Преимущества и предназначение:

- высокий пусковой крутящий момент (0,5 Гц, в 1,5 раза выше номинального крутящего момента), значительная устойчивость к перегрузкам, гибкость и удобство в эксплуатации, PID в прямом и обратном направлении и др.

- Преобразователи частоты этой серии можно раз делить на мини-преобразователи частоты, преобразователи частоты общего типа (мощные инвертеры), преобразователи частоты для вентиляторов и водяных насосов (для малых нагрузок). Они способны адаптироваться к высоким нагрузкам, стабильны и надежны в работе, поддерживают функцию автоматического энергосбережения и др.

- Преобразователи частоты могут применяться для управления электрическими двигателями и другими автоматическими системами (например, в бумажной и текстильной промышленности, для подачи воды, бетона, красок и красителей, в городских системах, в пищевой, химической и горной промышленности, в металлургии).

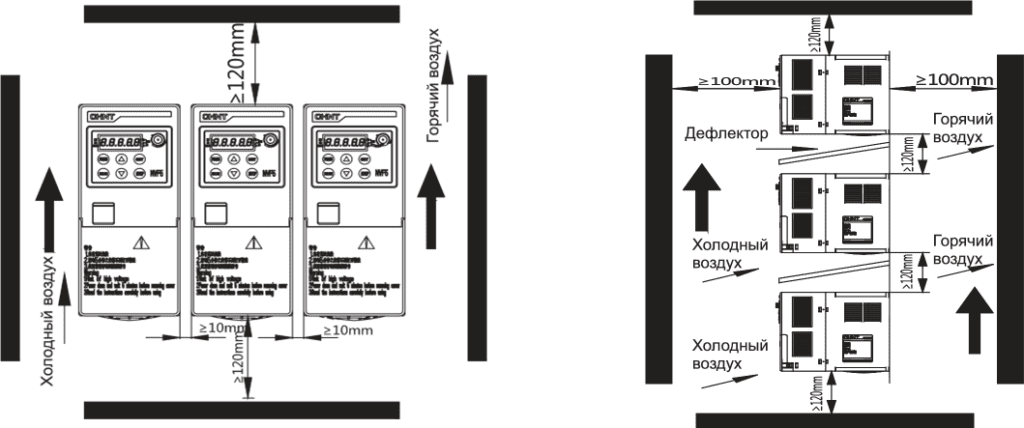

Необходимые установочные размеры

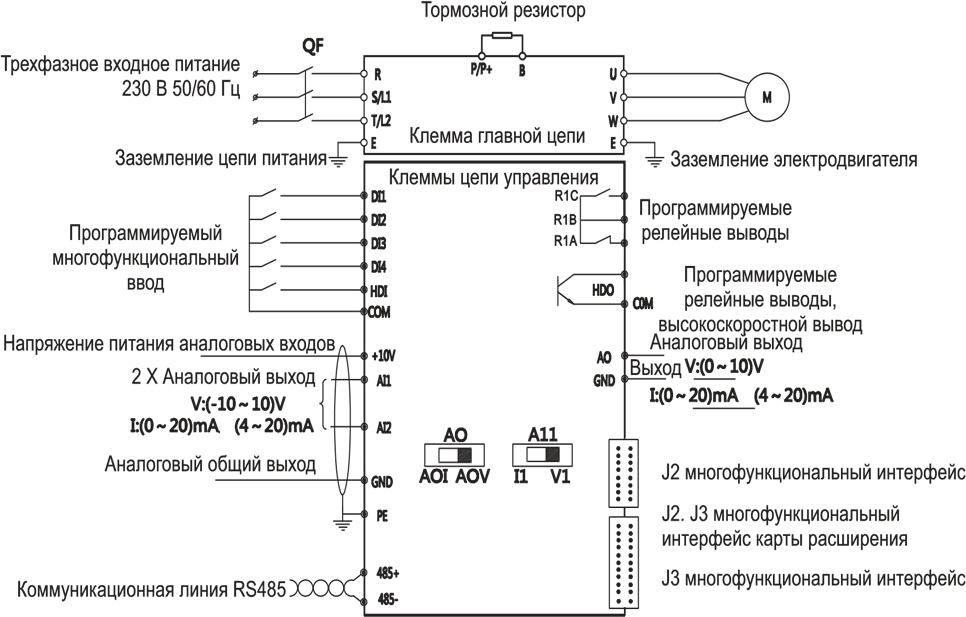

Описание контакта питания

| Обозначение | Наименование | Описание |

|---|---|---|

| R , S , T | Вход основного источника питания | Входные клеммы трехфазного питания переменного тока, соединенные с сетью заземления |

| L1 , L2 | Вход основного источника питания | Входные клеммы трехфазного питания переменного тока, соединенные с сетью заземления |

| U , V , W | Выход инвертора | Выходные клеммы трехфазного питания переменного тока, соединенные с электродвигателем переменного тока |

| Заземление | Клеммы заземления, обеспечивают надежное заземление | |

| P+ P- | Клеммы шины постоянного тока | Однофазный тип DC+ и DC |

| P B | Клеммы внешнего тормозного резистора | Клеммы трехфазного тормозного резистора |

| P+ B | Клеммы внешнего тормозного резистора | Клеммы однофазного тормозного резистора |

Базовая схема электрических соединений

- DIP-выключатель AO: Левый (0–20) мА или (4–20) мА Аналоговый токовый вывод;

- Правый (0–10) В Аналоговый вывод напряжения.

- Dip-выключатель AI1: Левый, (0~20) мА или (4–20) мА Аналоговый токовый ввод;

- Правый, (0–10) В Аналоговый вывод напряжения.

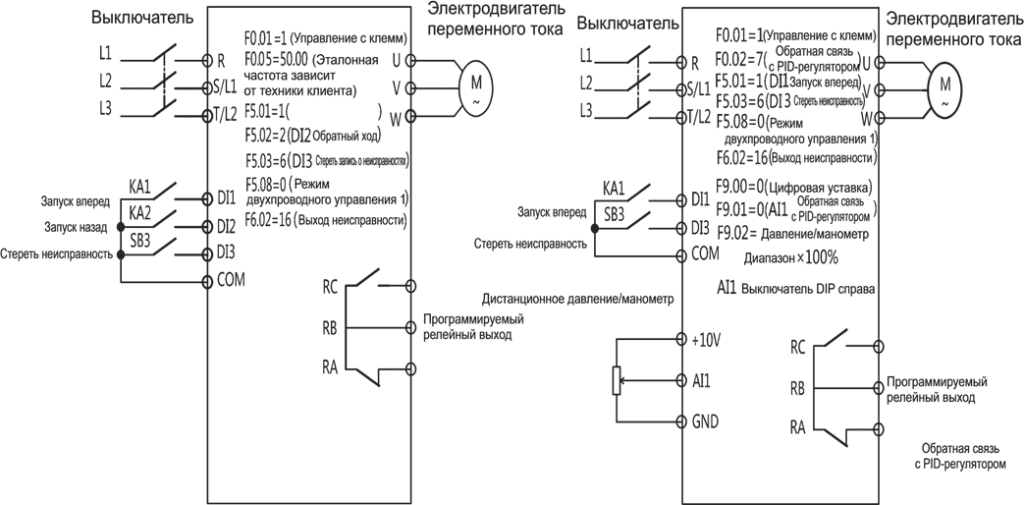

Пример подключения:

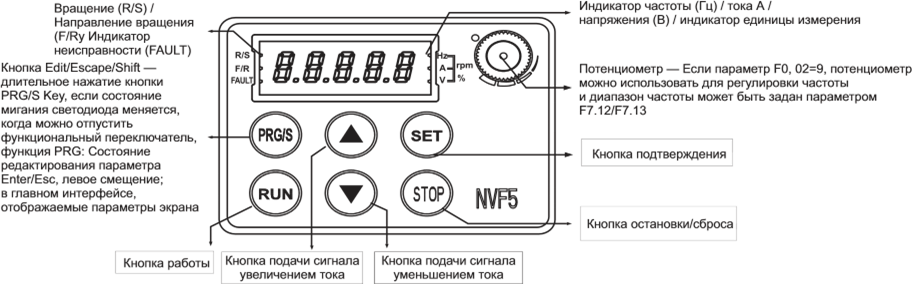

Панель управления и индикаторы

| Кнопка | Описание |

| Выбор режима меню параметров (F7.11) Режим меню простых параметров (U1)Режим меню пользовательских параметров (U2)Режим меню пользовательских инженерно-технических параметров (U3) | |

| Система отображает главный интерфейс Комбинаторная кнопка блокировки В режиме пользовательского меню, меню первого уровня Добавление параметров пользователя | |

| Система отображает главный интерфейс Комбинаторная кнопка разблокировки В режиме пользовательского меню, меню следующего уровня Удаление параметров пользователя |

Список параметров ЧП

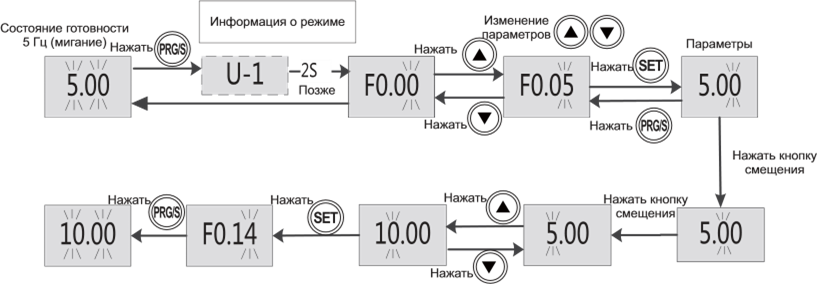

Пример задания параметра:

| Код | Наименование | Описание параметра | По умолчанию |

|---|---|---|---|

| F0.00 | Режим управления электродвигателями |

0: Векторное управление без датчиков 1: Резервирование 2: Режим V/F |

0 |

| F0.01 | Источник команды | 0: Цельная клавиатура 1: Цифровой вывод 2: Коммуникационный 3: Панель дистанционного управления |

0 |

| F0.02 | Справ. значение основной частоты |

0: Цифровая уставка 1: AH 2: AI2 3: Резервирование 4: Справ. зн. на высокочастотном импульсном входе HDI 5: Предв. настройка справ. зн. скорости 6: Справ. ПЛК 7: Справ. PID закрытого контура 8: Резервирование 9: Справ. потенциометра |

0 |

| F0.05 | Цифровая уставка | F0.09-Мин. частота~F0.08-Макс. частота | 5.00 Гц |

| F0.14 | Время ускорения 1 | (0,0–6500,0) с | Зависит от Серии |

| F0.15 | Время снижения скорости 1 | (0,0–6500,0) с | Зависит от Серии |

| F0.20 | Заводские настройки параметров | 0: Без действия 1: Удалить журнал регистрации ошибок 2: Сбросить до заводских настроек (кроме параметров электродвигателя NP и параметра F7.11) 3: Сбросить группу пользовательских параметров до заводских настроек (кроме параметров электродвигателя NP и параметра F7.11) 4: Все параметры сбрасываются до заводских настроек 5: Вспомогательные параметры 6: Использование вспомогательных параметров 7: Сохранение вспомогательных параметров Примечание: Только при использовании вспомогательных параметров вспомогательные параметры можно сохранить. Иначе при отключении и повторной подаче питания к инвертору, кроме обновленных параметров, другие параметры всегда возвращаются к начальному значению. |

0 |

| F2.00 | Тип электродвигателя | 0: Индукционный электродвигатель переменного тока 1: Резервирование 2: Резервирование |

|

| F2.01 | Питание электродвигателя NP | (0,1–1000,0) кВт | Зависит от типа электродвигателя |

| F2.02 | Напряжение электродвигателя NP |

0 В — Номинальное напряжение инвертора | Зависит от типа электродвигателя |

| F2.03 | Ток электродвигателя NP | (0,1–1000,0) A | Зависит от типа электродвигателя |

| F2.04 | Частота электродвигателя NP | 0,01 Гц ~ F0.07 | Зависит от типа электродвигателя |

| F2.05 | Количество полюсов двигателя | 2 ~ 24 | 4 |

| F2.06 | Обороты электродвигателя NP | 0-60000 об/мин | 1430 об/мин |

| F2.22 | Автоматическая настройка электродвигателя | 0: Выключено 1: Статическая настройка 2: Настройка вращения |

0 |

| F7.11 | Режим меню параметров |

1: Режим простого меню 2: Режим пользовательского меню 3: Режим технологического меню |

1 |

Список возможных неисправностей и ошибок ЧП

| Код | Тип неисправности | Причина неисправности | Действие (срабатывание) |

|---|---|---|---|

| E.OC1 E.OC2 E.OV1 E.OV2 E.OV3 |

— Перегрузка инвертора по току во время ускорения — Перегрузка инвертора по току во время торможения — Перегрузка инвертора по току во время работы на постоянной скорости — Перегрузка инвертора по напряжению во время ускорения — Перегрузка инвертора по напряжению во время торможения — Перегрузка инвертора по напряжению во время работы на постоянной скорости |

Низкое напряжение сети Напрямую и быстро запустите вращение двигателя Неправильные данные с паспортной таблички двигателя Слишком низкая мощность инвертора Неподходящая кривая V/F Потенциальная энергетическая нагрузка или большая инерционная нагрузка Ускорение/торможение Время слишком мало Быстрое изменение нагрузки Короткое замыкание электродвигателя на землю Неправильное напряжение питания Запустите снова электродвигатель на высоких оборотах Потенциальная энергетическая нагрузка или большая инерционная нагрузка Увеличьте время торможения Проверьте настройку параметров ASR в векторном режиме управления Большая инерционная нагрузка |

Проверьте время ускорения увеличения подачи питания Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Отрегулируйте кривую напряжения/частоты или отрегулируйте ручное усиление крутящего момента Добавить реген. Компоненты тормоза Проверка нагрузки Проверьте кабель двигателя Проверьте питание инвертора Запустите инвертор при остановленном электродвигателе Добавить реген. Компоненты тормоза Увеличьте время торможения См. раздел «Группа параметров F3» и как задать ASR |

| E.SPI | Ослабленная фаза на входе | Ослабленная фаза R.S.T | Проверка проводки на клемме основного питания Проверьте напряжение питания Проверьте кабель двигателя Проверьте двигатель и кабель |

| E.SPO | Ослабленная фаза на выходе | Ослабленная фаза U.V.W | Проверка проводки на клемме основного питания Проверьте напряжение питания Проверьте кабель двигателя Проверьте двигатель и кабель |

| E.FO | Срабатывание защиты силового модуля | Замыкание между фазами линии трехфазного питания или короткое замыкание на землю Мгновенная перегрузка инвертора по току Засорение вентиляционного канала или повреждение вентилятора Температура окружающей среды слишком высокая Ослабление проводки ввода/вывода или розетки Форма волны тока неисправна ввиду вывода Ослабление фазы и другие причины Повреждение вспомогательного источника питания, пониженное напряжение привода Неисправность БТИЗ-модуля Отклонения в работе панели управления |

Повторная укладка проводки, убедитесь в наличии изоляции электродвигателя См. устранение сверхтока Очистите канал вентилятора и замените вентилятор Низкая температура окружающей среды Проверьте проводку и проложите новую, Проверка проводки Попросите техническую поддержку Chint |

| E.OH1 | Перегрев теплоотвода | Температура окружающей среды слишком высокая Засорение канала вентилятора Повреждение вентилятора Неисправность IGBT Ошибка цепи проверки температуры |

Примите меры к снижению температуры окружающей среды Очистите вентиляционный канал или замените вентилятор Попросите техническую поддержку Chint |

| E.OH2 | Перегрев выпрямительного моста | Температура окружающей среды слишком высокая Засорение канала вентилятора Повреждение вентилятора Неисправность IGBT Ошибка цепи проверки температуры |

Примите меры к снижению температуры окружающей среды Очистите вентиляционный канал или замените вентилятор Попросите техническую поддержку Chint |

| E.OL1 | Перегрузка двигателя | Неправильная степень перегрузки электродвигателя Двигатель глохнет или частая смена нагрузки Длительная работа на низкой скорости с чрезмерной нагрузкой Низкое напряжение сети Неподходящая кривая напряжения/частоты Неправильные данные с заводской таблички электродвигателя Чрезмерная нагрузка Чрезмерный ток пост. тока Ускорение Время слишком мало |

Неправильная степень перегрузки электродвигателя Проверьте нагрузку электродвигателя Выбор преобразователя частоты Проверьте напряжение сети Отрегулируйте кривую напряжения/ частоты или отрегулируйте ручное усиление крутящего момента Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Снизьте пост. ток торможения Увеличьте длительность торможения Увеличьте время разгона |

| E.OL2 | Перегрузка инвертора | Неправильная степень перегрузки электродвигателя Двигатель глохнет или частая смена нагрузки Длительная работа на низкой скорости с чрезмерной нагрузкой Низкое напряжение сети Неподходящая кривая напряжения/частоты Неправильные данные с заводской таблички электродвигателя Чрезмерная нагрузка Чрезмерный ток пост. тока Ускорение Время слишком мало |

Неправильная степень перегрузки электродвигателя Проверьте нагрузку электродвигателя Выбор преобразователя частоты Проверьте напряжение сети Отрегулируйте кривую напряжения/ частоты или отрегулируйте ручное усиление крутящего момента Автоматическая настройка электродвигателя Увеличьте уровень питания инвертора Снизьте пост. ток торможения Увеличьте длительность торможения Увеличьте время разгона |

| E.tE | Автоматическая настройка | Заданы неправильные данные электродвигателя Автоматическая настройка обратного вращения запрещена при обратном ходе Плохой контакт линии соединения электродвигателя Превышение времени автоматической настройки |

Задание данных электродвигателя Запретить обратное направление Проверьте кабель двигателя Проверьте Параметр F0.08 (Максимальная частота), меньше ли он номинальной частоты |

| E.StG | Короткое замыкание электродвигателя на землю | Короткое замыкание электродвигателя на землю | Проверьте кабель двигателя |

| E.LL | Неисправность потери нагрузки | Ток инвертора менее значения Параметра FE.18 |

Проверьте наличие потери нагрузки и проверьте настройки параметра FE.17, FE.18, FE.18 |

Скачать полную инструкцию.

RU

- Manuals

- Brands

- CHINT Manuals

- Inverter

- NVF5 Series

Manuals and User Guides for CHINT NVF5 Series. We have 2 CHINT NVF5 Series manuals available for free PDF download: User Instructions, Quick Start-Up Wizard

CHINT NVF5 Series User Instructions (148 pages)

Brand: CHINT

|

Category: Inverter

|

Size: 4.55 MB

Table of Contents

-

Table of Contents

3

-

Chapter 1 Safety Information

5

-

Safety Definition

5

-

Safety Precautions

5

-

Precautions for Users

7

-

Notice of Scrap

9

-

-

Chapter 2 Product Overview

10

-

Catalog Numbers Description

10

-

Nameplate Description

10

-

Specifications and Models

10

-

Technical Specifications

11

-

Product Appearance and Diagram

13

-

Product Dimensions and Weights

14

-

IP22 Top Protective Cover Description

15

-

-

Chapter 3 Installation and Wiring

17

-

Peripherial Components Description

17

-

Peripherial Components Selection and Guideline

17

-

Installation

20

-

Description of the Cover

21

-

Wiring of Power Terminal and I/O Terminal

22

-

I/O Terminal Description

26

-

EMC Precautions

28

-

-

Chapter 4 Integral Keypad

30

-

Integral Keypad Instructions

30

-

Integral Keypad LED Light and Display

31

-

Parameter Menu Mode

33

-

Integral Keypad Lock and Password Setting

36

-

-

Chapter 5 Simple Parameter Menu and Commissioning Process

38

-

Simple Parameter Menu List

38

-

Simple Commissioning Process

40

-

-

Chapter 6 Parameter Function Description

42

-

Start Source Setting

42

-

Frequency Reference Setting

46

-

Start and Stop Setting

61

-

Motor Auto Tuning

66

-

V/F Parameters

68

-

Vector Control Parameters

71

-

Overcurrent Stall Protection

75

-

Overvoltage Stall Depress

75

-

Protective Function

76

-

Monitoring Function

82

-

I/O Terminal Parameter Setting

82

-

Ride through Function

89

-

Jogging

90

-

Skip Frequency

91

-

Forward and Reverse Switch

91

-

Regenerative Braking

92

-

Frequency Detection Output(Fdt

92

-

Output Current Zero Point Detection

93

-

Running Timer

93

-

Start at Power up

94

-

Sleep Wake Mode

94

-

-

Chapter 7 Troubleshooting

95

-

Diagnostic

95

-

Abnormal Operation and Solution

99

-

-

Chapter 8 Maintenance

101

-

Maintenance Instructions

101

-

Maintenance Items

101

-

Routine Maintenance

102

-

Regular Maintenance

102

-

Spare Parts Replacement

103

-

Storage

104

-

-

Appendix A RS485-MODBUS Communication Instructions

105

-

Networking Mode

105

-

Interface Mode

105

-

Communication Mode

105

-

Protocol Format

106

-

Protocol Application

107

-

Control Command, State Information and Fault Information

109

-

Parameter Management

112

-

Network Wiring

113

-

Definition of Communication Exception Code

113

-

-

Appendix B Parameter List

115

-

Appendix C Accessiories

146

-

Quality Commitment

147

Advertisement

CHINT NVF5 Series Quick Start-Up Wizard (8 pages)

Brand: CHINT

|

Category: Inverter

|

Size: 0.96 MB

Table of Contents

-

Installation and Wiring

2

-

Analog Voltage Output

3

-

Integral Keypad

4

-

Simple Parameter Menu and Commissioning Process

5

Advertisement

Related Products

-

CHINT NVF5-0.4/TD2

-

CHINT NVF5-0.75/TD2-B

-

CHINT NVF5-0.75/TD2

-

CHINT NVF5-0.4/TD2-B

-

CHINT NVF5-2.2/TD2

-

CHINT NVF5-1.5/TD2

-

CHINT NVF5-1.5/TD2-B

-

CHINT NVF5-2.2/TD2-B

-

CHINT NVF5-0.4/TS4-B

-

CHINT NVF5-0.75/TS4-B

CHINT Categories

Circuit breakers

![]()

Switch

Controller

Relays

Industrial Electrical

More CHINT Manuals