Metasys Ventilation Controller Application for the DX-9100 ………….3

Introduction…………………………………………………………………………………………..*3

Key Concepts………………………………………………………………………………………… 5

Johnson Controls CO 2 Concentration Samplers…………………………………………………… *5

MVC-2000-1 Package ……………………………………………………………………………………… *5

DX-9100 ………………………………………………………………………………………………………… *7

CO 2 Sensor……………………………………………………………………………………………………. *7

Air Valve …………………………………………………………………………………………………………. 8

Air Pump…………………………………………………………………………………………………………. 8

Air Filter …………………………………………………………………………………………………………. *8

Sample System ………………………………………………………………………………………………. *9

HVAC System Requirements……………………………………………………………………………. 10

Location Considerations ………………………………………………………………………………….. 10

Procedure Overview …………………………………………………………………………….*12

Detailed Procedures …………………………………………………………………………….. 13

Installing a UPM…………………………………………………………………………………………….. *13

Trending Data……………………………………………………………………………………………….. *15

Checking the Solenoid Valves …………………………………………………………………………. *16

Calculating the OA Flow …………………………………………………………………………………. *16

* Indicates those sections where changes have occurred since the last printing.

© 2000 Johnson Controls, Inc.

Part No. 24-8395-26 Rev. —

Code No. LIT-653425

Metasys Ventilation Controller Section

T

B

ECHNICAL

ULLETIN

M-Applications

653

Issue Date

1000

www.johnsoncontrols.com

FANs 636.4, 1628.4

Configuration Guides Section

Configuration Guide

Issue Date 0900

© 2000 Johnson Controls, Inc.

1

Code No. LIT-6364030 www.johnsoncontrols.com

DX-9100 Extended Digital Plant Controller Page 5

• Introduction *5

• Hardware Configuration 10

Software Configuration 11

• DX-9100 Software Elements 11

• Configuration Tools 11

• Configuring the Controller 14

• DX-9100 Controller Selection 15

• DX-9100 Global Data 15

• Configuration Number (Version 1.1 or Later) 17

• Password Feature (Versions 1.4, 2.3, 3.3, or Later) 17

• Analog Input Configuration 18

• Digital Input Configuration 25

• Analog Output Configuration 26

• Digital Output Configuration 32

• DO: Output Type 34

• Constants and Result Status 40

• Extension Module Configuration *42

• Network Analog Input Configuration (Version 3 Only) *51

• Network Digital Input Configuration (Version 3 Only) 52

• Network Analog Output Configuration (Version 3 Only) 53

• Network Digital Output Configuration (Version 3 Only) 55

• Programmable Function Module Configuration 57

• Control Algorithm Theory 63

DX-9100 Configuration Guide

* Indicates those sections where changes have occurred since the last printing.

2

Configuration Guides—DX-9100 Configuration Guide

• Algorithm 01 — PID Control Module

Page

65

• Algorithm 02 — On/Off Control Module 78

• Algorithm 03 — Heating/Cooling PID Control Module (Dual PID) 86

• Algorithm 04 — Heating/Cooling On/Off Control Module (Dual On/Off) 98

• Numerical Calculation and Other Function Module Configurations 107

• Algorithm 11 — Average 107

• Algorithm 12 — Minimum Select 109

• Algorithm 13 — Maximum Select 111

• Algorithm 14 — Psychrometric Calculation °C 113

• Algorithm 15 — Psychrometric Calculation °F 116

• Algorithm 16 — Line Segment 119

• Algorithm 17 — Input Selector 121

• Algorithm 18 — Calculator 123

• Algorithm 19 — Timer Functions 125

• Algorithm 20 — Totalization 129

• Algorithm 21 — Comparator 133

• Algorithm 22 — Sequencer 136

• Algorithm 23 — Four Channel Line Segment (Version 1.1 or Later) 152

• Algorithm 24 — Eight Channel Calculator (Version 1.1 or Later) 154

• Time Program Functions 156

• Time Schedule Configuration 157

• Optimal Start/Stop Configuration 161

• Programmable Logic Control Configuration 174

• Dial-up Feature with an NDM *188

• Trend Log (Versions 1.4, 2.3, 3.3, or Later) 192

• Supervisory Mode Control Settings (General Module) *195

• Controller Diagnostics 204

• Power Up Conditions 204

• Download/ Upload *206

• Calibration Values 209

* Indicates those sections where changes have occurred since the last printing.

Configuration Guides—DX-9100 Configuration Guide

3

Appendix A: SX Tool Item Description and Tables Page 211

• Description of Items 211

• Item List 213

• Floating Point Numbers 215

• EEPROM Items 215

Appendix B: Item Structure 217

• General Module Items Structure *217

• Programmable Function Module Items Structure 223

• Analog Input Module Items Structure 226

• Analog Output Module Items Structure 228

• Digital Output Module Items Structure 229

• Extension Module Items Structure 230

• Time Scheduling Items Structure *236

• Optimal Start/Stop Items Structure 237

• Network Information Module Items Structure 238

• Network Digital Output Module Items Structure 239

• Network Analog Output Module Items Structure 241

• Network Digital Input Module Items Structure 243

• Network Analog Input Module Items Structure 244

Appendix C: Programmable Function Module Items 247

• Algorithm 1 — PID Controller 247

• Algorithm 2 — On/Off Controller 249

• Algorithm 3 — Heating/Cooling PID Controller 251

• Algorithm 4 — Heating/Cooling On/Off Controller 253

• Algorithm 11 — Average Calculation 256

• Algorithm 12 — Minimum Selection 257

• Algorithm 13 — Maximum Selection 258

• Algorithm 14 — Psychrometric Calculation °C 259

* Indicates those sections where changes have occurred since the last printing.

4

Configuration Guides—DX-9100 Configuration Guide

• Algorithm 15 — Psychrometric Calculation °F

Page

260

• Algorithm 16 — Line Segment Function 261

• Algorithm 17 — Input Selector 262

• Algorithm 18 — Calculator 263

• Algorithm 19 — Timer Function 264

• Algorithm 20 — Totalization 266

• Algorithm 21 — Eight Channel Comparator 269

• Algorithm 22 — Sequencer 271

• Algorithm 23 — Four Channel Line Segment Function 274

• Algorithm 24 — Eight Channel Calculator 276

Appendix D: Logic Variables 279

• Description of Logic Variables 279

• Logic Variable Tables 280

Appendix E: Analog Items and Logic Variables for the

Trend Log Module *287

* Indicates those sections where changes have occurred since the last printing.

Configuration Guides—DX-9100 Configuration Guide

5

DX-9100 Extended Digital Plant

Controller

This document covers all three versions of the DX-9100 Extended Digital

Controller, including the DX-912x L

ON

W

ORKS

® version. They include:

Version 1 – provides up to eight output modules, which are configured to

give two analog outputs and six digital outputs (triacs).

Version 2 – provides six additional analog output modules, giving a total

of eight analog outputs.

Version 3 – the DX-912x L

ON

W

ORKS

version brings peer-to-peer

communication to the feature set of the Version 2 controller,

and enhanced alarm reporting capability when used as an

integral part of an Building Automation System (BAS).

In this document, BAS is a generic term, which refers to the

Metasys® Network, Companion™, and Facilitator™ supervisory systems.

The specific system names are used when referring to system-specific

applications.

The DX-9100 is the ideal digital control solution for multiple chiller or

boiler plant control applications, for the Heating, Ventilating, and Air

Conditioning (HVAC) process of air handling units or for distributed

lighting and related electrical equipment control applications. It provides

precise Direct Digital Control (DDC) as well as programmed logic control.

In a standalone configuration, the DX-9100 Controller has both the

hardware and software flexibility to adapt to the variety of control

processes found in its targeted applications. Along with its outstanding

control flexibility, the controller can expand its input and output point

capability by communicating with I/O Extension Modules on an expansion

bus, and provides monitoring and control for all connected points via its

built-in Light-Emitting Display (LED). Versions 1 and 2 can communicate

on the N2 Bus as well as on the System 91 Bus*, providing point control

to the full BAS Network or to the N30 system or Companion/Facilitator

System. The Version 3 controller uses the L

ON

W

ORKS

(Echelon®) N2 Bus

of the Metasys Control Module (NCM311 or NCM361 in Europe,

NCM300 or NCM350 elsewhere) in place of the N2 Bus.

*The terms System 91 Bus and Metasys Control Station are not used in North America.

Introduction

6

Configuration Guides—DX-9100 Configuration Guide

The DX-9100 has two packaging styles. In Version 1, all terminals for

field wiring are located within the controller enclosure. Versions 2 and 3

require a separate field wiring mounting base or cabinet door mounting

frame, which enables all field wiring to be completed before the controller

is installed.

Figure 1: Version 1 (DX-9100-8154)

Figure 2: DX-9100-8454 (Version 2)/DX-912x-8454 (Version 3)

with Mounting Base

Note: The mounting base differs for DX-9120 and DX-9121.

Configuration Guides—DX-9100 Configuration Guide

7

The DX-9100 processes the analog and digital input signals it receives,

using twelve multi-purpose programmable function modules, a software

implemented Programmable Logic Controller (PLC), time schedule

modules, and optimal start/stop modules; producing the required outputs

(depending on the module configuration), operating parameters, and

programmed logic.

Configuration of all versions of the DX-9100 Controller are achieved by

using a Personal Computer (PC) with GX-9100 Graphic Configuration

Software (Version 5 or later) supplied by Johnson Controls. Changes to

the configuration can be made by using an SX-9120 Service Module

(Version 3.1 or later).

The DX-9100 unit (Versions 1 and 2) has two communication links.

One is called the N2 Bus or Bus 91 (the term Bus 91 is not used in

North America) and is used to interface to a supervisory unit. The other

link is called the XT Bus and is used to expand the DX-9100 input/output

capability by interfacing up to eight XT-9100 or XTM-905 extension

modules. The DX-9100 input/output can be extended by up to 64 remote

input/outputs, analog or digital, depending on the type of the connected

extension modules and XP expansion modules.

Point connections are made on XP modules, which are monitored and

controlled by the XT-9100 or XTM-905 modules. For more details, refer

to the XT-9100 Technical Bulletin in the System 9100 Manual (FAN 636.4

or 1628.4). One XP module can provide either eight analog points or

eight digital points. Two XP modules connected to one extension module

provides eight analog and eight digital points, or sixteen digital points.

Version 1 or 2 of the DX-9100 can be used as a standalone controller or it

can be connected to a BAS through the RS-485 serial communications bus

(N2 Bus or Bus 91).

Version 3 of the controller (DX-912x-8454) brings peer-to-peer

communication to the feature set of the Version 2 controller, and enhanced

alarm reporting capability when used as an integral part of a Metasys BAS

Network.

The new communications features are provided by the L

ON

W

ORKS

Network, which enables Version 3 controllers to pass data from one to

another and to send event-initiated data to the NCM350 (NCM361 in

Europe) Network Control Module, in the BAS. The L

ON

W

ORKS

(Echelon)

N2 Bus is used in place of the N2 Bus, and the NCM300 or NCM350

(NCM311 or NCM361 in Europe) must be fitted with a L

ON

W

ORKS

(Echelon) driver card.

The Version 3 controller retains all the input/output point and control

capabilities of the Version 2 controller, including the point expansion

feature using extension modules and expansion modules.

Versions 1 and 2

(N2 Bus)

Version 3

(L

ON

W

ORKS

N2 Bus)

8

Configuration Guides—DX-9100 Configuration Guide

In addition to the Version 2 features, the Version 3 controller has network

input and output points, which can be configured to transmit and receive

data over the L

ON

W

ORKS

Bus. Each controller may have up to 16 network

analog input modules, 16 network analog output modules, 8 network

digital input modules, and 8 network digital output modules. While

network analog input and output modules each contain a single analog

value, the network digital input and output modules each contain 16 digital

states, which are transmitted as a block between controllers. The

transmission of point data is managed by the L

ON

W

ORKS

Network and is

independent of the supervisory functions of the BAS Network Control

Module (NCM). A network of Version 3 controllers can be installed to

share analog and digital data between controllers on a peer-to-peer basis; a

Network Control Module is not required unless the network is to be

supervised by a BAS.

Complex control strategies may now be performed in multiple DX-912x

controllers without the need for network data exchange routines in a

supervisory controller. Applications include the control of multiple,

interdependent air handling units, and large hot water or chilled water

generating plants with components distributed in various locations within

the building.

The Version 3 controller has been approved as a L

ON

M

ARK

device and

conforms to the L

ON

M

ARK

specification for network data transmission.

R

Figure 3: L

ON

M

ARK

Trademark

Further information about compatibility and interoperability with other

L

ON

M

ARK

devices may be requested from your local Johnson Controls

office.

L

ON

M

ARK

Compatibility

Configuration Guides—DX-9100 Configuration Guide

9

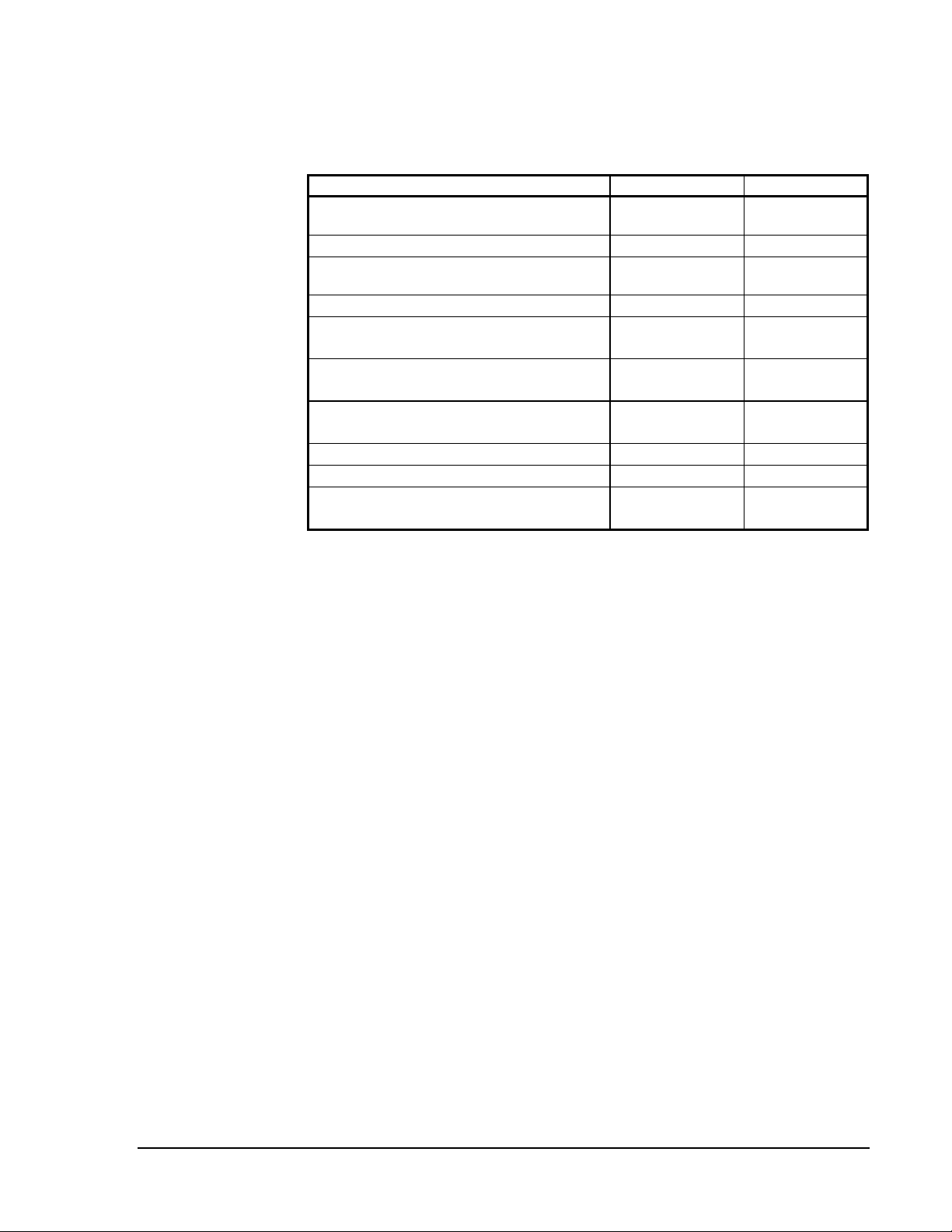

Refer to Table 1 for additional information on System 9100 controllers:

Table 1: Related Information

Document Title Code Number FAN

DX-9100 Extended Digital Controller

Technical Bulletin

LIT-6364020 636.4, 1628.4

DX-9100 Configuration Guide

LIT-6364030 636.4, 1628.4

GX-9100 Software Configuration Tool

User’s Guide

LIT-6364060 636.4, 1628.4

L

ON

W

ORKS

N2 Bus Technical Bulletin

LIT-6364100 636.4

XT-9100 Technical Bulletin

LIT-6364040

LIT-1628440

636.4

1628.4

XT-9100 Configuration Guide

LIT-6364050

LIT-1628450

636.4

1628.4

NDM Configurator Application Note

LIT-6364090

LIT-1628490

636.4

1628.4

Scheduling Technical Bulletin

LIT-636116 636

Point History Technical Bulletin

LIT-636112 636

SX-9100 Service Module User’s Guide

LIT-6364070

LIT-1628470

636.4

1628.4

Related

Information

10

Configuration Guides—DX-9100 Configuration Guide

For full details of the hardware configuration, refer to the DX-9100

Extended Digital Controller Technical Bulletin(LIT-6364020) and the

XT-9100 Technical Bulletin (LIT-6364040).

In summary, the DX-9100 has the following interfaces, inputs, and

outputs:

•

One N2 Bus (Bus 91) RS-485 port for BAS communication

•

One L

ON

W

ORKS

N2 Bus for BAS communication and peer-to-peer

communication with other controllers on the same bus (maximum of

30 controllers on one L

ON

W

ORKS

Bus)

•

One XT Bus (RS-485 port) for up to 8 extension modules and a

maximum of 64 inputs/outputs

•

One port for service module (SX-9120) communication

•

Eight digital input ports for connection to voltage-free contacts

•

Eight analog input ports; the DX-9100 accepts 0-10 VDC or 0-20 mA

signals from active sensors, or can be connected to Nickel 1000

(Johnson Controls or DIN standard), Pt1000, or A99 passive

RTD sensors, as selected via jumpers on the circuit board

•

Six isolated triac digital outputs to switch external 24 VAC circuits

with devices such as actuators or relays

•

Two analog output ports, 0-10 VDC or 0-20 mA, as selected via

jumpers on the circuit board; also, 4-20 mA may be selected by

configuration

•

Four analog outputs, 0-10 VDC or 0-20 mA, as selected via jumpers

on the circuit board; also, 4-20 mA may be selected by configuration

•

Four additional analog outputs, 0-10 VDC only

•

One RS-232-C port for local downloading and uploading software

configurations (N2 Bus protocol)

The software configuration determines how these inputs and outputs are

used, and their range and application.

The DX-9100 must be supplied with a 24 VAC power source. All models

are suitable for 50 Hz or 60 Hz through software configuration.

Hardware

Configuration

Versions 1 and 2

Version 3

All Versions

Version 1

Versions 2 and 3

Configuration Guides—DX-9100 Configuration Guide

11

Software Configuration

The DX-9100 is a microprocessor-based programmable controller. It has

the following software elements:

•

eight analog input modules

•

eight digital input modules

•

two analog output modules in Version 1;

eight analog output modules in Versions 2 and 3

•

six digital output modules

•

up to 64 additional inputs/outputs from up to 8 extension modules

•

twelve programmable function modules with algorithms for control

and calculation

•

eight analog constants and 32 digital constants

•

one programmable logic control module with 64 logic result statuses

•

eight time schedule modules

•

two optimal start/stop modules

•

sixteen network analog input modules

•

eight network digital input modules

•

sixteen network analog output modules

•

eight network digital output modules

A user configures the controller using the GX-9100 Graphic Software

Configuration Tool. The SX-9120 Service Module is used to troubleshoot

and adjust individual parameters. Techniques for both tools are described

in the following sections.

For complete documentation on both tools, see the GX-9100 Software

Configuration Tool User’s Guide and the SX-9120 Service Module User’s

Guide in FAN 636.4 or 1628.4.

Following is a brief description of the main features of the GX-9100

Software Configuration Tool. Note that the term, click on, means to

position the cursor on the module or menu and then press the appropriate

mouse button to select it.

Note: When using the GX Tool, after entering a parameter, always click

on OK to confirm.

DX-9100

Software

Elements

Version 3 Only

Configuration

Tools

12

Configuration Guides—DX-9100 Configuration Guide

To enter data into a module displayed on the screen of the GX Tool, place

the cursor on the module, click once on the right mouse button and the

module menu will appear:

Data…

Delete

Connect… F5

Disconnect… F4

Show Selected

Show User Names

dxcon004

Figure 4: Module Menu

Place the cursor on Data and press either mouse button. A Data Window

appears containing all module data. Use the <Tab> key or mouse to move

the cursor from field to field. To make an entry, move the cursor to the

entry field and type in the information. To go to the second page in the

Data Window (if there is one), click on the Data-2 field. To return to the

first page, click on OK or Cancel.

To exit a window, click on OK to confirm entries, or Cancel to discard

them, while in the first page.

The following table shows the accuracy that may be lost due to rounding

errors. Numbers with a modulus of greater that 2047 may be rounded up or

down by 0.1% as follows:

Table 2: Rounding Errors

Range Rounding (+/-)

2048-4095

2

4096-8191

4

8192-16383

8

16384-32767

16

The rounding is due to the external communications bus protocol and does

not compromise the precision of the internal control processes.

Entering Data

into Modules

Entering Values

Configuration Guides—DX-9100 Configuration Guide

13

The Data Window contains User Name and Description entry fields. Up to

8 characters may be entered in the User Name field, and the Description

field can have up to 24 characters.

The Data Window also contains an Output Tag field for module outputs

(i.e., source points), which can be connected to another module as inputs

(destinations) and an Input Tag field for module inputs. To enter User

Names for outputs, position the cursor over the Output Tag field and press

the left mouse button once. To enter User Names for inputs, select the

Input Tag field.

To expand a module displayed on the screen of the GX Tool, in order to

view input/output connections, place the cursor over the module and

double-click on the left mouse button. Input connections appear in the left

column with @ attached to the Tag Name, and output connections are

shown in the right column, except for output modules where all

connections appear in one column. To close a module, place the cursor

over the expanded module and double-click on the left mouse button.

Connections are made using one of the four methods outlined below.

Note that only the first method is referred to later in this guide. An existing

connection must be disconnected before making a new connection.

•

The first method is to expand the source and destination modules by

moving the cursor to each module in turn and double-clicking the left

mouse button. Move the cursor over the desired output of the source

module and the cursor appears as an output arrow. Hold down the left

mouse button and drag the arrow to the desired destination input.

When the left mouse button is released, a connection line will be

drawn between the two modules.

•

The second method is to select the source module by positioning the

cursor over the module and pressing the left mouse button and then

the <F5> key. A list of the possible source output connections for that

module will be shown. Move the cursor to the desired output to select

it (it will appear highlighted) and click on OK (alternatively,

double-click on the desired output). To complete the connection,

select the destination module by pressing the left mouse button and

then the <F5> key. A list of the possible destination inputs for that

module will be shown. Select the desired destination from the dialog

box and click on OK (alternatively, double-click on the desired

destination). A connection line will be drawn between the

two modules.

Entering User

Names

Making

Connections

14

Configuration Guides—DX-9100 Configuration Guide

•

The third method is to select the source module by positioning the

cursor over it and pressing the right mouse button. The module menu

will appear. Select Connect and a list of possible source outputs for

that module will appear in a dialog box. Move the cursor to the

desired output to select it (it will appear highlighted) and click on OK

(alternatively, double-click on the desired output). Then select the

destination module by positioning the cursor on it and pressing the

right mouse button. The module menu will appear. Select Connect

and a list of possible destination inputs for that module will be shown.

Move the cursor to the desired input to select it and click on OK

(alternatively, double-click on the desired input). A connection line

will be drawn between the two modules.

•

The fourth method is to go to the destination module data window,

move the cursor to a connection field, press the <*> key on the

keyboard, and the available source output tags will be displayed for

selection.

Configuring the controller involves:

•

defining characteristics and parameters of the input and output

modules, the programmable function modules for control and

calculation, the extension modules, and the programmable logic

control module

•

defining connections between the modules in order to achieve the

desired sequence of control

•

setting the time scheduling, optimal start/stop, and realtime clock

parameters

Proceed in the following order:

1. Select the controller type (Versions 1, 2, or 3).

2. Define DX-9100 Global Data under the Edit menu.

3. Define Job Information under the Edit menu.

4. Define analog and digital input characteristics.

5. Define analog and digital output characteristics.

6. Define extension module structures and characteristics.

7. When applicable, define network inputs and outputs for the Version 3

controller (L

ON

W

ORKS

Bus).

8. Define programmable function module/algorithm characteristics.

9. Define time schedule and exception day settings.

10. Define programmable logic control module.

Configuring the

Controller

Configuration Guides—DX-9100 Configuration Guide

15

Select the controller version under the Controller menu:

•

DX Version 1.1, 1.2, 1.3, or

•

DX Version 1.4, or

•

DX Version 2.0, 2.1, 2.2, or

•

DX Version 2.3, 2.4 or

•

DX Version 3.0, 3.1, 3.2, or

•

DX Version 3.3 or 3.4

The SX Tool will display the controller type when first connected to the

controller. No user selection is required.

Via the GX Tool

At the menu bar at the top of the screen, select Edit-Global Data and a window

appears. Under Frequency, click on 50 or 60 Hz. Then click on OK to confirm

the setting. (To discard an entry, click on Cancel.)

Via the SX Tool

Under General Module, set bit X7 of Item DXS1 (RI.32):

•

X7 = 0 50 Hz power line

•

X7 = 1 60 Hz power line

When this flag is set to cancel or 1, the override-type Items listed below

are reset after each power up of the controller.

When set to maintained or 0, these override-type Items are maintained

through the power failure.

•

Shutoff mode request

•

Startup mode request

•

Enable Digital Output (Triac) Supervisory Control

•

Set Digital Output (Triac) On

•

Output Hold mode (Analog and Digital)

•

Programmable Function Module Hold

•

Time Schedule Module Hold mode

DX-9100

Controller

Selection

Via GX Tool

Via the SX Tool

DX-9100 Global

Data

Set Power Line

Frequency

(50 or 60 Hz)

Set Initialize on

Power Up Flag

16

Configuration Guides—DX-9100 Configuration Guide

Via the GX Tool

Select Edit-Global Data. Under Init. on Power Up, click on maintained

or cancelled.

Via the SX Tool

Under General Module, set bit X8 of Item DXS1 (RI.32):

X8 = 0 No initialization on power up (commands from BAS maintained)

X8 = 1 Initialization on power up (commands from BAS cancelled)

In the controller, four bytes are reserved for digital input counters and

accumulators in programmable modules. When the DX-9100 is connected

to a BAS, the counter type flag must be set to 0 because the system will

only read 15 bits (maximum reading of 32,767). For BASs that can read

four bytes, or for standalone applications, the flag may be set to 1. The

counter will then read a maximum value of 9,999,999 and then reset to 0.

See Supervisory Mode Control Settings (General Module) further in this

document.

Via the GX Tool

Select Edit-Global Data. Under Counter Type, click on one of the

following:

•

15-bit (BAS)

•

4-byte

Via the SX Tool

Under General Module, set in bit X4 of Item DXS1 (RS.32):

X4 = 0 Selects 15-bit counters

X4 = 1 Selects 4-bit counters

For temperature unit selection, refer to the Analog Input Configuration

section below.

For daylight saving time, refer to the Time Program Functions section

later in this document.

Counter Type

Flag

Global Data

Notes

Configuration Guides—DX-9100 Configuration Guide

17

A configuration number may be entered for configuration identification

purposes. The number will be displayed on the front panel of the controller

during initialization. The configuration number is also read and used by

the DX LCD Display to identify which of the display configurations in its

database to use for this controller.

Select Edit-Global Data. Enter the appropriate number in the

User Config Code field.

Under General Module, enter the appropriate number in

Item ALG (RI.33).

The password is used to protect a configuration when loaded into a

controller. Once the password has been downloaded into the controller

with the configuration, the controller will only allow a subsequent

download or upload when the password is entered in the Download or

Upload dialog box of the GX Software Configuration Tool. The password

is encrypted by the GX Tool before download.

!

WARNING: If the password is lost and the user does not have

access to the original configuration file that includes

the password, then the controller must be returned

to the supplier or the Johnson Controls factory to

have the memory cleared.

IMPORTANT: A password of 0 disables the protection feature.

The password feature is only available with firmware

Versions 1.4, 2.3, 3.3, or later. In older versions, the

password feature was not implemented.

Note: The password feature is enabled by an entry in the GX9100.ini file

of the GX Tool. The GX Tool software is delivered without this

entry. Refer to the GX-9100 Software Configuration Tool User’s

Guide (LIT-6364060) for details.

Select Edit-Global Data. Enter the password (one to four alphanumeric

characters) in the Password field. Enter 0 if the password feature is not

required. The default password is 0000.

The password cannot be accessed via the SX Tool. A GX Tool must be

used.

Configuration

Number

(Version 1.1 or

Later)

Via the GX Tool

Via the SX Tool

Password

Feature

(Versions 1.4,

2.3, 3.3, or

Later)

Via the GX Tool

Via the SX Tool

18

Configuration Guides—DX-9100 Configuration Guide

The DX-9100 Controller can accept up to eight analog inputs, which are

active (voltage or current) or passive (RTD). Each analog input is defined

and configured by the following parameters:

•

User Name and Description (GX only)

•

Input Signal/Range

•

Measurement Units

•

Enable Square Root

•

Alarm on Unfiltered Value

•

Alarm Limits

•

Filter Time Constant

Via the GX Tool

To assign the input as active or passive, position the cursor on the

appropriate box and double-click the left mouse button. Then position the

cursor accordingly and click the left mouse button once to select either

Active or Passive.

Select AIn using the right mouse button. Then select Data in the module

menu, and enter as appropriate:

User Name (maximum 8 characters)

Description (maximum 24 characters)

For active inputs, at the Type of Active Input field, enter:

0 = 0-10 VDC

1 = 4-20 mA

2 = 0-20 mA

Analog Input

Configuration

AI: Input Signal

and Ranging

User Name and

Description

Configuration Guides—DX-9100 Configuration Guide

19

Each analog input module performs the conversion of the input signal to a

variable numeric value expressed in engineering units obtained using the

high range and low range.

High Range (HR) = Enter the equivalent number for reading at

high signal input (10 V, 20 mA)

Low Range (LR) = Enter the reading at low signal input

(0 V, 0 mA, 4 mA)

AI = (PR% / 100) * (HR — LR) + LR

where: PR% = analog value in % of physical input signal

For passive inputs at the Type of Passive Input field, enter:

1 = Ni1000 (Johnson Controls characteristic)

2 = Ni1000 Extended Temperature Range (Johnson Controls

characteristic)

3 = A99 (Johnson Controls characteristic)*

4 = Pt1000 (DIN characteristic)

5 = Ni1000 (L. & G. characteristic) (Firmware, Version 1.1 or later)

6 = Ni1000 (DIN characteristic) (Firmware, Version 1.1 or later)

*Note: The North American Johnson Controls silicon sensors

(TE-6000 series) have very similar characteristics to the

A99 sensor. At 21°C (70°F) and 25°C (77°F) the reference values

are identical. At -40°C (-40°F), the reading will be 0.8°C (1.5°F)

high. At 38°C (100°F), the reading will be 0.3°C (0.5°F) high.

For Resistance Temperature Device (RTD) inputs, the range of the

displayed value is fixed according to the type of sensor. The high/low

range entries will not have any effect on the actual sensor readout. The

configured high and low ranges determine the control range of any control

module to which it is connected. (The difference between the High Range

value and the Low Range value is equivalent to a proportional band

of 100%.)

At the High/Low control range field, enter the required value:

High Range (Control) =

Low Range (Control) =

20

Configuration Guides—DX-9100 Configuration Guide

Via the SX Tool

Under Analog Inputs configure Item AITn (RI.00):

(Low Byte)

X7 = 0 0-10 Volts

X7 = 1 0-20 mA, 0-2 V or RTD

X8 = 1 20% suppression (2-10 V or 4-20 mA)

(High Byte)

X11 X10 X9 = 000 Active Sensor (Linear)

X11 X10 X9 = 001 Ni 1000 RTD Passive Sensor

(Johnson Controls)

(-45 to 121°C [-50 to 250°F])

X11 X10 X9 = 010 Ni 1000 RTD High Temperature

Sensor

(21 to 288°C [70 to 550°F])

X11 X10 X9 = 011 RTD Sensor A99 (Johnson Controls)

(-50 to 100°C [-58 to 212°F])

X11 X10 X9 = 100 RTD Sensor Platinum 1000 (DIN)

(-50 to 200°C [-58 to 392°F])

Version 1.1 or Later

X11 X10 X9 = 101 Ni 1000 RTD (L. & G.)

(-50 to 150°C [-58 to 302°F])

X11 X10 X9 = 110 Ni 1000 RTD (DIN)

(-50 to 150°C [-58 to 302°F])

For active inputs, the analog input module performs the conversion of the

input signal to a variable numeric value expressed in engineering units

obtained using the high range at Item HRn (RI.01) and low range at Item

LRn (RI.02).

For RTD passive inputs, the range of the displayed value is fixed

according to the type of sensor. The configured range determines the

control range of any control module to which it is connected.

Via the GX Tool

To choose between Celsius and Fahrenheit for active and passive sensors,

select Edit-Global Data. Under Temperature Units, select Celsius or

Fahrenheit.

AI: Measurement

Units

Configuration Guides—DX-9100 Configuration Guide

21

To set the measurement units for active sensors, select the AIn module,

and then Data to call up the Data Window. Enter in the Measurement

Units field:

0 = None

1 = Temperature (C or F as entered under Edit-Global Data)

2 = Percent (%) (Version 1 only)

In a Version 1 controller the units are displayed on the front panel of the

controller as °t, %, or none.

Via the SX Tool

Under Analog Inputs, configure Item AITn (RI.00). The measurement and

temperature units of each analog input can be selected with the following

bits (low byte):

X4 X3 X2 X1 = 0000 No Units

X4 X3 X2 X1 = 0001 Celsius

X4 X3 X2 X1 = 0010 Fahrenheit

X4 X3 X2 X1 = 0011 Percent (Version 1 only)

For RTD sensor inputs, Celsius and Fahrenheit units must be selected.

Changing individual units for each AI can only be done via the SX Tool.

This function allows the linearization of the differential pressure signal

from a 0-10 VDC or 0/4-20 mA active sensor; the function is effective

over the selected range and is only available for active sensors.

AI = sqrt (PR%/100) * (HR — LR) + LR

Where PR% = the Analog Value in % of the physical input signal range;

HR = High Range Value; and LR = Low Range Value.

Via the GX Tool (option only available with active sensor)

Select AIn. Then select Data in the module menu. At the Square Root

field, enter 0 to disable the square root function, or 1 to enable the square

root function.

Via the SX Tool

Under Analog Inputs, configure Item AITn (RI.00) (low byte):

X5 = 1 Enable Square Root of Input

X5 = 0 Disable Square Root of Input

An alarm from the High Limit and Low Limit Alarm values will be

generated from the unfiltered input.

AI: Enable

Square Root

AI: Alarm on

Unfiltered Value

22

Configuration Guides—DX-9100 Configuration Guide

Via the GX Tool

Select AIn. Then select Data in the module menu. At the Alarm Unfiltered

field, enter 0 to set an alarm on a filtered value, or 1 to set an alarm on an

unfiltered value.

Via the SX Tool

Under Analog Inputs, configure Item AITn (RI.00) (low byte):

X6 = 1 Alarm on Unfiltered Value

X6 = 0 Alarm on Filtered Value

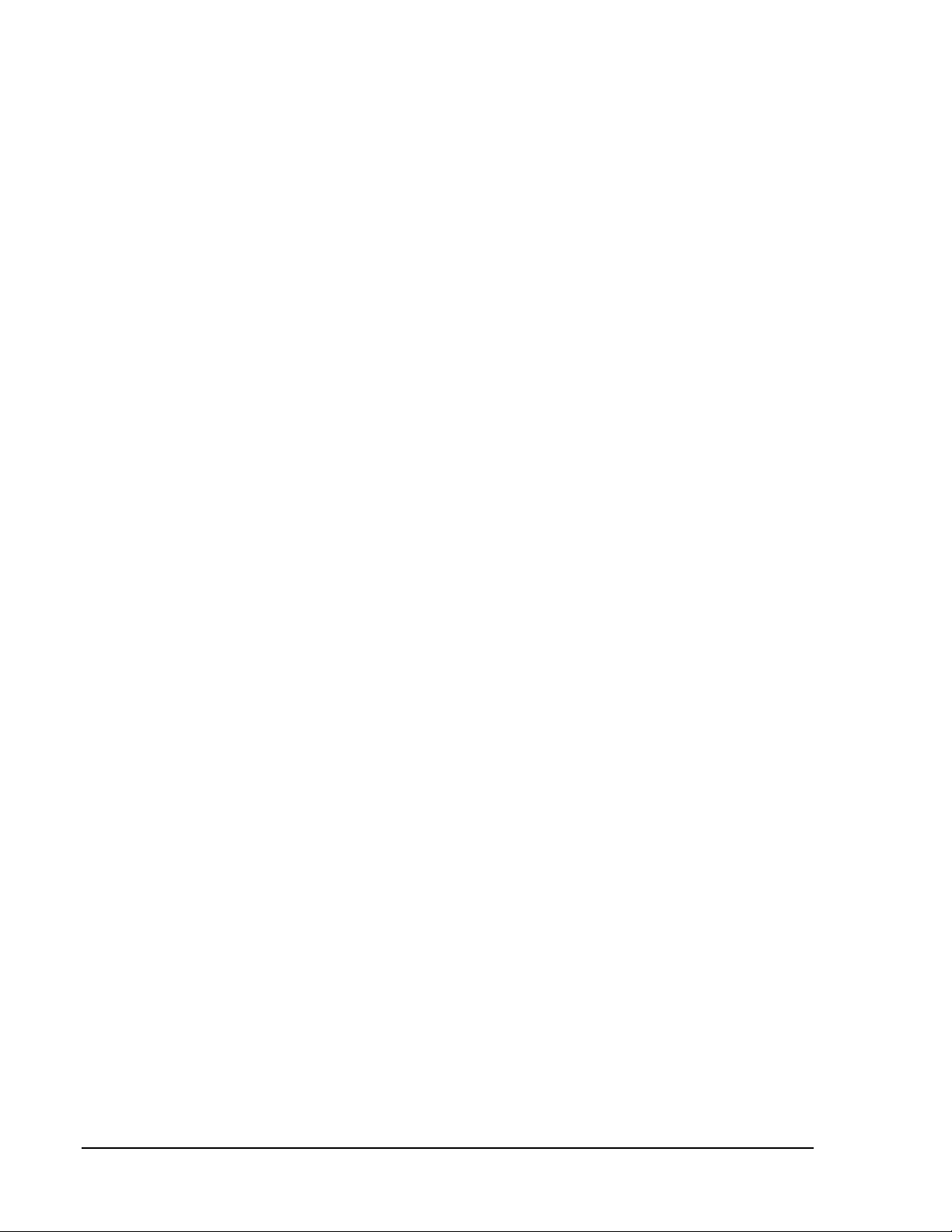

The high limit and the low limit define at which levels the analog input

reading will generate an alarm, either for remote monitoring or for internal

use within the control sequences in the DX-9100. A limit differential

defines when a point comes out of alarm.

Note: The limits cannot be deleted. If you do not want alarms, enter

limits beyond the high/low range of the sensor.

AI

Val ue

High Limit

Low Limit

No Alarm

High Alarm

Low Alarm

No Alarm

Differential

Differential

dxcon005

Figure 5: How Alarm Limits Function

Via the GX Tool

Select AIn. Then select Data in the module menu. At the respective field,

enter the required value:

High Limit =

Low Limit =

Limit Differential =

AI: Alarm Limits

Configuration Guides—DX-9100 Configuration Guide

23

The low limit and high limit alarm processing can be disabled. In the menu

bar, select Edit-Add Alarm Disable. The corresponding module (box) will

appear on screen. Make connections as described earlier under

Configuration Tools — Making Connections.

Note: The Alarm Disable feature is sometimes referred to as Auto

Shutdown in the BAS.

Via the SX Tool

Under Analog Inputs, the alarm limits differential is adjustable with Item

ADFn (RI.06). The high limit is at Item HIAn (RI.03), the low limit is at

Item LOAn (RI.04).

The low and high limit alarm processing can be disabled by making a

logical connection to Item ALD@ — Alarm Disable Condition Source

(General Module RI.31).

For Both SX and GX

When the logic signal connected to ALD@ or Alarm Disable Condition

Source is true (1), alarm states on analog inputs will be frozen until the

logical signal returns to false (0). (Alarm states on analog inputs to XT

modules are not frozen by the ALD@ connection.)

The Filter Time Constant Ts (seconds) is used to filter out any cyclic

instability in the analog input signals. The calculations are:

FV

t

= FV

t-1

+ [1/(1 + T

s

)] * (AI

t

— FV

t-1

)

Where: FV

t

= Filtered Analog Value at current time

FV

t-1

= Filtered Analog Value at previous poll

AI

t

= Actual Analog Value at current time

Via the GX Tool

Select AIn. Then select Data in the module menu. At the Filter Constant

(sec) field, enter a number within the recommended range 0 to 10.

Via the SX Tool

Under Analog Inputs, the Filter Time Constant is selected at Item FTCn

(RI.05).

1. You can read the AI values, and read and modify the alarm limit

values using the DX front panel. See Display Panel and Keypads in

the DX-9100 Extended Digital Controller Technical Bulletin

(LIT-6364020) in FAN 636.4 or 1628.4.

AI: Filter Time

Constant

AI Notes

24

Configuration Guides—DX-9100 Configuration Guide

2. The alarm condition of one or more analog inputs is also indicated by

an LED (AL) on the front panel. If the LED is steady, the current AI is

in alarm; if flashing, another AI is in alarm.

3. Using the SX Tool, analog input values can be read at Analog Inputs

Item AIn (RI.07), and the percent of range value can be read at Item

AI%n (RI.08). The value as an ADC count can be read at Item ADCn

(RI.09).

4. Using the SX Tool, analog input alarm statuses can be read at General

Module Item AIS (RI.07), or at Analog Input Item AISTn (RI.10),

where bits X1 and X2 indicate the high and low alarm conditions,

respectively.

5. Under Analog Inputs, the analog Item AISTn (RI.10), bits X3 and X4,

indicate an input over-range (input about 2% of range above HR)

condition and an input under-range (input about 2% of range below

LR) condition, respectively. (This information is available on the

SX Tool only.)

6. Calibration coefficients for active and passive analog inputs are stored

in the EEPROM of the DX. See the Calibration Values section further

in this document.

Source Points (Outputs)

AIn The current value of the analog input.

AI%n The current value of the analog input in percent (%) of range.

AIHn A 1 if the analog input is above its high limit and not below the

high limit — limit differential.

AILn A 1 if the analog input is below the low limit and not above the

low limit + limit differential.

OVRn A 1 when the value of an active analog input is more than

about 2% above its high range (overrange condition), or a

passive analog input is open circuited.

UNRn A 1 when the value of an active analog input is more than

about 2% below its low range (underrange condition), or a

passive analog input is short circuited.

Destination Points (Inputs)

None.

Note: The following destination point is applicable to all analog inputs:

ALDS@ The connection to disable alarm processing on analog inputs

AI1 — AI8.

GX Labels

Configuration Guides—DX-9100 Configuration Guide

25

The DX-9100 Controller can accept up to eight digital inputs, which will

be considered active when driven to a common digital ground by an

external volt-free contact. The DI is defined and configured by the

following parameters:

•

User Name and Description (GX only)

•

Prescaler

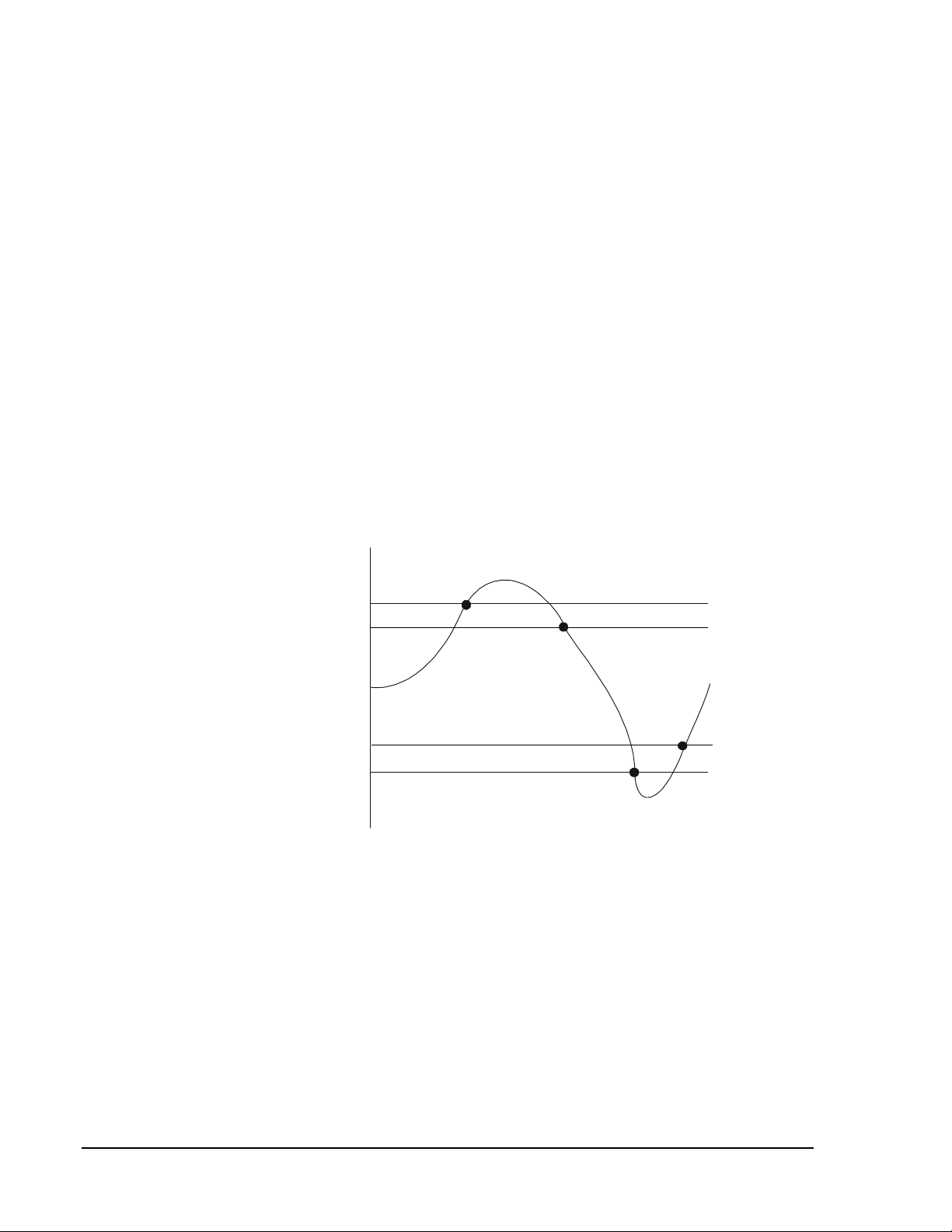

The digital input transitions are counted as follows:

Pulse

Counter

CNTRn

Count

Transition

DICn

Prescale

Factor

PCn

Digital

Input

DIn

dxcon006

Figure 6: Digital Input Transitions

The Pulse Counter (CNTRn) counts all state transitions of the bit-Item

DICn. A state transition at DICn occurs when the number of transitions

from 1 to 0 of DIn Digital Input equals the value of the Prescaler Factor

(PCn). For example, if PCn is equal to 1, then every 1 to 0 state transition

at the DI will add 1 to CNTRn. If equal to 3, then three changes from 1 to

0 will add 1 to CNTRn. The maximum transition rate of DIn is 10 pulses

per second (minimum 50 ms On and 50 ms Off).

Via the GX Tool

Select DIn. Then select Data in the module menu.

At the User Name field, enter the name, which can have a maximum of

eight characters.

At the Description field, enter the descriptive text, which can have a

maximum of 24 characters.

At the Prescaler (counts) field, enter a number between 1 and 255.

Via the SX Tool

Under General Module, enter the prescaler for each digital input at Items

PC1 (RI.22) to PC8 (RI.29).

1.

You can read the DI’s status and counter values using the DX front

panel. See Display Panel and Keypads in the DX-9100 Extended

Digital Controller Technical Bulletin (LIT-6364020) in FAN 636.4

or 1628.4.

2. On the SX Tool, the digital input status (DIn), the count transition

status (DICn) and the pulse counter values can be read under General

Module at the Items given in Figure 6.

Digital Input

Configuration

DI: User Name,

Description,

Prescaler

DI Notes

26

Configuration Guides—DX-9100 Configuration Guide

Source Points (Outputs)

DIn The current status of the digital input.

DICn Toggles from 0 to 1 or 1 to 0 when the number of digital input

transitions (counts) equals the prescaler.

Destination Points (Inputs)

None.

The DX-9100 Controller has two analog outputs (numbered 1 and 2),

controlled by two analog output modules, and six digital (triac) outputs

(numbered 3 to controlled by six logic output modules.

Versions 2 and 3 of the DX-9100 have an additional six analog outputs

(numbered 9 to 14) controlled by six analog output modules.

The analog output module provides the interface between a 0-10 VDC or

0/4-20 mA hardware output and a numeric value scaled to a 0-100% range

using a high and low range variable.

Each analog output is defined and configured by the following parameters:

•

user name and description (GX Only)

•

type of output

•

numeric source

•

increase/decrease source (if any)

•

low and high ranges

•

forcing mode and level

•

hold or auto on power up

•

output limits, enable limits

Via the GX Tool

Select AOn. Then select Data in the module menu. At the field

User Name, enter the name.

At the Description field, enter the description.

Then enter the output code:

0 = Disabled

1 = 0 to 10 VDC

2 = 0 to 20 mA (not available for Outputs 11-14)

3 = 4 to 20 mA (not available for Output 11-14)

GX Labels

Analog Output

Configuration

AO: Output Type

Configuration Guides—DX-9100 Configuration Guide

27

Via the SX Tool

Under Output Modules, the output type can be configured in Item AOTn

(RI.00). To define the output signal set the bits as follows:

X2 X1 = 00 Output Disabled

X2 X1 = 01 Output 0-10 V

X2 X1 = 10 Output 0-20 mA (not available for Outputs 11-14)

X2 X1 = 11 Output 4-20 mA (not available for Outputs 11-14)

This defines the source of the numeric control signal that drives the output

module. The output module can, alternatively, have two logic sources: the

source of the increase signal and the source of the decrease signal. The rate

of increase or decrease is fixed at 1% per second.

Via the GX Tool

Expand both source and AOn modules. Place the mouse on the source

point. Hold down the left mouse button and drag the cursor to the center of

AO@. The connection will be made when the mouse button is released.

If logic variables (Increase/Decrease) are used as a source to drive the

analog output, then the source module and AOn module must be expanded

as described above. Place the cursor on the logic source point. Press the

mouse button and while keeping it pressed, drag the cursor to INC@ in the

AOn module. Release the mouse button to make the connection. Repeat

the same procedure for the DEC@ connection.

Via the SX Tool

Under Output Modules, Item AO@n (RI.01) defines the source of the

numeric control signal. Alternatively, the source of the increase signal is

defined in Item INC@n (RI.10), and the source of the decrease signal is

defined in Item DEC@n (RI.11).

This defines the source of a logic variable that forces the Analog Output to

a forcing level between 0 and 100%. When the logic source is 1, the AO

will be forced to the % entered in Forcing Level. When the logic source

is 0, the AO will be commanded to position via the source point.

Note: If a PID is connected to the AO and the AO is forced, the PID will

experience force-back, which means the PID is also in Hold mode

at this time and its output is forced to the value of the analog

output.

AO: Source

AO: Forcing

Mode and Level

28

Configuration Guides—DX-9100 Configuration Guide

Via the GX Tool

Select AOn. Then select Data in the module menu. At the

Forcing Level (%) = field, enter a number between 0 and 100%.

Double-click on AOn to expand the module. Double-click on the source

module. Place the cursor on the logic source point. Press the mouse button

and while keeping it pressed, drag the cursor to AOF@. Release the mouse

button to make the connection.

Via the SX Tool

Under Output Modules, Item AOF@n (RI.02) defines the source of a logic

variable that forces the output to the forcing level, which is defined in Item

OFLn (RI.05).

Upon power restoration, the AO can optionally be forced to a Hold

(Manual) or Auto (Hold reset) condition, irrespective of the Hold

condition before the power failure and overriding the Initialization on

Power Up setting for the controller and overrides sent from the front panel

or BAS.

Via the GX Tool

Select AIn. Then select Data in the module menu. Then enter 1 for the

appropriate power up condition, if required:

Hold on Power Up = (1 = Yes)

Auto on Power Up = (1= Yes)

If both Hold and Auto are enabled, Hold has higher priority. If both are

disabled, the current setting under the Initialization on Power Up field

determines the output.

Via the SX Tool

Under Output Modules, set bits X7 and X8 of Item AOTn (RI.00) as

follows:

bit X8 = 0 The Hold mode is not altered after a power failure.

bit X8 = 1 The Hold mode is set at power up to the status set in bit X7.

bit X7 = 0 The Hold mode is set to hold at power up if bit X8 is set.

bit X7 = 1 The Hold mode is reset (set to 0) at power up if bit X8 is set.

AO: Hold or Auto

On Power Up

Configuration Guides—DX-9100 Configuration Guide

29

The High Range Item (HRO) defines the level of the control source signal

(AOn), which would correspond to an output of 100%.

The Low Range Item (LRO) defines the level of the control source signal

(AOn), which would correspond to an output of 0%.

If LROn < AOn < HROn OUTn = 100 * (AOn — LROn)/(HROn —

LROn)%

If AOn <= LROn OUTn = 0% (0 V, 0/4 mA)

If AOn >= HROn OUTn = 100% (10 V, 20 mA)

When the source point is equal to the high range, then the output will be at

the maximum signal (10 V/20 mA). When the source point is equal to low

range, then the output will be at the minimum signal (0V, 0/4 mA).

Via the GX Tool

Select AIn. Then select Data in the module menu. At the High Range and

Low Range fields, enter the appropriate numbers within the range of the

source signal:

High Range =

Low Range =

Via the SX Tool

Under Output Modules, set the High Range at Item HROn (RI.03) and the

Low Range at Item LRO (RI.04).

The output high limit defines the maximum output in percent. The output

low limit defines the minimum output in percent. These limits are enabled

by a logic connection and are only operative when the logic source is at 1.

When the limits are enabled:

If OUTn > HLOn

OUTn = HLOn

If OUTn < LLOn

OUTn = LLOn

AO: Range

AO: Output

Limits, Enable

Limits

30

Configuration Guides—DX-9100 Configuration Guide

Via the GX Tool

Select AOn. Then select Data in the module menu. At the

High Limit % and Low Limit % fields, enter the desired number (0-100%).

For Enable Limits, expand both source and AOn modules. Position the

cursor on the source point. Press the mouse button, and while keeping it

pressed, drag the cursor to ENL@. Release the mouse button to make the

connection.

Via the SX Tool

Under Output Modules, set the following:

High Limit on Output = Item HLOn (RI.08)

Low Limit on Output = Item LLOn (RI.09)

The limits are enabled by a logic connection to Item ENL@n (RI.12).

1. The AO can be read and overridden (placed in hold) from the DX

front panel. See Display Panel and Keypads in the DX-9100 Extended

Digital Controller Technical Bulletin (LIT-6364020) in FAN 636.4 or

1628.4.

2. On the SX Tool, the analog output values can be read in percent at

Item OUTn (RI.06) and can be modified when the module is in Hold

mode.

3. On the SX Tool, Analog output control and status can be seen at

Item AOCn (RI.07) in the following bits:

X1 = 1 OUHn Output in Hold mode (Manual)

X2 = 1 AOHn Output at High Limit … 100%

X3 = 1 AOLn Output at Low Limit … 0%

X4 = 1 AOFn Output is Forced

X6 = 1 OULn Output is Locked (Both INC@n and DEC@n

are true)

4. The analog output module can be set in Hold on the DX front panel or

by the PLC, the SX Tool, a BAS, or by configuration on power up.

AO Notes

Configuration Guides—DX-9100 Configuration Guide

31

Source Points (Outputs)

AOFn A 1 when an analog output (AO) is being externally forced.

AOHn A 1 when the analog output is equal to or above its high range.

AOLn A 1 when the analog output is equal to or below its low range.

OUHn A 1 when an analog or digital output is in Hold mode from

either the DX front panel or BAS.

OUTn The value of the analog output (including PAT or DAT).

Destination Points (Inputs)

AO@ The numeric connection to control an analog output.

AOF@ The connection to force an analog output to a specified value.

DEC@ The connection to decrement an analog type output, PAT/DAT

digital type output or a sequencer module. While connection is

a logic 1, the output will decrease at a rate dependent on the

type of module.

ENL@ The connection to enable output limits of an analog type output

(PAT and DAT included).

INC@ The connection to increment an analog type output, PAT/DAT

digital type output or a sequencer module. While connection is

a logic 1, the output will increase at a rate dependent on the

type of module.

GX Labels

32

Configuration Guides—DX-9100 Configuration Guide

The DX-9100 Controller has six digital output modules that are used to

control six triacs. The digital output module provides the interface

between a triac output and a numeric or logic variable. The modules can

be programmed as one of five main output types.

Some of the output types drive two consecutive outputs. In that case the

second, consecutive module will be disabled, as it cannot be executed.

For each digital output module one must define:

•

the type of output

•

User Name and Description

For digital output modules defined as PAT or DAT, you must also define:

•

the source

•

increase/decrease source (if any)

•

the source of the feedback (if any) (PAT only)

•

the low and high ranges

•

the Forcing Mode and Level

•

Hold or Auto on power up

•

output limits, enable limits source (if any)

•

the PAT full stroke time or DAT cycle

•

the PAT deadband or DAT minimum on/off time

The types of configurations are described next, followed by the steps

needed to configure the outputs.

The PAT output type uses a pair of triacs and a numeric source.

Position Adjust Type control is also known as incremental control. Using

High Range and Low Range parameters, the value of the numerical source

is normalized to a 0-100% value and is used as the required position for

the output.

The PAT output may have a physical feedback value signal (0-100%) from

an analog input or other numerical variable. In this configuration the

output module will drive the first triac of the pair (increase or up signal) as

long as the feedback value is less than the required position. It will drive

the second triac of the pair (decrease or down signal) as long as the

feedback value is greater than the required position. A deadband

(in percent) is specified to avoid unnecessary cycling of the triac outputs

when the feedback signal is approaching the required position, and

compensates for any hysteresis or mechanical tolerances in the driven

device.

Digital Output

Configuration

PAT Position

Adjust Type

Configuration Guides—DX-9100 Configuration Guide

33

When the PAT output does not have a physical feedback signal, it operates

on the amount of change in the required position. To synchronize the PAT

output module to the driven device, whenever the required position goes to

100%, the first triac (increase) will be switched on for the calculated time

and will remain on for the specified Full Stroke Time of the driven device.

Whenever the required position goes to 0%, the second triac (decrease)

will be switched on for the calculated time and will remain on for the

specified Full Stroke Time. If the required position remains at 100% or

0%, the appropriate triac will be switched on for the Full Stroke Time

every two hours to ensure that the driven device remains at its end position

over an extended period of time. For all other values of the required

position, the PAT output module calculates the appropriate increase or

decrease time, based on the Full Stroke Time, to bring the driven device

from the last required position to the current required position, and

switches the appropriate triac on for this time. The triac will not be

switched if the change in the required position is less than the specified

deadband. The calculation of the PAT time is performed on each processor

cycle (every second), and the minimum triac on time is 100 msec.

Note: The DX display panel shows the required position value (OUTn)

for the digital output module associated with the first triac output.

The DAT output type provides a time-based duty cycle output that is

proportional to the value of a numeric source. Using High Range and

Low Range parameters, the value of the numerical source is normalized to

a 0-100% value as is used as the required duty cycle. For example, with a

25% duty cycle and a DAT cycle time of 600 seconds, the triac output will

be switched on for 150 seconds and off for 450 seconds. At 0% required

duty cycle the triac is always off, and at 100% duty cycle the triac is

always on. To avoid short on pulses when the required duty cycle is close

to 0%, or short off pulses when the required duty cycle is close to 100%, a

minimum on/off time may be specified (in percent of duty cycle). For

applications with a short DAT duty cycle (< 10 sec) it should be noted that

the absolute minimum on or off time of the output triac is 100 msec. The

DAT will always complete a calculated on or off period before

recalculating the next off or on time from the current value of the numeric

source. The DAT recalculates after its on time and after its off time so a

full on/off cycle may not equal the repetition cycle if the numeric source is

changing.

This type provides a single maintained on/off triac output. It can be driven

by either a logic source or numeric source where a positive value would

equal an on and a zero or negative value would equal an off.

DAT Duration

Adjust Type

On/Off

34

Configuration Guides—DX-9100 Configuration Guide

This type uses a pair of triac outputs and requires a logic source. A start

command (logic source changes from 0 to 1) sends a one second pulse to

the first triac of the pair and a stop command (logic source changes from

1 to 0) sends a one second pulse to the second triac.

Note: The DX display panel shows the status of the logic source to the

digital output module associated with the first triac output. This

displayed status is also the last command (on or off) to the triac

pair. The display does not indicate the actual triac status.

This type provides a single momentary triac output from a logic source.

When the logic source becomes a 1, a one second pulse is sent to the triac.

When the logic source changes to 0, a one second pulse is sent to the same

triac.

Via the GX Tool

Double-click on DOn with the left mouse button. Then select one of the

following: PAT, DAT, On/Off, STA/STO, or PULSE. Select DOn using

the right mouse button. Then select Data in the module menu. Enter the

user name and description in the respective fields.

Via the SX Tool

For each digital output module the type of output can be selected with the

following bits under Output Modules in Item DOTn (RI.00):

X3 X2 X1 = 000 Output disabled or paired.

X3 X2 X1 = 001 On/Off — driven from a logic source.

X3 X2 X1 = 010 On/Off — driven from a numeric source

(< 0 = off, > 0 = on).

X3 X2 X1 = 011 DAT (Duration Adjust Type) output, or

time-based proportional duty cycle, driven from

a numeric source.

X3 X2 X1 = 100 PAT without feedback: combination of two

outputs, driven from a numeric source.

Note: The next output is automatically taken from

the next Digital Output Module in numerical

sequence.

X3 X2 X1 = 101 PAT with Feedback: combination of two outputs,

driven from a numeric source with an associated

feedback connection.

STA/STO

PULSE

DO: Output

Type

User Name and

Description

Configuration Guides—DX-9100 Configuration Guide

35

X3 X2 X1 = 110 Start/Stop: combination of two outputs driven from a

logic source. This module gives the start command,

and the next digital output (in numerical sequence)

gives the stop command. Each triac switches on for

one second.

X3 X2 X1 = 111 Pulse Type: the output generates a one second pulse

for each state transition of a logic source.

This defines the source of the signal that will drive the output module.

PAT and DAT output modules, alternatively to one numeric source, can

have two logic sources: the source of the increase signal and the source of

the decrease signal. The rate of increase or decrease for PAT type outputs

is derived from the full stroke time. For DAT type outputs the rate is

1% per second.

Via the GX Tool

Expand both source and DOn modules. Position the cursor on the source

point. Press the mouse button, and while keeping it pressed, drag the

cursor to DOn@. Release the mouse button to make the connection.

Alternatively, for PAT and DAT modules, you can select sources for

increase and decrease. Connections are made in the usual way between the

increase source point and INC@, and between the decrease source point

and DEC@ in the DOn module.

Via the SX Tool

Under Output Modules, the signal source is defined by

Item DO@n (RI.01). PAT and DAT output modules can, alternatively,

have two logic sources. The source of the increase signal is defined in

Item INC@n (RI.13), and the source of the decrease signal is defined in

Item DEC@n (RI.14).

This defines the source of the analog feedback (0-100%) that is needed for

the PAT with feedback type module.

Via the GX Tool

Expand the source and destination modules. Position the cursor on the

source point. Press the mouse button, and while keeping it pressed, drag

the cursor to FB@. Release the mouse button to make the connection.

Via the SX Tool

Under Output Modules, Item FB@n (RI.02) defines the source of the

analog feedback.

DO: Source

DO: Feedback

for PAT

36

Configuration Guides—DX-9100 Configuration Guide

The High Range (HRO) defines the level of the control numeric source

signal, which will correspond to the maximum output of 100%.

The Low Range (LRO) defines the level of the numeric control source

signal, which will correspond to the minimum output of 0%.

The requested output is scaled to obtain:

OUTn = 100 * (DOn — LROn) / (HROn — LROn) %

Where DOn is the value of the control signal to the module (source value).

Via the GX Tool

Select DOn. Then select Data in the module menu. At the High Range and

Low Range fields, enter the desired numbers within the range of the source

control signal.

Via the SX Tool

Under Output Modules, set the following:

High Range at Item HROn (RI.04)

Low Range at Item LROn (RI.05)

This defines the source of a logic signal that forces the logic module

output to a forcing level. When the logic connection is a 1, the output will

go to a forced level; when 0, the output will go to normal control.

Via the GX Tool

Select DOn. Then select Data in the module menu. At the Forcing Level

field, enter a number from 0 to 100%.

Expand the source and destination modules. Position the cursor on the

logic source point. Press the mouse button, and while keeping it pressed,

drag the cursor to DOF@. Release the mouse button to make the

connection.

Via the SX Tool

Under Output Modules, Item DOF@n (RI.03) defines the source;

Item OFLn (RI.10) defines the forcing level.

Upon power restoration, the DO can optionally be forced to a Hold or

Auto (Hold reset) condition, irrespective of the Hold condition before the

power failure and overriding the Initialization on Power Up setting for the

controller.

DO: Range

(PAT or DAT)

DO: Forcing

Mode and Level

(PAT or DAT

DO: Hold or Auto

On Power Up

(PAT or DAT

Configuration Guides—DX-9100 Configuration Guide

37

Via the GX Tool

Select DOn. Then select Data in the module menu. Then enter 1 for the

appropriate power up condition, if required:

Hold on Power up = (1 = Yes)

Auto on Power up = (1= Yes)

If both Hold and Auto are enabled, Hold takes priority. If both are

disabled, the current setting under the Initialization on Power Up field

determines the output.

Via the SX Tool

Under Output Modules, set bits X7 and X8 of Item DOTn (RI.00) as

follows:

bit X8 = 0 The Hold mode is not altered after a power failure.

bit X8 = 1 The Hold mode is set at power up to the status set in bit X7.

bit X7 = 0 The Hold mode is set to hold at power up if bit X8 is set.

bit X7 = 1 The Hold mode is reset (set to 0) at power up if bit X8 is set.

The output high limit defines the maximum output in percent. The output

low limit defines the minimum output in percent. These limits are enabled

by a logic connection and are only operative when the logic source is as 1.

When the limits are enabled:

If OUTn > HLOn

OUTn = HLOn

If OUTn < LLOn

OUTn = LLOn

Via the GX Tool

Select DOn. Then select Data in the module menu. At the

High Range Limit % and Low Limit % fields, enter the desired numbers

(0-100%).

Expand source and destinations modules. Position the cursor on the source

point. Press the mouse button, and while keeping it pressed, drag the

cursor to ENLn@ in the destination module. Release the mouse button to

make the connection.

DO: Output

Limits (PAT with

Feedback or

DAT

38

Configuration Guides—DX-9100 Configuration Guide

Via the SX Tool

Under Output Modules, set the following:

High Limit on Output = Item HLOn (RI.08)

Low Limit on Output = Item LLOn (RI.09)

The limits are enabled by a logic connection to Item ENL@n (RI.15).

The full stroke time (in seconds) needs to be defined for PAT type

modules. This is the time it takes the electromechanical actuator to drive

the controlled device from fully open to fully closed or vice versa.

The DAT cycle (in seconds) also needs to be defined. This is the duration

adjust time proportion base for a DAT type output.

Via the GX Tool

For PAT, select DOn. Then select Data in the module menu. At the Stroke

Time (sec) field, enter the electro-mechanical actuator stroke time.

For DAT, select DOn. Then select Data in the module menu. At the

Repetition Cycle (sec) field, enter the cycle.

Via the SX Tool

Under Output Modules, Item FSTn (RI.06) defines the full stroke time

(in seconds) for PAT type modules.

The same Item defines the DAT cycle (in seconds).

The PAT deadband is the change in output value required to initiate triac

switching in a PAT type output.

The DAT minimum On/Off time defines in percent of cycle the shortest on

period when the required output approaches 0%, and the shortest off

period when the required output approaches 100%.

Via the GX Tool

For PAT, select DOn. Then select Data in the module menu. At the

Deadband field, enter the desired number (normally a whole number

between 0 and 5%).

For DAT, select DOn. Then select Data in the module menu. At the

Minimum On/Off (%) field, enter the desired number in percentage of

repetition cycle (normally between 0 and 5%).

DO: PAT Full

Stroke Time or

DAT Cycle

DO: PAT

Deadband

DAT Minimum

On/Off Time

Configuration Guides—DX-9100 Configuration Guide

39

Via the SX Tool

Under Output Modules, Item DBn (RI.07) defines the PAT deadband.

The same Item defines the DAT Minimum On/Off in % of output.

1. The DOs can be read and overridden (put in hold) from the DX front

panel. See Display Panel and Keypads in the DX-9100 Extended

Digital Controller Technical Bulletin (LIT-6364020) in FAN 636.4

or 1628.4.

2. On the SX Tool, the output values can be read in percent at Output

Modules, Item OUTn (RI.11). For PAT and DAT type modules the

range is 0-100%. The other types have an output of 0 (off) or 100 (on)

percent.

3. Digital Output Control and Status can be seen at Item DOCn (RI.12)

on the SX Tool in the following bits:

X1 = 1 OUHn Output in Hold mode (manual)

X2 = 1 DOHn Output at High Limit … 100%

X3 = 1 DOLn Output at Low Limit … 0%

X4 = 1 DOFn Output is Forced

X5 = 1 AFBn Incorrect Feedback

(The incorrect feedback bit is set whenever one of the PAT output

triacs is switched on and the feedback signal does not change within

five seconds.)

X6 = 1 OULn Output is Locked (both INC@n and DEC@n are

true)

4. The triac output status can be read on the SX Tool under General

Module, at Item TOS (RI.05).

5. The digital output module can be set in Hold (Manual) on the DX

front panel or by the PLC, the SX Tool, a BAS, or by configuration on

power up.

DO Notes

40

Configuration Guides—DX-9100 Configuration Guide

Source Points (Outputs)

AFB A 1 when the DO PAT associated feedback value is not

responding to changes in the DO PAT command value.

DOn The status of the digital output.

DOFn A 1 when the digital output PAT or DAT is being externally

forced.

DOHn A 1 when the digital output PAT or DAT is at its defined high

limit.

DOLn A 1 when the digital output PAT or DAT is at its defined low

limit.

OUHn A 1 when an analog or digital output is in Hold mode from

either the DX front panel or BAS.

OUTn The value of the analog output (including PAT or DAT).

Destination Points (Inputs)

DEC@ The connection to decrement an analog type output, PAT/DAT

digital type output or a sequencer module. While connection is

a logic 1, the output will decrease at a rate dependent on the

type of module.

DO@ The connection to control a digital output.

DOF@ The connection for forcing a digital output to a specified value.

ENL@ The connection to enable output limits of an analog type output

(PAT and DAT included).

FB@ The connection to the feedback of a PAT. Usually a signal from

a potentiometer on the controlled device.

INC@ The connection to increment an analog type output, PAT/DAT

digital type output or a sequencer module. While connection is

a logic 1, the output will increase at a rate dependent on the

type of module.

There are eight Analog Constants in the DX-9100. The value of each

constant can be set by the SX-9120 Service Module, GX-9100

Configuration software, or BAS, used in an analog connection to provide a

constant analog value for a programmable function module or output

module. In a Version 2 or 3 controller, the analog constants may also be

set at the DX front display panel. These values are not located in

EEPROM and therefore can be written to via the BAS.

GX Labels

Constants and

Result Status

Analog

Constants

Configuration Guides—DX-9100 Configuration Guide

41

Via the GX Tool

Select PM from the toolbar, and then Analog Constants. An ACO module

(box) appears. Place it where desired on screen. Select ACO. Then select

Data in the module menu. Enter the values as required. Select OK to

reconfirm entries, or Cancel to discard them.

Via the SX Tool

Under General Module, set Items AC01 — 8 (RI. 34-41).

There are 32 Digital Constants in the DX-9100. The value of each constant

can be set by the SX-9120 Service Module, GX-9100 Graphic

Configuration Tool, or BAS, and used in a logic connection to provide a

logic value for a programmable function module, output module or PLC

module. In a Version 2 controller, the digital constants may also be set at

the front display panel. These values are not located in EEPROM and

therefore can be written to via the BAS.

Via the GX Tool

Select PM from the toolbar, and then Digital Constants. A DCO module

(box) appears. Place it where desired on screen. Select DCO. Then select

Data in the module menu. Enter the values as required. Select OK to

reconfirm entries, or Cancel to discard them.

Via the SX Tool

Under General Module, set Items LCOS1 and LCOS2 (RI.10, RI.11).

LCOS1 is DCO1-16. LCOS2 is DCO17-32.

There are 64 Logic Result Status variables in the DX-9100 (in Version 1.0,

only 32 are available). The value of each status variable can be set by the

OUT, OUTNOT, SET, or RST instruction of the PLC module, and can be

used in a logic connection to provide a logic value for a programmable

function module, output module, or PLC module. The variables can also

be used to transmit status conditions to a BAS. These values are read only

and can only be changed by PLC execution.

Via GX Tool

Select PM from the toolbar, and then select LRS1-32 (or LRS33-64). A

module (box) will appear. Place it as desired on screen. Connections can

be made in the usual way. (See Configuration Tools — Making Connections

earlier in this document.)

Digital

Constants

Logic Result

Status:

42

Configuration Guides—DX-9100 Configuration Guide

Via SX Tool