- Возможность работы с прозрачными этикетками, этикетами любого цвета, с голографией т.д.;

- 3 режима обучения на работу с этикетками различной плотности;

- Время отклика менее 300 мкс;

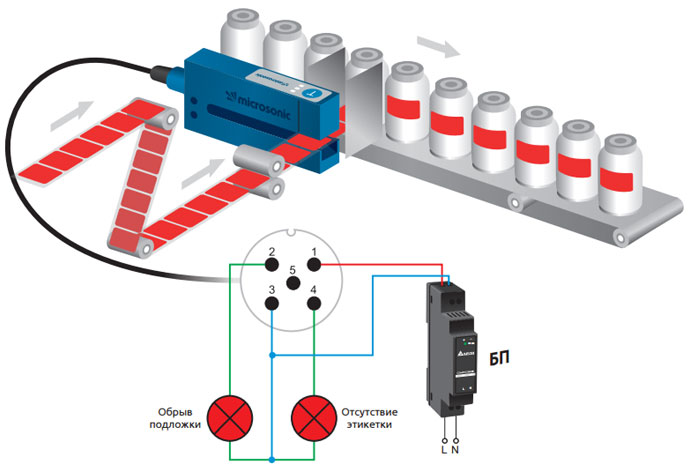

- 2 дискретных выхода для контроля наличия этикетки / обрыв ленты;

- Габаритные размеры полностью соответствуют размерам оптических датчиков этикеток;

- Возможность настройки посредством LinkControl (требуется LCA-2 Koffer).

Контроль этикетки на производстве

Контроль этикетки на производстве фармакологических средств Применение датчика esf-1 позволяет успешно контролировать момент наклейки этикетки на каждое изделие благодаря очень малому времени отклика 300 мкс. При этом в случае обрыва ленты, датчик одновременно информирует об этом это путем срабатывания 2-го дискретного выхода

| Артикул | esf-1/CF | esf-1/CDF |

|---|---|---|

| Выходы | 1×Push-Pull (PNP/NPN) | 1×Push-Pull + 1 PNP |

| Характеристики выходов | Push-Pull, +UB -4 В, -UB +2 В, Imax = 100 мА, с защитой от КЗ, переключаемый НО/НЗ |

PNP, +UВ -3 В, Imax= 100 мА, защита от КЗ |

| Подключение | коннектор M8×1, 4-контакта | коннектор M12×1, 5-контактов |

| Управление | кнопка «Teach-in» | кнопка «Teach-in» + pin-5 |

| Время отклика | От 300 мкс до 2,25 мс, в зависимости от материала |

| Параметр | Значение |

|---|---|

| Частота ультразвука | 500 кГц |

| Рабочие поверхности | полотно от 20 до 400 г/м², ламинированная бумага и плёнки до 0,2 мм толщиной, самоклеющиеся плёнки, этикетки, наклейки с подложкой и т.д. |

| Напряжение питания, UB | = 20…30 В |

| Материал корпуса | анодированный алюминий пластик: PBT,PA |

| Материал сенсора | полиуретан эпоксидная смола с содержанием стекла |

| Степень защиты | IP65 |

| Индикаторы | 3 LED-индикатора (красный, жёлтый, зелёный) |

| Рабочая температура | +5…+60 °С |

| Температура хранения | -40…+85 °С |

При коммутации индуктивной нагрузки (катушек соленоидных

клапанов, э/м реле, контакторов) транзисторным выходом датчика,

рекомендуется обеспечить дополнительную защиту схемотехники

от возникающих импульсных перенапряжений.

Например, использовать устройство защиты от перенапряжений microsonic SF1 (поставляется отдельно).

| esf-1/C | / | ||

|---|---|---|---|

| Количество и тип выходов | |||

| 1 × Push-Pull (PNP/NPN) | F | ||

| 1 × Push-Pull + 1 PNP | DF | ||

| Интерфейс | |||

| IO-Link v 1.1 | A | ||

| Нет | — |

Пример: esf-1/CDF

Номер заказаesf-1/CDF/A

-

1 х Push-Pull + 1 х PNP

рабочий диапазонпленка с весом 20 г / м 2 до > 400 г / м 2, металлические ламинированные листы и пленки до 0,2 мм, самоклеящаяся пленка , наклейки на материал подложки

Модельgabelförmig

режим работыIO-Link

обнаружение метки/стыка

особенностиIO-Link

Smart Sensor Profile

средств измеренийимпульсном режиме с оценкой амплитуды

Преобразователь частоты500 kHz

рабочее напряжение UB20 — 30 VDC, защита от обратной полярности

пульсации напряжения± 10 %

ток холостого потребления≤ 50 mA

тип соединения5-контактным разъемом M12 инициатора

Выход 1релейный выход, метка/стык обнаружены

Push-Pull, UB-3 V, -UB+3 V,Imax = 100 mA

НЗК/НОК выбираемые, защита от короткого замыкания

Выход 2релейный выход

метка/стык обнаружены

web ошибка

PNP: I max = 200 mA (+U B -2 В)

НЗК/НОК выбираемые

защита от короткого замыкания

время реакцииот 300 мкс до 2,25 мс, в зависимости от материала

задержка до наличия< 300 ms

вход 1Вход COM порт синхронизационный вход teach-in вход

название продуктаesf-1/CDF/A

Код продукта16950

SIO поддержка режимада

COM режимеCOM2 (38,4 kBaud)

минута Время цикла4 ms

Формат данных процесса32 Bit PDI

Содержание данных процессаBit 0: initial state Pin 4; Bit 1: initial state Pin 2; Bit 2: web break; Bit 8-15: scale (Int. 8); Bit 16-31: measured value (Int. 16)

ISDU paramterIdentification, switched output, add-ons, temperature compensation, operation

Система командSP1 Teach-in, SP2 Teach-in, factory settings

SmartSensorProfilда

IODD версияIODD версии 1.1

Ширина вил6 mm

Вилка глубины70 mm

материаланодированный алюминий

ультразвукового преобразователяполиуретановой пены, эпоксидной смолы с содержанием стекла

Класс защиты по EN 60529IP 65

Рабочая температура+5°C до +60°C

температура хранения-40 ° C до +85 ° C

вес80 g

последующие версиибольшая ширина вилки / глубина

управления1 push-button

com input

возможности для настройкиРежим «обучения» через кнопки режим «обучения» через COM вход на контакт 5

LCA-2 c LinkControl

IO-Link

Synchronisationда

Индикаторы1x зелёный светодиод: рабочее состояние, 1x жёлтый светодиод: состояние выхода, второй контакт, 1x красный светодиод: состояние выхода, четвёртый контакт

особенностиIO-Link

Smart Sensor Profile

IO-Link Data Sheet

esf-1/CDF/A

esf-1/7/CDF/A

esf-1/15/CDF/A

microsonic GmbH / Phoenixseestraße 7 / 44263 Dortmund / Germany

T +49 231 975151-0 / F +49 231 975151-51 / E [email protected] / W microsonic.de

The content of this document is subject to technical changes. Specifications in this document are

presented in a descriptive way only. They do not warrant any product features.

MV-DO-198513-629461

1

IO-Link Data Sheet

Physical layer

esf-1/CDF/A

Ultrasonic label and splice sensor with pnp and PushPull switching output with IO-Link interface.

The fork depth is 55 mm.

esf-1/7/CDF/A

Ultrasonic label and splice sensor with pnp and PushPull switching output with IO-Link interface.

The fork depth is 70 mm.

esf-1/15/CDF/A

Ultrasonic label and splice sensor with pnp and PushPull switching output with IO-Link interface.

The fork depth is 150 mm.

Vendor Name

microsonic GmbH

Vendor ID

419 (0x01a3)

Device ID

72 (0x000048)

IO-Link Specification

1.1

Transmission Rate

COM 2 (38,400 Bd)

Process Data Length

32 Bit PDI

Minimum Cycle Time

4 ms

IO-Link Port Type

A (<200mA)

SIO Mode Supported

Yes

Smart Sensor Profile

Yes

Block Parameter

Yes

Data Storage

Yes

Product Name

Product ID

esf-1/CDF/A

16950

esf-1/7/CDF/A

16953

esf-1/15/CDF/A

16952

Pin assignment

IO-Link mode

The sensors esf-1/CDF/A, esf-1/7/CDF/A and esf-1/15/CDF/A are

IO-Link capable in accordance with IO-Link specification 1.1. Each

sensor has an IO-Link communication interface on pin 4.

Direct access to process and diagnosis data is possible via the IOLink interface. The parameterization of the sensors is possible during operation.

IODD description file

The sensors have a common device description file. The IODD contains:

› Communication features

› Device parameter with allowed values

and default value

› Identification-, processing and

diagnostic data

› Device data

› Text description

› Picture of the device

› Logo of the manufacturer

2

Label and splice sensor

A label sensor has the task to detect labels glued to a backing material. For this purpose, the label sensor evaluates the signal level

difference between the backing material and the backing material

with labels.

then stored in the parameter material adjustment. The thresholds

to detect labels and splices are then calculated and stored in SP1

and SP2. The parameters are newly determined with each Teach-in

process.

A splice sensor has the task to detect a splice in a web material.

The end and beginning of the web material can be joined together

as a splice and glued with an adhesive tape, or can be glued overlappingly. For this purpose, the splice sensor evaluates the signal

level difference between the web material and the splice.

The Teach-in procedure can be carried out manually with the button on the label and splice sensor or with pin 5 via the controls.

The signal differences between backing material and backing material with labels or web material and splice can be very slight. To

ensure a reliable distinction, the label as well as the splice sensor

has to learn each respective material: During the Teach-in process,

the ultrasonic transmitter output and ampflification factor of the

internal analog amplifier will be adjusted to the backing material

of the labels or the web material. The determined parameters are

Many parameters of the sensor are accessible via IO-Link. The parameter can be read or even partly written. The parameters can

be read out to set up a recipe management. Optionally, Teach-in

procedures via button or pin 5 can be started with IO-Link.

The label and splice sensor has to be calibrated to every material via the Teach-in procedures. For data storage or recipe management, the material-specific parameters can be read out and

written back. It is not recommendable to change the determined

parameters via IO-Link afterwards.

3

Process data

The process data are cyclically transmitted data. The length of the

process data of esf-1 sensors are 4 byte.

Byte 1

31

30

29

28

27

Byte 2

26

25

24

23

22

21

Byte 3

15

14

13

12

11

20

19

18

17

16

2

1

0

Byte 4

10

9

8

7

6

Description

Value range

5

4

3

0

=

1 Initial state (SSC1)

0 = False

1 = True

1

=

2 Initial state (SSC2)

0 = False

1 = True

2

=

Web break

0 = False

1 = True

8

15

=

Process data scale

-1

Process data

0...1,023 = Measured value

32,764 = No measurement data

-32,760 = Outside the detection range (-)

32,760 = Outside the detection range (+)

16

31

=

Scale

is the scaling of the process data. The measured value of the

sensor is calculated as stated

Process data x 10(Scale) = measured value

For example: 642 x 10 -1 = 64,2

Measurement data channel description

Index

Subindex

Term

Data type

16512

0

Measurement data channel description

Record

Access

Default value

1

Lower limit

UInt32

RO

0

2

3

Upper limit

UInt32

RO

1,023

Unit code

UInt16

RO

0

4

Scale

Int8

RO

-1

Lower limit

The lower limit is the smallest measured value that the sensor can

output.

Upper limit

The upper limit is the biggest measured value that the sensor can

output.

Unit code

The measuring value is dimensionsless.

Scale

is the scaling of the process data. The measured value of the

sensor is calculated as stated:

Process data x 10(Scale) = measured value

For example: 642 x 10 -1 = 64,2

4

Teach-in

Index Subindex

Term

Data type Access

2

System Commando

UInt8

WO

58

Teach-in channel

UInt8

RW

0

0 = SSC1: Default: pin 4 (push-pull)

1 = SSC1: Pin 4 (push-pull)

59

Teach-in status

UInt8

RO

0

Bit 0...3:

0 = Idle

1 = SP1 success

2 = SP2 success

3 = SP12 success

4 = Wait for command

5 = Busy

7 = Error

0

Teach-in configuration

Record

1

Splice threshold

UINT8

RW

20

5...50 %; resolution in %

2

Teach-in type

UINT8

RW

0

0 = Label dynamic

1 = Label static

2 = Splice

Material adjustment

UINT32

RW

400

500

Event number

dec

hex

36003

0x8ca3

Default value Value range

75 = Teach-in start

76 = Teach-in next step / end

79 = Teach-in abort

Event type

Event description

Warning

Material adjustment data record does not match the sensor.

System Commando

The system command is used to execute application commands,

Teach-in commands and IO-Link specific commands.

and stored in SSC1 and in material adjustment.

In addition, the threshold values are determined and stored in

SSC2 for optional splice evaluation.

Teach-in channel

The target channel of the Teach-in can be selected via this index.

SSC1 can be parametericed.

1 = Label static

With this static Teach-in for labels, the sensor first learns the backing material, then the backing material with label. The calculated

parameters are stored in SSC1.

In addition, the threshold values are determind and stored in SSC2

for optional splice evaluation.

Teach-in status

The Teach-in status indicates the state of the current adjustment.

Splice threshold

The threshold value for the splice is the percentage reduction on

SP1, see description Switched Signal Channel (SSC), and the percentage surcharge on SP2, see description SSC. To detect a splice,

the measuring value has to be below or above the value of the

splice threshold. After changing the splice threshold, the Teach-in

procedure for the splice sensor has to be started again.

Teach-in type

0 = Label dynamic

The backing material with labels must be guided through the fork

at a constant speed. With this Teach-in type, the parameters for

backing material and backing material with labels are determined

esf-1 as label sensor

5

Teach-in

2 = Splice

The web material is guided through the fork at a constant speed.

The parameters for the backing material are determined and stored in the parameter material adjustment as well as in SSC1 and

SSC2.

Material adjustment

The parameter material adjustment is the hardware-specific adjustment from a previous Teach-in procedure. The material adjustment is sensor-specific and should not be transmitted from one

sensor to another.

The parameter material adjustment can be used together with the

settings of SSC1, SP1 and SP2 as well as SSC2, SP1 and SP2 to

create a material management for this sensor. If the material adjustment does not match the sensor or was not generated by the

sensor, a warning event (36003) is set by the sensor. This event will

not be cancelled until the parameter material adjustment matches

the sensor again.

esf-1 as splice sensor

Teach-in - procedure for Teach-in initiated by the master

Teach-in type label dynamic

Initialization

1. In parameter <Teach-in type> (index 400.2) write the value 0 for "Label dynamic".

2. Insert backing material with labels into the fork.

Teach-in process

1. Move the backing material with labels through the fork at approx. 100 ... 200 mm/sec.

2. Write the value 75 for "Teach-in start" in parameter <system command> (index 2).

Read out the parameter <Teach-in status> (index 59).

3.1 If the parameter <Teach-in status> (index 59) contains the value 5, repeat step 3 after a waiting time of e.g. 500 ms.

3.2 If the parameter <Teach-in status> (index 59) contains the value 1, 2 or 3, the process is successfully completed.

End

3.3 If the parameter <Teach-in status> (index 59) contains the value 7, the Teach-in procedure was not successful.

Abort

3.4 If the parameter <Teach-in status> (index 59) still contains the value 5 after a time to be defined (e.g. 10 seconds),

continue with step 4.

4. Write the value 79 for "Teach-in abort" in parameter <system command> (index 2).

The sensor aborts the adjustment.

Abort

6

Teach-in - procedure for Teach-in initiated by the master

Teach-in type label static

Initialization

1. In parameter <Teach-in type> (index 400.2) write the value 1 for "static label".

2. Place 5 to 30 cm of backing material without labels in the fork.

Teach-in procedure

1. Write the value 75 for "Teach-in start" in parameter <system command> (index 2).

2. Move the backing material in the fork slowly back and forth over the length at least 3 times, this process must take at least 3 seconds.

3. Write the value 76 for "Teach-in next step / end" in parameter <system command> (index 2).

4. Place the backing material with labels in the fork. Make sure that the fork now measures a label in the middle.

5. Write the value 76 for "Teach-in next step / end" in parameter <system command> (index 2).

6. Move the label in the fork slowly back and forth over the label length at least 3 times. Make sure that only the label and not the

edge of the label is measured.

7. Write the value 76 for "Teach-in next step / end" in parameter <system command> (index 2).

8. Read the parameter <Teach-in status> (index 59).

8.1 If the parameter <Teach-in status> (index 59) contains the value 1, 2 or 3, the Teach-in process is successfully completed.

End

8.2 If the parameter <Teach-in status> (index 59) contains the value 7, the Teach-in process was not successful.

Abort

Teach-in type splice

Initialization

1. In parameter <Teach-in type> (index 400.2) write the value 2 for "splice".

2. Select the value for the splice threshold in parameter <splice threshold> (index 400.1). The recommended default value is 20%.

3. Insert web material without splice into the sensor.

Teach-in procedure

1. Write the value 75 for "Teach-in start" in parameter <system command> (index 2).

2. Move the web material slowly through the fork, depending on the material, 20 cm (plastic foils) to 2 m (recycled paper).

The process must take at least 3 seconds.

3. Write the value 76 for "Teach-in next step / end" in parameter <system command> (index 2).

4. Read out the parameter <Teach-in status> (Index 59).

4.1 If the parameter <Teach-in status> (Index 59) contains the value 1, 2 or 3, the Teach-in process is successfully completed.

End

4.2 If the parameter <Teach-in status> (Index 59) contains the value 7, the Teach-in process was not successful.

Abort

7

SSC - Switched Signal Channel

SSC1 - Switched Signal Channel 1 - Pin 4

Index Subindex

Term

Data type Access

60

0

SSC1 parameter

Record

1

SP1, setpoint 1

Int16

2

SP1, setpoint 2

Int16

0

SSC1 configuration

Record

1

Logic

2

61

100

Default value

Value range

RW

300

0..1,023; resolution in 0,1

RW

508

0..1,023; resolution in 0,1

UInt8

RW

0

0 = High active

1 = Low active

Mode

UInt8

RW

1

0 = Output deactivated

1 = Only lower threshold (SP1) (label/splice)

2 = Both thresholds (SP1 and SP2) (splice)

130 = Only upper threshold (SP2) (splice)

0

SSC1 advanced

configuration

Record

2

Switch-off delay

UInt8

RW

0

0…255; resolution in measuring repetition rates

Default value

Value range

SSC2 - Switched Signal Channel 2 - Pin 2

Index Subindex

Term

Data type Access

62

0

SSC2 parameter

32-bit

Record

1

SP1, setpoint 1

Int16

RW

300

0..1,023; resolution in 0,1

2

SP2, setpoint 2

Int16

RW

508

0..1,023; resolution in 0,1

0

SSC2 Configuration

32-bit

Record

1

Logic

UInt8

RW

0

0 = High active

1 = Low active

2

Mode

UInt8

RW

132

0 = Output deactivated

1 = Only lower threshold (SP1) (label/splice)

2 = Both thresholds (SP1 and SP2) (splice)

130 = Only upper threshold (SP2) (splice)

132 = Web break

134 = Missing label

135 = Mismatched label length

0

SSC2 advanced

configuration

Record

2

Switch-off delay

UInt8

63

100

RW

0…255; resolution in measuring repetition rates

8

SSC - Switched Signal Channel

SP1, Setpoint 1 and SP2, Setpoint 2

SP1 and SP2 are the threshold levels to detect label and splice.

These threshold values are determined by a Teach-in procedure.

Mode

is selected by the Teach-in type and can optionally be changed

later. The special functions "Web break", "Missing label" and

"Mismatched label length" are available for SSC2, which can

only selected via IO-Link.

0 = Output deactivated

The switching output is deactivated and is not set.

1 = Only lower threshold (SP1) (label/splice)

If the measured value of the sensor is below the value of SP1, the

output is set. SP2 is not used in this evaluation.

This is the default setting for scanning labels.

2 = Both thresholds (SP1 and SP2) (splice),

If the measured value of the sensor is below the value of SP1 and

above the value of SP2, the output is set.

This is the default setting for detecting a splice.

130 = Only upper threshold (SP2) (splice)

If the measured value of the sensor is above the value of SP2, the

output is set.

132 = Web break

The output is set as soon as the sensor detects a web break.

134 = Missing label

The output is set if the sensor detects a missing label. The prerequisite for this is a constant material flow at a constant speed.

135 = Mismatched label length

The output is set if the sensor detects a faulty label (± 50% of the

usual length). The prerequisite for this is a constant material flow

at a constant speed.

Logic

0 = High active

The output is set = +UB

1 = Low active

The output is set = -UB

Switch-off delay

The switch-off delay specified as the number of measurement

repetition rate extends the status output set. The measurement

repetition rate is dependent on scanned material. With the same

switch-off delay, but with different materials, the real switch-off

delay varies in ms.

9

User interface

Index Subindex

Term

Data

type

370

0

Button and pin 5

Record

1

Teach-in input

2

371

372

Access

Default value

Value range

UInt8

RW

1

0 = Inactive

1 = Button and pin 5 active

2 = Only pin 5 active

3 = Only button active

Manual Teach-in mode

UInt8

RW

0

0 = Standard Teach-in methods

1 = QuickTeach label sensor

2 = QuickTeach splice sensor

0

LED

Record

1

Mode

UInt8

RW

1

0 = off

1 = on

4 = Find me!

0

Teach-in feedback

Record

1

Mode

UInt8

RW

0

0 = Inactive

1 = Feedback on pin 2 and pin 4

2 = Feedback on pin 2

3 = Feedback on pin 4

Event code

Type

Description

dezimal

hex

36000

0x8CA0 Notification

Teach-in is not successful.

36001

0x8CA1 Notification

Teach-in is successful.

36004

0x8CA4 Warning

Manual Teach-in is executed.

The sensor has three LEDs, a button and a control input via pin 5.

Teach-in input

0 = Inactive

1 = Button and pin 5 active

2 = Only pin 5 active

3 = Only button active

The LEDs can be switched off in normal operation and only

temporarily activated for a teach-in. In Find me! operation, all

LEDs of the sensor flash simultaneously. This helps to locate the

sensor in a machine.

The Teach-in input parameter can be used to switch off specific

input options.

Teach-in feedback mode

0 = Inactive

1 = Feedback on pin 2 and pin 4

2 = Feedback on pin 2

3 = Feedback on pin 4

Manual Teach-in mode

0 = Standard Teach-in methods

1 = QuickTeach label sensor

2 = QuickTeach splice sensor

The Teach-in feedback is intended for the QuickTeach in SIO mode:

If the controller initiates a QuickTeach in SIO mode via pin 5 (or if

the button is pressed), the controller can query at pin 2 and/or pin

4 whether this teach-in was successful.

The selection of the Teach-in mode facilitates the manual Teach-in

of the sensor. If the sensor is only used for one operating mode

- label or splice - you can use QuickTeach to set a simplified Teachin, which you must activate and define once. The QuickTeach label

sensor corresponds to the Teach-in type Label dynamic (Index

400.2 = 0). The QuickTeach splice sensor corresponds to the

Teach-in type splice (Index 400.2 = 2).

This function is activated with the parameter Teach-in feedback

mode (Index 372.1).

If QuickTeach is successfully performed via pin 5 (or the key),

output pin 2, pin 4 or both will be set for 300 ms 200 ms after the

end of this process.

LED mode

0 = off

1 = on

4 = Find me!

10

User interface

QuickTeach

1

Pin 5 or button

A)

0

1

Pin 2 / Pin 4

0

QuickTeach

successful

B)

Normal operation

200 ms

{

300 ms

Query window

for the control

A) With QuickTeach labels, the controls can reset pin 5 at an early

stage as soon as there is a change of flankes "QuickTeach successful" has been detected. Or the controls ask 200 ms after pin 5 has

been reset in the 300 ms wide query window whether QuickTeach

was successful.

B) With QuickTeach splice, the change of flankes "QuickTeach successful" only occurs 200 ms later after the controls have reset pin 5.

In the 300 ms wide query window, the controls can query whether

QuickTeach was successful.

11

Synchronization

Index Subindex

Term

Data type Access

350

0

Synchronization

Record

1

Mode

UInt8

RW

Default value

Value range

0

0 = off

1 = on

control inputs must be connected to each other and mode 1 (=

on) must be selected.

If several esf-1 sensors are operated in a confined space, they

can influence each other. To avoid this, the esf-1 sensors can be

synchronized with each other. For this purpose, all Teach-in/Com

Temperature compensation

Index Subindex

Term

Data type Access

300

0

Temperatur compensation

Record

1

Mode

UInt8

RW

Default value

Value range

0

0 = off

1 = on

compensation. Only when the ambient temperature fluctuates by

more than 20 °C in a short time should temperature compensation

be switched on as an option.

The sensor is equipped with an internal temperature sensor, which

can compensate the temperature dependence of the amplitude

loss in the air. Normally it is not necessary to activate temperature

Sensor diagnosis

Index Subindex

Term

Data type Access

2000

0

Temperature

Record

1

Sensor temperature

Int16

RO

Default value

Value range

200

-560...1,560; resolution in 0,1 °C

Default value

Value range

The sensor displays the current sensor temperature.

Measurement diagnosis

Index Subindex

Term

Date type Access

2001

0

Measurement

Record

1

Measurement repetition

rate in SIO mode

UInt16

RO

30

30...195

resolution in 0,1 ms

2

Measurement repetition

rate in IO-Link mode

UInt16

RO

400

400...13,000

resolution in 0,1 ms

3

Quality of the last

Teach-in

UInt8

RO

Measurement repetition rate in SIO mode

The value indicates the repetition rate of the sensor when it is

operated with the current material adjustment in SIO mode.

Measurement repetition rate in IO-Link mode

The value specifies the repetition rate under IO-Link. This

depends on the master, which determines the time.

0...255:

0 = low quality

255 = high quality

Quality of the last Teach-in

The quality of the Teach-in is a value to provide a direct

comparison between several identical adjustment processes with

the same material. The larger it is, the better the adjustment.

12

Identification

Index

Term

Data type

Access

Default value

13

ProfileCharacteristic

Array UINT16

RO

14

PDInputDescriptor

Array OctetString3

RO

16

VendorName

String

RO

microsonic GmbH

17

VendorText

String

RO

Unser Herz schallt ultra.

18

ProductName

String

RO

19

ProductID

String

RO

20

ProductText

String

RO

21

SerialNumber

String

RO

23

FirmwareRevision

String

RO

24

ApplicationSpecificTag

String

RW

ProfileCharacteristic

The ProfileCharacteristic is an array of all profiles and function

classes supported by the sensor.

PDInputDescriptor

The PDInputDescriptor displays the breakdown of all data present

in the PDI in an array.

VendorName

The VendorName contains the name of the manufacturer.

VendorText

The VendorText contains the claim of the manufacturer.

ProductName

The ProductName contains the designation of the sensor used.

Ultrasonic sensor

***

ProductID

The ProductID contains the part number of the sensor used.

ProductText

The ProductText describes the sensor used.

SerialNumber

The SerialNumber is defined by the manufacturer.

FirmwareRevision

The FirmwareRevision shows the firmware version of the application used by the manufacturer.

ApplicationSpecificTag

The ApplicationSpecificTag can be used to store information

about the location or use of this sensor in the sensor setting.

System Command

Index Subindex

Term

Data type Access

2

System Command

UInt8

RW

Default value

Value range

130 = Restore factory settings

Back to factory setting

If the value 130 is written into index 2, all parameters of the

sensor are reset to factory setting.

13

Parameter access

The sensor is cyclically requested by the master to communicate.

With each communication the measured value is sent from the

sensor to the master. Part of this communication is the Indexed

Service Data Unit channel (ISDU channel). This channel is used to

write or read data acyclically to the sensor. This means that writing

or reading a parameter can take several communication cycles.

Error Code

Each communication of the master via the ISDU channel is

answered by the sensor. The sensor only processes aparameter

after it has been fully transmitted. Parameters, diagnostic data,

events and system commands are sent via this ISDU channel.

If the sensor discovers errors during parameter accessing, it reports

these with corresponding error codes.

Description

dezimal

hex

0

0x0000

No error

32768

0x8000

Device application error – no details

32785

0x8011

Index not available

32786

0x8012

Subindex not available

32800

0x8020

Service temporarily not available

32801

0x8021

Service temporarily not available – local control

32802

0x8022

Service temporarily not available

32803

0x8023

Access denied

32816

0x8030

Parameter value out of range

32817

0x8031

Parameter value above limit

32818

0x8032

Parameter value below limit

32819

0x8033

Parameter length overrun

32820

0x8034

Parameter length underrun

32821

0x8035

Function not available

32822

0x8036

Function temporarily unavailable

32832

0x8040

Invalid parameter set

32833

0x8041

Inconsistent parameter set

32898

0x8082

Application not ready

Device Access Locks

Index Subindex

Term

Data type Access

Default value

12

Device Access Locks

UInt16

RW

0

Bit 0: Parameter (write) Access Lock

RW

0

0 = off

1 = on

Bit 2: Local Parameterization Lock

RW

0

0 = off

1 = on

Bit 3: Local User Interface Lock

RW

0

0 = off

1 = on

The Device Access Locks are a specified IO-Link function. The

parameter DeviceAccessLocks enables the control of the device

behavior. Device functions can be deactivated via defined bits in

this parameter.

Parameter (write) Access Lock

If this bit is set, write access to application parameters and some

IO-Link specific parameters is disabled.

Value range

Local Parameterization Lock

If this bit is set, the parameterization is disabled via local

operating elements such as button / pin 5 on the device.

Local User Interface Lock

If this bit is set, use of the user interface on the device is disabled

and the display is switched off.

14

Events

Code

Type

Description

dezimal

hex

16384

0x4000

Error

Temperature fault

16912

0x4210

Warning

Device temperature over-run

16928

0x4220

Warning

Device temperature under-run

36000

0x8ca0

Notification

Manual Teach-in is not successful.

36001

0x8ca1

Notification

Manual Teach-in is successful.

36003

0x8ca3

Warning

Material adjustment data record does not match the sensor.

36004

0x8ca4

Warning

Manual Teach-in is executed.

Events are sent from the sensor to the master. This is done asynchronously via the ISDU channel of IO-Link. The master acknowledges these events in the sensor and stores them in the master

memory. There a PLC can read out the events. Several events can

be present simultaneously in the sensor.

Events are divided into three types.

•

"Notifications" are for general information or non-critical

states of the sensor and are sent each time the sensor state

occurs again.

•

"Warnings" indicate a possible functional limitation of the

sensor. These events are present until the reason for the function restriction is eliminated or switched off.

•

"Error" events indicate a sensor that is not functional. These

events are present until the reason for the function restriction

is removed or switched off.

Manual Teach-in is successful

A Teach-in via button or pin 5 was executed and successfully completed. The parameters have changed.

Material adjustment data record does not match the sensor

The transfered parameter material adjustment does not match

with this sensor. The function of the sensor cannot be guaranteed.

Manual Teach-in is executed

At the sensor, a Teach-in is carried out via button or pin 5. (During

a Teach-in process, the status of the outputs are frozen.)

Temperature fault

The operating temperature of the sensor has been significantly

exceeded, the function cannot be guaranteed. The sensor may be

damaged.

Device temperature over-run

The operating temperature of the sensor has be exceeded. A correct functioning of the sensor cannot be ensured.

Device temperature under-run

The operating temperature of the sensor has fallen below the minimum. A correct functioning of the sensor cannot to ensured.

Manual Teach-in is not successful

A Teach-in via button or pin 5 was executed and terminated incorrectly. The parameters have not changed.

15

Device status

Index Subindex

Term

Data type

Access

Default value

Value range

32

Int16

Error count

RO

0

0...65,535

36

UInt8

Device status

RO

0

0 = Device is OK.

1 = Maintance required

2 = Out of specification

3 = Functional check

4 = Failure

37

Array

Detailed device

status

RO

0

Error count

As soon as an event of the type error is detected in the sensor,

the error counter is incremented. The counter is set to 0 each

time operating voltage is switched on.

Device status

If no events can be read out or the sensor is switched from SIO

mode to IO-Link mode and the sensor is still to be monitored, it

is recommended to read this variable cyclically. The device status

shows the entire status of the sensor depending on the problem

that has occurred.

Detailed device status

In the detailed device status, all active error and warning events

are listed until they are reset by the sensor as soon as the root

cause has been eliminated.

Data storage

The sensors support data storage according to IO-Link version 1.1.

Data storage enables the master to store the entire parameter

set of the sensor. If the sensor has to be replaced, the data set is

loaded from the master into the replacement device.

The parameter material adjustment and SP1 as well as SP2 are

hardware dependent. After exchanging a sensor it is recommended

to carry out the material adjustment again.

The data storage is completely controlled by the master and is a

function of IO-Link to be configured in the master. Nothing has to

be configured in the sensor.

Block parameterization

Index

2

Subindex

Term

Data type

Access

System Commando

UInt8

WO

The block parameterization is a specified IO-Link function. The use

of this function is recommended if several parameters have to be

changed simultneously.

Each individual parameter write access is immediately implemented

in the sensor. This also includes a consistency check against other

parameters and immediate transfer to the application if the inspection is successful. If parameters are transferred in an unfavourable

sequence, the consistency check may fail.

Default value

Value range

1 = ParamUploadStart

2 = ParamUploadEnd

3 = ParamDownloadStart

4 = ParamDownloadEnd

5 = ParamDownloadStore

6 = ParamBreak

In block parameterization, on the other hand, all parameters are

first written and then the consistency check is performed for all

transferred parameters. The parameters are only stored in the sensor if this consistency check was successful.

This block parameterization also applies analogously to reading out

parameters.

16

Appendix: IO-Link data overview

Index Subindex

Term

Data Type

Access

2

System Commando

UInt8

WO

Device Access Locks

UINT16

12

13

Default Value

1 = ParamUploadStart

2 = ParamUploadEnd

3 = ParamDownloadStart

4 = ParamDownloadEnd

5 = ParamDownloadStore

6 = ParamBreak

75 = Teach-in start

76 = Teach-in next step /

end

79 = Teach-in abort

130 = Restore factory

settings

RW

0

Bit 0: Parameter (write)

Access Lock

RW

0

0 = off

1 = on

Bit 2: Local Parameterization Lock

RW

0

0 = off

1 = on

Bit 3: Local User Interface Lock

RW

0

0 = off

1 = on

ProfileCharacteristic

Array

UINT16

PDInputDescriptor

Array OctetString3

16

VendorName

String

microsonic GmbH

17

VendorText

String

Unser Herz schallt ultra.

18

ProductName

String

19

ProductID

String

20

ProductText

String

21

SerialNumber

String

23

FirmwareRevision

String

24

ApplicationSpecificTag

String

32

Error count

Int16

RO

0

36

Device status

UInt8

RO

0

37

Detailed device status

Array

RO

0

Process data input

OctetString4

RO

Teach-in channel

UInt8

RW

0

Teach-in status

UInt8

R/O

0

14

40

58

59

Value Range

Ultrasonic sensor

***

0 = Device is OK.

1 = Maintance required

2 = Out of specification

3 = Functional check

4 = Failure

0 = SSC1: Default: Pin 4 (push-pull)

1 = SSC1: Pin 4 (push-pull)

Bit 0..3:

0 = Idle

1 = SP1 success

2 = SP2 success

3 = SP12 success

4 = Wait for command

5 = Busy

7 = Error

17

Appendix: IO-Link data overview

Index Subindex

Term

Data Type

60

0

SSC1 parameter

Record

1

SP1, Setpoint 1

61

62

63

100

101

300

350

Access

Default Value Value Range

Int16

RW

300

0..1,023; resolution in 0,1

Int16

RW

392

0..1,023; resolution in 0,1

0

0 = High active

1 = Low active

2

SP1, Setpoint 1

0

SCC1 configuration

1

Logic

UInt8

RW

2

Mode

UInt8

RW

0

SSC2 parameter

Record

1

SP1, Setpoint 1

Int16

RW

300

0..1,023; resolution in 0,1

2

SP2, Setpoint 2

Int16

RW

392

0..1,023; resolution in 0,1

0

SSC2 configuration

Record

1

Mode

UInt8

RW

132

0 = Output deactivated

1 = Only low threshold (SP1) (label/splice)

2 = Both thresholds (SP1 and SP2) (splice)

130 = Only high threshold (SP2) (splice)

132 = Web break

134 = Missing label

135 = Mismatched label length

2

Logic

UInt8

RW

0

0 = High active

1 = Low active

0

SSC1 advanced

configuration

Record

1

Switch-On delay

UInt8

RW

0

0…255;

resolution in measurement cycle

2

Switch-Off delay

UInt8

RW

0

0…255;

resolution in measurement cycle

0

SSC2 advanced

configuration

Record

1

Switch-On delay

UInt8

RW

0

0…255;

resolution in measurement cycle

2

Switch-Off delay

UInt8

RW

0

0…255;

resolution in measurement cycle

0

Temperature

compensation

Record

1

Mode

UInt8

RW

0

0 = off

1 = on

0

Synchronization

Record

1

Mode

UInt8

RW

0

0 = off

1 = on

0 = Output deactivated

1 = Only low threshold (SP1) (label/splice)

2 = Both thresholds (SP1 and SP2) (splice)

130 = Only high threshold (SP2) (splice)

18

Appendix: IO-Link data overview

Index

Subindex

Term

Data Type

370

0

Button and pin 5

Record

1

Teach-in input

2

371

372

400

Access

Default Value

Value Range

UInt8

RW

1

0 = Inactive

1 = Button and pin 5 active

2 = Only Pin 5 active

3 = Only Taste active

Manual Teach-in mode

UInt8

RW

0

0 = Standard Teach-in methods

1 = QuickTeach label sensor

2 = QuickTeach splice sensor

0

LED

Record

1

Mode

UInt8

RW

1

0 = off

1 = on

4 = Find me!

RW

0

0 = Inactive

1 = Feedback on pin 2 and pin 4

2 = Feedback on pin 2

3 = Feedback on pin 4

0

Teach-in feedback

Record

1

Mode

UInt8

0

Teach-in configuration

Record

1

Splice threshold value

UInt8

RW

20

5..50 %, resolution in 1 %

2

Teach-in type

UInt8

RW

0

0 = Dynamic label

1 = Static label

2 = Splice dynamic

Material adjustment

UInt8

RW

Temperature

Record

RO

200

-560.. 1,056; resolution in 0,1 °C

500

2000

0

1

Sensor temperature

Int16

2001

0

Measurement

Record

1

Measurement

repetition rate in

SIO mode

UInt16

RO

30

30...195

resolution in 0,1 ms

2

Measurement

repetition rate in

IO-Link mode

UInt16

RO

400

400...13,000

resolution in 0,1 ms

3

Quality of the last

Teach-in

UInt8

RO

16512

0...255:

0 = low quality

255 = high quality

0

Measurement data

channel description

Record

1

Lower limit

UInt32

RO

0

0...1,023

2

Upper limit

UInt32

RO

1,023

0...1,023

3

Unit code

UInt16

RO

0

4

Scale

Int8

RO

-1

19

Appendix: IO-Link data overview

Events

Type

Description

16384

Code

0x4000

Error

Temperature fault

16912

0x4210

Warning

Device temperature over-run

16928

0x4220

Warning

Device temperature under-run

36000

0x8ca0

Notification

Manual Teach-in is not successful.

36001

0x8ca1

Notification

Manual Teach-in is successful.

36003

0x8ca3

Warning

Material adjustment data record does not match the sensor.

36004

0x8ca4

Warning

Manual Teach-in is executed.

Error Codes

Error Code

Term

dezimal

hex

0

0x0000

No error

32768

0x8000

Device application error – no details

32785

0x8011

Index not available

32786

0x8012

Subindex not available

32800

0x8020

Service temporarily not available

32801

0x8021

Service temporarily not available – local control

32802

0x8022

Service temporarily not available

32803

0x8023

Access denied

32816

0x8030

Parameter value out of range

32817

0x8031

Parameter value above limit

32818

0x8032

Parameter value below limit

32819

0x8033

Parameter length overrun

32820

0x8034

Parameter length underrun

32821

0x8035

Function not available

32822

0x8036

Function temporarily unavailable

32832

0x8040

Invalid parameter set

32833

0x8041

Inconsistent parameter set

32898

0x8082

Application not ready

20

esp-4/3CDD/M18 E+S

Microsonic esp-4/3CDD/M18 E+S User Manual,

3 pages

dbk+5/3CDD/M18 E+S

Microsonic dbk+5/3CDD/M18 E+S User Manual,

3 pages

LCA-2

Microsonic LCA-2 User Manual,

51 pages

hps+25/DD/TC/E/G1

Microsonic hps+25/DD/TC/E/G1 User Manual,

3 pages

crm+25/IU/TC/E

Microsonic crm+25/IU/TC/E User Manual,

3 pages

sks-15/D

Microsonic sks-15/D User Manual,

2 pages

sks-15/CI

Microsonic sks-15/CI User Manual,

2 pages

zws-15/CI/QS

Microsonic zws-15/CI/QS User Manual,

2 pages

zws-7/CD/QS

Microsonic zws-7/CD/QS User Manual,

2 pages

zws-15/CD/QS

Microsonic zws-15/CD/QS User Manual,

2 pages

mic+25/D/TC

Microsonic mic+25/D/TC User Manual,

3 pages

mic+25/IU/TC

Microsonic mic+25/IU/TC User Manual,

3 pages

mic+25/DIU/TC

Microsonic mic+25/DIU/TC User Manual,

3 pages

mic+25/DDIU/TC

Microsonic mic+25/DDIU/TC User Manual,

3 pages

mic-25/IU/M

Microsonic mic-25/IU/M User Manual,

2 pages

pico+15/I

Microsonic pico+15/I User Manual,

2 pages

pico+15/F

Microsonic pico+15/F User Manual,

3 pages

nano-15/CI

Microsonic nano-15/CI User Manual,

2 pages

nano-15/CD

Microsonic nano-15/CD User Manual,

2 pages

lcs+340/F

Microsonic lcs+340/F User Manual,

3 pages

Ultrasonic-Sensors

Operating Instructions

Ultrasonic label and splice sensor with 1 or 2 switched outputs

esf-1/CF esf-1/CDF esf-1/15/CDF

Functional principle

An ultrasonic transmitter in the lower tine of the fork beams a fast sequence of pulses through the backing material. The sound pulses cause the backing material to vibration, so that a greatly attenuated sound save is beamed from the opposite side. The receiver in the upper tine of the fork receives and evaluates this sound wave.

The backing material transmits a different signal level from the level with label or from a splice. The difference between the backing material and backing with label or the web material and splice can be very subtle. To ensure reliable detection, the esf-1 sensor must therefore initially learn the signal level for the backing or web material.

The esf-1 sensor can be used as a label sensor or a splice sensor.

With its three Teach-in methods, the esf-1 sensor can optimally be adjusted to any task configuration.

With QuickTeach, there is also a simplified Teach-in procedure available.

Product description

■Assured detection of labels made of paper, metal or (transparent) plastic.

■Detection of splices of paperwebs, plastic webs or metal webs.

■Detection of materials with weights from <20 g/m2 to >>400 g/m2; sheet metals and plastic films up to 0,2 mm thickness.

■3 Teach-in methods + QuickTeach.

■Parameterisable with LinkControl.

■Response time of 300 µs until label/splice is detected.

■Two fork depths of 67 mm and 150 mm.

Safety tips

■Read instruction manual before commissioning.

■Connection, installation and adjustment may only be carried out by trained technicians.

■Not a safety component as defined by the EU Machinery Directive.

Installation

Install the esf-1 in such a way that the tine with the button is on top. This installation orientation permits you to keep the measuring track optimally clean.

Connect the connection line with the 4-pin M8 connector as shown in Fig 1, and that with the 5-pin M12 connector as shown in Fig. 2.

|

2 |

4 |

|||

|

1 |

3 |

colour |

||

|

1 |

operating voltage +UB |

brown |

||

|

3 |

operating voltage -UB |

blue |

||

|

4 |

label/splice output F |

black |

||

|

2 |

Teach-In/Com |

white |

||

Fig. 1: Pin assignment of esf-1/CF and colour coding for microsonic connection lines

|

2 |

1 |

||||

|

3 |

5 |

4 |

colour |

||

|

1 |

operating voltage +UB |

brown |

|||

|

3 |

operating voltage -UB |

blue |

|||

|

4 |

label/splice output F |

black |

|||

|

2 |

web break output D |

white |

|||

|

5 |

Teach-in/Com |

grey |

|||

Fig. 2: Pin assignment of esf-1/CDF an esf-1/15/CDF and colour coding of the microsonic connection lines

Commissioning

Turn the power supply to the esf-1 on.

|

operation |

LED green LED yellow LED red |

|||

|

mode |

||||

|

ready to |

on |

— |

— |

|

|

operate |

||||

|

backing |

on |

off |

off |

|

|

material |

||||

|

label/splice |

on |

on |

off |

|

|

web break |

on |

off |

on |

|

|

error in |

on |

off |

on |

|

|

Teach-In |

||||

Fig. 3: LED display

Teach-in with push-button and control input

The Teach-in process can optionally be carried out with the button on the top tine of the fork or with the Teach-in input on pin 5 on the M12 connector or pin 2 on the M8 connector.

Pointer

■The Teach-in/Com control input is parallel with the push-button.

■+UB connected to the control input correponds to a key press.

Standard Teach-in

There are 3 Teach-in methods available:

■Dynamic Teach-in of label

■Separate Teach-in for backing material and labels

■Splice sensor

QuickTeach

With QuickTeach, you have a simplified Teach-in process that you have to activate once before initial commissioning.

Pointer

■To use QuickTeach, you have to decide whether the sensor will act as a label or a splice detector.

■Once QuickTeach is activated, you can’t switch between NCC/NOC any more.

■The QuickTeach functionality is available for sensors with lot numbers > 12xxxxx.

Insert the web material into the fork and carry out one of the three standard Teach-in methods or QuickTeach.

Working

The esf-1 continually performs measurements and sets the switched outputs based on its results.

Factory setting

The esf-1 sensors have the following settings configured at the factory:

esf-1/CF

■Label/splice output F on NOC.

■QuickTeach is deactivated.

esf-1/CDF and esf-1/15/CDF

■Label/splice output F on NOC.

■Output D2 on web break display.

■Output web break on NOC.

■QuickTeach is deactivated.

Synchronisation

If multiple esf-1 sensors are operated in tight quarters, they can influence one another. To avoid this, the esf-1 sensors can be synchronised. To do this, all Teach-in/com control inputs are connected together (see Figs. 1 and 2 for the connector pinouts).

Pointer

■A Teach-in using the control input can also be carried out with synchronisation active.

Parameterisation with LinkControl

The esf-1 can be extensively parameterised with LinkControl. To do this, you need the optionally available LCA-2 LinkControl adapter and the LinkControl software for Windows©.

Use in LinkControl

Install the LinkControl software onto your PC.

Connect the LinkControl adapter to your PC using the USB cable. Connect esf-1 to the LCA-2 as shown in the table in Fig. 4. Connect the cable for the power supply to the LCA-2 on the other side of the T plug.

Start the LinkControl software and follow the instructions on the screen.

|

Pin |

adapter |

Pin |

||

|

(esf-1) |

cable colour |

(LCA-2) |

||

|

+UB |

1 |

brown |

1 |

|

|

-UB |

3 |

blue |

3 |

|

|

Com |

2/5 |

grey |

5 |

Fig. 4: Connection of esf-1 to the LCA-2

You can change the following settings:

■NOC/NCC function of the switched outputs.

■Switched output function D.

There is also a graphical representation of the measured values available.

Maintenance

The esf-1 is maintenance-free. For significant deposits of dirt, we recommend carefully blowing out the measuring track with clean, oil-free compressed air.

2004/108/EG