Срок поставки:

по запросу

Цена с НДС 20%

0.00 € по курсу 1 евро = 104.00 рублей 04.09.2023

Заказать консультацию по телефону

Бесплатная доставка от 30 000₽

Способы отплаты: банковским переводом, при получении, Сбербанк онлайн

Микропроцессорные регуляторы температуры DATALOGIC-DATASENSOR серии Q характеризуются высокой точностью регулирования. При невысокой цене данные термоконтроллеры обладают всеми необходимыми функциями для работы с наиболее распространенными датчиками температуры. В терморегуляторах DATALOGIC-DATASENSOR QD применяются два ярких дисплея различных цветов. Встроенная оригинальная диагностическая функция LFA может обнаруживать неисправности в петле регулирования, например, такие как короткое замыкание термопары или поломку термосопротивления.

|

Маркировка

|

Дисплей

|

Питание

|

Функция на выходе

|

Order No.

|

|

Термоконтроллер DATALOGIC-DATASENSOR QS-00

|

один

|

12.. 24 V AC/ DC

|

реле

|

974021000

|

|

Термоконтроллер DATALOGIC-DATASENSOR QS-01

|

транзистор

|

974021010

|

||

|

Термоконтроллер DATALOGIC-DATASENSOR QS-10

|

80.. 240 V AC

|

реле

|

974021020

|

|

|

Термоконтроллер DATALOGIC-DATASENSOR QS-11

|

транзистор

|

974021030

|

||

|

Термоконтроллер DATALOGIC-DATASENSOR QD-00

|

два

|

12.. 24 V AC/ DC

|

реле

|

974031000

|

|

Термоконтроллер DATALOGIC-DATASENSOR QD-01

|

транзистор

|

974031010

|

||

|

Термоконтроллер DATALOGIC-DATASENSOR QD-10

|

80.. 240 V AC

|

реле

|

974031020

|

|

|

Термоконтроллер DATALOGIC-DATASENSOR QD-11

|

транзистор

|

974031030

|

Купить термоконтроллеры DATALOGIC-DATASENSOR QD и QD Вы можете в нашей компании. Возможны изменения в маркировке, некоторые модели могут быть сняты с производства и заменены другими.

Купить термоконтроллеры DATALOGIC-DATASENSOR QD и QD Вы можете в нашей компании. Возможны изменения в маркировке, некоторые модели могут быть сняты с производства и заменены другими.

основной 4-разрядный с красными символами (10мм высота) плюс 4-разрядный с зелеными символами (7мм высота) в версиях QD или светодиодная полоса в версиях QS

a:2:{s:4:»TEXT»;s:126:»В комплектацию не входят: ответные разъемы для подключения в систему»;s:4:»TYPE»;s:4:»HTML»;}

Рабочее напряжение на входе:

80- 240 В AC (50.. 60 Hz) или 12- 24 В DC

одноконтурный термоконтроллер

on/off or PID selection, maximum or minimum, with AT initial autotuning and ADT permanent autoadaptive functions

Бесплатный самовывоз из пунктов выдачи заказов

г. Смоленск, ул. Нормандия-Неман, д. 3, офис 210.

Пн — Пт 9:00 — 18:00

Сб, Вс — выходной

Доставка по России

Транспортными компаниями (до терминала либо до двери)

СДЭК, Деловые Линии, ЕМС Почта России, DPD

Оперативная доставка в Санкт-Петербург, Екатеринбург, Новосибирск, Нижний Новгород, Краснодар, Самару, Челябинск, Казань, Пермь, Ростов-на-Дону, Уфу, Воронеж, Ижевск, Иркутск, Красноярск, Белгород.

Доставка в Казахстан и Беларусь

Отправляем товары транспортной компанией СДЭК

Доставка по Москве

Стоимость доставки 350 р. за исключением крупногабаритного товара (обговаривается отдельно)

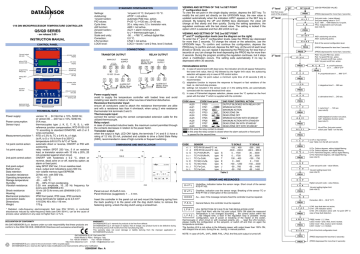

VIEWING AND SETTING OF THE 1st SET POINT st 1 configuration level To view the set point in the single display version, depress the SET key. To modify the set point act directly on the UP/DOWN keys, the new value is updated automatically when the indication UPDT appears or the SET key is pressed. By keeping the UP and DOWN keys depressed, the value will change at first slowly and then quickly. During the setting operations, the regulation continues with the last stored value. The setting is locked if the option LOC1 is selected and the LED LOCK is lit up. STANDARD CONFIGURATION Settings: Autotuning: 1st point action: PID values: Cycle time: Adt function: 2st point action.: Sensor: Scale and unity: Correction: LFA function: LOCK level: 1/16 DIN MICROPROCESSOR TEMPERATURE CONTROLLER QS/QD SERIES - sw release 2.00 - INSTRUCTION MANUAL CONTROL PANEL 1st point.=0 °C; 2nd point.=10 °C. ATOF = not active. automatic Pidd max. action. P=20 °C; I=120 sec.; D=30 sec. 20 s. relay vers.;12 s. transistor vers. Adt0 = not active. AL21 = alarm minimum action. tc-J = thermocouple type J. -50 ... +760 °C, without digital filter. 0,0 °C. LFA0 = not active. LOC3 = levels 1 and 2 free, level 3 locked. VIEWING AND SETTING OF THE 2nd SET POINT nd rd 2 and 3 configuration levels (see the diagram on the right) nd rd To enter the 2 and 3 configuration levels, keep the PROG key depressed for more than 2 seconds. To change the values or the selections, use the UP/DOWN keys. To confirm and continue the configuration, depress the PROG key; to confirm and exit, depress the SET key. At the end of each level [End2] or [End3], you can repeat it depressing the PROG key for less than 2 seconds or you can change the level depressing the PROG key for more than 2 seconds. During the program scrolling the regulation continues, but it stops when a modification occurs. The setting exits automatically if no key is depressed within 30 seconds. CONNECTIONS TRANSITOR OUTPUT process value display POWER SUPPLY MAIN OUT active LOCK function LED set value display programming PROG key + increasing UP key setting SET key MAIN OUT 250 Vac 5A max RESISTIVE LOAD Load decreasing DOWN key RELAY OUTPUT - 12 VDC 20 mA process value display ALARM OUT ALARM OUT 250 Vac 3A max 250 Vac 3A max 2nd point output ON LED active autotuning blinking LED electronic block extraction trigger TECHNICAL DATA Power supply: Power consumption: Sensor input: Measurement precision *: 1st point control action: 1st point output: 2nd point control action: 2nd point output: Refresh time: Data retention: Insulation resistance: Operating temperature: Storage temperature: Humidity: Vibration resistance: Shock resistance: Housing: Mechanical protection: Connection leads: Dimensions: Weight: RESISTIVE LOAD RESISTIVE LOAD deviation LED bar POWER SUPPLY version 12 … 24 Vdc/Vac ± 10%, 50/60 Hz; or version 80 … 240 Vac ± 10%, 50/60 Hz. 5VA max. thermocouples type J, K, E, T, R, S, L; with reference junction compensation; RTD Pt100 Ω/0 °C according to standard DIN43760; with 2 or 3 wires connection. RTD ± 0.3% fs, TC ± 0.4% fs, ±1 digit; (tc-R, tc-S ± 1% fs from 0 to 200°C) temperature drift 0.01% fs/°C of Tamb. automatic direct or reverse, ON/OFF or PID with autotuning. relay version SPDT 250 Vac, 5 A on resistive load; or transistor version with 12 Vdc ± 20%, 20 mA protected against short circuit. ON/OFF with hysteresis ± 0.2 °C, direct or reverse, dead zone on or off, stand-by option; as alarm or fixed point. relay SPST 250 Vac, 3 A on resistive load. input, output and indications every 500 ms. non volatile memory type EEPROM. 20 MΩ min. with 500 Vdc. -10 … +55 °C. -20 … +65 °C. 35 … 85% rH non condensing. 0.35 mm amplitude, 10…55 Hz frequency for every axis (EN60068-2-6) 18 ms (30 G) for every axis (EN60068-2-27) Power supply input: avoid to supply the temperature controller with loaded lines and avoid installing near electric motors or other sources of electrical disturbance. Resistance thermometer input: ensure all conductors used to attach the resistance thermometer are alike and with a resistance less than 4 ohm/each; when using 2 wire resistance thermometer link terminals 2 and 3. Thermocouple input: connect the sensor using the correct compensated extension cable for the utilized thermocouple. Relay output: in case of connected inductive loads, the maximum current permitted through the contacts decreases in relation to the power factor. Transistor output: when the output is high, LED ON1 lights, the terminals 7 (+) and 8 (-) have a rating of 12 Vdc 20 mA, protected and suitable to drive a Solid State Relay (SSR), recommended in case of high currents or frequent switching. 118 100.2 10 48 QS SERIES °C -10 -5 0 Insert the controller in the panel cut out and mount the fastening spring from the back pushing it to the panel until the dog clutch locks; to remove the fastening spring, unlock the dog clutch using a screwdriver. * Radiated, radio-frequency electromagnetic field (see ENV 50140), or conducted disturbances induced by radio-frequency fields (see ENV 50141), can be the cause of process value variations in any case not higher than ± 2 % fs. DECLARATION OF CONFORMITY We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the 2004/108 CEE, 2006/25/CE Directives and successive amendments. SENSOR RTD Pt100 ohm/0°C RTD Pt100 ohm/0°C TC Pt10%Rh-Pt, TC Pt13%Rh-Pt, TC Cu-CuNi, TC NiCr-CuNi, TC NiCr-NiAl, TC Fe-Cuni, TC Fe-Cuni, int. dec. type type type type type type type S R T E K J L Table 2 °C SCALE -150 ... 450 -99.9 ... 450.0 0 ... 1700 0 ... 1700 100 ... 400 0 ... 600 -100 ... 1250 -50 ... 760 -50 ... 760 °F SCALE -200 ... 850 -99.9 ... 850.0 30 ... 3000 30 ... 3000 -150 ... 750 0 ... 1100 -150 ... 2300 -50 ... 1400 -50 ... 1400 DATASENSOR S.p.A. Via Lavino 265 40050 Monte S. Pietro - Bologna - Italy Tel: +39 051 6765611 Fax: +39 051 6759324 http://www.datasensor.com e-mail: [email protected] DATASENSOR S.p.A. cares for the environment: 100% recycled paper. DATASENSOR S.p.A. reserves the right to make modifications and improvements without prior notification. 826000941 Rev. A level (PROG depressed for more than 2 seconds) 2nd point code - (value follows). 2nd point setting value in °C/°F. ALxx: -999 … +999 relative to 1st point. FPxx: independent over full scale. (see note A) A L 2 1 1 0 PROG A t O F AtOf: autotuning not active. AtOn: autotuning active. E n d 2 End of the second configuration level. PROG (PROG depressed for less than 2 seconds) PROG (PROG depressed for more than 2 seconds) Pidd: 1st point PID max. action. Pidr: 1st point PID min. action. OnFd: 1st point on/off max. action. OnFr:1st point on/off min. action. rd 3 level P i d d H PROG 1. 0 H: on/off hysteresis ± 0.1 … ± 99.9 °C/°F PROG P 2 0 P: proportional band 1 … 999 °C/°F. PROG i 1 2 0 i: integrative time 0 … 960 sec. PROG d 3 0 d: derivative time 0 … 240 sec. PROG t 1 2 t: cycle time 1 … 120 sec. (see note B) PROG A d t 0 Adt0:Adaptative function not active. Adt1: Adaptative function active. (see note C) PROG A L 2 1 ALxx/FPxx: 2nd point control action.(see Table 1 on the left) PROG c J tc-x/rt-x: input sensor. (see Table 2 on the left and note D) PROG U °C n PROG U°Cn: Celsius degrees, without digital filtering. U°Cd: Celsius degrees, with digital filtering. U°Fn: Fahrenheit degrees, without digital filtering. U°Fd: Fahrenheit degrees, with digital filtering. (see note E) L S P Lower set point code - value follows. - 5 0 1st point setting lower limit. (see note D) PROG H S P Higher set point code - value follows. UnFL Underflow, indication below the sensor range. Short circuit of the sensor RTD PT100. 7 6 0 OvFL Overflow, indication over the sensor range. Breaking of the sensor TC or RTD PT100 or interruption of the connection. PROG 8888 Au...-test, if the message remains fixed the controller must be repaired. FAIL General failure; the controller must be repaired. °0. 1st point setting higher limit. (see note D) 0 Correction -99.9 … 99.9 °C/°F. LFA1 WARRANTY DATASENSOR S.p.A. warrants its products to be free from defects. DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during the warranty period of 36 months from the manufacturing date. This warranty does not cover damage or liability deriving from the improper application of DATASENSOR products. 2 PROG t ERROR AND MESSAGGES mm Exit from every point of the program nd (QS-ES PROCESS VALUE) SET VALUE SET Table 1 +5 +10 Panel cut-out: 45.5x45.5 mm. Panel thickness (suggested): 1 … 4 mm. ABS IP50 front panel, IP20 case, IP00 contacts screw terminals for cabled up to 2,5 mm². 1/16 DIN; 48 x 48 x 118 mm. 175 g. CODE alarm CODE fixed point 2ND POINT CONTROL ACTION AL20 OUTPUT BLOCKED WITH RELAY OFF FP20 AL21 MINIMUM ACTION FP21 AL22 MAXIMUM ACTION FP22 AL23 DEAD ZONE ON FP23 AL24 DEAD ZONE OFF FP24 AL25 MINIMUM ACTION WITH STAND-BY FP25 AL26 MAXIMUM ACTION WITH STAND-BY FP26 AL27 DEAD ZONE ON WITH STAND-BY FP27 AL28 DEAD ZONE OFF WITH STAND-BY FP28 In this area the relay contact is closed. In this area the relay contact is closed when the alarm set-point or fixed point is passed for the second time. CODE rt l rt d tc S tc r tc t tc E tc C tc J tc L DIMENSIONS AND INSTALLATION 7.8 PROGRAMMING NOTES A) in case of second point with dead zone, the indication [2 LO] will appear followed by the lower limit value, then [2 HI] followed by the higher limit value; the autotuning selection will appear only in case of PID control action. B) in case of relay 1st point output, a minimum cycle time of 20 seconds [t 20] is recommended. C) adaptative function to improve the response to frequent or fast variations of the load, i.e. start and stop process. D) settings not included in the sensor scale or in the setting limits, are automatically corrected with the nearest threshold limit value. E) in case of Fahrenheit degrees selection, please cover the °C symbol on the front panel with the label °F which is supplied with the controller. 48 1st point output ON LED 1st level LFA: DETECTION OF FAULTS IN THE REGULATION LOOP Loop Fault Alert: with the 1st point output 100% ON state the measured temperature is not changed according ... the control action within the LFA2 s...red integral time; a fault in the regulation loop is possible: wrong configuration, lack of power or breaking of the heater or the cooler, thermocouple in short circuit or with reversed polarity, etc. ... reset the LFA function, please modify the configuration or the set-point, or switch off and then on again the temperature controller. The function LFA is not active in the following cases: with output lower than 100% ON, with integral time at zero, during the au...tuning, in manual position. PROG L F A 0 PROG L O C 3 PROG E n d 3 LFA0: loop fault alert not active. LFA1: LFA indication active. LFA2: LFA indication active with 1st point OFF in case of loop fault detection. FREE: levels 1, 2, 3 free. LOC3: levels 1 and 2 free, level 3 locked. LOC2: level 1 free, levels 2 and 3 locked. LOC1: levels 1, 2, 3 locked. End of the third configuration level. NOTE: In case of OvFL, UnFL, 8888, FAIL, LFA2, the first point output is turned off. PROG (PROG depressed for less than 2 seconds) PROG (PROG depressed for more than 2 seconds)

QS00

/

974021000

Images are for illustrative purposes only

Manufacturer: Datasensor

QS TEMPERATURE CONTROLLER

More Information…

One Free UK delivery per day for all online orders over £20.00 (Exc Vat)

Limited time only

- Information

- Specification

- Related

- Delivery

- International Delivery

- Alternatives

QS TEMPERATURE CONTROLLER

Distributed by Kempston Controls

Kempston Controls is electrical and electronic components distributor, providing fuses, sensors, control components, industrial automation equipment and more. If you would like to discuss any of the parts which you see on our online store, please contact our dedicated sales centre on +44 (0) 1933 411411.

More about Kempstons

All shipping options below are for United Kingdom. Delivery prices below are Exc VAT.

| Web Promo Carriage |

UK standard delivery, usually within 1 — 2 days

(1 per day, minimum order £20.00) |

£0.00 |

| Standard 1-2 Days | UK standard delivery, usually within 1 — 2 days | £10.00 |

| Next Day* | UPS Next Day service* | £10.00 |

| Express* | UPS Express delivery by 12:00pm* | £25.00 |

| Saturday** | UPS Saturday service** | £40.00 |

| Collect | Collection is available from our site — please call if your order is urgent | £0.00 |

Greyed out shipping options indicate services not available, as the certain criteria has not been met. (i.e. it’s after the cut off time or items in your basket are not in stock for Next Day, Express or Saturday delivery)

* Delivery services are subject to exception areas, click exceptions to view the affected areas or use the ‘shipping estimator’ tool to view delivery options.

International Delivery

We can provide international shipping to 240+ countries worldwide. Please select your country so we can provide you with delivery date and cost estimates.

International Priority – Terms DAP to Delivery Address

For our overseas customers, we offer a very competitive and fast delivery service; however, if you prefer to collect using your own courier, then we can also arrange that at no extra cost.

Our technical team can help find an alternative! Fill in the below to get started.

What our Customers are saying

1/8 DIN MICROPROCESSOR TEMPERATURE CONTROLLER

ES/ED SERIES

— sw release 2.00 —

INSTRUCTION MANUAL

FRONT PANEL

Process value

display

set value

display

2nd point output

ON LED

1st point

output ON LED

active LOCK

LED function

setting SET

key

increasing

UP key

programming

PROG key

Electronic block extraction screw

TECHNICAL DATA

Power supply:

version 12 … 24 Vdc/Vac ± 10%, 50/60 Hz;

or version 80 … 240 Vac ± 10%, 50/60 Hz.

Power consumption:

5VA max.

Sensor input:

thermocouple type J, K, E, T, R, S, L; with reference

junction compensation; RTD Pt100 Ω/0 °C according

to standard DIN43760; with 2 or 3 wires connection.

Measurement precision *:

RTD ± 0.3% fs, TC ± 0.4% fs, ±1 digit;

(tc-r, tc-S ± 1% fs from 0 to 200°C)

temperature drift 0.01% fs/°C of Tamb.

1st point control action:

automatic direct or reverse, ON/OFF or PID with

autotuning; manual with output setting from 0 to

100%.

1st point output:

relay version SPDT 250 Vac, 5 A on resistive load;

or transistor version with 15 Vdc ± 20%, 20 mA

short-circuit protected.

2nd point control action:

ON/OFF with hysteresis ± 0.2 °C, direct or reverse,

dead zone on or off, stand-by option; alarm or fixed

point.

2nd point output:

relay SPDT 250 Vac, 5 A on resistive load.

Refresh time:

input, output and indication every 500 ms.

Data retention:

non volatile memory type EEPROM.

Insulation resistance:

minimum 20 MΩ at 500 Vdc.

Operating temperature:

-10 … +55 °C.

Storage temperature:

-20 … +65 °C.

Humidity:

35 … 85% rH non condensing.

Vibration resistance:

0.35 mm amplitude, 10…55 Hz frequency for every

axis (EN60068-2-6)

Shock resistance:

18 ms (30 G) for every axis (EN60068-2-27)

Housing:

ABS

Mechanical protection:

IP50 front panel, IP20 case, IP00 contacts

Connection leads:

screw terminals for cables up to 2.5 mm².

Dimensions:

1/8 DIN; 48x96x125 mm

Weight:

400 g.

*

Radiated radio-frequency electromagnetic fields (see ENV 50140), or conducted

disturbances induced by radio-frequency fields (see ENV 50141), can be the cause of

process value variations in any case not higher than ± 2 % fs.

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

Tel: +39 051 6765611

http://www.datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without prior notification.

STANDARD CONFIGURATION

Settings:

1st pt.=0 °C; 2nd pt.=10 °C.

Autotuning:

AtOF = not active.

1st point action:

automatic Pidd max. action.

PID values:

P=20 °C; I=120 s.; D=30 s.

Cycle time:

20 s. relay vers.;12 s. transistor vers.

Adt function:

Adt0 = not active.

2nd point action.:

AL21 = alarm minimum action.

Sensor:

tc-J = thermocouple type J.

Scale and unity:

-50…+760 °C, without digital filter.

Correction:

0.0 °C

LFA function:

LFA0 = not active.

LOCK level:

LOC3 = levels 1 and 2 free, level 3 locked.

CONNECTIONS

Process value

display

1. OUTPUT

2. OUTPUT

deviation or

output LED bar

TRANSISTOR

VERSION

special function

LED (not used)

250Vac 5A

RESISITIVE

RESISITIVE

active

autotuning

1. OUTPUT

2. OUTPUT

blinking LED

RELAY

active MAN

VERSION

function LED

decreasing

250Vac 5A

250Vac 5A

RESISITIVE

RESISITIVE

DOWN key

manual function

key

Power supply input:

do not supply the temperature controller directly through power lines and

avoid installing near electric motors or other sources of electrical disturbance.

Resistance thermometer input (RTD):

ensure all conductors used to attach the resistance thermometer are alike and

with a resistance less than 4 ohms/each; when using a 2 wire resistance

thermometer, link terminals 13 and 14 together.

Thermocouple input (TC):

connect the sensor using the correct compensated extension cable for the

utilized thermocouple.

Relay output:

in case of connected inductive loads, the maximum current permitted through

the contacts decreases in relation to the power factor.

Transistor output:

when the output is high, the ON1 LED lights, the terminals 1 (+) and 3 (-) have

a rating of 15 Vdc 20 mA, protected and suitable to drive a Solid State Relay

(SSR), recommended in case of high currents or frequent switching.

DIMENSIONS AND INSTALLATION

137

12

125

Panel cut-out: 45.5×91 mm

Panel thickness (suggested): 1 … 4 mm

Insert the controller from panel front face, fix the metallic bracket on the rear

of the controller with the proper nuts.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during

the warranty period of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of

DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro — Bologna — Italy

Fax: +39 051 6759324

e-mail: info@datasensor.com

826000951 Rev. A

VIEWING AND SETTING OF THE 1st SET POINT

st

1

configuration level

To view the set point in the single display version, depress the SET key. To

modify the set point act directly on the UP/DOWN keys, the new value is

updated automatically when the indication UPDT appears or the SET key is

pressed. By keeping the UP or DOWN keys depressed, the value will change

at first slowly and then quickly. During the setting operations, regulation

continues with the last stored value. The setting is locked if the option LOC1

is selected and the LOCK LED is lit up.

MANUAL REGULATION OF THE OUTPUT POWER

To change from automatic regulation (closed loop) to manual (open loop),

keep the AUTO/MAN key depressed until the MAN LED turns on. The output

power is at zero, make the 1st point setting operations to set the value from

M0 to M100%. The regulator maintains the set value if switched off in manual

regulation. To return to automatic regulation, keep the AUTO/MAN key

depressed until the MAN LED turns off.

VIEWING AND SETTING OF THE 2nd SET POINT

nd

rd

2

and 3

configuration levels (see the diagram on the right)

nd

rd

To enter the 2

and 3

configuration levels, keep the PROG key depressed

POWER SUPPLY

for more than 2 seconds. To change the values or the selections, use the

UP/DOWN keys. To confirm and continue the configuration, depress the

PROG key; to confirm and exit, depress the SET key. At the end of each level

[End2] or [End3], you can repeat it by depressing the PROG key for less than

2 seconds or you can change the level by depressing the PROG key for more

(5VA

than 2 seconds. During the program scrolling the regulation continues, but it

250Vac 5A

stops when a modification occurs. The setting exits automatically if no key is

depressed within 30 seconds.

POWER SUPPLY

PROGRAMMING NOTES

A) in case of second point with dead zone, the indication [2 LO] will appear followed by

the lower limit value, then [2 HI] followed by the higher limit value; the autotuning

selection will appear only in case of PID control action.

(5VA

B) in case of relay 1st point output, a minimum cycle time of 20 seconds [t 20] is

recommended.

C) adaptative function to improve the response to frequent or fast variations of the

load, i.e. start and stop process.

D) settings not included in the sensor scale or in the setting limits, are automatically

TC

corrected with the nearest threshold limit value.

B

b

A

E) in case of Fahrenheit degrees selection, please cover the °C symbol on the front

RTD

panel with the label °F which is supplied with the controller.

ALARM

FIXED POINT

AL20

FP20

AL21

FP21

AL22

FP22

AL23

FP23

AL24

FP24

AL25

FP25

AL26

FP26

AL27

FP27

AL28

FP28

In this area the relay contact is closed.

In this area the relay contact is closed when the alarm set-point or fixed point

is passed for the second time.

CODE

SENSOR

r t l

RTD Pt100 ohm/0°C int.

r t d

RTD Pt100 ohm/0°C dec.

t c S

TC Pt10%Rh-Pt,

t c r

TC Pt13%Rh-Pt,

48

t c t

TC Cu-CuNi,

t c E

TC NiCr-CuNi,

t c C

TC NiCr-NiAl,

t c J

TC Fe-Cuni,

t c L

TC Fe-Cuni,

ERROR AND TEST MESSAGGES

Underflow, indication below the sensor range. Short circuit of the sensor

U n F L

RTD Pt100 or interruption of the compensation connection.

Overflow, indication over the sensor range. RTD Pt100 or TC sensor

O v F L

broken or interruption of the main connection.

8 8 8 8

Au…-test, if the message remains fixed the controller must be repaired.

mm

F A I L

General failure; the controller must be repaired.

L F A 1

LFA: DETECTION OF FAULTS IN THE REGULATION LOOP

Loop Fault Alert: with the 1st point output 100% ON state the measured

temperature is not changed according … the control action within the

L F A 2

s…red integral time; a fault in the regulation loop is possible: wrong

configuration, lack of power, heater or cooler broken, thermocouple short-

circuited or polarity reversed, etc. … reset the LFA function, please modify the

configuration or the set-point, or switch the temperature controller off and then on again.

The function LFA is not active in the following cases: with output lower than 100% ON,

with integral time at zero, during the au…tuning, in manual position.

NOTE: In case of OvFL, UnFL, 8888, FAIL, LFA2, the first point output is turned off.

1

st

level

Exit from every

point of the program

nd

2

level

rd

3

level

2ND POINT CONTROL ACTION

Output blocked with relay off

Minimum action

Maximum action

Dead zone on

Dead zone off

Minimum action with stand-by

Maximum action with stand-by

Dead zone on with stand-by

Dead zone off with stand-by

Table 1

°C SCALE

°F SCALE

-150 … 450

-200 … 850

-99.9 … 450.0

-99.9 … 850.0

type S

0 … 1700

30 … 3000

type R

0 … 1700

30 … 3000

type T

-100 … 400

-150 … 750

type E

0 … 600

0 … 1100

type K

-100 … 1250

-150 … 2300

type J

-50 … 760

-50 … 1400

type L

-50 … 760

-50 … 1400

Table 2

(QS-ES PROCESS VALUE)

SET

SET VALUE

PROG

(PROG depressed for more than 2 seconds)

2nd point code — (value follows).

A L 2 1

2nd point setting value in °C/°F.

ALxx: -999 … +999 relative to 1st point.

1

0

FPxx: independent over full scale.

(see note A)

PROG

AtOf: autotuning not active.

A t O F

AtOn: autotuning active.

End of the second configuration level.

E n d 2

PROG

(PROG depressed for less than 2 seconds)

PROG

(PROG depressed for more than 2 seconds)

Pidd: 1st point PID max. action.

Pidr: 1st point PID min. action.

P i d d

OnFd: 1st point on/off max. action.

OnFr:1st point on/off min. action.

PROG

H

1.

0

H: on/off hysteresis

± 0.1 … ± 99.9 °C/°F

PROG

P

2

0

P: proportional band 1 …999 °C/°F.

PROG

i 1 2 0

i: integrative time 0 …960 sec.

PROG

d

3

0

d: derivative time 0 …240 sec.

PROG

t

1

2

t: cycle time 1 …120 sec.

(see note B)

PROG

A d t 0

Adt0:Adaptative function not active.

Adt1: Adaptative function active.

(see note C)

PROG

A L 2 1

ALxx/FPxx: 2nd point control

action.(see Table 1 on the left)

PROG

tc-x/rt-x: input sensor.

t

c

J

(see Table 2 on the left and note D)

PROG

U°Cn: Celsius degrees, without digital filtering.

U°Cd: Celsius degrees, with digital filtering.

U ° C n

U°Fn: Fahrenheit degrees, without digital filtering.

U°Fd: Fahrenheit degrees, with digital filtering.

(see note E)

PROG

L S P

Lower set point code — value follows.

—

5

0

1st point setting lower limit.

(see note D)

PROG

H S P

Higher set point code — value follows.

7 6 0

1st point setting higher limit.

(see note D)

PROG

° 0.

0

Correction -99.9 … 99.9 °C/°F.

PROG

LFA0: loop fault alert not active.

L F A 0

LFA1: LFA indication active.

LFA2: LFA indication active with 1st point OFF in

case of loop fault detection.

PROG

L O C 3

FREE: levels 1, 2, 3 free.

LOC3: levels 1 and 2 free, level 3 locked.

LOC2: level 1 free, levels 2 and 3 locked.

PROG

LOC1: levels 1, 2, 3 locked.

End of the third configuration level.

E n d 3

PROG depressed for less than 2 seconds)

PROG

(PROG depressed for more than 2 seconds)

PROG

Артикул

974021000

Бренд

Datasensor

Цена

—

Оставить заявку

Описание

Datasensor QS-00

В связи с изменениями курсов мировых валют и

пересмотром цен производителями, цены на товары могут отличаться от

заявленных на сайте. Просьба актуальные цены уточнять у менеджера. Мы делаем

все возможное, чтобы цены на сайте были актуальными.

Похожие товары

При заказе у нас вы получаете:

Доставка до дверей

Оперативно доставляем

оборудование в любую точку РФ

17 лет на рынке

Мы надежный партнер по поставкам

промышленного оборудования

Честная цена

Прямые поставки от заводов и

минимальная торговая наценка

Гарантия до 24 месяцев

Предоставляется официальная

гарантия завода-изготовителя

Официальный дилер

Огромный список заводов-изготовителей,

с которыми мы сотрудничаем

Все грузы застрахованы

С нами Вы уверены в качестве

поставляемого оборудования

Не нашли то, что искали?

Наш менеджер поможет вам с поиском оборудования

и запчастей, ответит на любые вопросы.