Преимущества и предназначение:

- высокий пусковой крутящий момент (0,5 Гц, в 1,5 раза выше номинального крутящего момента), значительная устойчивость к перегрузкам, гибкость и удобство в эксплуатации, PID в прямом и обратном направлении и др.

- Преобразователи частоты этой серии можно раз делить на мини-преобразователи частоты, преобразователи частоты общего типа (мощные инвертеры), преобразователи частоты для вентиляторов и водяных насосов (для малых нагрузок). Они способны адаптироваться к высоким нагрузкам, стабильны и надежны в работе, поддерживают функцию автоматического энергосбережения и др.

- Преобразователи частоты могут применяться для управления электрическими двигателями и другими автоматическими системами (например, в бумажной и текстильной промышленности, для подачи воды, бетона, красок и красителей, в городских системах, в пищевой, химической и горной промышленности, в металлургии).

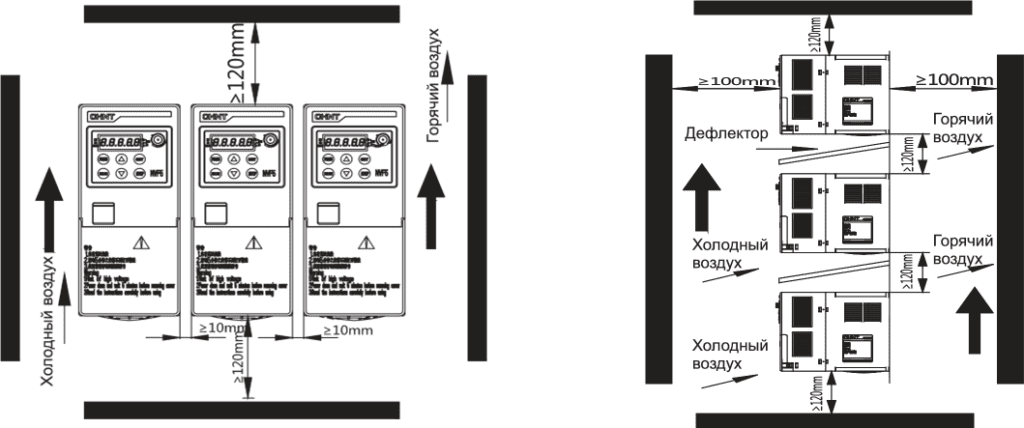

Необходимые установочные размеры

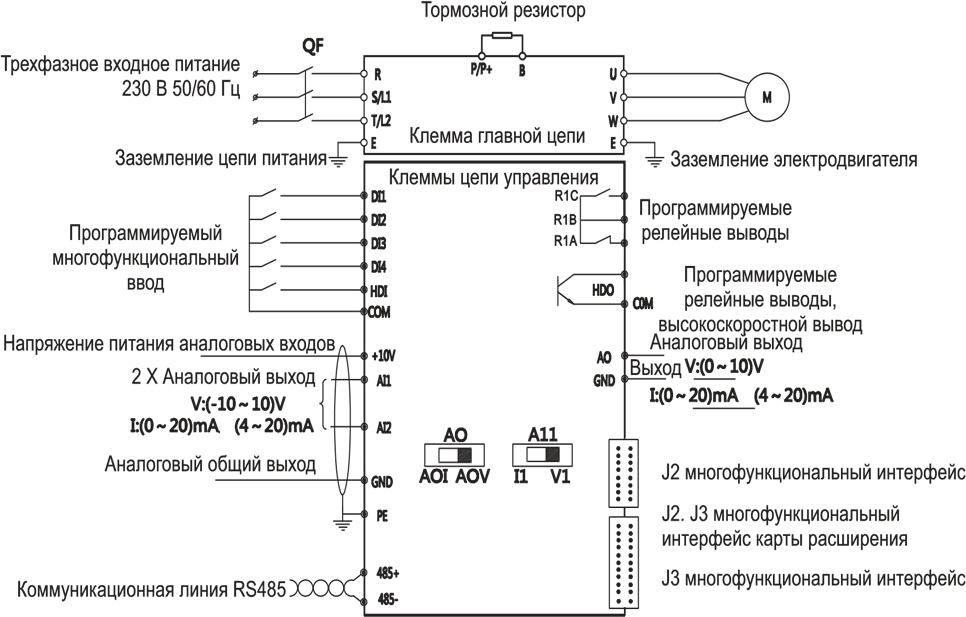

Описание контакта питания

| Обозначение | Наименование | Описание |

|---|---|---|

| R , S , T | Вход основного источника питания | Входные клеммы трехфазного питания переменного тока, соединенные с сетью заземления |

| L1 , L2 | Вход основного источника питания | Входные клеммы трехфазного питания переменного тока, соединенные с сетью заземления |

| U , V , W | Выход инвертора | Выходные клеммы трехфазного питания переменного тока, соединенные с электродвигателем переменного тока |

| Заземление | Клеммы заземления, обеспечивают надежное заземление | |

| P+ P- | Клеммы шины постоянного тока | Однофазный тип DC+ и DC |

| P B | Клеммы внешнего тормозного резистора | Клеммы трехфазного тормозного резистора |

| P+ B | Клеммы внешнего тормозного резистора | Клеммы однофазного тормозного резистора |

Базовая схема электрических соединений

- DIP-выключатель AO: Левый (0–20) мА или (4–20) мА Аналоговый токовый вывод;

- Правый (0–10) В Аналоговый вывод напряжения.

- Dip-выключатель AI1: Левый, (0~20) мА или (4–20) мА Аналоговый токовый ввод;

- Правый, (0–10) В Аналоговый вывод напряжения.

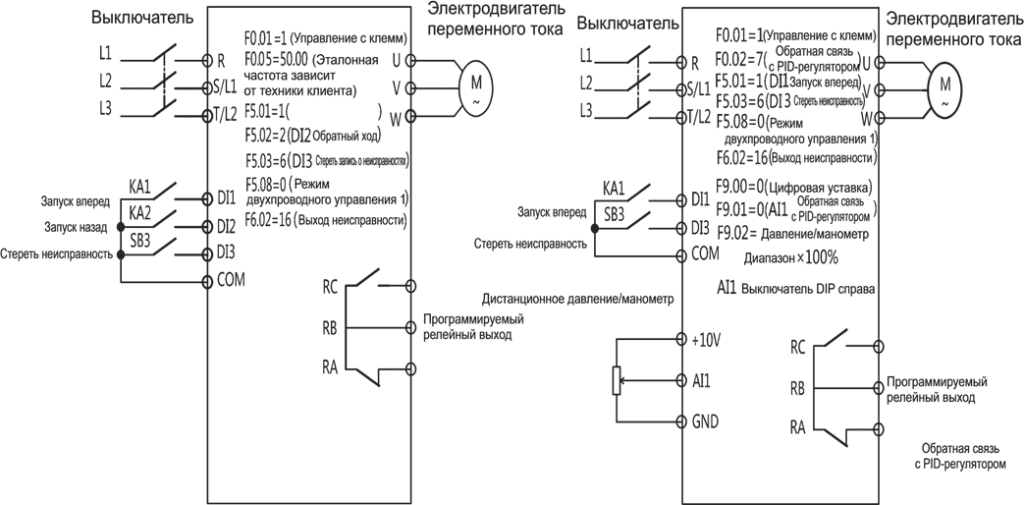

Пример подключения:

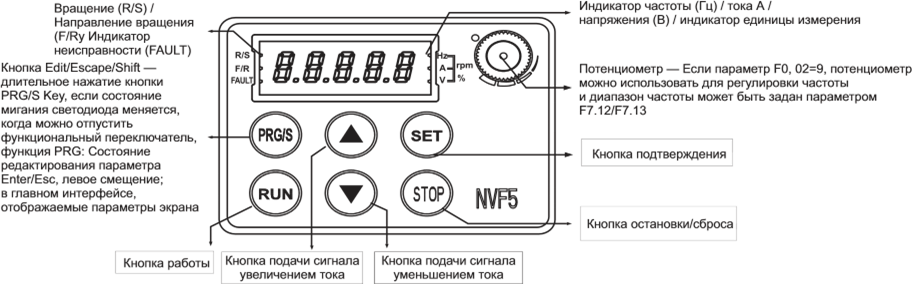

Панель управления и индикаторы

| Кнопка | Описание |

| Выбор режима меню параметров (F7.11) Режим меню простых параметров (U1)Режим меню пользовательских параметров (U2)Режим меню пользовательских инженерно-технических параметров (U3) | |

| Система отображает главный интерфейс Комбинаторная кнопка блокировки В режиме пользовательского меню, меню первого уровня Добавление параметров пользователя | |

| Система отображает главный интерфейс Комбинаторная кнопка разблокировки В режиме пользовательского меню, меню следующего уровня Удаление параметров пользователя |

Список параметров ЧП

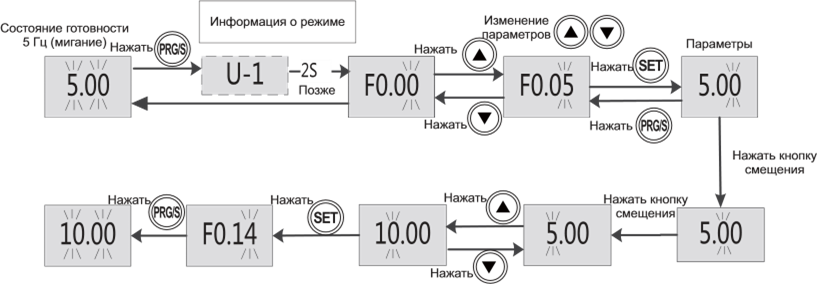

Пример задания параметра:

| Код | Наименование | Описание параметра | По умолчанию |

|---|---|---|---|

| F0.00 | Режим управления электродвигателями |

0: Векторное управление без датчиков 1: Резервирование 2: Режим V/F |

0 |

| F0.01 | Источник команды | 0: Цельная клавиатура 1: Цифровой вывод 2: Коммуникационный 3: Панель дистанционного управления |

0 |

| F0.02 | Справ. значение основной частоты |

0: Цифровая уставка 1: AH 2: AI2 3: Резервирование 4: Справ. зн. на высокочастотном импульсном входе HDI 5: Предв. настройка справ. зн. скорости 6: Справ. ПЛК 7: Справ. PID закрытого контура 8: Резервирование 9: Справ. потенциометра |

0 |

| F0.05 | Цифровая уставка | F0.09-Мин. частота~F0.08-Макс. частота | 5.00 Гц |

| F0.14 | Время ускорения 1 | (0,0–6500,0) с | Зависит от Серии |

| F0.15 | Время снижения скорости 1 | (0,0–6500,0) с | Зависит от Серии |

| F0.20 | Заводские настройки параметров | 0: Без действия 1: Удалить журнал регистрации ошибок 2: Сбросить до заводских настроек (кроме параметров электродвигателя NP и параметра F7.11) 3: Сбросить группу пользовательских параметров до заводских настроек (кроме параметров электродвигателя NP и параметра F7.11) 4: Все параметры сбрасываются до заводских настроек 5: Вспомогательные параметры 6: Использование вспомогательных параметров 7: Сохранение вспомогательных параметров Примечание: Только при использовании вспомогательных параметров вспомогательные параметры можно сохранить. Иначе при отключении и повторной подаче питания к инвертору, кроме обновленных параметров, другие параметры всегда возвращаются к начальному значению. |

0 |

| F2.00 | Тип электродвигателя | 0: Индукционный электродвигатель переменного тока 1: Резервирование 2: Резервирование |

|

| F2.01 | Питание электродвигателя NP | (0,1–1000,0) кВт | Зависит от типа электродвигателя |

| F2.02 | Напряжение электродвигателя NP |

0 В — Номинальное напряжение инвертора | Зависит от типа электродвигателя |

| F2.03 | Ток электродвигателя NP | (0,1–1000,0) A | Зависит от типа электродвигателя |

| F2.04 | Частота электродвигателя NP | 0,01 Гц ~ F0.07 | Зависит от типа электродвигателя |

| F2.05 | Количество полюсов двигателя | 2 ~ 24 | 4 |

| F2.06 | Обороты электродвигателя NP | 0-60000 об/мин | 1430 об/мин |

| F2.22 | Автоматическая настройка электродвигателя | 0: Выключено 1: Статическая настройка 2: Настройка вращения |

0 |

| F7.11 | Режим меню параметров |

1: Режим простого меню 2: Режим пользовательского меню 3: Режим технологического меню |

1 |

Список возможных неисправностей и ошибок ЧП

| Код | Тип неисправности | Причина неисправности | Действие (срабатывание) |

|---|---|---|---|

| E.OC1 E.OC2 E.OV1 E.OV2 E.OV3 |

— Перегрузка инвертора по току во время ускорения — Перегрузка инвертора по току во время торможения — Перегрузка инвертора по току во время работы на постоянной скорости — Перегрузка инвертора по напряжению во время ускорения — Перегрузка инвертора по напряжению во время торможения — Перегрузка инвертора по напряжению во время работы на постоянной скорости |

Низкое напряжение сети Напрямую и быстро запустите вращение двигателя Неправильные данные с паспортной таблички двигателя Слишком низкая мощность инвертора Неподходящая кривая V/F Потенциальная энергетическая нагрузка или большая инерционная нагрузка Ускорение/торможение Время слишком мало Быстрое изменение нагрузки Короткое замыкание электродвигателя на землю Неправильное напряжение питания Запустите снова электродвигатель на высоких оборотах Потенциальная энергетическая нагрузка или большая инерционная нагрузка Увеличьте время торможения Проверьте настройку параметров ASR в векторном режиме управления Большая инерционная нагрузка |

Проверьте время ускорения увеличения подачи питания Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Отрегулируйте кривую напряжения/частоты или отрегулируйте ручное усиление крутящего момента Добавить реген. Компоненты тормоза Проверка нагрузки Проверьте кабель двигателя Проверьте питание инвертора Запустите инвертор при остановленном электродвигателе Добавить реген. Компоненты тормоза Увеличьте время торможения См. раздел «Группа параметров F3» и как задать ASR |

| E.SPI | Ослабленная фаза на входе | Ослабленная фаза R.S.T | Проверка проводки на клемме основного питания Проверьте напряжение питания Проверьте кабель двигателя Проверьте двигатель и кабель |

| E.SPO | Ослабленная фаза на выходе | Ослабленная фаза U.V.W | Проверка проводки на клемме основного питания Проверьте напряжение питания Проверьте кабель двигателя Проверьте двигатель и кабель |

| E.FO | Срабатывание защиты силового модуля | Замыкание между фазами линии трехфазного питания или короткое замыкание на землю Мгновенная перегрузка инвертора по току Засорение вентиляционного канала или повреждение вентилятора Температура окружающей среды слишком высокая Ослабление проводки ввода/вывода или розетки Форма волны тока неисправна ввиду вывода Ослабление фазы и другие причины Повреждение вспомогательного источника питания, пониженное напряжение привода Неисправность БТИЗ-модуля Отклонения в работе панели управления |

Повторная укладка проводки, убедитесь в наличии изоляции электродвигателя См. устранение сверхтока Очистите канал вентилятора и замените вентилятор Низкая температура окружающей среды Проверьте проводку и проложите новую, Проверка проводки Попросите техническую поддержку Chint |

| E.OH1 | Перегрев теплоотвода | Температура окружающей среды слишком высокая Засорение канала вентилятора Повреждение вентилятора Неисправность IGBT Ошибка цепи проверки температуры |

Примите меры к снижению температуры окружающей среды Очистите вентиляционный канал или замените вентилятор Попросите техническую поддержку Chint |

| E.OH2 | Перегрев выпрямительного моста | Температура окружающей среды слишком высокая Засорение канала вентилятора Повреждение вентилятора Неисправность IGBT Ошибка цепи проверки температуры |

Примите меры к снижению температуры окружающей среды Очистите вентиляционный канал или замените вентилятор Попросите техническую поддержку Chint |

| E.OL1 | Перегрузка двигателя | Неправильная степень перегрузки электродвигателя Двигатель глохнет или частая смена нагрузки Длительная работа на низкой скорости с чрезмерной нагрузкой Низкое напряжение сети Неподходящая кривая напряжения/частоты Неправильные данные с заводской таблички электродвигателя Чрезмерная нагрузка Чрезмерный ток пост. тока Ускорение Время слишком мало |

Неправильная степень перегрузки электродвигателя Проверьте нагрузку электродвигателя Выбор преобразователя частоты Проверьте напряжение сети Отрегулируйте кривую напряжения/ частоты или отрегулируйте ручное усиление крутящего момента Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Снизьте пост. ток торможения Увеличьте длительность торможения Увеличьте время разгона |

| E.OL2 | Перегрузка инвертора | Неправильная степень перегрузки электродвигателя Двигатель глохнет или частая смена нагрузки Длительная работа на низкой скорости с чрезмерной нагрузкой Низкое напряжение сети Неподходящая кривая напряжения/частоты Неправильные данные с заводской таблички электродвигателя Чрезмерная нагрузка Чрезмерный ток пост. тока Ускорение Время слишком мало |

Неправильная степень перегрузки электродвигателя Проверьте нагрузку электродвигателя Выбор преобразователя частоты Проверьте напряжение сети Отрегулируйте кривую напряжения/ частоты или отрегулируйте ручное усиление крутящего момента Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Снизьте пост. ток торможения Увеличьте длительность торможения Увеличьте время разгона |

| E.tE | Автоматическая настройка | Заданы неправильные данные электродвигателя Автоматическая настройка обратного вращения запрещена при обратном ходе Плохой контакт линии соединения электродвигателя Превышение времени автоматической настройки |

Задание данных электродвигателя Запретить обратное направление Проверьте кабель двигателя Проверьте Параметр F0.08 (Максимальная частота), меньше ли он номинальной частоты |

| E.StG | Короткое замыкание электродвигателя на землю | Короткое замыкание электродвигателя на землю | Проверьте кабель двигателя |

| E.LL | Неисправность потери нагрузки | Ток инвертора менее значения Параметра FE.18 |

Проверьте наличие потери нагрузки и проверьте настройки параметра FE.17, FE.18, FE.18 |

Скачать полную инструкцию.

RU

- Manuals

- Brands

- CHINT Manuals

- Inverter

- NVF5 Series

- User instructions

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for CHINT NVF5 Series

Summary of Contents for CHINT NVF5 Series

-

Page 2

Preface Thank you for choosing Chint NVF5 series Inverter. NVF5 series Inverter adopts the speed sensorless vector control technology, It has the features of fast load response, low frequency high torque and strong overload capability,Realized the precise control of industrial equipments.NVF5 series inverter has performance of stable voltage output、torque limited、speed track、simple PLC、process… -

Page 3: Table Of Contents

NVF5 Series User Manual Table of Content Table of Contents Chapter 1 Safety Information …………..- 1 — 1.1 Safety Definition ………………..- 1 — 1.2 Safety Precautions ………………. — 1 — 1.3 Precautions for Users ………………- 3 — 1.4 Notice of Scrap ………………..

-

Page 4

NVF5 Series User Manual Table of Content 6.14 Skip Frequency ……………….. — 87 — 6.15 Forward and Reverse Switch …………… — 87 — 6.16 Regenerative Braking ………………. — 88 — 6.17 Frequency Detection Output(FDT) …………- 88 — 6.18 Output Current Zero Point Detection …………- 89 — 6.19 Running Timer ……………….. -

Page 5: Chapter 1 Safety Information

In the event of personal injury and equipment damage caused by noncompliance with the safety guidelines by you or your clients, Chint can not assume any responsibility. 1.1 Safety Definition…

-

Page 6

NVF5 Series User Manual Chapter 1 Safety Information It is not permitted to install the inverter in an environemnt containing explosive gases in case of the danger of explosion! It is not permitted to insall the inverter at a place directly exposed in sunlight in case of the danger of equipment damage! … -

Page 7: Precautions For Users

NVF5 Series User Manual Chapter 1 Safety Information Danger The inverter must be covered with the cover plate before power on in case of the danger of electric shock and explosion! The inverters which have been stored for more than 2 years must been done precharge experiment.

-

Page 8

NVF5 Series User Manual Chapter 1 Safety Information speed range of motor bearings and mechanical devices must be ensured, please inquiry in advance if having questions. Lubrication of The gearbox, gears and other mechanical devices needing mechanical lubrication probably be damaged when running at a low speed for a devices long term , please inquiry in advance if having questions. -

Page 9: Notice Of Scrap

NVF5 Series User Manual derating be used with dreating. The following figure shows a relation curve of application the rated current of the inverter and altitude. Current 100% Altitude 1000m 2000m 3000m 1.4 Notice of Scrap Danger The electrolytic capacitor of the main circuit and the electrolytic capacitor on the printed board may explode in the burning process.

-

Page 10: Chapter 2 Product Overview

NVF5 Series User Manual Chapter 2 Product Overview Chapter 2 Product Overview 2.1 Catalog Numbers Description NVF5 Number of Inverter Input Product Applicable T: Universal Input Voltage Brake Unit Phases Model Motor Power Model Rating B: Standard (kW) D: Single 2:230V…

-

Page 11: Technical Specifications

NVF5 Series User Manual Chapter 2 Product Overview Table 2.1 Inverter Model and Specification Output Power Input Adaptiv Brak Power Curren Catalog No. Capacity Current e Motor Supply Unit NVF5-0.4/TD2 NVF5-0.4/TD2-B NVF5-0.75/TD2 10.3 0.75 Optio Single-Phase NVF5-0.75/TD2-B nal(e AC 230V mbed NVF5-1.5/TD2…

-

Page 12

NVF5 Series User Manual Chapter 2 Product Overview Speed range SVC : 1:100 ; V/F:1 : 50 Speed control ±0.5% of peak speed in SVC mode accuracy Digital setting : 0.01Hz ; Frequency resolution Analog setting : Max. frequency×0.5 %… -

Page 13: Product Appearance And Diagram

NVF5 Series User Manual Chapter 2 Product Overview (Temperature at(45~50)℃,derate 1% for every 1 ℃ ( 5 ~ 95 )% RH , non-condensing Humidity Vibration Vibration accel. speed≤5.8m/s² ( -40 ~+ 70 ) ℃ Storage IP20(Standard) , IP22 with accessories…

-

Page 14: Product Dimensions And Weights

NVF5 Series User Manual Chapter 2 Product Overview Figure 2-5-2 NVF5-3.7/TS4-B~NVF5-7.5/TS4-B Appearance Diagram 2.6 Product Dimensions and Weights Figure 2-6-1 NVF5-0.4/TD2~NVF5-2.2/TD2/NVF5-0.4/TS4-B~NVF5-2.2/TS4-B Appearance Diagram — 10 -…

-

Page 15: Ip22 Top Protective Cover Description

NVF5 Series User Manual Chapter 2 Product Overview Figure 2-6-2 NVF5-3.7/TS4-B~NVF5-7.5/TS4-B Appearance Diagram And Installtion Dimension Table 2.3Dimensions and Weights(Unit:mm) Mounting Weight Catalog No. hole d NVF5-0.4/TD2 NVF5-0.4/TD2-B NVF5-0.75/TD2 Φ5.3 125.2 137.5 NVF5-0.75/TD2-B NVF5-1.5/TD2 NVF5-1.5/TD2-B NVF5-2.2/TD2 Φ5.3 146.7 137.5 1.25 NVF5-2.2/TD2-B…

-

Page 16

NVF5 Series User Manual Chapter 2 Product Overview An optional Top Protective Cover may be selected to realize IP 22 protection level.The Top Protective Cover consists of two parts:Protective Cover and Bracket.You can refer to the figure 2-6-3 to install( a Installing Bracket ;b InstallingProtective Cover) ,Apperance after being installed… -

Page 17: Chapter 3 Installation And Wiring

NVF5 Series User Manual Chapter 3 Installation and Wiring Chapter 3 Installation and Wiring 3.1 Peripherial Components Description 3.2 Peripherial Components Selection and Guideline — 13 -…

-

Page 18

NVF5 Series User Manual Chapter 3 Installation and Wiring Recommend Recommend Cable Input Current ed Circuit Specificatio Catalog No. Breaker Contactor mm² NVF5-0.4/TD2 NVF5-0.4/TD2-B NVF5-0.75/TD2 10.3 NVF5-0.75/TD2-B NVF5-1.5/TD2 15.5 NVF5-1.5/TD2-B NVF5-2.2/TD2 NVF5-2.2/TD2-B NVF5-0.4/TS4-B NVF5-0.75/TS4-B NVF5-1.5/TS4-B NVF5-2.2/TS4-B NVF5-3.7/TS4-B 12.1 NVF5-5.5/TS4-B 13.1 NVF5-7.5/TS4-B… -

Page 19

NVF5 Series User Manual Chapter 3 Installation and Wiring Power Motor Resistance Power Supply Catalog No. Power Brake Unit Value Ω NVF5-0.4/TD2 NVF5-0.4/TD2-B NVF5-0.75/TD2 0.75 NVF5-0.75/TD2-B Optional 230V (embedded) NVF5-1.5/TD2 NVF5-1.5/TD2-B NVF5-2.2/TD2 NVF5-2.2/TD2-B NVF5-0.4/TS4-B NVF5-0.75/TS4-B 0.75 NVF5-1.5/TS4-B Standard NVF5-2.2/TS4-B 380V~440V (embedded) NVF5-3.7/TS4-B… -

Page 20: Installation

NVF5 Series User Manual Chapter 3 Installation and Wiring R is actual brake resistor resistance,P is brake resistor power. 3.2.3 Output AC Reactor Descriptions The cable between Inverter and Motor should not be too long.If the cable is too long,the distributed capacitance will be large, the harmonic current will be generated easily.

-

Page 21: Description Of The Cover

Step2:Check whether the internal accessories of the inverter are complete; Step3:Check wheter the installation environment、installation distance、installation position are correct; If there are any abnormal,please contact Chint technical support. 3.4 Description of the cover — 17 -…

-

Page 22: Wiring Of Power Terminal And I/O Terminal

NVF5 Series User Manual Chapter 3 Installation and Wiring Figure 3-4-1 NVF5-0.4/TD2 ~ NVF5-2.2/TS4-B Cover Diagram Figure 3-4-2 NVF5-3.7/TS4-B~NVF5-7.5/TS4-B Cover Diagram 3.5 Wiring of Power Terminal and I/O Terminal 3.5.1 Power Terminal Description NVF5-0.4/TD2~ NVF5-2.2/TS4-B Screwdriver can only be used PH0 most ,…

-

Page 23

NVF5 Series User Manual Chapter 3 Installation and Wiring (2) Three-Phase 380V series(NVF5-0.4/TS4-B~7.5/TS4-B) Figure 3-5-2 Power Terminals NVF5-0.4/TS4-B~7.5/TS4-B Table 3.2 Power Terminals Descriptions Terminal Name Function Description The three-phase AC input R、S、T Main Power Supply Input terminals ,connecting with the power grid The Single-Phase AC input L1、L2… -

Page 24

NVF5 Series User Manual Chapter 3 Installation and Wiring Analog Input Voltage Single End Signal Range : Input AI1 ( -10 ~ +10 ) V DIP switch select current Analog or voltage of AI1, AI1 and Input Current Input Analog AI2 dafaults are voltage Signal :… -

Page 25

NVF5 Series User Manual Chapter 3 Installation and Wiring +24V Power Internal Isolation + 24V Common Supply between COM and Common R1A-R1B : N.C. ; R1B-R1C : N.O. Programmable Relay Relay Relay Contact Capacity : Output Terminals,refer to Output Output parameter F6.02… -

Page 26: I/O Terminal Description

NVF5 Series User Manual Chapter 3 Installation and Wiring 3.5.4 Wiring Checking Step One:Whether the inverter rated power and rated input voltage match with the motor specifications; Step Two: The single-phase input power supply is connected with inverter input power terminals L1, L2;…

-

Page 27

NVF5 Series User Manual Chapter 3 Installation and Wiring (2) Source pole (Sink pole) mode, using internal +24V power supply of the inverter, PLC is NPN type and common emitter type mode. Figure 3-6-2 Using Inverter Internal +24V Power Supply Connecting Mode 3.6.2 Multifunctional DO Terminal Using Description… -

Page 28: Emc Precautions

NVF5 Series User Manual Chapter 3 Installation and Wiring Figure 3-6-4 HDO Connection Mode2 3.7 EMC Precautions The inverter can produce electromagnetic interference,this interference will affect automation devices instruments probably.Correct installation reduce electromagnetic nosie of devices and improve the interference resistance . To ensure that the inverter can run normally for a long time, please refer to the following installation description.

-

Page 29

NVF5 Series User Manual Chapter 3 Installation and Wiring grounding to realize 360-degree circular connection. It is prohibited to twist the shielding layer before connecting it to the inverter in case that the shielding effect is lowered greatly or even lost. -

Page 30: Chapter 4 Integral Keypad

NVF5 Series User Manual Chapter 4 Integral Keypad Chapter 4 Integral Keypad 4.1 Integral Keypad Instructions Figure 4-1-1 LED Integral Keypad Table 4.1 Key Function Description of the Keypad Description Long press PRG/S key,if the LED flash state is changed,then you can loosen this function switch key.

-

Page 31: Integral Keypad Led Light And Display

NVF5 Series User Manual Chapter 4 Integral Keypad Enter key(Save a change/Enter next level parameter menu) When parameter F0.02 = 9,the potentiometer can be used on adjusting frequency.Also you can modify parameter F7.12 and F7.13 to adjust frequency range. 、…

-

Page 32

NVF5 Series User Manual Chapter 4 Integral Keypad Table 4.3 Correspondence between display symbols and characters / numbers Meaning Meaning Meaning Meaning Display Display Display Display The 3 unit indicators correspond to units such as Hz, A, V and so on,Shown as figure… -

Page 33: Parameter Menu Mode

NVF5 Series User Manual Chapter 4 Integral Keypad 4.3 Parameter Menu Mode 4.3.1 Parameter Menu Mode Description For user quickly find and use parameter codes,NVF5 has three types of parameter menu mode. :Include some basic commissioning parameters(See Simple Parameter Menu Chapter 5-Simple Menu Description)…

-

Page 34

NVF5 Series User Manual Chapter 4 Integral Keypad Change param- Parameter menu Ready status: eter No. Pamameters mode information 5.00Hz flash using Press Press 5.00 F0.00 F7.11 later Press Press Press Parameter menu Press Press mode information Press Press 2S later 5.00… -

Page 35

NVF5 Series User Manual Chapter 4 Integral Keypad Below example show the custom parameter adding process by adding parameters F0.00 and F1.02,see figure 4-3-4 The second The first Successfully Parameter menu Ready status: level menu: level menu: added info. mode information 5.00Hz flash… -

Page 36: Integral Keypad Lock And Password Setting

NVF5 Series User Manual Chapter 4 Integral Keypad (3) Engineering Menu Mode Parameter Setting Engineering Menu includes all parameters of inverter(See Appendix B) ,open for qualified personnel to conduct professional commissioning. Illustrate by setting parameter F0.05, modify 5.00Hz to 10.00Hz, see below operation progress,you can refer to this to modify other parameters.

-

Page 37

1 minute,the inverter will be locked again. If the password is cleared,the keypad displays P.CLr ( If users forget the setting password,you can ask for Chint technical support for getting help)… -

Page 38: Chapter 5 Simple Parameter Menu And Commissioning Process

NVF5 Series User Manual Chapter 5 Simple Parameter Menu and Commissioning Process Chapter 5 Simple Parameter Menu and Commissioning Process 5.1 Simple Parameter Menu List Code Name Attribute Parameter Description Default 0:Sensorless Vector Control Motor ◎ F0.00 1:Reserve Control Mode 2:V/F Mode…

-

Page 39

NVF5 Series User Manual Chapter 5 Simple Parameter Menu and Commissioning Process 0:No Effect 1:Fault Log Clear 2: Set to Factory Default ( Except Motor Parameters Parameter F7.11) 3 : Reset Custom Parameter Group to Factory Default(Except Motor Parameters Parameter F7.11)… -

Page 40: Simple Commissioning Process

NVF5 Series User Manual Chapter 5 Simple Parameter Menu and Commissioning Process 1:Simple Menu Mode Parameter ◎ F7.11 2:Custom Menu Mode Menu Mode 3:Engineering Menu Mode 5.2 Simple Commissioning Process — 36 -…

-

Page 41

NVF5 Series User Manual Chapter 5 Simple Parameter Menu and Commissioning Process Refer to Chapter 3 -“Installation Confirm the main and Wiring” for check correct circuit and control wiring circuit correct After power on, the default 5.00Hz Power on will be displayed on NVF5 integral… -

Page 42: Chapter 6 Parameter Function Description

NVF5 Series User Manual Chapter 6 Parameter Function Description Chapter 6 Parameter Function Description 6.1 Start Source Setting Command control is used to control inverter start、stop、run forward、run reverse、 jog. There are 4 types of command control:Integral Keypad、Terminal、Comm.、Remote Keypad,Command reference channel can be selected by parameter F0.01.

-

Page 43

NVF5 Series User Manual Chapter 6 Parameter Function Description same time,the inverter will stop. +24V STOP Reverse Forward STOP Figure 6-1-1 Two Wire Control Mode1 Parameters Setting as below: Code Name Values Description Command Channel F0.01 Terminal Control Selection Terminal… -

Page 44

NVF5 Series User Manual Chapter 6 Parameter Function Description F5.08 Terminal Control Two Wire Control Mode2 Mode Selection F5.01 Function Forward(“Enable”) Selection F5.02 Reverse Function (“Forward/Reverse Selection Running”) Three Wire Mode 1: In this mode,DI3 is Run Enable input terminal, the direction is separately controlled by DI1、DI2.Shown as below figure,in this mode when SB1 is closed,when pressing… -

Page 45

NVF5 Series User Manual Chapter 6 Parameter Function Description In this mode,DI3 is Run Enable input terminal,after Running command is given by DI1,DI2 control the direction.As shown in the below figure,when SB1 is closed,when pressing SB2 the inverter will start,when K is opened the inverter will run forward,when K is closed the inverter will run reverse;when SB1 is opened the inverter will stop. -

Page 46: Frequency Reference Setting

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.2 Frequency Reference Setting There are threr kinds of frequency reference modes,Main frequency reference、Aux. frequency reference、Main and aux. frequency reference sum mode. 6.2.1 Main Frequency Reference Selection Set parameter F0.02,select main frequency reference.There are 9 kinds of main frequency reference modes.

-

Page 47

NVF5 Series User Manual Chapter 6 Parameter Function Description Digital Given F0.09 ~ F0.07 F0.08 50.00Hz Digital Given 0.00 Hz ~ F0.08 F0.09 0.00Hz Ones Place: After Speed Setting Integral Keypad(UP/DN) : Frequency setting storage when power off : Frequency… -

Page 48

NVF5 Series User Manual Chapter 6 Parameter Function Description Set AI Voltage / Current F5.33 ~ F5.36 Curve 3Setting input sacale F5.37 ~ F5.44 Curve 4Setting (Step4)AI curve setting modes: F5.21 ~ F5.22 AI1、AI2 Filter Setting AI curve selection and filter time setting … -

Page 49

NVF5 Series User Manual Chapter 6 Parameter Function Description 3 are same) : Frequence setting% Max. Ref. level Min. Ref. level Reference V Max.Ref. Min. Ref. Figure 6-2-1 AI Curve 1 Setting The curve 4 is similar as curve 1 ~ 3,most 4 point curve can be set up which can achieve more flexible correspondence.When setting curve 4, the minimum input voltage,… -

Page 50

NVF5 Series User Manual Chapter 6 Parameter Function Description Curve 4 Break Point 2 (-100.0~+100.0)% F5.42 60.0% x. Output Setting Curve 4 Max. Reference F5.41 ~ +11.00V F5.43 10.00V Frequenc Curve 4 Max. Reference (-100.0~+100.0)% F5.44 100.0% Setting AI Curve Selection: The setting curves of the analog input terminals AI1 and AI2 are selected by the bits and ten bits of the parameter F5.24. -

Page 51

NVF5 Series User Manual Chapter 6 Parameter Function Description Code Name Default Setting Range Description 0: HDI-High Speed Pulse Input 0 ~ 1 F5.00 HDI Input Type Selection 1:Common DI (Same as DI1~DI4) 0.0 KHz ~ F5.17 HDI Min. Input Pulse F5.15… -

Page 52

NVF5 Series User Manual Chapter 6 Parameter Function Description Setting Paramet Range Comm ents Preset 100.0 (-100.0~100.0)% FA.31 Speed1 % is Preset (-100.0~100.0)% FA.32 Scale Speed 2 percent Preset (-100.0~100.0)% FA.33 age of Speed 3 F0.07- Preset (-100.0~100.0)% FA.34 Max. -

Page 53

NVF5 Series User Manual Chapter 6 Parameter Function Description 1 : Store stop step and frequency Hundreds Place : Store when power off 0:No Store 1 : Store stop step and frequency Thousands Place : Step Time Unit Selection 0:Second 1:Minute… -

Page 54

NVF5 Series User Manual Chapter 6 Parameter Function Description Time 3 3 : Accel./Decel. Time 4 Step 1Running FA.02 20.0 0.0~ 6500.0 Time FA.03 Step 2 Setting 0x0000 Same as FA.01 Step 2Running FA.04 20.0 0.0~ 6500.0 Time FA.05 Step 3 Setting 0x0000 Same as FA.01… -

Page 55

NVF5 Series User Manual Chapter 6 Parameter Function Description 0:Digital GIven 1:AI1 Back FA.46 Channel 0~4 2:AI2 Selection 3:Reverse 4:HDI Simple Running T6~T12 Simple PLC Step Complete Indication Simple PLC Cycle Complete indication Figure 6-2-3 Simple PLC as Main Frequency Reference There are 3 kinds of operation mode for inverter Simple PLC function:Single cycle… -

Page 56

NVF5 Series User Manual Chapter 6 Parameter Function Description Simple PLC Running T6~T12 T14 T15 RUN Command Figure 6-2-5 Simple PLC Single Cycle then Hold The Final Value Mode Continuous Cycle: First Cycle Second Cycle RUN Command Figure 6-2-6 Simple PLC Continuous Cycle Mode 6.2.7 Process PID Main Frequency Setting… -

Page 57

NVF5 Series User Manual Chapter 6 Parameter Function Description F9.00 PID ref. source F9.02 selection PID para. switch para.1(F9.03~F9.05) F9.15 Reserved para.2(F9.17~F9.19) close loop switch condition(F9.20~ adjust feature F9.22) PID pause Comm. ( ) DI1~DI4 function 43 command PID offset limit Multi-segment (… -

Page 58

NVF5 Series User Manual Chapter 6 Parameter Function Description 8:Reserve Reference Digital (0.0 ~ 100.0)% F9.02 50.0% Given Setting 0.0 ~ 100.0 F9.03 20.0 0.01 ~ 10.00 F9.04 2.00 0.000 ~ 10.000 F9.05 0.000 (0.01 ~ 50.00)s F9.06 Sampling Period 0.50s… -

Page 59

NVF5 Series User Manual Chapter 6 Parameter Function Description 0.0% ~ F9.22 F9.21 Switch Offset 1 20.0% F9.21 ~ 100.0% F9.22 Switch Offset 2 80.0% Close Loop Preset (0.0 ~ 100.0)% F9.23 0.0% Value Preset Value (0.00 ~ 650.00)s F9.24 0.00s… -

Page 60

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.2.8 Communication Mian Frequency Setting See Appendix A – Modbus Communication Protocol 6.2.9 Auxiliary Frequency Input Setting Set parameter F0.03 to select Aux. Frequency as speed reference,the setting mode is same as main frequency setting mode,refer to “6.2.1 Main Frequency Reference… -

Page 61: Start And Stop Setting

NVF5 Series User Manual Chapter 6 Parameter Function Description Frequency highest Limit: Limit max. output frequency, motor is not allowed to run over the highest limit frequency; Frequency Lowest Limit:Limit min. output frequency,motor is not allowed to run below the lowest limit frequency;…

-

Page 62

NVF5 Series User Manual Chapter 6 Parameter Function Description Set parameter F1.00=0 , directly start inverter ,suitable for most kinds of load.Set parameter F1.01-direct starting frequency:suitable for some constant torque load. Freq. Hz Setting Freq. Start Freq. time Start Freq. Holding time… -

Page 63

NVF5 Series User Manual Chapter 6 Parameter Function Description Outmut freq. Motor speed Acceleration Motor speed tracking time Time Figure 6-3-3 Speed Tracking and then Start Time Sequence Chart 6.3.2 Stop Mode The NVF5 has three kinds of stop modes,ramp deceleration stop、coast stop、ramp stop+DC injection braking stop.Set parameter F1.05 to select stop mode. -

Page 64

NVF5 Series User Manual Chapter 6 Parameter Function Description Freq. Running freq. Time Deceleration time Stop command Figure 6-3-4 Ramp Decel. Stop Time Sequence Chart Coast Stop Set parameter F1.05=1,inverter coast stop. When the stop command is effective,the inverter immediately stops output and the motor will execute coast stop. -

Page 65

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.3.3 Accel./Decel. Time and Curve Setting The acceleration time refers to the time required for the inverter to accelerate from zero to F0.07-maximum output frequency;the deceleration time refers to the time required for the inverter to decelerate from F0.07-maximum output frequency to zero. -

Page 66: Motor Auto Tuning

NVF5 Series User Manual Chapter 6 Parameter Function Description on Series Depend (0.0 ~ 6500.0)s F8.07 Decel.Time 3 on Series Depend (0.0 ~ 6500.0)s F8.08 Accel. Time 4 on Series Depend (0.0 ~ 6500.0)s F8.09 Decel.Time 4 on Series 0:Linear Acceleration Accel./Decel.

-

Page 67

NVF5 Series User Manual Chapter 6 Parameter Function Description (0 ~ 60000)rpm F2.06 Motor NP RPM 1430 rpm (0.001~65.535)Ω ( Inverter Power <=55kW) Motor Stator Depend on F2.07 (0.0001~6.5535)Ω Impedance motor type ( Inverter Power >55kW) (0.001~65.535)Ω ( Inverter Power <=55kW)… -

Page 68: V/F Parameters

NVF5 Series User Manual Chapter 6 Parameter Function Description difficult to separate and do not allow rotate auto tuning operation; Correctly input motor nameplate data:F2.00 ~ F2.06 ; 2. Modify parameter F2.22 to 1,press Run key to start inverter; 3. When the keypad displays“-TUN-”,auto tuning complete;…

-

Page 69

NVF5 Series User Manual Chapter 6 Parameter Function Description Torque Boost 0.00Hz ~F0.07 50.00Hz F4.02 Cut-off Point Multi-point F4.05 ~ F2.04 0.00Hz F4.03 Frequency Point 3 Multi-point (0.0 ~ 100.0) % 0.0% F4.04 Voltage Point 3 Multi-point F4.07 ~ F4.03 0.00Hz… -

Page 70

NVF5 Series User Manual Chapter 6 Parameter Function Description Output Vol. V (f1,V1) multi-point VF Max. curve point 1 Output Vol. (f2,V2) multi-point VF curve point 2 (f3,V3) multi-point VF curve point 3 Output freq. f Normal running freq. Figure 6-5-2 Custom Multi-Point V/F Curve ●… -

Page 71: Vector Control Parameters

NVF5 Series User Manual Chapter 6 Parameter Function Description Voltage (0.0 ~ 100.0) 100% motor VF Separation Voltage F4.13 0.0% Digital Given rated voltage VF Separation Voltage (0.0 ~ 10.0)s F4.14 0.5s Rising Time VF Separation Voltage (0.0 ~ 10.0)s F4.15…

-

Page 72

NVF5 Series User Manual Chapter 6 Parameter Function Description 1 : Torque Regulation Speed Loop Kp 1 ( Low 1 ~ 100 F3.01 Speed ASR1-P) Speed Loop Ki Time 1 (Low (0.01 ~ 10.00) s F3.02 0.50s Speed ASR1-I) Switch Frequency1 0 Hz ~… -

Page 73

NVF5 Series User Manual Chapter 6 Parameter Function Description Figure 6-6-1 Speed Loop PI Parameter Switch ● Speed loop slip compensation coefficient This parameter can adjust the accuracy of motor speed stability. When the frequency of the motor is lower than the output frequency of the inverter, the parameter can be increased. -

Page 74

NVF5 Series User Manual Chapter 6 Parameter Function Description Accel. Time Torque Control (0.00 ~ 650.00)s F3.25 0.10s Decel. Tim Forward Speed (0.0~100.0)% F3.26 Limit in Torque 100.0% Mode Reverse Speed (0.0~100.0)% F3.27 Limit in Torque 100.0% Mode ● Speed Regulator、Torque Regulator Mode Selection Speed / Torque Mode is switched by parameter F3.00 ,also it can be switched by… -

Page 75: Overcurrent Stall Protection

NVF5 Series User Manual Chapter 6 Parameter Function Description Torque Regulation Kp 0 ~ 60000 F3.13 2000 Torque Regulation Ki 0 ~ 60000 F3.14 1300 The integral regulator of the current loop does not use integral time as dimension, but directly sets integral gain.

-

Page 76: Protective Function

NVF5 Series User Manual Chapter 6 Parameter Function Description Output Vol. Over voltage stall point Time Output Freq. Time Figure 6-8-1 OverVoltage Stall Action Diagram Code Name Default Setting Range Description 0:Ineffective Overvoltage Stall 1:Effective 0 ~ 2 FE.04 Protection :…

-

Page 77

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.9.2 Motor Overload Protection Code Name Default Setting Range Description 0:Ineffective Motor Overload 0 ~ 1 FE.00 Protection Selection 1:Effective Motor Overvoload 0.20 ~ 10.00 FE.01 1.00 Protection Gain 0:Ineffective Motor… -

Page 78

NVF5 Series User Manual Chapter 6 Parameter Function Description overload early alarm. When the early alarm level of motor overload FE.03 is set to 100%, the alarm advance is 0. At this time, the early alarm and overload protection occur simultaneously. -

Page 79

NVF5 Series User Manual Chapter 6 Parameter Function Description Load Loss (0.0 ~ 60.0)s FE.19 Detection 1.0s Time 6.9.5 Fault Reset Fault reset provides 2 method: Manual reset、 Auto rest (Restricted by auto reset time) 1. Moudle Fault、 Overcurrent Fault etc: Auto reset is prohibited, only manual reset;… -

Page 80

NVF5 Series User Manual Chapter 6 Parameter Function Description E.SPI(Same as ones place) Hundreds Place: Output Phase Loss E.SPO (Same as ones place) Thousands Place : External Fault E.EF (Same as ones place) Place : Ones Comm. Abnormal E.CE 0:Coast Stop 1:Stop per Stop… -

Page 81

NVF5 Series User Manual Chapter 6 Parameter Function Description loss,recover to setting frequency when load recover Tens Place:PID Feedback Loss Running Mode-E.FbL 0:Coast Stop 1:Stop per Stop Mode 2:Keep Running Hundreds Place: Excessive Speed Deviation- E.dEv ( Same as tens place)… -

Page 82: Monitoring Function

NVF5 Series User Manual Chapter 6 Parameter Function Description ( Corresponding Max. Frequency) 6.10 Monitoring Function 6.10.1 Monitoring Parameters Customers can directly monitor the parameters of inverter running state and standby state through the integral keypad, and can select the display state parameters by the keypad by setting parameters.

-

Page 83

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.11.1 Digital Input Setting(DI) NVF5 series has 5 mutifunctional Digital inputs,and HDI terminal can be used for High Speed Pulse input,Terminal setting are as below Code Name Default Setting Range Description 0 ~… -

Page 84

NVF5 Series User Manual Chapter 6 Parameter Function Description parameters、PID parameters)are restored,DI is off,inverter recovers to the memory state before. Stop command is effective to all running mode, Ramp Stop When it is ON,the Stop Mode is set according to parameterF1.05… -

Page 85

Reserve Current RunningTime Inverter current running time is cleared to 0 Clear 6.11.2 Digital Output Terminal Function(DO) NVF5 series has 1 standard Digital Output terminal,1 multifunctional Relay Output terminal, terminal configuration is as below. Code Name Default Setting Range Description 0 ~… -

Page 86

NVF5 Series User Manual Chapter 6 Parameter Function Description Relay Output 0 ~ 63 F6.02 Selection F6.03 Reserve Output Terminal Effective Status 0x0000 ~ 0x0003 F6.04 0x0000 Setting(HDO、RO) Output Delay (0.0 ~ 3600.0) s F6.05 0.0s Time HDO Output Setting (0.0 ~… -

Page 87

NVF5 Series User Manual Chapter 6 Parameter Function Description Torque Limiting Torque Command is in torque limiting progress, Process DO is effective. Speed Direction Indicate motor running direction The frequency of the inverter is within a certain range of target frequency.(Target frequency Frequency Reach ±F6.13 Value×Max. -

Page 88

Reach effective. 6.11.3 Analog Input Function(AI) NVF5 Series has 2 Analog Input terminals -AI1、AI2,with -10V ~ +10V、4mA ~ 20mA,AI2 can select V or mA signal by Dip switch on the PCB board.AI setting mode,See Parameter“6.2.3 Analog Main Frequency Setting”. 6.11.4 Analog、Pulse Output Function(AO、HDO)… -

Page 89: Ride Through Function

NVF5 Series User Manual Chapter 6 Parameter Function Description (0.0~1000.0)V DC Bus Voltage (0 ~ 10)V (0 ~ 10)V (0.01 ~ 100.00)kHz Pulse Input (0 ~ 1000)A Output Current (0 ~ 1000)V Output Voltage -2 times Motor Rated Current ~ + 2 Output Torque(+/-)…

-

Page 90: Jogging

NVF5 Series User Manual Chapter 6 Parameter Function Description Judgement Voltage of 100% equals (60.0 ~ 100.0) FE.16 Instantaneous Power 80.0% Standard DC Failure Bus Voltage ● Deceleration Operation Mode: When the power line recovers, the Output Frequency of the inverter will be restored to the target frequency according to the accel. Time.

-

Page 91: Skip Frequency

NVF5 Series User Manual Chapter 6 Parameter Function Description 6.14 Skip Frequency By setting the Skip Frequency, inverter can avoid the mechanical resonance point of the load.NVF5 can be set three Skip Frequency,if all Skip Frequency are set to 0,Skip…

-

Page 92: Regenerative Braking

NVF5 Series User Manual Chapter 6 Parameter Function Description Freq. Hz Time t Forward/Reverse switch deadband time Figure 6-15-1 Forward and Reverse Switch 6.16 Regenerative Braking When the motor decelerates, if the load is too large and the decal. time is too short, the DC Bus voltage of the inverter may rise to the overvoltage level.

-

Page 93: Output Current Zero Point Detection

NVF5 Series User Manual Chapter 6 Parameter Function Description Output Freq. FDT1 FDT1 Level Time Time Figure 6-17-1 Frequency Detection 6.18 Output Current Zero Point Detection For setting Zero point detection value of output current. Code Name Default Setting Range…

-

Page 94: Start At Power Up

NVF5 Series User Manual Chapter 6 Parameter Function Description Timer Running (0.0 ~ 6500.0)min F8.33 0.0min Timer 6.20 Start At Power Up Enable/disable inverter automatically start on power up with different Start Commands and the Auto Restart delay time. Code…

-

Page 95: Chapter 7 Troubleshooting

7.1.2 Fault description and Trouble shooting If a fault appreas,Please see for an explanation of the fault code and check by youself firstly before asking for help from Chint or Chint channels.When you need support,please contact Chint or Chint channels.

-

Page 96

NVF5 Series User Manual Chapter 7 Troubleshooting Adjust V/F cruve or adjust 6、 Unsuitable V / F curve manual torque boost Check the input power 1、 Low grid voltage supply Inverter 2、 Decel. Time too short Increase decel. time Decel. -

Page 97

NVF5 Series User Manual Chapter 7 Troubleshooting Protection interphase short circuit or motor insulation ground short circuit 2、 Inverter instantaneous See overcurrent handling overcurrent Clear the fan duct or 3、 Fan duct blockage or fan replace damage the fan 4、High ambient temperature… -

Page 98

NVF5 Series User Manual Chapter 7 Troubleshooting manual torque boost 1、 Incorrect Motor Nameplate Motor auto tuning Enlarge inverter power rate 2、Excessive load Reduce DC brake current, increase brake 3、Excessive DC Brake Inverter time E.OL2 Overload Increase accel. time 4、 Accel. Time too short 5、… -

Page 99: Abnormal Operation And Solution

NVF5 Series User Manual Chapter 7 Troubleshooting ground Check whether load loss or Inverter Current is Smaller than Load Loss E.LL the value of Parameter parameter FE.17、FE.18、 Fault FE.18 FE.19 parameter setting Check PID feedback signal Inverter PID Feedback is…

-

Page 100

NVF5 Series User Manual Chapter 7 Troubleshooting zero speed, and automatically reset” setting and fault the running cause indicator light Check external interrupt External interrupt settings and fault source 0 Frequency Setting Check frequency setting Start frequency is higher Check start frequency… -

Page 101: Chapter 8 Maintenance

NVF5 Series User Manual Chapter 8 Maintenance Chapter 8 Maintenance 8.1 Maintenance Instructions Due to the influence of temperature, humidity, dust and vibration in the environment, internal component aging and wear of the inverter and many other reasons will lead to the potential faults;…

-

Page 102: Routine Maintenance

NVF5 Series User Manual Chapter 8 Maintenance 5. Check whether the DC Bus filter capacitors discolor, Peculiar smell, bubbling, leakage, etc. 8.3 Routine Maintenance The inverter must run in the standard environment. If some unexpected situations occur during operation, the user should follow the instructions in the table below to do routine maintenance job.

-

Page 103: Spare Parts Replacement

NVF5 Series User Manual Chapter 8 Maintenance 2.Whether the power terminals are in poor contact, whether copper bus bar connections are with overheating signs; 3.Whether the power cables, control cables are damaged, especially the casing in contact with the metal surface is with cut marks;…

-

Page 104: Storage

NVF5 Series User Manual Chapter 8 Maintenance Discriminant criteria: Whether there is liquid leakage, whether the safety valve has projected, measurement of the electrostatic capacitance and insulation resistance. 3.Relay Possible damaged reason: Corrosion, frequent action.。 Discriminant criteria: Opening and closing failure.

-

Page 105: Appendix A Rs485-Modbus Communication Instructions

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Appendix A RS485-MODBUS Communication Instructions A.1 Networking Mode NVF5 inverter provides RS485 communication interface and adopts the international standard Modbus communication protocol for Master-Slave communication. Users can achieve centralized control (set the control command and running frequency of inverter, modification of the related parameters, monitoring of inverter status and fault information etc.) through PC/PLC, host computer monitoring software etc., to adapt to the specific…

-

Page 106: Protocol Format

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions A.4 Protocol Format Modbus protocol supports both RTU and ASCII modes. The corresponding frame format is shown below. RTU Mode Modbus data frame Start Slave Check Command Data code code address (at least 3.5 characters free)

-

Page 107: Protocol Application

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions In ASCII mode, the frame head is»0x3A», the default frame tail is“0x0D, 0x0A”, and the frame tail can be configured by users. In this mode, besides the frame head and tail, the other data bytes are all sent in ASCII code;…

-

Page 108

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Group number mapping of the inverter function parameter is the upper bytes of Modbus register address (0~F corresponding values are 0x00~0x0F); Group Index (parameter number in the group) mapping is the lower bytes of Modbus register address (00~99 corresponding values are 0x00~0x63). -

Page 109: Control Command, State Information And Fault Information

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Type 16-bit unsigned bit data type 32-bit unsigned bit data type 8-bit signed bit data type 16-bit signed bit data type 32-bit signed bit data type No magnification factor 1X magnification…

-

Page 110

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Power Read-write Description Address Explanation Down property Saving 0x00:No command 0x01:Forward running 0x02:Reverse running Communication 0x03:Run stop Command(F0.01 = 0x3200 0x04:Forward jog 2Communication 0x05:Reverse jog Command) 0x06:Jog stop 0x07:Free stop 0x08:Fault reset bit00:… -

Page 111

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Power Read-write Description Address Explanation Down property Saving bit12 : Inverter fault (1 effective) bit13:Speed control (1 effective) bit14:Torque control (1 effective) bit15:Undervoltage (0 undervoltage) 0x3400 Output Frequency 0x3401 Setting Frequency… -

Page 112: Parameter Management

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions Power Read-write Description Address Explanation Down property Saving function code. Information feedback to the host computer is the dexadecimal data instead of fault code. A.7 Parameter Management Modbus master station can obtain the parameter group quantity and group number from the CPU through the corresponding command, as well as the internal parameter number .

-

Page 113: Network Wiring

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions …… …… …… Obtain number Obtain the number of 0x43xx parameters parameters in Group (xx= Max-1) in Group Max parameters A.8 Network Wiring A.8.1 Topology structure RS-485-Modbus repeater is not configured. There is a trunk cable which is directly connected with all devices (daisy-chained) or connected through short branch cable.

-

Page 114

NVF5 Series User Manual Appendix A RS485-MODBUS Communication Instructions 0x04 Slave equipment fault 0x05 Confirm 0x06 Slave equipment busy 0x08 Memory parity error 0x0A Gateway path is not available 0x0B Gateway target device failed to respond 0x10 CRC check code error… -

Page 115: Appendix B Parameter List

NVF5 Series User Manual Appendix B Parameter list Appendix B Parameter list Items Description Function Parameter Group and Parameter No Code Full Name of Parameter Name Parameter Parameter Function Descriptions Description Unit: Unit Name Unit Name Unit Name Centigr ℃…

-

Page 116

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change F0 Basic Program Group 0:Sensorless Vector Control ◎ F0.00 Motor Control Mode 1:Reserve 2:V/F Mode 0:Integral Keypad 1:Digital Terminal ○ F0.01 Command Source 2:Communication 3:Remote Panel 0:Digital Given… -

Page 117

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change ○ 0.00Hz ~ F0.08 F0.09 Minimum Frequency 0.00 Hz Basic Operating ○ 0.00Hz ~ F0.07 F0.10 50.00 Hz Frequency Depend on ● (0 ~ 480)V F0.11 Max. -

Page 118

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 2:No effect in Decel. Mode 0:No Effect 1:Fault Log Clear 2: Set to Factory Default ( Except Motor Parameters Parameter F7.11) 3 : Reset Custom Parameter Group to Factory Default(Except… -

Page 119

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Starting frequency DC braking ○ (0.0 ~ 100.0)s F1.07 0.0s wait time ( 0.0 ~ 100.0 ) % ( Rated DC braking ○ F1.08 0.0% current Current)… -

Page 120

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change (0.001 ~ 65.535) mH (Inverter Power > 55kW) (0.1 ~ 6553.5)mH(Inverter Motor Mutual Power <= 55kW) Depend on ◎ F2.10 (0.01 ~ 655.35)mH(Inverter motor type inductance Power >… -

Page 121

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change ○ 0 ~ 60000 F3.14 Torque Regulation Ki 1300 0:Integral Keypad 1:AI1 2:AI2 3:Reserve Torque Reference ◎ F3.19 4 : HDI High Speed Pulse Selection Reference 5:Reserve… -

Page 122

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Multi-point ◎ ( 0.0 ~ 100.0)% F4.04 0.0% Voltage Point 3 Multi-point ◎ F4.07 ~ F4.03 F4.05 0.00Hz Frequency Point 2 Multi-point ◎ ( 0.0 ~ 100.0)% F4.06… -

Page 123

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 8:Reserve 9:Running Pause 10: Ramp Stop 11:DC Brake Deceleration 12:Coast Stop 13:Terminal Accel. UP 14:Terminal Decel. DOWN 15:Switch to Keypad Command 16 : Swith Digital Input Command 17:Switch to Comm.Command… -

Page 124

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 45:PID Invert 46:PID Parameter Switch 47:Reserve 48:DC Brake 49:Frequency Setting Effective Terminal 50:Reserve 51:Current RunningTime Clear 52~63:Reserve Range:0x0000 ~ 0x001F Binary Setting: 0:Normal Logic DI Terminal Effective 1:Invert… -

Page 125

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Time ○ F5.20 Reserve ○ (0.00 ~ 10.00)s F5.21 AI1 Filter 0.05s ○ (0.00 ~ 10.00)s F5.22 AI2 Filter 0.05s ○ F5.23 Reserve Range:0x0000~0x0333 Place : AI1… -

Page 126

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Curve 4 Break Point 1 ○ F5.37 ~ F5.41 F5.39 3.00V Reference Curve 4 Break Point 1 ○ (-100.0 ~ +100.0)% F5.40 30.0% Setting Curve 4 Break Point 2 ○… -

Page 127

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 15:Inverter Ready 16:Fault Output 17~18:Reserve 19:In Torque Limiting Process 20:Speed Direction 21:PFC 22:Frequency Reach 23:Reserve 24:In Load Loss Progress 25:Zero Current Status 26:Current Reach1 27:Current Reach 2 28:Temperature Reach… -

Page 128

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 2:Setting Frequency(0~ Max. Output Frequency) 3:Ramp Reference Frequency ( After Accel./Decel. ) ( 0~ Max. Output Frequency) 4:Output RPM(0~ Max. Output Frequency) 5:Output Current1(0~2 times Inverter Rated Current)… -

Page 129

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change ( FAR ) Detection Width ○ 0.00 Hz ~ F0.07 F6.14 FDT1 Level 50.00Hz ○ (0.0 ~ 100.0)% F6.15 FDT1 Lagging 5.0% ○ 0.00 Hz ~ F0.07 F6.16… -

Page 130

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Bit12:Torque Reference Value (%Light) Bit13:PLC Current Step No. Bit14:Reference RPM Bit15:Reserve Range:0x0000~0x000F Bit00:AI1 Value(V Light) Bit01:AI2 Value(V Light) Running Status ○ F7.06 0x0000 Bit02: Reserve Selection2 Bit03 :… -

Page 131

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Percentage Keypad Potentiometer Max. Corresponding ○ (0.0~100.0)% F7.13 100.0% Max. Frequency Percentage F8 Enhanced Parameter Group ~ ○ 0.10 Max. Output F8.00 Jog Frequency 5.00Hz Frequency F0.07 ○… -

Page 132

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Output Current Over ○ (0.00~600.00)s F8.23 Limit Detection Delay 0.00s Time Current Reach ○ (0.0~300.0)% F8.24 100.0% Detection Value 1 Current Reach ○ (0.0~300.0)% F8.25 Detection Value 0.0%… -

Page 133

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 0:AI1 1:AI2 2:Reserve 3:AI1+AI2 ◎ F9.01 Feedback Selection 4:AI1-AI2 5:MIN(AI1,AI2) 6:MAX(AI1,AI2) 7: HDI 8:Reserve Reference Digital ○ ( 0.0 ~ 100.0)% F9.02 50.0% Given Setting ○… -

Page 134

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change ○ F9.18 0.01 ~ 10.00 2.00 ○ F9.19 0 ~ 10.000 0.000 0:Ineffective Parameter Switch ○ 1:DI Switch F9.20 Selection 2:Switch Automaticlly Based On Offset ○… -

Page 135

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 0:Second 1:Minute Range : 0x0000 ~ 0x0315 Ones Place: Frequency Source 0:Multi-Step Frequency 1:AI1 2:AI2 3:Reserve 4:HDI 5:PID Output ○ FA.01 Step 1 Setting Tens Place:Running Direction 0x0000 0:Forward… -

Page 136

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change ○ 0.0 ~ 6500.0 FA.22 Step 11 Running Time 20.0 ○ FA.23 Step 12 Setting Same as FA.01 0x0000 ○ 0.0 ~ 6500.0 FA.24 Step 12 Running Time 20.0… -

Page 137

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 6:115200bps 0:No Check(8-N-2)for RTU 1:Odd Check(8-O-1)for RTU 2:Even Check(8-E-1)for RTU 3:No Check(7-N-2)for RTU 4:Odd Check(7-O-1)for RTU 5:Even Check(7-E-1)for RTU ○ Fb.02 Data Bit Checking 6:No Check(8-N-2)for ASCII 7:Odd Check(8-O-1)for ASCII… -

Page 138

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Frequency ● (0.00 ~ 600.00)Hz Fd .03 Setting(After 0.00Hz Accel./Decel.) (-300.0 ~ +300.0)%(Motor ● Fd .04 Torque Reference 0.0% Rated Torque) ● (0.00 ~ +600.00)Hz Fd .05 Output Frequency 0.00Hz… -

Page 139

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Range:0x0000~0xFFFF 0:Off; 1:On Ones Place: ● Fd .18 DI Terminal Status 0x0000 BIT0~BIT3:DI1~DI4 Tens Place: BIT0:HDI BIT1~BIT3:Reserve Range:0x0000~0xFFFF 0:Off; 1:On ● Fd .19 DO Terminal Status 0x0000 Ones Place:… -

Page 140

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Fan Running Elapsed ● 0 ~ Max.65535Hours Fd .38 Time (0 ~ 999.9)kVA(Depend On Set By ● Fd .39 Rated Capacity Factory Series) (0 ~ 999) V (Depend On Set By ●… -

Page 141

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Protection Current 0:Ineffective Ground Short Circuit ○ FE.09 Protection Selection 1:Effective 0:Ineffective Instantaneous power ○ FE.13 1:Deceleration Off Action Selection 2:Decel. Stop Judgement Voltage of ○… -

Page 142

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 0:No fault- No 1:Accel. Overcurrent-E.OC1 2:Decel. Overcurrent-E.OC2 : Constant Speed Overcurrent-E.OC3 4:Accel. Overvoltage-E.OU1 5:Decel. Overvoltage-E.OU2 6:Constant Speed Overvoltage- E.OU3 7:Reserve 8:Input Phase Loss-E.SPI 9:Output Phase Loss-E.SPO 10:IGBT Protection-E.FO… -

Page 143

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change 34 : Rapid Current Limit Overtime-E.CbC : Inverter Hardware Overcurrent Abnormal-E.Inv 36:Load Loss-E.LL 37 : PID Feedback Loss in Running Mode-E.FbL : Motor Over Temperature-E.OT 39:Reserve 40:Reserve… -

Page 144

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Place : External Thousands E.EF ( Same as ones Fault- place) 0x0000 ~ 0x2222 Comm. Abnormal Ones Place: -E.CE 0:Coast Stop 1:Stop per Stop Mode 2:Keep Running Protection Selection2 ○… -

Page 145

NVF5 Series User Manual Appendix B Parameter list Code Name Setting Range Default Change Thousands Plac:Reserve 0 ~ 4 0:Current Frequency Continuing Running 1:Setting Frequency ○ FE.43 Frequency Slection 2:Upper Limit Frequency when Faulted 3:Lower Limit Frequency 4:Abnormal Reserve Frequency (0.0 ~ 100.0)… -

Page 146: Appendix C Accessiories

NVF5 Series User Manual Appendix C Accessiories Appendix C Accessiories Name Description Catalog No. For meeting IP22 protection level use,please refer to the installation guideline Top protective cover NVF5-FH — 142 -…

-

Page 147: Quality Commitment

If there are any agreement, with the principle of the priority of agreement. 6.Chint sales region office, Chint qualified channels of China can provide post sales services for inverter products. — 143 -…

CHINT NVF5 Series Inverter PDF User Guides and Manuals for Free Download: Found (2) Manuals for CHINT NVF5 Series Device Model (User Instructions, Quick Start-up Wizard)

More Inverter Device Models:

-

FXA

FXAEP2800I

FXAEP2800IInstruction manual (Original instructions) GB pg 7-17Käyttöohje(Alkuperäisten ohjeiden käännös) FI pg 18-29Bruksanvisning (Översättning av originalinstruktionerna) SE pg 30-40Bruksanvisning (Oversettelse av de opprinnelige instruksjonene) NO pg 41-52Руководство пользователя(Пе …

FXAEP2800I Inverter, 120

-

stayer

GAV2800

esitgbpfrManual de instruccionesGAV2800GAV5500EGAV7500EÁrea Empresarial Andalucía — Sector ICalle Sierra de Cazorla nº7C.P: 28320 Pinto (Madrid) [email protected] www.grupostayer.comIstruzioni d’usoOperating instructionsManual de instruçõesInstructions d’emploi …

GAV2800 Inverter, 40

-

Goodwe

ES Series

ES SERIES USER MANUALHYBRID INVERTERJIANGSU GOODWE POWER SUPPLY TECHNOLOGY CO.,LTDNo. 90 Zijin Rd., New District, Suzhou, 215011, China www.goodwe.com [email protected] Master APP SEMS Portal APP LinkedIn Company’soffical websiteVer 1.02020-09-24 …

ES Series Inverter, 20

-

Parker

AC30P

AC30 seriesVariable Speed Drive HA503711U002 Issue 1: Hardware Installation Manual Frames K — Naerospaceclimate controlelectromechanicalfiltrationfluid & gas handlinghydraulicspneumaticsprocess controlsealing & shieldingENGINEERING YOUR SUCCESS. …

AC30P Inverter, 176

Recommended Documentation:

|

|

Related Devices:

|

Types of Manuals:

The main types of CHINT NVF5 Series instructions:

- User guide — rules of useing and characteristics

- Service manual — repair, diagnostics, maintenance

- Operation manual — description of the main functions of equipment

Inverter Instructions by CHINT:

-

Cobra CPI2590

Intro Operation CustomerAssistanceWarrantyNotesNoticeMain IconsSecondary IconsCaution WarningInstallationCustomer AssistanceOur Thanks to YouIntro Operation CustomerAssistanceWarrantyNotesNoticeMain IconsSecondary IconsCaution WarningInstallationIntroductionThank you for purchasing the Cobra Power Inverter CPI2590. Pro …

CPI2590 Inverter, 15

-

Steca Solarix PI 500-12

Steca Solarix PI 500-12 (-60/-L60) / PI 550-24 (-60/-L60) PI 1100-24 (-60/-L60) / PI 1500-48 (-60/-L60) Montage- und BedienungsanleitungInstallation and operating instructionsInstrucciones de montaje y manejoInstructions de montage et de serviceIstruzioni di montaggio e d‘uso754.923 | Z02 | 15.51DE EN ES FR IT …

Solarix PI 500-12 Inverter, 64

-

Honda EU2000i Companion

31Z0770000X31-Z07-7000o2008 Honda Motor Co., Ltd. -All Rights Reserved2eY16000.2008.07Printed in JapanOwner’s ManualGENERATOREU2000iBlackDIC F10100X31-Z07-7000 EU2000iSee page 78 forInitial Use InstructionsCompanionCompanion …

EU2000i Companion Portable Generator, 92

-

KStar SOHO Series

SOHO Intelligent Household Inverter User Manual Version V1.1 Revision Date 2015-11-05 Shenzhen KSTAR Science and Technology Co., Ltd. provides customers with full-around technical support. Users may contact the nearest KSTAR local sales office or service center, and can also contact with the company headquarter …

SOHO Series Inverter, 16

-

Selectronic Australia LD350-12

LD350-12 Volt Owners Manual . LD350-12 Operating Manual Serial No _____________________________ Purchase Date ______________ Note — Your 2 Year Warranty can only be valid once your warranty card is completed and returned to Selectronic Australia USTRALIAELECTRONIC A S Contents Page No. In …

LD350-12 Inverter, 11

-

Schumacher PID-760

Model: PID-760Power InverterConverts 12V DC battery power to 120V AC household power OWNERS MANUAL PLEASE SAVE THIS OWNERS MANUAL AND READ BEFORE EACH USE. This manual will explain how to use the inverter safely and effectively. Please read and follow these instructions and precautions carefully. …

PID-760 Inverter, 12

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

NVF5 Series User Manual

Code

F0.09

Minimum Frequency

Basic

F0.10

Frequency

F0.11

Max. Output Voltage

Integral

F0.12

(UP/DN)Regulation

Rate

(UP/DN)

F0.13

Control

F0.14

Accelerate Time 1

F0.15

Decelerate Time 1

F0.16

Carrier Frequency

PWM

F0.17

Adjust Automatically

F0.18

Reserve

Automatic

F0.19

Regulating

Name

0.00Hz ~ F0.08

Operating

0.00Hz ~ F0.07

(0 ~ 480)V

Keypad

(0.01 ~ 99.99)Hz/s

Ones

Setting

Keypad(UP/DN)

Storage When Power Off

Storage When Power Off

Tens

Setting

Keypad(UP/DN)

When Stop

Regulation

Initial When Stop

Hundreds Place:After Speed

Setting

Terminals(UP/DN)

Storage When Power Off

Storage When Power Off

Thousands Place:After Speed

Setting

Terminals(UP/DN)

When Stop

Initial When Stop

(0.0 ~ 6500.0)s

(0.0 ~ 6500.0)s

(0.5 ~ 16.0)kHz

0:No

Frequency

1:Yes

0 ~ 3

0:No Effect

Voltage

1:Always Effective

Setting Range

Place : After

Speed

by

Integral

0:Frequency Setting non

1 : Frequency

Setting

Place : After

Speed

by

Integral

0 : Frequency Miantain

1 : Frequency Restor to

by

Digital

0:Frequency Setting non

1 : Frequency

Setting

by

Digital

0 : Frequency Miantain

1 : Frequency Restor to

— 113 —

Appendix B Parameter list

Default

Change

0.00 Hz

50.00 Hz

Depend on

Series

1.00 Hz/s

0x0000

Depend on

Series

Depend on

Series

Depend on

Series

1

◎

0

2

○

○

●

○

○

○

○

○

○

○