Instruction manual AutoChief C20

46 AA-00391-A

2.13 RPM measurement functions

2.13.1 Dual engine speed detector system for MAN B&W ME

Engines The AutoChiefC20 is furnished with two independent RPM

measurement systems. These systems will at all time ensure correct

reading of the RPM pickups and give alarm in case of

irregularities.There is a hardwired connection for activating overspeed shut

down from the RPME to the ESU (Safety system). The RPM detector

system is used to detect over speed, critical RPM, wrong rotation

as well as driving a variety of RPM indicators located on bridge,

in control room and engine side.2.13.2 RPM detector failure RPM monitoring is critical for

starting and running of the engine, So if the RPM measuring system

is experiencing a redundant detector failure the engine is

inhibited for starting. A principle diagram of the RPM detector

system is shown below:RPMEPick-ups RPMERPMD

Notchfilter

Low passfilter

Displayfilter

ESU

-

Instruction manual AutoChief C20

AA-00391-A 47

3 OPERATING INFORMATION

3.1 Introduction This chapter describes normal operation from

the different control locations for a normal delivery. This covers

operation from the following locations:Bridge Bridge Wings Engine Control Room Local Control Stand The

operational description is built on the case that the engine shall

be started ahead, stopped and reversed for starting astern from

each control location. Normal events during these operations are

described. More advanced operations is not covered in this

chapter. -

Instruction manual AutoChief C20

48 AA-00391-A

3.2 Operation from Bridge

3.2.1 Preparing engine for start in ECR Before starting the

engine it has to be made ready for start.1. Use the Rotary knob and scroll to the soft key Engine

State2. Press the Rotary knob for activating Engine State.

0 %

0 % 0%

50

1000

25 75

100806040200

-100-80-60-40-20

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

Stand by Emmis.mode ECR Eng N. Ready System Ready

FUEL INDEX

LEVERSETP

Engine State

0 %100-100

-50 500

PITCH ANGLE

0 rpm1200

30 9060

FIXED RPM 1

3. Observe the start block conditions and act accordingly.

ECR Eng N. Ready System ReadyStand by

Start BlockedReady for StartDelayed StartPreparing

StartStartingSTATEStart failedSTART FAIL / BLOCK

Start air distributor blocked

Main start air valve blocked

Turning gear engaged

ENGINE /CPP NOT READY

Control air vented

Start air pressure low

Start blocked

Engine blockedRepeated StartRunningStoppingEngine Tripped

HOME

Engine not readyEngine not ready

Aux. Blower Failure

Eng./CPP Not ReadyCPP Hydraulic pressureCPP Not Zero

-

Instruction manual AutoChief C20

AA-00391-A 49

CPP Pump Start

CPP Pump 1Running

4. The CPP hydraulic pump has to be started before the engine is

ready for start.5. Select the picture ME/CPP Main from the HOME picture.

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

Stand by Eng N. Ready System Ready

Engine State

PITCH ANGLE

0 rpm

0 %

-100

-50 500Propulsion Modes

Main Engine

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

ECR

CPP Pump Start

CPP Pump Stop

CPP Pump 1Running

CPP Pump 2Running

6. Move to the field CPP Pump Start and activate the field by

pushing the rotary knob7. Observe that one of the CPP pump starts

8. By selecting the Engine state display you will observe that

the engine state is now Delayed StartECR Eng. Ready System ReadyStand by

Start BlockedReady for StartDelayed StartPreparing

StartStartingSTATEStart failedSTART FAIL / BLOCK

Start air distributor blocked

Main start air valve blocked

Turning gear engaged

ENGINE /CPP NOT READY

Control air vented

Start air pressure low

Start blocked

Engine blockedRepeated StartRunningStoppingEngine Tripped

HOME

Engine not readyEngine not ready

Aux. Blower Failure

Eng./CPP Not ReadyCPP Hydraulic pressureCPP Not Zero

-

Instruction manual AutoChief C20

50 AA-00391-A

3.2.2 Transfer control from ECR to Bridge

Bridge

ECR

Local

At sea

Stand by

FWE

STOP

EmergencyStop

Bridge

ECR

Local

Bridge

ECR

Local

Incommand

Soundoff

Alarmackn.

1. Press the pushbutton Bridge on the LTU in ECR.

2. The led in the pushbutton marked bridge flickers, buzzers

sounds in ECR and Bridge.3. The upper section of the ACP mimic Home, changes status.

Control transfer Eng Ready System ReadyStand by

4. Press the pushbutton Bridge on the LTU on the bridge.

5. The led in the pushbutton marked ECR extinguishes.

6. The led in the pushbutton Bridge turns to steady light.

Buzzers on the bridge and in ECR turns off7. The upper section of the Home mimic changes status.

Bridge Eng Ready System ReadyStand by 8. Control station is now

bridge, and the led In Commandis lit on the ACP

-

Instruction manual AutoChief C20

AA-00391-A 51

3.2.3 Start Auxilliary blowers

1. Select the B&W modes page.

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

Engine State The B&W Modes page will appear on the

screen.2. Navigate to the field Preparing Start. At Sea Bridge Eng

Ready System ReadyEngine Running Mode

Emmission Mode

Prepare Start

Economy Mode

Spare

Spare

Preparing Start

Start Blocked

3. This function will start the auxiliary blowers and the field

below the preparing Start will change the text to Ready for start

when the sequence is ready.ECR Eng Ready System ReadyStand by

Start BlockedReady for StartDelayed StartPreparing

StartStartingSTATEStart failedSTART FAIL / BLOCK

Start air distributor blocked

Main start air valve blocked

Turning gear engaged

ENGINE /CPP NOT READY

Control air vented

Start air pressure low

Start blocked

Engine blockedRepeated StartRunningStoppingEngine Tripped

HOME

Engine not readyEngine not ready

Aux. Blower Failure

Eng./CPP Not ReadyCPP Hydraulic pressureCPP Not Zero

-

Instruction manual AutoChief C20

52 AA-00391-A

3.2.4 Start engine

ME Start

1. Select the ME/CPP Main page.

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

Engine State The B&W Modes page will appear on the

screen.Stand by Eng Ready System Ready

PITCH ANGLE

0 rpm

0 %

-100

-50 500Propulsion Modes

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

Bridge

CPP Pump Start

CPP Pump Stop

CPP Pump 1Running

CPP Pump 2Running

2. Select the field ME Start.

3. Observe that the engine starts by monitoring the ME RPM

indicator in the upper right corner of the mimic pictureStand by Eng Ready System Ready

PITCH ANGLE

75 rpm

0 %

-100

-50 500Propulsion Modes

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

Bridge

CPP Pump Start

CPP Pump Stop

CPP Pump 1Running

CPP Pump 2Running

4. The default Propulsion mode is Fixed RPM mode 1. The

engines rpm will stabilize at the pre-defined rpm level for this

mode. -

Instruction manual AutoChief C20

AA-00391-A 53

3.2.5 Change propulsion mode

Fixed rpm 2

1. Select the ME/CPP Main page.

HOMEME/CPP MainB&W ModesSafety System

Fine TuningMisc MenuControl Pos.LimitersAlarms

Engine State The B&W Modes page will appear on the

screen.Stand by Eng Ready System Ready

PITCH ANGLE

75 rpm

0 %

-100

-50 500Propulsion Modes

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

Bridge

CPP Pump Start

CPP Pump Stop

CPP Pump 1Running

CPP Pump 2Running

For changing the propulsion modes select from the dedicated

field:2. Select the field Fixed RPM 2.

3. Observe that the engines rpm increases from Fixed rpm level 1

to fixed rpm level 2Stand by Eng Ready System Ready

PITCH ANGLE

98 rpm

0 %

-100

-50 500Propulsion Modes

ME Start

ME Stop

Fixed rpm 1 Fixed rpm 2Sep.rpm Combinator 100

0 120

30 9060

ME RPM

Bridge

CPP Pump Start

CPP Pump Stop