-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

sales@artisantg.com

artisantg.com

(217) 352-9330 |

|

Click HERE

Find the Instek GTP-060A-4 at our website:

Related Manuals for GW Instek GOS-620FG

Summary of Contents for GW Instek GOS-620FG

-

Page 1

sales@artisantg.com artisantg.com (217) 352-9330 | Click HERE Find the Instek GTP-060A-4 at our website:… -

Page 2

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 3: Table Of Contents

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 4

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 5

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 6

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 7

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 8: Product Introduction

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 9

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 10

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 11

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 12

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 13

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 14: Precautions Before Operation

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 15

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 16

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 17

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 18

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 19

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 20: 4-2.Rear Panel

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 21

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 22: Operation Method

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 23

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 24: Dual.channel Operation

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 25: Add Operation

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 26

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 27

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 28: S.tim E I D I V Control

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 29: Operation

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 30: Calibration

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 31: Maintenance

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 32: Cleaning

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 33: Block Diagram

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

-

Page 34

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com… -

Page 35

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com…

Table of Contents for GW Instek GOS-620FG:

-

5-2.Dual-channel Operation Set the VERT MODE switch to DUAL to display trace in CH2 (The procedure is ‘ same as CHI described in previous section). At this step, the calibrator signal appears in CHI is Square wave, but it appears in CH2 is a straight line as no signal applied to this channel yet. Now, apply the calibrator signal to the vertical input terminal of CH2 through the probe with the same procedure as for CHI. Set the AC-GND-DC switch to AC,

-

After setting the switches and control knobs as mentioned, connect the power cord to the AC line outlet, then follow the procedure describes as follows: 1) Press the POWER switch and make sure that the power LED is turned on. In about 20 seconds, a trace will appear on the CRT screen. If no trace appears in about 60 seconds, counter check the switch and control setting. 2) Adjust the

-

The following instructions are executed by qualified personnel only. To avoid electrical shock, do not perform any servicing other than the operating instructions unless you are qualified to do so. 6-1.Fuse Replacement If the fuse blows, the power lamp indicators will not light and the instrument will not start. The fuse holder should not normally be opened unless a problem has been caused to the unit. Try to dete

-

EC Declaration of Conformity We GOOD WILL INSTRUMENT CO.,LTD. (1) NO. 95 — I I, Pao Chung Rd., Hsin-Tien City, Taipei Hsien, Taiwan (2) Plot 522, Lorong Perusahaan Baru 3, Prai Industrial Estate, 13600 Prai, Penang, Malaysia declare, that the below mentioned product GOS-620FG are herewith confirmed to comply with the requirements set out in the Council Directive on the Ap

-

5.0PERATION METHOD 5-1.Basic Operation—Single-channel Operation Before connecting the power cord to an AC line outlet, make sure that the AC line voltage input switch on the rear panel of the instrument is correctly set for the AC line voltage. After ensuring the voltage setting, set the switches and controls of the instrument as shown below: Setting Disengage position(0FF) Mid-position Mid-position CH 1 Released(ALT) Released Mid-position 0.5V/DIV CAL(c1ockwise position) GND CHI Item POWER

-

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

-

4-1.Front Panel CRT : (6) POWER Main power switch of the instrument. Turn on the switch to light the LED (5). (2).INTEN Control the brightness of the spot or trace. (3) FOCUS Focus the trace to the sharpest image. (4) TRACE ROTATION Semi-fix potentiometer for aligning the horizontal trace in parallel with graticule lines. (33)FILTER The filter is easy for waveform viewing. Vertical Axis: (8) CH 1 (X) input The vertical input terminal of CH 1 i

-

SAFETY TERMS AND SYMBOLS These terms may appear in this manual or on the product: WARNING. Warning statements identify condition or practices that could result in injury or loss of life. CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property. The following symbols may appear in this manual or on the product: DANGER ATTENTION Protective Frame or chassis High Voltage refer to Manual Conductor Terminal

-

6) Z-Axis Input: Intensity modulation capability permits time or frequency markers to be added. Trace blank with positive signal, TTL compatible. 7) X-Y operation: Set the switch to X-Y to operate the instrument as an X-Y oscilloscope. CHI can be applied as a horizontal deflection (X-axis) while CH2 provides vertical deflection (Y-axis).

Built-in Function Generator with BNC output of 50 ‘2. 9) Three kinds of waveforms are available with 50R output. 10)Waveform frequency is u

Built-in Function Generator with BNC output of 50 ‘2. 9) Three kinds of waveforms are available with 50R output. 10)Waveform frequency is u -

(30)s WP.VAR Vernier control knob of the sweep time used when CAL and the sweep time is calibrated to the vh!ue preset in TIMEDIV. The sweep of TIMEBIV can be varied continuously when shaft is not in CAL position. Rotate the control knob to CAL position and the sweep time is calibrated to the preset value of the TIMEDIV. Counterclockwise rotate the control knob to the bottom to delay the sweep by 2.5

-

0 CNSURE THE POWER IS REMOVED FROM IHE INSTRUMENT BEFORE REPMCING THE FUSE POWER MAX 40 WAIlS, 45VA IEClDlO 25W CAT I1 I I Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

-

PECIFICATIONS GOS-620FG 20MHz OSCILLOSCOPE + FUNCTION GENERATOR ,OSCILLOSCOPE lsensitivitv 15m~ — 5VIDIV. 10 stem in 1-2-5 seauence — -~~- — ~ Sensitivity Accuracy 53% ( x 5 MAG : 55%). Vernier Vertical sensitivity To 112.5 or less of panel-indicated value. DC-20MHz ( x 5MAG: DC-7MHz). ‘ERTICAL AXIS Frequency bandwidth AC coupling: Low limit frequency of 10Hz. (With reference to IOOkHz, 8DIV. Frequency response at -3dB). Rise time Approx. 17.

-

TV-H Set the MODE switch to TV-H mode and select horizontal sync pulses for sweep triggering to view composite video waveforms. Select horizontal sync pulses as a triggering to view horizontal lines of video. A sweep time of about 10 usldiv is appropriate for displaying lines of video. Display the exact number of desired waveforms by setting SWP VAR control knob. This oscilloscope synchronizes with only (-) polarity, that is, the sync pulses are negative and the video is positive as shown in Fig. 5-3. Fig. 5-3 (2)Functions of

-

(44)FREQUENCY Knob Rotate the knob clockwise to get higher frequency and reverse the rotation of knob to get lower frequency. (45)AMPLITUDEIDC LEVEL Adjustment Knob Rotate outside knob clockwise to get higher amplitude and reverse the rotation of knob to get lower amplitude. The inside knob is for DC Level adjustment, it works only when the knob being pulled up. Pull up the knob and rotate it clockwise to get positive DC Level, and reverse the rotation of knob to get negative DC Level. Others: (1) CAL This ter

-

5-8.Calibration of Probe As explained previously, the probe makes up a wide range attenuator. Unless phase compensation is properly done, the displayed waveform will be distortion causing measurement errors. Therefore, the probe must be properly compensated before use. Connect 10:l probe BNC to the INPUT terminal of CHI or CH2 and set VOLTSIDIV switch at 50mV. Connect the probe tip to the calibration voltage output terminal and adjust the compensation trimmer on probe for optimum Square wave (minimum overshoot, rounding

-

(217) 352-9330 | [email protected] | artisantg.com -~ ARTISAN ® ~I TECHNOLOGY GROUP Your definitive source for quality pre-owned equipment. Artisan Technology Group Full-service, independent repair center with experienced engineers and technicians on staff. We buy your excess, underutilized, and idle equipment along with credit for buybacks and trade-ins . Custom engineering so your equipment works exactly as you specify. •

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of GW Instek GOS-620FG device using right now.

ОСЦИЛЛОГРАФ

УНИВЕРСАЛЬНЫЙ ДВУХКАНАЛЬНЫЙ GOS-620

(Краткая

инструкция

для пользователя)

ПРЕДУПРЕЖДЕНИЕ

!!! Позиционными

переключателями «MODE»,

«SOURCE»,

«AC,

GND, DC»

пользоваться

с особой осторожностью.

Осциллограф

имеет 4-е группы органов управления,

объединенных по функциональному

назначению и компактно размещенных в

определенных зонах передней панели

осциллографа.

1.

«Включение осциллографа и органы

управление лучом»

(расположены

под экраном)

POWER – Выключатель

сетевого питания,

[Отжат]1

INTER

– Регулятор

яркости изображения,

[В

среднем положении]

FOCUS

– Регулятор

фокуса изображения.

[В

среднем положении]

2.

«Органы

управления каналами вертикального

отклонения»,

графически выделенные под названием

«VERTICAL»

CH 1 – Вход

канала 1

CH 2 – Вход

канала 2

По

каждому каналу:

AC-DC-GND

– Переключатель

входов усилителей:

AC

–

Закрытый

вход,

DC

–

Открытый

вход,

GND

– Вход

усилителя заземлен.

[Включен]

POSITION

– Регулятор

положения лучей по вертикали,

[В

среднем положении]

VOLTS/DIV2

–

Дискретный

переключатель коэффициентов отклонения

(чувствительности).[0,5

В/Дел]

DIV3

– Плавная

регулировка коэффициентов отклонения;

для

установки номинальных коэффициентов

отклонений, указанных на дискретном

переключателе, ручка плавной регулировки

должна быть установлена в крайнее правое

положение при вращении по часовой

стрелке,

PULLx5MAG

– Увеличение

чувствительности в 5 раз.

[Выключен]

Общее

управление каналами:

MODE – переключатель

режимов

работы вертикальных каналов осциллографа:

CH1 – Включен

1-й канал; на экране наблюдается сигнал

только канала 1,

CH2

– Включен

2-й канал; на

экране наблюдается сигнал только канала

2,

DUAL

–

Включены

два канала; на

экране наблюдаются сигналы обоих

каналов,

[Включен]

ADD

– Режим

алгебраического суммирования; на

экране наблюдается сумма или разность

(при нажатой кнопке CH

2 INV –

инверсия сигнала по 2-му каналу) сигналов

1-го и 2го каналов,

CH

2 INV –

Инверсия

сигнала по 2-му каналу

ALT/CHOP

– Переключатель

режимов коммутатора каналов; в

лабораторных работах находится в отжатом

состоянии. (автоматическая подстройка

режимов коммутации).

3.

«Органы

управления разверткой»,

графически выделенные под названием

«HORIZONTAL»

POSITION

– Регулятор

положения лучей по горизонтали.

[В

среднем положении]

TIME/DIV12

– Дискретный

переключатель коэффициентов развертки

(скорости развертки).

[0,5 мc/Дел]

SWP.

VAR

– Плавное

изменение скорости развертки; для

установки номинальных коэффициентов

развертки, указанных на дискретном

переключателе, ручка плавной регулировки

должна быть установлена в крайнее правое

положение «CAL»

при

вращении по часовой стрелке.

x10MAG

– Увеличение

скости развертки в 10 раз.

[Выключен]

4.

«Органы управления синхронизацией»,

графически выделенные под названием

«TRIGGER»

MODE

– Переключатель

режимов запуска развертки:

AUTO

– Автоколебательный

режим работы генератора развертки,

[Включен]

NORM

–

Ждущий режим работы генератора развертки,

TV-V,

TV-H –

Кадровая и строчная развертка ТВ сигнала;

в лаб. работе не используется

SOURCE

–

Переключатель режима синхронизации

(источника синхронизации):

CH1

– Синхронизация

сигналом 1-го канала,

[Включен]

CH2

– Синхронизация

сигналом 2-го канала,

LINE –

Синхронизация

от

питающей сети,

EXT

– Внешняя синхронизация

сигналом, поданным на вход

TRIG IN.

TRIG IN – Вход

для сигналов внешней синхронизации.

LEVEL – Регулятор

уровня синхронизации (уровня сигнала,

при котором срабатывает блок синхронизации).

[В среднем

положении]

SLOPE

–

Переключатель управляющего фронта

сигнала синхронизации:

«

+ » –

синхронизация развертки от положительного

перепада сигнала синхронизации

(положительным фронтом),

«–

» –

синхронизация развертки от отрицательного

перепада сигнала синхронизации

(отрицательным фронтом).

TRIG

IN – Развертка

поочередно синхронизируется сигналами

от 1-го и 2-го каналов. [Отжат]

—

— — — — — — — — — — — — — — — — — —

Режим

работы осциллографа X

– Y

В этом режиме

обеспечивается возможность раздельного

управления внешними сигналами отклонением

луча осциллографа по оси Х и

оси Y; при этом входом оси

Х является вход «CH 1» канала 1, а входом

оси Y является вход «CH 2»

канала 2.

Для

включения такого режима переключатель

TIME/DIV

устанавливается

в положение X – Y . Регулировка

чувствительности по осям Х и Y

осуществляется переключателями

коэффициентов отклонения «VOLTS/DIV»

соответственно по каналу 1 и каналу 2.

Такой режим, в частности, может быть

использован для построения фигур

Лиссажу.

—

— — — — — — — — — — — — — — — — — —

При

включении (POWER)

осциллографа с

рекомендованными выше начальными

установками переключателей на экране

осциллографа должны появиться две (или

одна спаренная) горизонтальные линии.

В случае отсутствия этих линий необходимо

регуляторами

(POSITION)

положения лучей

по

вертикали и

горизонтали

добиться появления этих лучей на экране;

при необходимости увеличить интенсивность

(INTER)

и

изменить фокусировку (FOCUS)

луча.

Полученные

линии следует сфокусировать (FOCUS)

и установить удобную

для наблюдения яркость(INTER);

установить линии вдоль оси Х (жирная

линия сетки); часто бывает полезным

визуально наблюдать начало развертки,

при этом левый край линий должен немного

отступать от левого края экрана.

В

дальнейшем переключатели и регуляторы

осциллографа устанавливаются в

необходимые положения в зависимости

от решаемых задач и в соответствии с

назначениями этих органов управления.

(! не забыть снять с заземления

(GND) переключатели

(AC-DC-GND) входов

усилителей используемых в работе

каналов).

Калибратор

осциллографа выполнен

схемотехнически в виде отдельного

блока, активный выход (CAL)

которого расположен в нижнем левом углу

передней панели (конструктивно выполнен

в виде одного лепестка; «земляной»

провод общий со всей схемой осциллографа).

Выходной сигнал калибратора –

прямоугольные импульсы напряжения

положительной полярности с амплитудой

2В

и частотой 1кГц.

Калибратор

может быть использован для проверки

работоспособности осциллографа. Для

этого поочередно сигнал генератора

подается на входы каналов вертикального

отклонения, используя их входные кабели

(! Обратить внимание, что сигнал подается

через активный, не «земляной» провод;

активным кабелем надо аккуратно коснуться

выходного лепестка генератора). При

установленном режиме каждого канала:

закрытый вход (АС),

коэффициент

отклонения ko

= 0,5

В/Дел, коэффициент развертки kр

= 0,5

мс/Дел, синхронизация от выбранного

канала, на экране должны наблюдаться

прямоугольные импульсы с двойной

амплитудой 4 деления и периодом 2 деления;

обратить внимание при этом на номинальную

(крайнее правое положение) установку

регуляторов (DIV,

SWP. VAR)

плавного изменения соответствующих

коэффициентов. В противном случае

обратиться к преподавателю.

Указания

по спецификации осциллографа.

Коэффициенты

отклонений, коэффициенты развертки и

параметры входов считываются с передней

панели осциллографа.

Дополнительные

сведения:

пределы

основной погрешности: коэффициентов

отклонения kо

= 3%,

коэффициентов

развертки kр

= 3%;

максимальная

нелинейность амплитудной характеристики

каналов н

= 5%,

максимальная

нелинейность развертки р

= 5%;

рабочая

полоса пропускания: для открытого входа

0-10МГц,

для

закрытого входа 10Гц – 10МГц.

1

В квадратных скобках указаы рекомендованные

состояния переключателей перед

включением осциллографа. Остальные

органы управления устанавливаются в

соответствии с решаемой задачей.

2

Вольты/деление, Сек./дел – под делениями

понимаются большие деления (см.) на

экране осциллографа.

3

Органы управления, не отмеченные

полужирным шрифтом, в лабораторных

работах, как правило, не используются.

2

Соседние файлы в папке Описание приборов

- #

- #

- #

Download Manual of GW Instek GOS-620FG Test Equipment for Free or View it Online on All-Guides.com.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your

definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

I

Trust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Instek GTP-060A-4 at our website: Click HERE

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff at our full-service, in-house repair center

Instra

View

SM

REMOTE INSPECTION

Remotely inspect equipment before purchasing with our interactive website at

www.instraview.com

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at

www.artisantg.com

for more information on price quotations, drivers, technical specifications, manuals, and documentation

Contact us:

(888) 88-SOURCE | [email protected] | www.artisantg.com

20MHz Dual Trace Oscilloscope

Model: GOS-620

i

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS PAGE

INTRODUCTION………………………………………………………………………………………………………..

1-1. Description………………………………………………………………………………………………….

1-2.Feature………………………………………………………………………………………………………

1

1

1

SPECIFICATION………………………………………………………………………………..

3. PRECAUTIONS BEFORE OPERATION…….………………………….…………………………………..

3-1.Unpacking the instrument…………………………………………………….……………………………

3-2.Checking the Line Voltage…………………………………………………………………………………

3-3.Environment…………………………………………………………………………………………………

5

5

5

6

3-4.Equipment Installation and Operation……………………………………………………………………

3-5.CRT Intensity……………………………………………………………………………………………….

3-6.Withstanding Voltage of Input Terminals…………………………………………………………………

INTRODUCTION…………………………………………………………………………………….

4-1.Front Panel………………………………………………………………………………………………….

4-2.Rear Panel……………………………………………………………………………………………………

METHOD………………………………………………………………………………………

5-1.Basic Operation………………………………………………………………………………………….….

5-2.Dual-channel Operation……………………………………………………………………………………

5-3.ADD Operation……………………………………………………………………………………………..

5-4.Triggering……………………………………………………………………………………………………

5-5.TIME/DIV ontrol……………………………………………………………………………………………

5-6.Sweep Magnification………………………………………………………………………………………..

5-7.X-Y Operation………………………………………………………………………………………………

5-8.Calibration…………………………………………………………………………………………………..

5-9.DC BAL Adjustment……………………………………………………………………………………….

5-10.Function Generator………………………………………………………………………………………..

6. MAINTENANCE……………………………………………………………………………………………………..

6-1.Fuse Replacement…………………………………………………………………………………………..

6-2.Line Voltage…………………………………………………………………………………………………

6-3.Cleaning………………………………………………………………………………………………………

19

20

21

21

15

16

16

19

21

22

22

22

22

6

6

6

7

7

7

13

13

ii

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

SAFETY TERMS AND SYMBOLS

These terms may appear in this manual or on the product:

WARNING. Warning statements identify condition or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

The following symbols may appear in this manual or on the product:

DANGER ATTENTION Protective Frame or chassis

High Voltage refer to Manual Conductor Terminal

Terminal

iii

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

FOR UNITED KINGDOM ONLY

NOTE

As the colours of the wires in main leads may not correspond with the colours marking identified in

This lead/appliance must only

your plug/appliance, proceed as follows:

be wired by competent persons

WARNING

The wire which is coloured Green & Yellow must be connected to the Earth terminal marked with

THIS APPLIANCE MUST BE

the letter E or by the earth symbol or coloured Green or Green & Yellow.

EARTHED

The wire which is coloured Blue must be connected to the terminal which is marked with the letter

IMPORTANT

The wires in this lead are

N or coloured Blue or Black.

coloured in accordance with

The wire which is coloured Brown must be connected to the terminal marked with the letter L or

the following code:

P or coloured Brown or Red.

Green/

If in doubt, consult the instructions provided with the equipment or contact the supplier.

Yellow: Earth

Blue: Neutral

This cable/appliance should be protected by a suitably rated and approved HBC mains fuse : refer

Brown: Live(Phase)

to the rating information on the equipment and/or user instructions for details. As a guide, cable of 0.75mm ² should be protected by a 3A or 5A fuse. Larger conductors would normally require

13A types, depending on the connection method used.

Any moulded mains connector that requires removal/replacement must be destroyed by removal of any fuse & fuse carrier and disposed of immediately, as a plug with bared wires is hazardous if a engaged in live socket. Any re-wiring must be carried out in accordance with the information detailed on this label.

iv

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

EC Declaration of Conformity

We

GOOD WILL INSTRUMENT CO.,LTD.

(1) 4F, No. 4, Lane 235, Pao-chiao Road., Hsin-Tien City, Taipei Hsien, Taiwan

(2) Plot 522, Lorong Perusahaan Baru 3, Prai Industrial Estate, 13600 Prai, Penang, Malaysia

declare under sole responsibility that the GOS-620 meets the intent of Directive 89/336/EEC ;

92/31/EEC ; 93/68/EEC for Electromagnetic Compatibility . Compliance was demonstrated to the

following specifications as listed in the industrial Technology Research institute :

EN50081-2:

Electromagnetic compatibility —

(1992)

Generic emission standard

Part 1: Residential, commercial and light industry

Conducted Emission

Radiated Emission

Current Harmonics

EN 55022

EN 55011

EN 61000-3-2

EN50082-2:

Electromagnetic compatibility —

(1992)

Generic immunity standard

Part 1: Residential, commercial and light industry class B(1994) Electrostatic Discharge IEC 1000-4-2 class B(1991) Radiated Immunity

(1995) Electrical Fast Transients

IEC 1000-4-3

IEC 1000-4-4

(1995)

(1995)

(1995)

Voltage Fluctuations EN 61000-3-3

Low Voltage Directive EN 61010-1

(1995)

(1993)

Surge Immunity

Voltage Dip/Interruption

IEC 1000-4-5

EN 61000-4-11

(1995)

(1994)

v

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

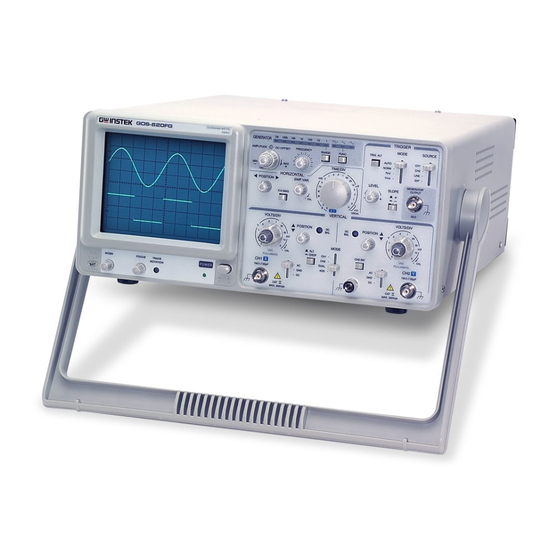

1. PRODUCT INTRODUCTION

1.1 Description

The GOS-620 oscilloscope is a portable-type, dual-channel oscilloscope, its bandwidth of DC is up to 20MHz, and its maximum sensitivity is 1mV/DIV. The time base provides a maximum sweep time of 0.2uS/DIV. The sweep speed becomes 100nS/DIV after magnifying 10 times. The oscilloscope uses a 6-inch rectangular type cathode-ray tube with red internal graticule.

The product is sturdy, easy to operate and exhibits high operational reliability.

1.2 Features

1) High intensity CRT with high acceleration voltage:

The CRT is a high beam transmission and high intensity type with a high acceleration voltage of 2kV. It displays readable traces clearly even at high sweep speeds.

2) Wide bandwidth and sensitivity:

In addition to wide bandwidth, DC-20MHz (-3dB), the instrument provides high sensitivity of 5mV/DIV (1mV/DIV at ×

5 MAG). A 20MHz frequency is obtained with improved triggering synchronization.

3) Alternate triggering:

Even with an observation of two different frequency waveforms, each waveform can be triggered stably.

4) TV sync triggering:

The oscilloscope has a sync separator circuit for TV-V and TV-H signals triggering.

5) CH1 Output:

A signal from 50

Ω output terminal of CH1 located on rear panel can be applied to frequency counter or other instruments.

6) Z-Axis Input:

Intensity modulation capability permits time or frequency markers to be added. Trace blank with positive signal, TTL compatible.

7) X-Y operation:

Set the switch to X-Y to operate the instrument as an X-Y oscilloscope. CH1 can be applied as a horizontal deflection (X-axis) while CH2 provides vertical deflection (Y-axis).

1

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.TECHNICAL SPECIFICATIONS

MODEL

SPECIFICATIONS

1.OSCILLOSCOPE

Sensitivity

Sensitivity Accuracy

5mV 〜 5V/DIV, 10 steps in 1-2-5 sequence.

≤3% ( × 5 MAG : ≤5%).

Vernier Vertical sensitivity To 1/2.5 or less of panel-indicated value.

DC〜20MHz ( × 5MAG: DC〜7MHz).

Frequency bandwidth

Rise time

Input impedance

AC coupling: Low limit frequency of 10Hz.

(With reference to 100kHz, 8DIV. Frequency response at -3dB).

Approx. 17.5nS (×5 MAG: Approx. 50nS).

Approx. 1M ohm // Approx. 25pF.

Square Wave Characteristics

Overshoot :

≤ 5% ( At 10mV/DIV range).

Other distortions and other ranges: 5% added to the above value.

DC Balance Shift Panel adjustable.

Linearity <±0.1DIV of amplitude change when waveform of 2 DIV at graticule center is moved vertically.

VERTICAL

AXIS

GOS-620 20MHz OSCILLOSCOPE

Vertical modes

CH1 : CH1 single channel.

CH2 : CH2 single channel.

DUAL : CH1 and CH2 are displayed. ALT or CHOP selectable at any sweep rate.

ADD : CH1 + CH2 algebraic addition.

Chopping Repetition Frequency Approx. 250kHz.

Input Coupling AC, GND, DC.

Maximum Input Voltage

300Vpeak (AC: frequency 1kHz or lower).

Set probe switch at 1: 1, the maximum effective readout is 40Vpp (14Vrms at Sine wave), set probe switch at 10: 1, the maximum effective readout is 400Vpp(140Vrms at Sine wave).

Common Mode Rejection Ratio 50:1 or better at 50kHz sinusoidal wave. (When sensitivities of CH1 and CH2 are set equally).

Isolation between channels >1000:1 at 50kHz.

(At 5mV/DIV range)

CH1 signal output

>30:1 at 20MHz.

At least 20 mV/DIV into a 50

Ω terminal, Bandwidth is 50Hz to 5MHz at least.

CH2 INV BAL.

Balanced point variation:

≤1 DIV (Reference at center graticule).

2

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

MODELSPECIFICATIONS

TRIGGERING

GOS-620 20MHz OSCILLOSOPE

Triggering source

Coupling

Slope

CH1, CH2, LINE, EXT (CH1 and CH2 can be selected only in the DUAL or ADD vertical mode).

In ALT mode, if the TRIG. ALT switch is pushed in, it can alternate triggering of two different source.

AC: 20Hz to full bandwidth.

+ / -.

20Hz 〜 2MHz : 0.5 DIV, TRIG-ALT:2 DIV, EXT : 200mV.

Sensitivity 2 〜 20MHz : 1.5 DIV, TRIG-ALT:3 DIV, EXT : 800mV.

TV : Sync pulse more than 1 DIV (EXT: 1V).

Triggering modes

EXT Triggering Signal Input

AUTO : Sweeps run in the free mode when no triggering input signal is applied.

(Applicable for repetitive signals of frequency 25Hz or over.).

NORM : When no triggering signal is applied, the trace is in the ready state, but is not displayed.

TV-V : This setting is used when observing the entire vertical picture of television signal.

TV-H : This setting is used when observing the entire horizontal picture of television signal.

(Both TV-V and TV-H synchronize only when the synchronizing signal is negative)

Input Impedance

Max. Input Voltage

Approx.: 1M ohm // approx. 25Pf.

300V (DC+AC peak), AC: Frequency not higher than 1kHz.

Sweep Time 0.2μSec 〜 0.5 Sec/DIV, 20 steps in 1-2-5 sequence.

Sweep Time Accuracy ±

3%.

HORIZIONAL

AXIS

Vernier Sweep Time Control

≤1/2.5 of panel-indicated value.

Sweep Magnification 10 times

×

10MAG Sweep Time Accuracy ±

5%, (20nSec〜50nSec are uncalibrated).

X-Y MODE

Linearity

Position shift caused by ×10MAG

Sensitivity

Frequency Bandwidth

X-Y Phase Difference

Sensitivity

±

3%, ×10MAG:±5% (20ns and 50ns are uncalibrated).

Within 2 div. at CRT screen center.

Same as vertical axis (X-axis:CH1 input signal; Y-axis:CH2 input signal.).

DC to at least 500kHz.

≤3

0 at DC 〜50kHz.

5 Vp-p (Positive-going signal decreases intensity).

3

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

MODEL

SPECIFICATION

Frequency Bandwidth

Z AXIS

Input resistance

Maximum Input Voltage

Waveform

Frequency

CALIBRATION Duty Ratio

VOLTAGE

Output Voltage

Output Impedance

Type

CRT

Acceleration Voltage

Effective Screen Size

Graticule

Trace Rotation

GENERAL

Power Source

Power Consumption

Operation Environment

Storage Temperature & Humidity

Accessories

GOS-620 20MHz OSCILLOSCOPE

DC 〜 2MHz.

Approx. 47K

Ω .

30V (DC+AC peak, AC frequency

≤1kHz).

Positive-going Square wave.

Approx. 1 kHz.

Within 48:52.

2 Vp-p ±2%.

Approx. 1 k

Ω .

6-inch rectangular type, internal graticule.

Approx. 2kV.

8 x 10 DIV (1 DIV = 10mm (0.39in)).

Internal

.

Provided.

AC115V, 230V

± 15% selectable, 50Hz or 60Hz.

Approx. 45VA, 40W(max.)

Indoor use

Altitude up to 2000 m

Ambient temperature :

To satisfy specifications :10

° to 35℃(50° to 95° F)

Maximum operating ranges: 0

° to 40℃(32 °to 104° F)

Relative humidity: 85% RH(max.) non condensing

Installation Category II

Pollution degree 2

-10

° to 70℃, 70%RH(maximum).

Power cord × 1, Instruction manual × 1

Probes × 2, GTL-101 × 1

4

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

Dimensions

Weight

310 (W) x 150 (H) x 455 (D) mm.

Approx.8k+gs (17.6lbs).

5

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

3. PRECAUTIONS BEFORE OPERATION

3.1 Unpacking the instrument

The product has been fully inspected and tested before shipping from the factory. Upon receiving the instrument, please unpack and inspect it to check if there is any damages caused during transportation. If any sign of damage is found, notify the bearer and/or the dealer immediately.

3.2 Checking the Line Voltage

The product can be applied any kind of the line voltage shown in the table below. Before connecting the power plug to an

AC line outlet, make sure the voltage selector of the rear panel is set to the correct position corresponding to the line voltage.

It might be damaged the instrument if connected to the wrong AC line voltage.

WARNING.

To avoid electrical shock, the power cord protective grounding conductor must be connected to ground.

The fuse must be changed following after the line voltage shown as below:

Line voltage

AC 115V

AC 230V

Range

97~132V

195~250V

Fuse

T 0.63A

250V

T 0.315A

250V

WARNING.

To avoid personal injury, disconnect the power cord bef o re removing the fuse holder.

6

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

3.3 Environment

The normal ambient temperature range of this instrument is from 0

° to 40°C (32° to 104°F). To operate the instrument over this specific temperature range may cause damage to the circuits.

Do not operate the instrument in a place where strong magnetic or electric field exists as it may disturb the measurement.

3.4 Equipment Installation and Operation

Ensure there is proper ventilation for the vent of the instrument. If it is not according to the specification to operate the instrument, the protection provided by the instrument may be impaired.

3.5 CRT Intensity

To prevent permanent damage to the CRT phosphor, do not let the CRT trace brighten excessively or stays the light spot for an unreasonable long time.

3.6 Withstanding Voltages of Input Terminals

The withstanding voltages of the instrument input terminals and probe input terminals are shown in the following table. Do not apply voltage higher than the specification. When set probe switch at 1: 1, the maximum effective readout is 40Vp-p

(14Vrms at Sine wave), set probe switch at 10: 1, the maximum effective readout is 400Vp-p (140Vrms at Sine wave).

Input terminal

CH1, CH2, inputs

Maximum input voltage

300Vpeak

EXT TRIG IN input 300Vpeak

CAUTION.

To avoid any damage, do not

Probe inputs

Z AXIS input

600Vpeak

30Vpeak

apply exceeding maximum input voltage of the

frequency less than 1 kHz to the instrument.

If an AC voltage which is superimposed on a DC voltage is applied, the maximum peak value of CH1and CH2 input voltages must not exceed

±300V, so is the AC voltages with a mean value of zero voltage, the maximum peak to peak value is

600Vp-p.

7

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

4.PANEL INTRODUCTION

z Fig. 4-1. Front Panel

33

R

OSCILLOSCOPE with FG GOS-620FG

20MHz

1

CAL

2Vp-p

INTEN

1 KHz

2

FOCUS TRACE

ROTATION

3 4

POWER

32 45 31 43 44 30 42 40 40 29 28 27 26 25 39 23

GENERATOR

AMPLITUDE

MIN

1M 100k 10k 1k

POSITION

PULL

DC-OFFSET

X10 MAG

100

FREQUENCY

MAX

HORIZONTAL

SWP. VAR.

CAL

10 1

TRIGGER

MODE

RANGE FUNC

TRIG. ALT

TIME/DIV mS

5

10

2

1

.5 .2 .1

50

20

10 mS

5

20

50

2

1

.1

.2

S

.5

.2

X-Y

VERTICAL

.5

x10

UNCAL

—

LEVEL

+

AUTO

NORM

TV-V

TV-H

SLOPE

+

—

CH1

CH2

LINE

EXT

SOURCE

GENERATOR

OUTPUT

50 W

VOLTS/DIV VOLTS/DIV

V

1

.5

.2

.1

50

2

5

CH1

VAR.

PULLx5MAG

X

5

20

10 mV

CAL

POSITION

AC

GND

DC

DC

BAL

ALT

CHOP

CH1

CH2

DUAL

ADD

MODE

DC

BAL

POSITION

CH2 INV

AC

GND

DC

V

1

.5

2

.2

.1

50

20

10 mV

5 5

VAR.

PULLx5MAG

CH2 Y

CAL

CAT

MAX. 300Vpk

CAT

MAX. 300Vpk

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

8

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

z Fig. 4-2 Rear Panel

38

34 35 24

Z-AXIS INPUT

CAT 30Vpk MAX.

WARNING

TO AVOID ELECTRIC SHOCK THE POWER CORD PROTECTIVE GROUNDING

CONDUCTOR MUST BE CONNECTED TO GROUND.

FOR CONTINUED FIRE PROTECTION. REPLACE ONLY WITH SPECIFIED

TYPE AND RATED FUSE.

NO OPERATOR SERVICEABLE COMPONENTS INSIDE. DO NOT REMOVE

COVERS. REFER SERVICING TO QUALIFIED PERSONNEL.

CH1 OUTPUT

20mV/DIV INTO 50

W

TRIG IN

ENSURE THE POWER IS REMOVED FROM

THE INSTRUMENT BEFORE REPLACING THE FUSE

115

0 23

AC

LINE VOLTAGE

SELECTION

115V

230V

RANGE

(50/60Hz)

97~132V

195~250V

FUSE

T 0.63A

250V

T 0.315A

250V

POWER MAX. 40 WATTS, 45VA

IEC1010 250V CAT

CAT

300Vpk

MAX.

37 36

9

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

4-1.Front Panel

CRT :

(6) POWER

Main power switch of the instrument. Turn on the switch to get the LED (5) lighted.

(2).INTEN

Control the brightness of the spot or trace.

(3) FOCUS

Focus the trace to the sharpest image.

(4) TRACE ROTATION

Semi-fix potentiometer for aligning the horizontal trace in parallel with graticule lines.

(33)FILTER

The filter is easy for waveform viewing.

Vertical Axis:

(8) CH1 (X) input

The vertical input terminal of CH1 is X-axis in X-Y operation.

(20)CH 2 (Y) input

The vertical input terminal of CH2 is Y-axis in X-Y operation.

(10) & (18) AC-GND-DC

Select connection mode between input signal and vertical amplifier.

AC AC

GND coupling

Vertical amplifier input is grounded and input terminals are disconnected.

DC DC coupling

(7) & (22) VOLTS/DIV

Select the vertical axis sensitivity from 5mV/DIV to 5V/DIV with 10 ranges totally.

10

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

(9) & (21) VARIABLE

Fine adjustment of sensitivity with a factor of

≥1/2.5 of the indicated value. The sensitivity is calibrated to specific value in the CAL position. When this knob is pulled out (x5 MAG state), it will multiply 5 by the amplifier sensitivity.

(13) & (17) CH1 & CH2 DC BAL

.

The knobs are used for adjusting the attenuator balance. See DC BAL adjustments for details.

(11) & (19)

56POSITION

Vertical positioning control of trace or spot.

(14)VERT MODE

:

Select operation modes of CH1 and CH2 amplifiers.

CH1 Operate the oscilloscope as a single-channel instrument by selecting CH1 alone.

CH2

DUAL

ADD

Operate the oscilloscope as a single-channel instrument by selecting CH2 alone.

Operate the oscilloscope as a dual-channel instrument by selecting CH1 and CH2.

The oscilloscope displays the algebraic sum (CH1 + CH2) or subtraction (CH1 — CH2) of the two signals

(the subtraction function effects only when push in CH2 INV (16) button).

(12)ALT/CHOP

When this switch is released in the dual-trace mode, the channel 1 and channel 2 inputs are alternately displayed

(normally used at faster sweep speeds).

When this switch is depressed in the dual-trace mode, the channel 1 and channel 2 inputs are chopped and displayed simultaneously. (normally used at slower sweep speeds)

.

(16)CH2 INV

When press CH2 INV button, it will inverts the CH2 input signal in CH2 and in ADD MODE, the channel 2 trigger signal pickoff is also inverted.

Triggering

(24)EXT TRIG IN input terminal

Input terminal is used for external triggering signal. To use this terminal, set SOURCE (23) to the EXT position.

(23)SOURCE

Select the internal triggering source signal, and the EXT TRIG IN input signal.

CH1

Press key DUAL or ADD of VERT MODE (14), select CH1 to get internal triggering source signal.

CH2

Press key DUAL or ADD of VERT MODE (14), select CH2 to get internal triggering source signal.

11

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

(27)TRIG.ALT

Set VERT MODE switch (14) in DUAL or ADD key, select CH1 or CH2 by the SOURCE switch (23), then press

TRIG.ALT switch (27), the internal triggering source signal will display alternately from CH1 and CH2.

LINE Display the triggering signal from AC power line frequency signal.

EXT Obtain the external triggering source signal by applying external signal to EXT TRIG IN input terminal (24).

(26)SLOPE

Triggering slope button.

“+”

“-”

(28)LEVEL

Triggering occurs when the trigger signal crosses the trigger level by positive-going course.

Triggering occurs when the trigger signal crosses the trigger level by negative-going course.

Display a synchronized stationary waveform and set a start point for the waveform.

Toward “+” The trigger level moves upward on the display waveform.

Toward “-” The trigger level moves downward on the display waveform.

(25)TRIGGER MODE

Trigger mode selection.

AUTO If no trigger signal applied or the trigger signal frequency is less than 25Hz, the sweep will be in the free run mode.

NORM If no trigger signal applied and sweep is in a stand-by state, there will be no trace appear.

TV-V Used for observing entire vertical picture of television signal.

TV-H Used for observing entire horizontal picture of television signal.

(Both TV-V and TV-H synchronize only when the synchronizing signal is negative.)

Time Base:

(29)TIME/DIV

Provide sweep time ranges from 0.2 us/div to 0.5 s/div with 20 steps totally.

X-Y Use the instrument as an X-Y oscilloscope by setting to X-Y position.

12

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

(30)SWP.VAR

Vernier control knob of the sweep time used when CAL and the sweep time is calibrated to the value preset in

TIME/DIV. The sweep of TIME/DIV can be varied continuously when shaft is not in CAL position. Rotate the control knob to CAL position and the sweep time is calibrated to the preset value of the TIME/DIV. Counterclockwise rotate the control knob to the bottom to delay the sweep by 2.5 time or more.

(32) 34POSITION

Adjust the trace or spot in horizontal position.

(31)×

10 MAG

Magnify 10 by pressing the button.

Others:

(1) CAL

This terminal delivers the calibration voltage of 2 Vp-p, 1kHz, positive square wave.

(15)GND

Ground terminal of oscilloscope mainframe.

4-2.Rear Panel

(34)Z AXIS INPUT

Input terminal for external intensity modulation signal.

(35)CH1 SIGNAL OUTPUT

Delivers a voltage of approximately 20mV/DIV from the CH1 signal to 50

Ω terminal for frequency counting.

AC POWER Input Circuit:

(36)AC Power input connector

Connect the AC power cord (supplied) to this connector.

(37)FUSE & line voltage selector

Fuse rating is shown in Page 7 Line voltage selector to select power sources.

(38)Studs

Studs is not only used as a stand for laying the oscilloscope on its back to operate it in the upward posture, also used for winding up the power cord.

13

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5.

OPERATION METHOD

5-1.Basic Operation—Single-channel Operation

Before connecting the power cord to an AC line outlet, make sure that the AC line voltage input switch on the rear panel of the instrument is correctly set for the AC line voltage. After ensuring the voltage setting, set the switches and controls of the instrument as shown below:

Item No Setting Item No Setting

position(OFF)

INTEN (2)

FOCUS (3)

VERT MODE (14) CH1

TRIG. ALT

TRIGGER MODE

(27) Released

(25) AUTO

TIME/DIV (29)

CH 2 INV (16) Released

56POSITION (11)(19) Mid-position

VOLTS/DIV (7)(22)

CAL(clockwise position)

SWP.VER (30)

34POSITION x10 MAG

(32)

(31)

Mid-position

Released

GND

CH1

14

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

After setting the switches and control knobs as mentioned, connect the power cord to the AC line outlet, then follow the procedure describes as follows:

1) Press the POWER switch and make sure that the power LED is on. In about 20 seconds, a trace will appear on the CRT screen. If no trace appears in about 60 seconds, counter check the switch and control setting.

2) Adjust the trace to an appropriate brightness and image with INTEN and FOCUS control knob respectively.

3) Align the trace with the horizontal central line of the graticule by adjusting the CH1 POSITION control knob and

TRACE ROTATION control knob (adjusted with screwdriver).

4) Connect the probe to the CH1 INPUT terminal and apply 2Vp-p CALIBRATOR signal to the probe tip.

5) Set the AC-GND-DC switch to AC, a waveform will be displayed on the CRT screen as shown in the figure 5-1. z FIG. 5-1

6)

7)

Adjust the FOCUS control knob to trace image sharply.

Display the signal waveform clearly by adjusting the VOLTS/DIV switch and

TIME/DIV switch to appropriate position.

Adjust the

56 POSITION and 34POSITION control knobs to appropriate position to align the waveform with the graticule, so that voltage (Vp-p) and period (T) can be read conveniently.

The descriptions above are the basic operating procedures for CH1 single-channel operation of oscilloscope. So is CH2 single-channel operation. For further operation methods will be explained in the subsequent paragraph.

15

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-2.Dual-channel Operation

Set the VERT MODE switch to DUAL to display trace in CH2 (The procedure is same as CH1 described in previous section). At this step, the calibrator signal appears in CH1 is Square wave, but it appears in CH2 is a straight line as no z Fig. 5-2 signal applied to this channel yet.

Now, apply the calibrator signal to the vertical input terminal of CH2 through the probe with the same procedure as for CH1. Set the AC-GND-DC switch to AC, and adjust vertical POSITION knobs (11) and (19), the signals will be displayed on both channels as shown in Figure 5-2.

When ALT/CHOP switch is released (ALT MODE), the input signals which applied respectively to CH1and CH2 appears on the screen alternately at each sweep. This setting is used when the sweep time is short in 2-channel observation.

When ALT/CHOP switch is pressed (CHOP MODE), the input signals which applied to CH1and CH2 are chopped and display on the screen at the same time with the frequency of 250kHz. This setting is used for low speed sweep.

Set to dual channel operation (DUAL or ADD mode), select CH1 or CH2 signal from SOURCE switch to get triggering source signal. If both CH1 and CH2 signals are in a synchronized relation, both waveforms will be displayed in stationary states. If not, only a signal stationary waveform will be appeared. If press TRIG. ALT push button, both waveforms can also be displayed in stationary states.

16

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-3.ADD Operation

An algebraic sum of the CH1 and CH2 signals can be displayed on the screen by setting the VERT MODE switch to ADD.

The displayed signal will be difference between CH1 and CH2 if press CH2 INV push button. Adjust

56

POSITION knob of CH1 or CH2 can make vertical position, to the advantage of the linearity of the vertical amplifiers, it’s better to set

56

POSITION knob of both channels in middle position.

5-4.Triggering

Proper triggering is essential for an efficient operation of the instrument. Users must make themselves familiar with the triggering functions and procedures thoroughly:

(1)Functions of MODE switch:

AUTO

Select automatic sweep operation by setting to AUTO mode, the sweep generator will freely generate a sweep without a trigger signal. However, it will automatically switch to triggering sweep operation if an acceptable trigger source signal is present. The AUTO mode is handy for observing the waveform when first set up the instrument, as it provides sweep function for waveform observation until properly set to other mode. Once starting to set the control mode, the operation often jumps back to the NORM trigger mode as it is much more sensitive. Automatic sweep must be used for DC measurements and signals with low amplitude in order not to trigger the sweep.

NORM The NORM mode provides normal triggering sweep operation. The sweep will not act until the selected trigger source signal crosses the threshold level by setting

TRIG LEVEL control knob. The triggering generate one sweep which will come to inactivate until another triggering

TV-V occurs. In the NORM mode, there will be no trace unless an adequate trigger signal is present. In the ALT mode of dual trace operation with NORM sweep selected, there will be no trace unless both CH1 and CH2 signals are adequate for triggering.

Set the MODE switch to TV-V mode, select vertical sync pulses for sweep triggering to view composite video waveforms. Select vertical sync pulses as a triggering to view vertical fields and frames of video. A sweep time of 2 ms/div is appropriate for viewing fields of video and 5 ms/div for complete frames (two interlaced fields) of video.

17

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

TV-H Set the MODE switch to TV-H mode and select horizontal sync pulses for sweep triggering to view composite video waveforms. Select horizontal sync pulses as a triggering to view horizontal lines of video. A sweep time of about 10 us/div is appropriate for displaying lines of video. Display the exact number of desired waveforms by setting SWP VAR control knob.

This oscilloscope synchronizes with only (-) polarity, that is, the sync pulses are negative and the video is positive as shown in Fig. 5-3. z Fig. 5-3

(2)Functions of SOURCE switch:

Apply the displayed signal itself or a trigger signal, which has a time relationship with the displayed signal, to the trigger circuit to display a stationary signal on the CRT screen. The SOURCE switch is used for selecting these trigger sources.

CH1

CH2

LINE

The internal trigger source is used most commonly.

The signal applied to the vertical input terminal is branched off away from the preamplifier and is fed to the trigger circuit through the VERT MODE switch. Since the trigger signal is the measured signal itself, a stable waveform can be readily displayed on the CRT screen. When in the DUAL or ADD operation, the selected signal through the SOURCE switch is used as a trigger source signal.

The AC power line frequency signal is used as a trigger signal. This method is effective when the measured signal has a relationship with the AC line frequency, especially for measurements of low level AC noise of audio equipment, thyristor circuits, etc.

EXT

The sweep is triggered by an external signal applied to the external trigger input terminal. An external signal which has a periodic relationship with the measured signal is used. Because the measured signal is not used as the triggering signal, the waveforms can be displayed more independent than the measured signal.

18

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

(3)Functions of TRIG LEVEL control knob and SLOPE button:

A sweep triggering is developed when the trigger source signal crosses a preset threshold level. Rotate TRIG LEVEL control knob to vary the threshold level. In the “+” direction, the trigger threshold shifts to a more positive value, and in the

“-“ direction, the trigger threshold shifts to a more negative value. When set the control knob in the center, the threshold level will be on the average of the signal used as the trigger source.

Adjust TRIG LEVEL control knob for the desired start point of sweep on a waveform. On sine wave signals, the phase at which sweep begins is variable. Note that if rotate TRIG LEVEL control knob toward its extreme “+” or “-”, no sweep will be developed in the NORM trigger mode because the trigger threshold exceeds the peak amplitude of the sync signal.

When set TRIG SLOPE button to the (+) position (up), the sweep is developed form the trigger source waveform as it crosses the threshold level in a positive-going direction. When set TRIG SLOPE button to the (-) position (down), a sweep triggering is developed from the trigger source waveform as it crosses the threshold level in a negative-going direction. The slope (polarity) trigger signal as shown in Figure 5-4. z

Fig. 5-4

(4) Function of TRIG ALT button:

The TRIG ALT button is used to select alternate triggering and display the selected DUAL-trace of VERT MODE (the switch control knob CH1, CH2, DUAL and ADD modes). In the alternate trigger mode (when select dual-trace operation), the trigger source alternates between CH1 and CH2 with each sweep. This is convenient for checking amplitudes, wave-shape, or waveform period measurements, and even permits simultaneously observing two waveforms which are not related to frequency or period. However, this setting is not suitable for phase or timing comparison measurements. For such measurements, both traces must be triggered by the same sync signal.

If press both CHOP and TRIG ALT buttons during dual-trace operation, synchronization of the display is not possible because the chopping signal will be triggered. Use ALT mode itself, or select CH1 or CH2 as trigger source.

19

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-5.TIME/DIV Control

Set the TIME/DIV switch to display the desired number of cycles of the waveform. If there are too many cycles displayed with good resolution, set to increase the sweep speed. If only a line is displayed, try to slow down the sweep speed. When the sweep speed is faster than the observed waveform, only part of it will be displayed, which may appear as a straight line for a Square wave or Pulse waveform.

5-6.Sweep Magnification

When a certain part of displayed waveform is needed to be expanded timewise, a faster sweep speed may be used.

However, if the required portion is apart from the starting point of the sweep, it may run off the CRT screen. In this case, push the

×10MAG button to expand 10 times the displayed waveform from the right to the left in the center of screen. The sweep time with the magnification operation is as follows:

(Value indicated by TIME/DIV switch) x 1/10

Thus, the unmagnified maximum sweep speed (1nSec/DIV) can be increased with the magnification as follows:

1

µSec/DIV x 1/10 = 100nSec/DIV z

FIG. 5-5

20

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-7.X-Y Operation

z FIG. 5-6

Set the TIME/DIV switch to X-Y position to operate the instrument as an X-Y oscilloscope. Each input is applied to the instrument as follows

X-axis signal (horizontal axis signal ) : CH1 INPUT.

Y-axis signal (vertical axis signal) : CH2 INPUT.

Note:

When high frequency signals are displayed in X-Y operation, pay attention to the frequency bandwidth and phase

difference between X and Y-axis.

The X-Y operation permits the oscilloscope to perform many state-of-the-art measurements which the conventional sweep operation could not make. The CRT display becomes an electronic graph of two instantaneous voltages. The display may be a direct comparison of the two voltages such as a vectorscope display of video color bar patterns. However, the X-Y mode can almost be used in graph of any dynamic characteristic if a transducer is adopted to change the characteristic (frequency, temperature, velocity, etc.) of voltage. One common application is frequency response measurements that the Y-axis corresponds to signal amplitude and the X-axis corresponds to frequency.

1. Set the TIME/DIV control knob to the X-Y position (fully counterclockwise), CH1 becomes the X-axis input and CH2 becomes the Y-axis input.

2. Adjust X and Y positions by using the horizontal

34

POSITION and CH2

56

POSITION control knobs respectively.

3. Adjust the amount of vertical (Y-axis) deflection by using CH2 VOLTS/DIV and VAR control knobs.

4. Adjust the amount of horizontal (X-axis) deflection by using CH1 VOLTS/DIV and VAR control knobs.

21

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

5-8.Calibration of Probe

As explained previously, the probe makes up a wide range attenuator. Unless phase compensation is properly done, the displayed waveform will be distortion causing measurement errors. Therefore, the probe must be properly compensated before use. Connect 10:1 probe BNC to the INPUT terminal of CH1 or CH2 and set VOLTS/DIV switch at 50mV. Connect the probe tip to the calibration voltage output terminal and adjust the compensation trimmer on probe for optimum Square wave

(minimum overshoot, rounding off and tilt). z FIG. 5-7

(a) Correct compensation (b) Over compensation

(c) Insufficient compensation

5-9.DC BAL Adjustments

The ATT balance of the vertical axis can be adjusted easily.

(1) Set the input coupling switches of CH1 and CH2 to GND and set the TRIG MODE to AUTO, then position the base line to the center.

(2) Adjust the VLOTS/DIV switch to 5mV-10mV and fix the line does not move.

5-10.Function Generator

The instrument also provides the basic features of Function Generator to satisfy general demand with simply and intuitional operation method by adjusting the control knobs directly from front panel for output waveform, amplitude, DC level and etc.

All the control knobs located in front panel are marked with the same color to prevent missetting.

22

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

6.MAINTENANCE

WARNING

The following instructions are executed by qualified personnel only. To avoid electrical shock, do not perform any servicing other than the operating instructions unless you are qualified to do so.

6-1.Fuse Replacement

If the fuse blows, the power lamp indicators will not light and the instrument will not start. The fuse holder should not normally be opened unless a problem has been caused to the unit. Try to determine and correct the cause of the blown fuse and replace with a fuse of correct rating and type (see page 7 ) on the rear panel (see fig. 4-2).

WARNING. For continued fire protection. Replace fuse only with 250V fuse of the specified type and rating, and disconnect power cord before replacing fuse.

6-2 Line Voltage Conversion

The primary winding of the power transformer is tapped to permit operation from 115V, or 230VAC 50/60Hz line voltage.

Conversion from one line voltage to another is done by changing the line voltage selector switch as shown in Fig. 4-2. The rear panel identifies the line voltage to which the unit was factory set. To convert to a different line voltage, perform the following procedure:

(1)Make sure the power cord is unplugged.

(2)Adjust the line voltage selector switch to the desired line voltage position.

(3)A change in line voltage may also require a corresponding change of fuse value. Install the correct fuse value as listed on rear panel.

6-3 Cleaning

To clean the instrument, use a soft cloth dampened in a solution of mild detergent and water. Do not spray cleaner directly onto the unit because it may leak into the cabinet and cause damage. Do not use chemicals containing benzine, benzene, toluene, xylene, acetone, or similar solvents. Do not use abrasive cleaners on any portion of the oscilloscope.

23

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

7.BLOCK DIAGRAM

24

Artisan Technology Group — Quality Instrumentation … Guaranteed | (888) 88-SOURCE | www.artisantg.com

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff at our full-service, in-house repair center

Instra

View

SM

REMOTE INSPECTION

Remotely inspect equipment before purchasing with our interactive website at

www.instraview.com

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at

www.artisantg.com

for more information on price quotations, drivers, technical specifications, manuals, and documentation

Contact us:

(888) 88-SOURCE | [email protected] | www.artisantg.com