- Manuals

- Brands

- Omron Manuals

- Controller

- SYSMAC CPM2A

Manuals and User Guides for Omron SYSMAC CPM2A. We have 3 Omron SYSMAC CPM2A manuals available for free PDF download: Programming Manual, Manual, Operation Manual

OMRON SYSMAC CPM2A Programming Manual (615 pages)

Brand: OMRON

|

Category: Controller

|

Size: 3.64 MB

Table of Contents

-

Table of Contents

6

-

Precautions

16

-

General Precautions

17

-

Intended Audience

17

-

Safety Precautions

17

-

Operating Environment Precautions

19

-

Application Precautions

20

-

-

Section 1 PC Setup

23

-

PC Setup

24

-

Changing the PC Setup

24

-

CPM1/CPM1A PC Setup Settings

25

-

CPM2A/CPM2C PC Setup Settings

29

-

SRM1(-V2) PC Setup Settings

35

-

-

Basic PC Operation and I/O Processes

38

-

Startup Mode

38

-

Hold Bit Status

39

-

Program Memory Write-Protection

39

-

RS-232C Port Servicing Time (CPM2A/CPM2C/SRM1(-V2) Only)

40

-

Peripheral Port Servicing Time

40

-

Cycle Monitor Time

40

-

Minimum Cycle Time

41

-

Input Time Constants

41

-

-

CPM2C Changes in SW2

43

-

Error Log Settings

43

-

-

-

Section 2 Special Features

46

-

Special Features

46

-

CPM2A/CPM2C Interrupt Functions

47

-

Processing the same Memory Locations with the Main Program

48

-

And Interrupt Subroutines

48

-

Interrupt Inputs

51

-

Interval Timer Interrupts

58

-

Precautions on Programming Interrupts

63

-

-

CPM2A/CPM2C High-Speed Counters

66

-

Using High-Speed Counters

68

-

Input Interrupts in Counter Mode

89

-

-

CPM1/CPM1A Interrupt Functions

98

-

Types of Interrupts

98

-

Input Interrupts

100

-

Masking All Interrupts

104

-

Interval Timer Interrupts

105

-

High-Speed Counter Interrupts

107

-

-

SRM1(-V2) Interrupt Functions

115

-

Types of Interrupts

115

-

-

CPM2A/CPM2C Pulse Output Functions

118

-

Interval Timer Interrupts

119

-

-

CPM2A/CPM2C Pulse Output Functions

119

-

Using Pulse Outputs with Variable Duty Ratio

132

-

Using Pulse Outputs with Trapezoidal Acceleration and Deceleration

138

-

-

CPM1A Pulse Output Functions

152

-

Programming Example in Continuous Mode

153

-

Programming Example in Independent Mode

153

-

Using Pulse Output Instructions

153

-

Changing the Frequency

154

-

Stopping Pulse Output

154

-

-

Synchronized Pulse Control (CPM2A/CPM2C Only)

155

-

Data Computation Standards

167

-

Pulse Outputs

167

-

Synchronized Pulse Control

167

-

-

Analog I/O Functions (CPM1/CPM1A/CPM2A/CPM2C Only)

168

-

Temperature Sensor Input Functions (CPM1A/CPM2A/CPM2C Only)

168

-

Compobus/S I/O Slave Functions (CPM1A/CPM2A/CPM2C Only)

168

-

Compobus/S I/O Master Functions (SRM1(-V2) and CPM2C-S Only)

169

-

Analog Controls (CPM1/CPM1A/CPM2A Only)

171

-

Quick-Response Inputs

174

-

CPM1/CPM1A Quick-Response Inputs

174

-

CPM2A/CPM2C Quick-Response Inputs

175

-

-

Macro Function

178

-

Calculating with Signed Binary Data

179

-

Differential Monitor

180

-

Definition of Signed Binary Data

180

-

Arithmetic Flags

180

-

Inputting Signed Binary Data Using Decimal Values

180

-

-

Expansion Instructions (CPM2A/CPM2C/SRM1(-V2) Only)

181

-

CPM2A/CPM2C/CPM2C-S Expansion Instructions

182

-

SRM1(-V2) Expansion Instructions

183

-

-

Using the CPM2A/CPM2C Clock Function

184

-

Data Area Words

184

-

Setting the Time

184

-

-

-

-

Section 3 Using Expansion Units

185

-

Section 3

185

-

Analog I/O Units

186

-

CPM1A-MAD01 Analog I/O Unit

186

-

CPM1A-MAD11 and CPM2C-MAD11 Analog I/O Units

197

-

-

Temperature Sensor Units

213

-

CPM1A/CPM2A Temperature Sensor Units

213

-

CPM2C Temperature Sensor Units

214

-

Using Temperature Sensor Units

215

-

Connecting Temperature Sensor Units

215

-

Ladder Programming

222

-

Two-Decimal-Place Mode

228

-

-

Compobus/S I/O Link Units

234

-

Devicenet I/O Link Unit

239

-

-

Using Expansion Units

185

-

-

Section 4 Communications Functions

245

-

Communications Functions

245

-

SECTION 4 Communications Functions

245

-

Introduction

246

-

Overview

246

-

Wiring Ports

246

-

-

CPM1/CPM1A Communications Functions

247

-

Host Link Communications

247

-

One-To-One NT Link Communications

248

-

One-To-One PC Link Communications

249

-

-

CPM2A/CPM2C Communications Functions

251

-

Host Link Communications

251

-

No-Protocol Communications

271

-

One-To-One NT Link Communications

280

-

One-To-One PC Link Communications

283

-

-

SRM1(-V2) Communications Functions

288

-

Host Link Communications

288

-

No-Protocol Communications

292

-

One-To-One NT Link Communications

297

-

One-To-N NT Link Communications

298

-

One-To-One PC Link Communications

299

-

-

Host Link Commands

301

-

Ir/Sr Area Read — Rr

301

-

Lr Area Read — Rl

302

-

Hr Area Read — Rh

302

-

Pv Read — Rc

302

-

Tc Status Read — Rg

303

-

DM Area Read — Rd

303

-

Ar Area Read — Rj

304

-

Ir/Sr Area Write — Wr

305

-

Lr Area Write — Wl

305

-

Hr Area Write — Wh

306

-

Pv Write — Wc

306

-

Tc Status Write — Wg

307

-

DM Area Write — Wd

308

-

Ar Area Write — Wj

308

-

Sv Read 1 — R

309

-

Sv Read 2 — R

310

-

Sv Change 1 — W

311

-

Sv Change 2 — W

312

-

Status Read — Ms

313

-

Status Write — Sc

314

-

Error Read — Mf

315

-

Forced Reset — Kr

317

-

Multiple Forced Set/Reset — Fk

318

-

Forced Set/Reset Cancel — Kc

319

-

Pc Model Read — MM

320

-

Test — Ts

320

-

Program Read — Rp

321

-

Program Write — Wp

321

-

Compound Command — Qq

322

-

Abort — Xz

324

-

Initialize

324

-

Txd Response — Ex

324

-

Undefined Command — IC

325

-

-

-

-

Section 5 Memory Areas

326

-

Memory Areas

326

-

Memory Area Functions

327

-

Memory Area Structure

327

-

SECTION 5 Memory Areas

328

-

Functions

330

-

-

I/O Allocation for CPM1/CPM1A/CPM2A Pcs

332

-

CPM1/CPM1A/SRM1(-V2) Flash Memory

332

-

CPU Units

332

-

Expansion I/O Units

336

-

Expansion Units

337

-

Examples of Expansion Unit and Expansion I/O Unit Allocation

338

-

-

I/O Allocation for CPM2C Pcs

342

-

CPU Units

342

-

Expansion I/O Units

344

-

Expansion Units

347

-

Examples of Expansion Unit and Expansion I/O Unit Allocation

348

-

-

-

Ladder-Diagram Programming

351

-

Basic Procedure

352

-

Instruction Terminology

352

-

Basic Ladder Diagrams

353

-

Controlling Bit Status

372

-

Work Bits (Internal Relays)

374

-

Programming Precautions

376

-

Program Execution

378

-

-

Instruction Set

379

-

SECTION 7 Instruction Set

379

-

Notation

382

-

Instruction Format

382

-

Data Areas, Definer Values, and Flags

382

-

Differentiated Instructions

384

-

Coding Right-Hand Instructions

385

-

Instruction Tables

388

-

Ladder Diagram Instructions

394

-

Bit Control Instructions

395

-

No Operation — Nop

399

-

End — End

399

-

INTERLOCK and INTERLOCK CLEAR — IL(02) and ILC(03)

399

-

JUMP and JUMP END — JMP(04) and JME

401

-

User Error Instructions: FAILURE ALARM and RESET — FAL(06) and SEVERE FAILURE ALARM — FALS

403

-

Step Instructions: STEP DEFINE and STEP START-STEP(08)/SNXT

403

-

STEP DEFINE and STEP START-STEP(08)/SNXT(09)

403

-

Timer and Counter Instructions

406

-

Shift Instructions

422

-

Data Movement Instructions

429

-

Data Control Instructions

439

-

Comparison Instructions

450

-

Conversion Instructions

457

-

BCD Calculation Instructions

475

-

Binary Calculation Instructions

485

-

Special Math Instructions

489

-

Logic Instructions

497

-

Increment/Decrement Instructions

501

-

Subroutine Instructions

502

-

Pulse Output Instructions

505

-

Special Instructions

515

-

Interrupt Control Instructions

519

-

Communications Instructions

523

-

-

-

Section 8

529

-

PC Operations and Processing Time

529

-

CPM1/CPM1A Cycle Time and I/O Response Time

530

-

The CPM1/CPM1A Cycle

530

-

-

CPM1/CPM1A Cycle Time

531

-

I/O Response Time

532

-

One-To-One PC Link I/O Response Time

533

-

Interrupt Processing Time

535

-

CPM1/CPM1A Instruction Execution Times

536

-

CPM2A/CPM2C Cycle Time and I/O Response Time

541

-

CPM2A/CPM2C Cycle Time

541

-

-

I/O Response Time

542

-

One-To-One PC Link I/O Response Time

543

-

Interrupt Processing Time

545

-

CPM2A/CPM2C Instruction Execution Times

546

-

SRM1(-V2) Cycle Time and I/O Response Time

555

-

The SRM1(-V2) Cycle

555

-

-

SRM1(-V2) Cycle Time

556

-

I/O Response Time

558

-

One-To-One PC Link I/O Response Time

559

-

Interrupt Processing Time

560

-

SRM1(-V2) Instruction Execution Times

561

-

-

Troubleshooting

567

-

Introduction

568

-

Programming Console Operation Errors

568

-

Programming Errors

569

-

User-Defined Errors

570

-

Operating Errors

571

-

Error Log

573

-

Host Link Errors

575

-

Troubleshooting Flowcharts

575

-

A Programming Instructions

576

-

B Error and Arithmetic Flag Operation

581

-

C Memory Areas

584

-

D I/O Assignment Sheet

601

-

E Program Coding Sheet

602

-

F List of FAL Numbers

605

-

G Extended ASCII

607

-

-

Index

608

-

Revision History

614

-

Advertisement

OMRON SYSMAC CPM2A Manual (187 pages)

Programmable Controllers

Brand: OMRON

|

Category: Controller

|

Size: 1.34 MB

Table of Contents

-

Table of Contents

6

-

Precautions

13

-

Precautions

14

-

Intended Audience

14

-

General Precautions

14

-

Safety Precautions

14

-

Operating Environment Precautions

15

-

Application Precautions

16

-

EC Directives

18

-

CPM2A 24-VDC CPU Unit Conformance to NK Standards

21

-

-

-

Section 1 Introduction

22

-

Section 1

22

-

Introduction

22

-

CPM2A Features and Functions

23

-

CPM2A Features

23

-

Overview of CPM2A Functions

28

-

-

Basic System Configurations

30

-

Stand-Alone CPU Unit

30

-

CPU Unit, Expansion Units, and Expansion I/O Units

30

-

-

Structure and Operation

33

-

CPU Unit Structure

33

-

Operating Modes

34

-

Operating Mode at Startup

34

-

PC Operation at Startup

35

-

Cyclic Operation and Interrupts

36

-

-

Functions Listed by Usage

39

-

Comparison with the CPM1A

42

-

Preparation for Operation

47

-

-

-

Section 2 Unit Specifications and Components

49

-

Section 2

49

-

Specifications

50

-

General Specifications of CPU Units

50

-

Characteristics

51

-

I/O Specifications

53

-

-

Unit Components

57

-

CPU Unit Components

57

-

Expansion I/O Unit Components

60

-

Analog I/O Unit Components

61

-

Temperature Sensor Unit Components

62

-

Compobus/S I/O Link Unit Components

63

-

Devicenet I/O Link Unit Components

64

-

-

-

Unit Specifications and Components

49

-

-

Section 3 Installation and Wiring

66

-

Section 3

66

-

Installation and Wiring

66

-

Design Precautions

67

-

Selecting an Installation Site

67

-

Power Supply Wiring

67

-

Power Supply Voltage

67

-

Interlock and Limit Circuits

67

-

Installation Site Conditions

68

-

Panel/Cabinet Installation

68

-

-

Installing the CPM2A

69

-

CPM2A Orientation

69

-

CPM2A Installation

69

-

Connecting an Expansion Unit or Expansion I/O Unit

71

-

-

Wiring and Connections

72

-

General Precautions for Wiring

72

-

Removing the Terminal Block

73

-

Ground Wiring

74

-

Power Supply Wiring

75

-

Input Wiring

77

-

Output Wiring

85

-

Programming Device Connections

100

-

Host Link Connections

101

-

No-Protocol Communications

104

-

OMRON PT Connections

104

-

One-To-One PC Link Connections

105

-

Compobus/S I/O Link Connections

106

-

-

-

-

Section 4 Using a Programming Console

107

-

Section 4

107

-

Compatible Programming Consoles

108

-

Changing the Cpm2A’s Mode with the Mode Switch

110

-

Connecting the Programming Console

111

-

Preparation for Operation

112

-

Entering the Password

112

-

-

Programming Console Operations

114

-

Overview

114

-

Clearing Memory

115

-

Clearing Memory Completely

116

-

Reading um Allocation Information

116

-

Reading/Clearing Error Messages

116

-

Buzzer Operation

117

-

Assigning Expansion Instruction Function Codes

118

-

Setting and Reading a Program Memory Address and Monitoring I/O Bit Status

118

-

Entering or Editing Programs

119

-

Instruction Search

122

-

Bit Operand Search

123

-

Inserting and Deleting Instructions

123

-

Checking the Program

125

-

Bit, Digit, Word Monitor

125

-

Differentiation Monitor

127

-

Binary Monitor

128

-

Three-Word Monitor

129

-

Signed Decimal Monitor

129

-

Unsigned Decimal Monitor

130

-

Three-Word Data Modification

130

-

Changing Timer, Counter SV

131

-

Hexadecimal, BCD Data Modification

132

-

Binary Data Modification

133

-

Signed Decimal Data Modification

133

-

Unsigned Decimal Data Modification

134

-

Force Set, Reset

135

-

Clear Force Set/Reset

136

-

Hex-ASCII Display Change

136

-

Displaying the Cycle Time

137

-

Reading and Setting the Clock

137

-

-

Programming Example

138

-

Preparatory Operations

138

-

Example Program

139

-

Programming Procedures

140

-

Checking the Program

143

-

Test Run in MONITOR Mode

143

-

-

-

Using a Programming Console

107

-

-

Section 5 Test Runs and Error Processing

144

-

Section 5

144

-

Initial System Checks and Test Run Procedure

145

-

Initial System Checks

145

-

Flash Memory Precautions

145

-

CPM2A Test Run Procedure

145

-

-

Self-Diagnostic Functions

146

-

Identifying Errors

146

-

User-Defined Errors

147

-

Non-Fatal Errors

147

-

Fatal Errors

148

-

Communications Errors

148

-

-

Programming Console Operation Errors

149

-

Programming Errors

149

-

Troubleshooting Flowcharts

150

-

Maintenance Inspections

158

-

Battery Replacement

159

-

-

Test Runs and Error Processing

144

-

-

Section 6 Expansion Memory Unit

161

-

Section 6

162

-

Expansion Memory Unit

162

-

Overview

162

-

Memory Areas

162

-

Precautions

162

-

-

Specifications and Nomenclature

163

-

Specifications

163

-

Nomenclature

163

-

-

Handling

164

-

Mounting/Removing EEPROM

164

-

-

PC Connections

165

-

Uploading Programs

166

-

SECTION 6 Expansion Memory Unit

166

-

Downloading Programs

168

-

-

Omron SYSMAC CPM2A Operation Manual (20 pages)

Brand: Omron

|

Category: Controller

|

Size: 0.08 MB

Table of Contents

-

Table of Contents

4

-

Precautions

7

-

Intended Audience

8

-

General Precautions

8

-

Safety Precautions

8

-

Operating Environment Precautions

9

-

Application Precautions

9

-

EC Directives

11

-

Introduction

15

-

CPM2A Features and Functions

15

-

Structure and Operation

15

-

Functions Listed by Usage

15

-

Comparison with the CPM1A

15

-

Preparation for Operation

15

Advertisement

Advertisement

Related Products

-

Omron Sysmac CPM2C

-

Omron SYSMAC CPM1

-

Omron SYSMAC CPM1A

-

Omron SYSMAC CP1L

-

Omron SYSMAC CP1E

-

OMRON SYSMAC CJ Series

-

Omron Sysmac CJ Series

-

Omron SYSMAC CQM1H

-

Omron SYSMAC CJ1W-MCH72

-

Omron SYSMAC CS/CJ Series

Omron Categories

Blood Pressure Monitor

Controller

Accessories

![]()

Switch

Inverter

More Omron Manuals

2. РАБОТА №1. ИЗУЧЕНИЕ ПРОГРАММИРУЕМОГО КОНТРОЛЛЕРА

OMRON SYSMAC CPM2A-30CDR

2.1. Цель работы

Ознакомиться с устройством и техническими характеристиками программируемого контроллера OMRON SYSMAC CPM2A-30CDR, приобрести навыки программирования, изучить основные функции и операции.

2.2.Содержание работы

1.Изучить назначение, технические характеристики контроллера OMRON SYSMAC CPM2A-30CDR, основные узлы и возможности лабораторного стенда.

2.Изучить систему команд и принципы программирования контроллера.

3.Дома при подготовке к работе выполнить синтез системы автоматизации согласно выданного варианта задачи. Составить программу для ввода в контроллер.

4.В лаборатории:

–пройти тестирование по системе команд и принципу программирования на контроллере CPM2A-30CDR;

–освоить графическую среду программного обеспечения;

–набрать на компьютере подготовленную программу, откомпилировать ее и ввести в контроллер. Убедиться в правильности работы программы.

2.3.Общие технические характеристики ПК CPM2A-30CDR

В лабораторном стенде используется промышленный контроллер CPM2A30CDR семейства CPM2A японской фирмы OMRON. Он представляет собой компактный промышленный контроллер класса «микро» с большим числом встроенных функций. Этот контроллер идеально подходит для встраивания в объект управления. На рис. 2.1 показан внешний вид контроллера.

Рис. 2.1. Программируемый контроллер CPM2A-30CDR

14

Пояснения к позиционным обозначениям рис. 2.1 даны в табл. 2.1. Таблица 2.1

|

№ п/п |

Объект |

Описание |

||||

|

Индикатор |

1 |

Есть питание контроллера |

||||

|

питания (PWR) |

0 |

Питания контроллера нет |

||||

|

Индикатор |

1 |

ПК находится в режиме RUN или MONITOR |

||||

|

ПК находится в режиме PROGRAM или |

||||||

|

работы (RUN) |

0 |

|||||

|

случилась фатальная ошибка |

||||||

|

Индикаторы |

||||||

|

Индикатор |

1 |

Связь с внешними устройствами есть |

||||

|

1 |

состояния |

связи (COMM) |

||||

|

0 |

Нет связи с внешними устройствами |

|||||

|

контроллера |

||||||

|

Индикатор |

1 |

Произошла фатальная ошибка (работа ПК |

||||

|

прекращается) |

||||||

|

ошибки (ERR) |

||||||

|

Произошла нефатальная ошибка (работа ПК |

||||||

|

или опасности |

мигает |

|||||

|

(ALM) |

продолжается) |

|||||

|

0 |

Нормальная работа |

|||||

|

2 |

Индикаторы |

входов |

Отображают состояние входов |

|||

|

3 |

Индикаторы выходов |

Отображают состояние выходов |

||||

|

4 |

Переключатель связи |

Переключает режимы связи с периферийными |

||||

|

устройствами |

||||||

|

5 |

Аналоговые регуляторы |

Позволяют регулировать уставку аналогового тайме- |

||||

|

ра |

||||||

|

6 |

Входные клеммы питания |

Подключение питания 24 В постоянного тока |

||||

|

7 |

Клемма функционального за- |

Заземление для защиты от помех и уменьшения рис- |

||||

|

земления |

ка поражения током. |

|||||

|

8 |

Клемма защитного заземления |

Заземление для уменьшения риска поражения током. |

||||

|

9 |

Входные клеммы |

Подключаются к входным цепям |

||||

|

10 |

Выходные клеммы |

Подключаются к выходным цепям |

||||

|

11 |

Отсек для батареи |

В нем находится батарея |

||||

|

Подключение стандартных устройств для програм- |

||||||

|

12 |

Периферийный порт |

мирования и связь по протоколу Host Link или связь |

||||

|

без протокола |

||||||

|

13 |

Порт RS-232C |

Используется для связи по протоколам Host Link, 1:1 |

||||

|

PC Link, 1:1 NT Link или для связи без протокола |

||||||

|

14 |

Гнездо расширения |

Гнездо для подключения дополнительных модулей |

||||

|

расширения |

||||||

Примечания:

1.Протокол Host Link используется для связи с компьютером. Осуществляется через адаптеры RS-232 и RS-422.

2.Связь 1:1 NT Link осуществляется через адаптер RS-232С. При этом контроллер можно подключить к программируемому терминалу.

3.Протокол 1:1 PC Link осуществляет связь с другими контроллерами CPM2*, CPM1*, CQM1, SRM1(-V2), C200HS/HX/HG/HE. При этом используется адаптер RS-232С.

4.Связь без протокола обеспечивает связь с компьютером без адаптеров.

Втабл. 2.2 представлены общие характеристики контроллера СРМ2А-30CDR.

15

Таблица 2.2

|

Параметр |

Характеристика |

|

|

Тип процессора |

СМР2А |

|

|

Высота/глубина модуля про- |

90/90 мм (AC220В) |

|

|

цессора |

||

|

30 (увеличивается до 100 за счет подключения дополнитель- |

||

|

Число входов/выходов |

||

|

ных модулей) |

||

|

Метод управления входа- |

Циклическое сканирование с прямым входом. Обработка с |

|

|

ми/выходами |

непосредственным обновлением |

|

|

Объем программной памяти |

4096 двухбайтных слов |

|

|

Длина команды |

1 шаг на команду, 1…5 слов на команду |

|

|

Типы команд |

Базовые: 14. |

|

|

Специальные: 105 типов, 185 команд |

||

|

Время исполнения |

Базовой команды: 0,64 мкс. |

|

|

Специальной команды: 7,8 мкс. |

||

|

Язык программирования |

Релейно-контактные схемы. Язык инструкций |

|

|

Счетчики/таймеры |

До 256 (общее количество): |

|

|

1-мс таймеры ТМНН; 10-мс таймеры TIMH(15); 100-мс тай- |

||

|

меры TIM; 1-с/10-с таймеры (в зависимости от установленно- |

||

|

го флага) TIML; декрементирующие счетчики CNT; ревер- |

||

|

сивные счетчики CNTR(12) |

||

|

Часы реального времени |

Показывают год, месяц, день недели, час, минуты и секунды |

|

|

(питается от встроенной батареи резервного питания) |

||

|

Энергонезависимое питание |

Память FLASH: программа и память DM только для чтения. |

|

|

Батарея резервного питания – срок службы – 5 лет |

||

|

Аналоговые уставки |

Две уставки (от 0 до 200 – двоично-десятичные) |

|

|

Диагностика |

Есть |

|

|

Защита паролем |

Есть |

|

|

Журнал ошибок |

Есть |

|

|

Встроенные RS-232C и пери- |

Есть |

|

|

ферийный порты |

Host Link, 1:1 РС Link, 1:1 NT Link, CompoBus/S (Slave) |

|

|

Сетевые протоколы |

||

|

Специальные функции (за счет |

Аналоговый ввод/вывод; Модуль температурных датчиков; |

|

|

подключения дополнительных |

Высокоскоростные счетчики (до 20 кГц) |

|

|

модулей) |

Импульсный выход (до 10 кГц) |

2.4. Подключение входных сигналов

Общая характеристика входов контроллера представлена в табл. 2.3.

|

Таблица 2.3 |

||||

|

Параметр |

Входы |

Значение |

||

|

Входное напряжение |

Все |

24В, постоянный ток |

||

|

00000 |

– 00001 |

8 мА |

||

|

Входной ток |

00002 – 00006 |

6 мА |

||

|

00007 |

и другие |

5 мА |

||

|

Напряжение уровня логической 1 |

00000 |

– 00001 |

Минимум 17 В, 5 мА |

|

|

00002 |

и другие |

Минимум 14,5 В, 1 мА |

||

|

Напряжение уровня логического 0 |

Все |

Максимум 5 В, 1мА |

16

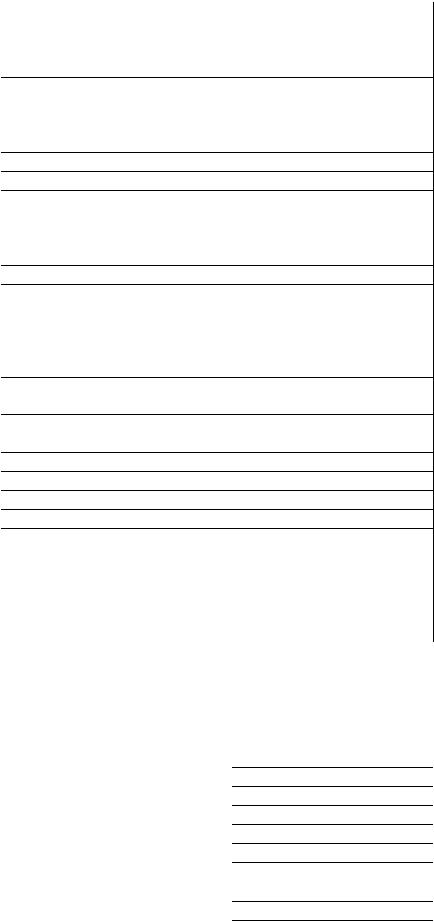

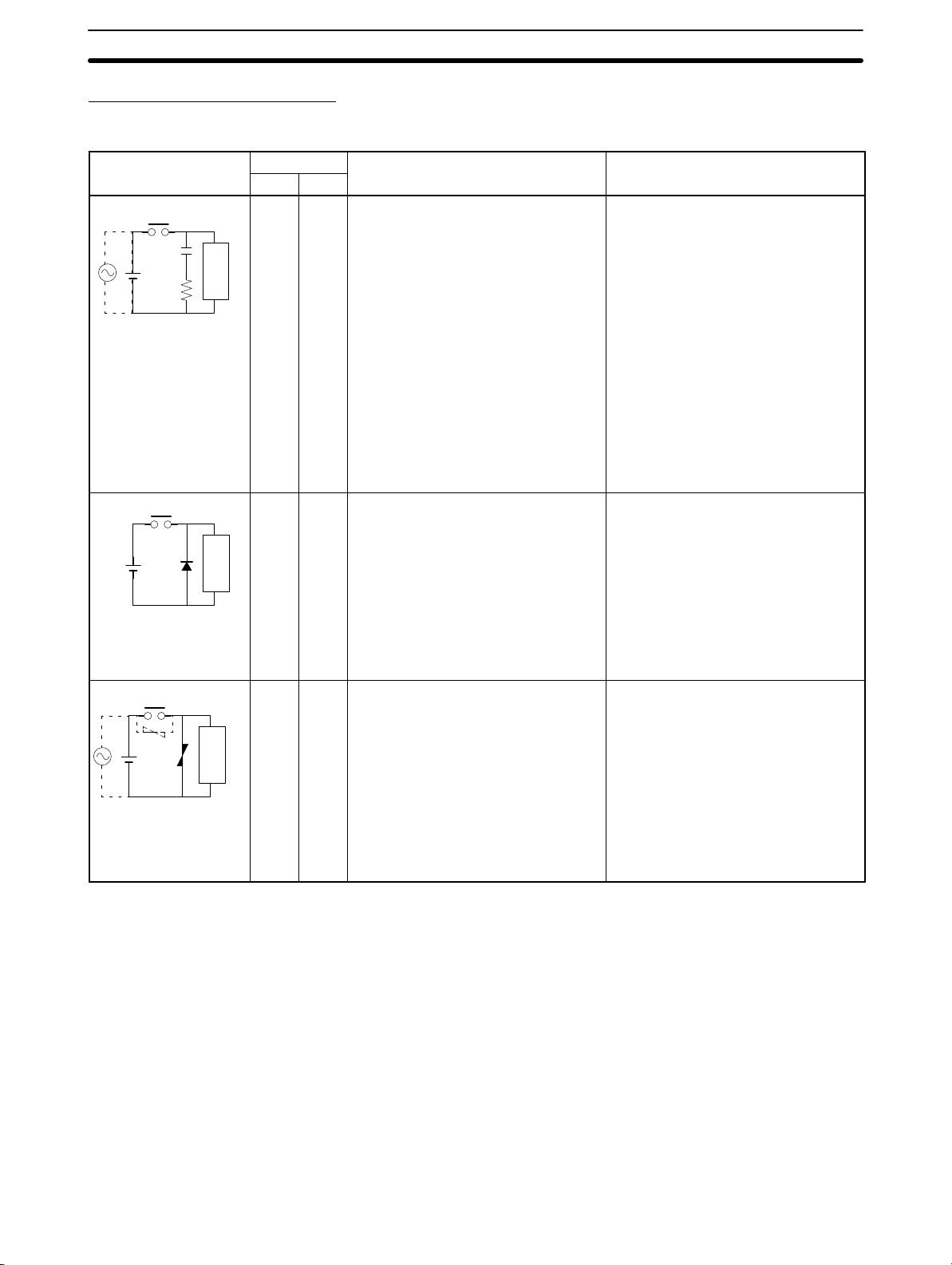

На рис. 2.2 представлены функциональные схемы входов контроллера.

а)

Рис. 2.2. Функциональные схемы входов 00000 – 00001 (а), 00002 – 00006 (б), 00007 – 00011 и 00100 – 00105 (в)

б)

в)

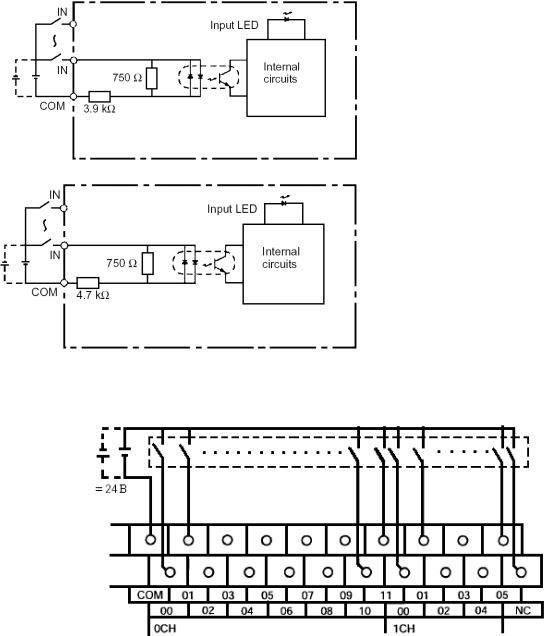

На рис. 2.3 дана схема подключения входов к клеммнику контроллера.

Рис. 2.3. Схема подключения входных сигналов для CPM2A-30CDR

17

На 24 входа имеется только одна общая точка. При этом внешний источник питания подсоединяется одним полюсом к общей точке COM1, а другим – к используемому входу контроллера (полярность не имеет значения).

2.5. Подключение выходных сигналов

Общая характеристика выходов контроллера представлена в табл. 2.4. Таблица 2.4

|

Параметр |

Значение |

|

Тип выхода |

Все выходы релейные |

|

Максимальная нагрузка |

2 А, 5 В постоянного тока |

|

Минимальная нагрузка |

10 мА, 5 В постоянного тока |

|

Прочность реле |

Электрическая: 300 000 операций. |

|

Механическая: 20 000 000 операций |

|

|

Задержка включения в 1 |

Максимум 15 мс. |

|

Задержка выключения в 0 |

Максимум 15 мс. |

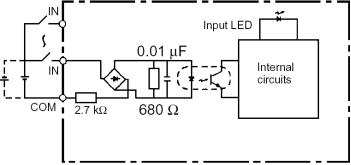

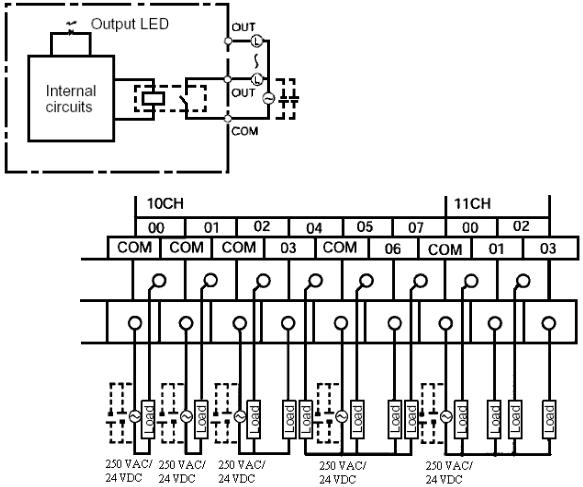

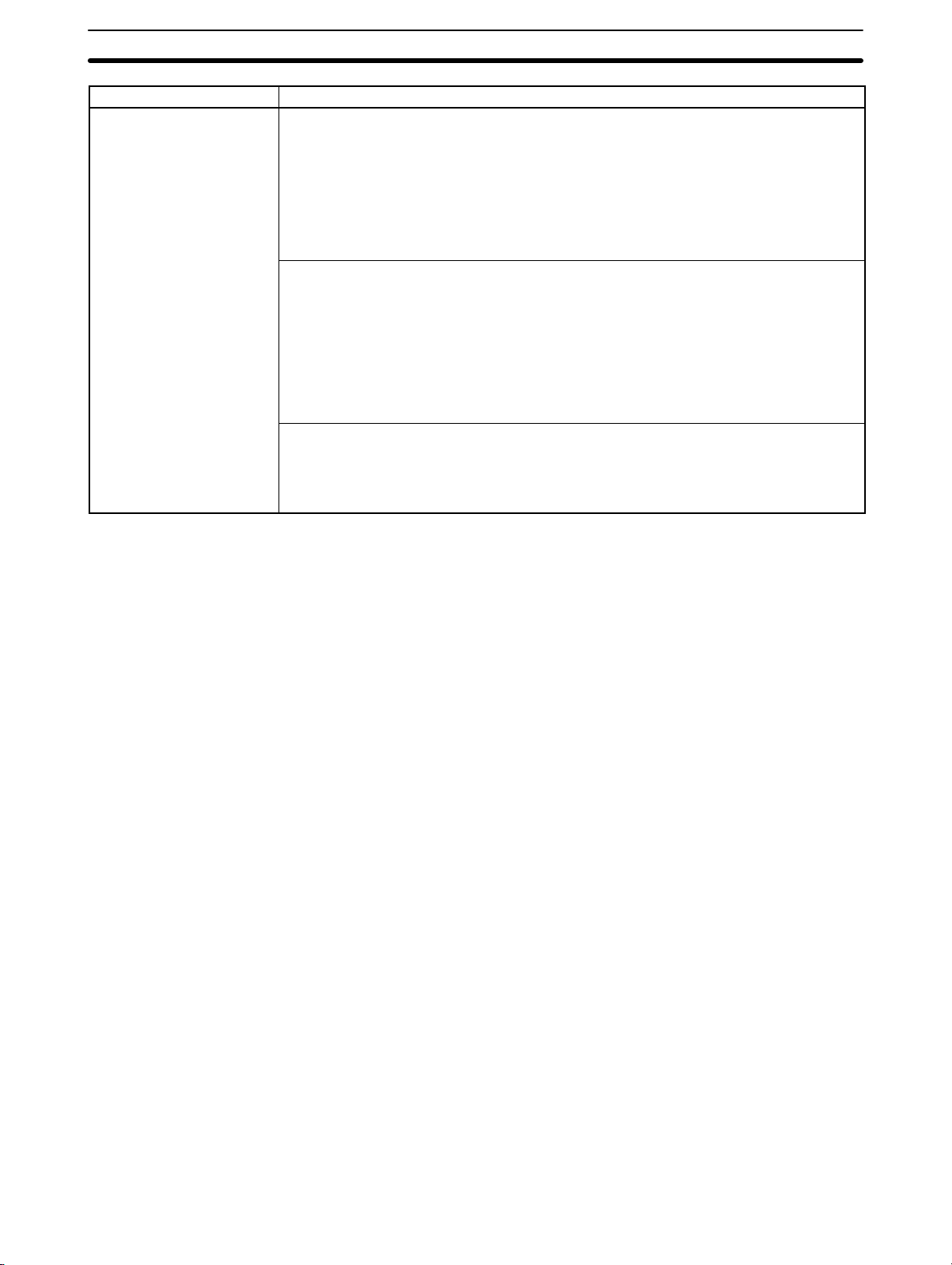

Выходы имеют функциональную схему, представленную на рис. 2.4. На рис. 2.5 приведена схема подключения выходных сигналов к клеммнику контроллера.

Рис. 2.4. Функциональная схема выходов

Рис. 2.5. Схема подключения выходных сигналов контроллера CPM2A

18

У выходов есть свои общие точки (см. рис. 2.5): СОМ1 – выход 01000; СОМ2 – выход 01001;

СОМ3 – выходы 01002, 01003; СОМ4 – выходы 01004 – 01007; СОМ5 – выходы 01100 – 01103; СОМ6 – выходы 01104 – 01107.

2.6.Распределение памяти контроллера

Втабл. 2.5 представлена карта памяти контроллера.

|

Таблица 2.5 |

||||

|

Область памяти |

Слова |

Биты |

Пояснения |

|

|

Область |

IR000 – IR009 |

IR00000 – IR00915 |

По этим адресам можно |

|

|

входов |

(10 слов) |

(160 бит) |

обращаться к внешним |

|

|

IR1 |

Область |

IR010 – IR019 |

IR01000 – IR01915 |

входам/выходам |

|

выходов |

(10 слов) |

(160 бит) |

||

|

Рабочая |

IR020 – IR049 |

IR02000 – IR04915 |

Эти биты можно использо- |

|

|

область |

IR200 – IR227 |

IR20000 – IR22715 |

вать в программе как внут- |

|

|

(58 слов) |

(928 бит) |

ренние переменные |

||

|

SR |

SR228 – SR255 |

SR22800 – SR25515 |

Флаги и биты контроля |

|

|

(28 слов) |

(448 бит) |

|||

|

– |

TR0 – TR7 |

Для временного хранения |

||

|

TR |

информации при ветвлении |

|||

|

в одном шаге программы |

||||

|

HR2 |

HR00 – HR19 |

HR0000 – HR1915 |

Энергонезависимая память |

|

|

(320 бит) |

(сохраняет данные после |

|||

|

выключения питания) |

||||

|

AR2 |

AR00 – AR23 |

AR0000 – AR2315 |

Флаги и биты контроля |

|

|

(384 бит) |

||||

|

LR00 – LR15 |

LR0000 – LR1515 |

Для прямой связи контрол- |

||

|

LR1 |

(256 бит) |

леров между собой |

||

|

Таймеры 2 |

TC000 – TC255 |

Одни и те же номера ис- |

||

|

(номера таймеров/счетчиков)3 |

пользуются для таймеров и |

|||

|

/счетчики |

счетчиков |

|||

|

Чтение |

DM0000 – DM1999 |

– |

В памяти данных можно |

|

|

обращаться только к сло- |

||||

|

DM2022 – DM 2047 |

||||

|

/запись2 |

вам. При выключении пи- |

|||

|

(2026 слов) |

тания данные теряются |

|||

|

Журнал |

DM2000 – DM2001 |

– |

Используется для хранения |

|

|

DM |

ошибок2 |

(22 слова) |

информации об ошибках |

|

|

Только |

DM6144 – DM6599 |

– |

Информация не может |

|

|

чтение4 |

(456 слов) |

быть изменена программой |

||

|

Установки |

DM6600 – DM6655 |

– |

Используется для хранения |

|

|

ПК4 |

(56 слов) |

различных установок кон- |

||

|

троллера |

19

Примечания:

1.Слова из областей памяти IR и LR могут использоваться как рабочие переменные программ, если они не используются по прямому назначению.

2.Содержимое областей памяти HR, AR, TC (таймеры/счетчики), DM (чтение/запись) сохраняются за счет батарейки, встроенной в контроллер. В ее отсутствие данные теряются и при включении принимаются значения по умолчанию.

3.Когда к области TC (таймеры/счетчики) обращаются как к слову, происходит обращение к регистру, в котором хранится текущее значение таймера/счетчика, а если как к биту, то к флагу завершения (Completion Flag).

4.Данные из области DM6144 – DM6655 не могут быть изменены из программы, но их можно редактировать с помощью устройства для программирования. Программа и данные из области DM6144 – DM6655 сохраняются во Flash-памяти.

5.Если используется символ #, то это означает, что используется константа в выбранном формате (табл. 2.6).

|

Таблица 2.6 |

|||||

|

Обозначение |

Размер |

Формат |

Примечания |

||

|

BOOL |

1 |

бит |

двоичный |

Используется для обозначения контактов и катушек |

|

|

CHANNEL |

≥1 слова |

любой |

Одиночное слово или более длинное значение без |

||

|

знака |

|||||

|

DINT |

2 |

слова |

двоичный |

Двоичное целое число |

|

|

INT |

1 |

слово |

двоичный |

Целое число |

|

|

LINT |

4 |

слова |

двоичный |

Длинное целое число |

|

|

REAL |

2 |

слова |

IEEE |

Числа с плавающей точкой. 32-разрядный формат |

|

|

IEEE |

|||||

|

десятичный |

Используется для числовых операндов, которые обо- |

||||

|

NUMBER |

– |

значаются с «#», «&», «+» или «–». Они могут ис- |

|||

|

пользоваться в двоичном или BCD-формате |

|||||

|

UDINT |

2 |

слова |

двоичный |

Двоичное целое число без знака |

|

|

UDINT_BCD |

2 |

слова |

двоично- |

Двоичное целое число BCD-формата без знака |

|

|

десятичный |

|||||

|

UINT |

1 |

слово |

двоичный |

Целое число без знака |

|

|

UINT_BCD |

1 |

слово |

двоично- |

Целое число BCD-формата без знака |

|

|

десятичный |

|||||

|

ULINT |

4 |

слова |

двоичный |

Длинное целое число без знака |

|

|

ULINT_BCD |

4 |

слова |

двоично- |

Длинное целое число BCD-формата без знака |

|

|

десятичный |

2.7. Система команд контроллера СРМ2А

Ниже приводятся команды, используемые при программировании контроллера. Для команд, перед которыми есть символ @, есть модификация, срабатывающая по переднему фронту управляющего сигнала. Если перед такой командой поставить символ @, то она будет срабатывать при поступлении переднего фронта управляющего сигнала в течение одного скана программы. Команды, имеющие код, представлены в табл. 2.7. В табл. 2.8 представлены команды, не имеющие кода.

20

Таблица 2.7

|

Лев. |

Правый разряд |

|||||||||

|

разр. |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

0 |

NOP |

END |

IL |

ILC1 |

JMP |

JMC |

@FAL |

FALS |

STEP |

SNXT |

|

1 |

SET |

KEEP |

CNTR |

DIFU |

DIFD |

TIMH |

@WSFT |

@ASFT |

– |

– |

|

2 |

CMP |

@MOV |

@MVN |

@BIN |

@BCD |

@ASL |

@ASR |

@ROL |

@ROR |

@COM |

|

3 |

@ADD |

@SUB |

@MUL |

@DIV |

@ANDW |

@ORW |

@XORW |

@XNRW |

@INC |

@DEC |

|

4 |

@STC |

@CLC |

– |

– |

– |

– |

@MSG |

@RXD |

@TXD |

– |

|

5 |

@ADB |

@SBB |

@MLB |

@DVB |

@ADDL |

@SUBL |

@MULL |

@DIVL |

@BINL |

@BCDL |

|

6 |

CMPL |

@INI |

@PRV |

@CTBL |

@SPED |

@PULS |

@SCL |

@BCNT |

@BCMP |

@STIM |

|

7 |

@XFER |

@BSET |

– |

@XCHG |

@SLD |

@SRD |

@MLPX |

@DMPX |

@SDEC |

– |

|

8 |

@DIST |

@COLL |

@MOVB |

@MOVD |

@SFTR |

@TCMP |

@ASC |

– |

– |

@INT |

|

9 |

– |

@SBS |

SBN |

RET |

– |

– |

– |

@IORF |

– |

@MCRO |

Таблица 2.8

|

AND |

AND |

AVG |

AVERAGE VALUE |

|

|

AND NOT |

AND NOT |

@FCS |

FCS CALCULATE |

|

|

AND LD |

AND LOAD |

@MAX |

FIND MAXIMUM |

|

|

CNT |

COUNTER |

@MIN |

FIND MINIMUM |

|

|

LD |

LOAD |

@NEG |

2’S COMPLEMENT |

|

|

LD NOT |

LOAD NOT |

PID |

PID CONTROL |

|

|

OR |

OR |

@PWM |

PULSE WITH VARIABLE DUTY RATIO |

|

|

OR LD |

OR LOAD |

@SCL2 |

SIGNED BINARY TO BCD SCALLING |

|

|

OR NOT |

OR NOT |

@SCL3 |

BCD TO SIGNED BINARY SCALLING |

|

|

OUT |

OUTPUT |

@SEC |

HOURS TO SECONDS |

|

|

OUT NOT |

OUTPUT NOT |

@SRCH |

DATA SEARCH |

|

|

RSET |

RESET |

@SUM |

SUM |

|

|

SET |

SET |

@XFRB |

TRANSFER BITS |

|

|

TIM |

TIMER |

ZCP |

AREA RANGE COMPARE |

|

|

TIML |

LONG TIMER |

ZCPL |

DOUBLE AREA RANGE COMPARE |

|

|

TMHH |

VERY HIGHSPEED TIMER |

@STUP |

CHANGE RS-232 SETUP |

|

|

@ACC |

ACCELERATION CON- |

SYNC |

SYNHRONIZED PULSE CONTROL |

|

|

TROL |

||||

2.8. Примеры использования команд

Далее приведены примеры использования некоторых команд (для более полного изучения системы команд необходимо воспользоваться руководством по программированию контроллеров SYSMAC CPM2A).

21

AND, ANDLD, ANDNOT, LD, LDNOT, OR, ORLD, ORNOT – команды релей-

но-контактной схемы

|

Области операндов |

В |

Бит |

IR, SR, AR, HR, TC, LR, TR |

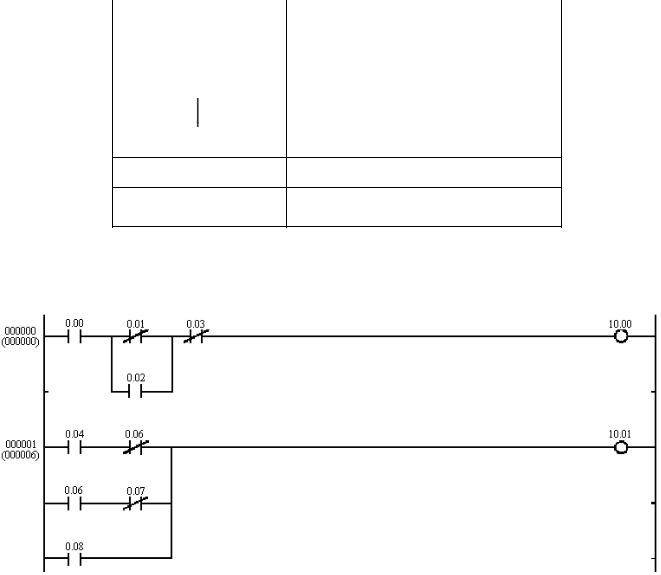

Ограничений количества любой из этих команд или порядка их применения нет, если программа вмещается в отведенную память. Ниже приведены примеры использования этих команд.

Контроллер использует два языка программирования: язык релейноконтактных схем РКС (лестничных диаграмм) и язык инструкций.

В табл. 2.9 представлен внешний вид элементов, используемых при составлении релейно-контактных схем.

Таблица 2.9

|

Элемент |

Описание |

|

Замыкающий контакт |

|

|

Размыкающий контакт |

|

|

Соединительная вертикальная линия |

|

|

Соединительная вертикальная линия |

|

|

Выход |

Выход с инверсией

Функциональный блок

На рис. 2.6 приведен пример использования рассматриваемых команд на языке РКС, а в табл. 2.10 представлена та же программа на языке инструкций.

Рис. 2.6. Пример программы на языке РКС

22

Таблица 2.10

|

Адрес |

Инструкция |

Операнд |

Адрес |

Инструкция |

Операнд |

|

00000 |

LD |

0.00 |

00007 |

ANDNOT |

0.06 |

|

00001 |

LDNOT |

0.01 |

00008 |

LD |

0.06 |

|

00002 |

OR |

0.02 |

00009 |

ANDNOT |

0.07 |

|

00003 |

ANDLD |

00010 |

ORLD |

||

|

00004 |

ANDNOT |

0.03 |

00011 |

OR |

0.08 |

|

00005 |

OUT |

10.00 |

00012 |

OUT |

10.01 |

|

00006 |

LD |

0.04 |

Обозначение таймера TIM в программе имеет вид:

|

Области операндов |

N |

Номер таймера |

# |

|

SV |

Заданное значение (сло- |

IR, SR, AR, HR, LR, DM, |

|

|

во BCD) |

# |

Если время включения входного сигнала меньше времени уставки (рис. 2.7), то выход таймера не включается.

Фаза завершения

Условие выполнения

Рис. 2.7. Циклограмма работы таймера

Заданные значения лежат в диапазоне 000,0…999,9. Десятичная точка не вводится. Каждый номер ТС от 000 до 255 (номер записывается в десятичном формате) можно использовать в качестве определителя только для одной команды таймера или счетчика. ТС 000–ТС 015 рекомендуется использовать в команде задания TIM, только если они не требуются для команды TIMH(15).

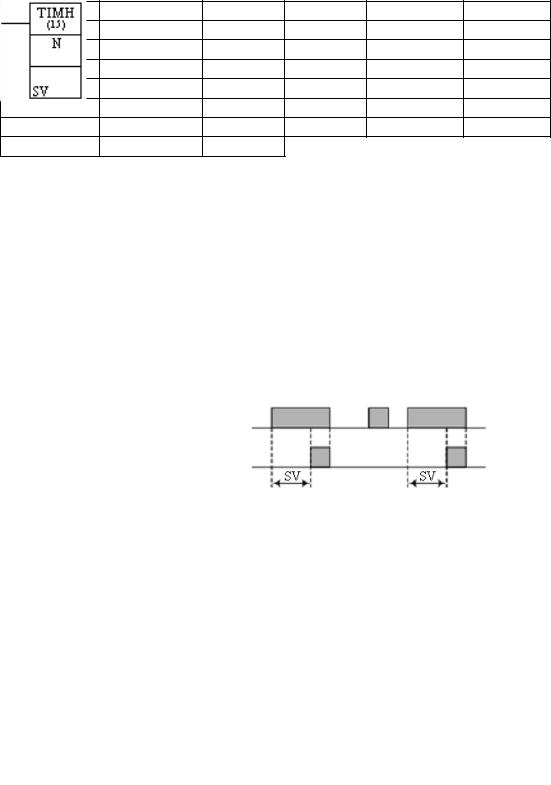

Обозначение высокоскоростного таймера TIMH(15) в программе имеет вид:

|

Области операндов |

N |

Номер таймера |

# |

|

SV |

Заданное значение (сло- |

IR, SR, AR, HR, LR, DM, |

|

|

во BCD) |

# |

Заданные значения лежат в диапазоне 00,00…99,99 (хотя можно ввести 00,00 и 00,01. 00,00 запретит таймер, т.е. сразу включает флаг завершения, а 00,01 не будет надежно считан). Десятичная точка не вводится.

23

Соседние файлы в папке АТПП-2

- #

- #

- #

- #

OPERATION MANUAL

Programmable Controllers

SYSMAC

CPM2A

Cat. No. W352-E1-07

CPM2A Programmable Controllers

Operation Manual

Revised November 2005

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3… 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

vi

TABLE OF CONTENTS

PRECAUTIONS xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CPM2A 24-VDC CPU Unit Conformance to NK Standards xxiii. . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 CPM2A Features and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Basic System Configurations 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Structure and Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Functions Listed by Usage 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Comparison with the CPM1A 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Preparation for Operation 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Unit Specifications and Components 29. . . . . . . . . . . . . . . .

2-1 Specifications 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Unit Components 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Installation and Wiring 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Design Precautions 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Selecting an Installation Site 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Installing the CPM2A 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Wiring and Connections 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Using a Programming Console 89. . . . . . . . . . . . . . . . . . . . .

4-1 Compatible Programming Consoles 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Programming Console Operations 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Programming Example 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Test Runs and Error Processing 127. . . . . . . . . . . . . . . . . . . .

5-1 Initial System Checks and Test Run Procedure 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Self-diagnostic Functions 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Programming Console Operation Errors 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Programming Errors 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Troubleshooting Flowcharts 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Maintenance Inspections 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Battery Replacement 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Expansion Memory Unit 145. . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Overview 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Specifications and Nomenclature 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Handling 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

TABLE OF CONTENTS

Appendices

A Standard Models 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Dimensions 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

About this Manual:

The CPM2A is a compact, high-speed Programmable Controller (PC) designed for control operations in

systems requiring from 10 to 120 I/O points per PC. There are two manuals describing the setup and

operation of the CPM2A: The CPM2A Operation Manual (this manual) and the CPM1/CPM1A/CPM2A/

CPM2C/SRM1(-V2) Programming Manual (W353). (The CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2)

Programming Manual is referred to as simply the Programming Manual in this manual.)

This manual describes the system configuration and installation of the CPM2A and provides a basic

explanation of operating procedures for the Programming Consoles. It also introduces the capabilities of

CX-Programmer, the SYSMAC Support Software (SSS) and SYSMAC-CPT Support Software. Read this

manual first to acquaint yourself with the CPM2A.

The Programming Manual (W353) provides detailed descriptions of the CPM2A’s programming functions

and application methods for Expansion Units. The SYSMAC Support Software Operation Manuals:

Basics and C-series PCs (W247 and W248) provide descriptions of SSS operations for the CPM2A and

other SYSMAC C-series PCs. The WS02-CXPjj-E CX-Programmer Operation Manual (W414) provides details of operations for the WS02-CXPjj-E CX-Programmer. The SYSMAC-CPT Support Soft-

ware Quick Start Guide (W332) and User Manual (W333) provide descriptions of ladder diagram operations in the Windows environment.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the CPM2A.

Section 1 gives a brief overview of the steps involved in developing of a CPM2A System, describes the

possible system configurations, and describes the CPM2A’s special features and functions.

Section 2 provides the technical specifications of the Units that go together to create a CPM2A PC and

describes the main components of the Units.

Section 3 describes how to install and wire a CPM2A PC.

Section 4 describes how to connect the Programming Console, and how to perform the various program-

ming operations.

Section 5 describes how to perform a test run and how to diagnose and correct the hardware and software errors that can occur during PC operation.

Section 6 describes how to use the CPM1-EMU01-V1 Expansion Memory Unit. Follow the handling precautions and procedures to properly use the Unit.

Appendix A provides tables of CPM2A Units and related products.

Appendix B provides the dimensions of CPM2A Units.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

БББББББББББББББББББББББББББББББ

a period of one year (or other period if specified) from date of sale by OMRON.

БББББББББББББББББББББББББББББББ

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

БББББББББББББББББББББББББББББББ

NON–INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

БББББББББББББББББББББББББББББББ

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

БББББББББББББББББББББББББББББББ

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

БББББББББББББББББББББББББББББББ

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

БББББББББББББББББББББББББББББББ

STRICT LIABILITY.

БББББББББББББББББББББББББББББББ

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

БББББББББББББББББББББББББББББББ

which liability is asserted.

БББББББББББББББББББББББББББББББ

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

БББББББББББББББББББББББББББББББ

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

БББББББББББББББББББББББББББББББ

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

БББББББББББББББББББББББББББББББ

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

БББББББББББББББББББББББББББББББ

the combination of products in the customer’s application or use of the products.

БББББББББББББББББББББББББББББББ

At the customer’s request, OMRON will provide applicable third party certification documents identifying

БББББББББББББББББББББББББББББББ

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

БББББББББББББББББББББББББББББББ

complete determination of the suitability of the products in combination with the end product, machine,

БББББББББББББББББББББББББББББББ

system, or other application or use.

БББББББББББББББББББББББББББББББ

The following are some examples of applications for which particular attention must be given. This is not

БББББББББББББББББББББББББББББББ

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

БББББББББББББББББББББББББББББББ

uses listed may be suitable for the products:

БББББББББББББББББББББББББББББББ

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

БББББББББББББББББББББББББББББББ

or uses not described in this manual.

БББББББББББББББББББББББББББББББ

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

БББББББББББББББББББББББББББББББ

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

БББББББББББББББББББББББББББББББ

industry or government regulations.

БББББББББББББББББББББББББББББББ

• Systems, machines, and equipment that could present a risk to life or property.

БББББББББББББББББББББББББББББББ

Please know and observe all prohibitions of use applicable to the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

БББББББББББББББББББББББББББББББ

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

БББББББББББББББББББББББББББББББ

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

БББББББББББББББББББББББББББББББ

consequence thereof.

xii

Disclaimers

CHANGE IN SPECIFICATIONS

БББББББББББББББББББББББББББББББ

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

БББББББББББББББББББББББББББББББ

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

БББББББББББББББББББББББББББББББ

key specifications for your application on your request. Please consult with your OMRON representative

БББББББББББББББББББББББББББББББ

at any time to confirm actual specifications of purchased products.

БББББББББББББББББББББББББББББББ

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

БББББББББББББББББББББББББББББББ

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

БББББББББББББББББББББББББББББББ

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

БББББББББББББББББББББББББББББББ

must correlate it to actual application requirements. Actual performance is subject to the OMRON

БББББББББББББББББББББББББББББББ

Warranty and Limitations of Liability.

БББББББББББББББББББББББББББББББ

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

БББББББББББББББББББББББББББББББ

ERRORS AND OMISSIONS

xiii

xiv

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller. You must read this section and understand the information contained before attempting to set up or operate a

PC system.

1 Intended Audience xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xvi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CPM2A 24-VDC CPU Unit Conformance to NK Standards xxiii. . . . . . . . . . . . . . . . . . . . . . . . . . .

xv

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

5Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), including the following items, in order to ensure safety in the system

if an abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

xvi

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

Operating Environment Precautions

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

WARNING When transferring programs to other nodes, or when making changes to I/O

!

memory, confirm the safety of the destination node before transfer. Not doing so

may result in injury.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, the input signals may not be readable.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

!

torque specified in the operation manual. The loose screws may result in burning

or malfunction.

4

Caution When connecting the PC to a personal computer or other peripheral device, ei-

!

ther ground the 0-V side of the PC or do not ground the PC at all. Although some

grounding methods short the 24-V side, as shown in the following diagram, never do so with the PC.

INCORRECT Grounding: Shorting the 24-V side of the Power Supply

Non-isolated DC

0 V

power supply

0 V 0 V

PC

24 V

4 Operating Environment Precautions

Caution Do not operate the control system in the following places:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in tempera-

ture.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Peripheral device

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

xvii

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC System can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC System.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always connect to a ground such that the grounding resistance does not exceed 100 Ω when installing the Units. Not connecting to the correct ground

may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

5Application Precautions

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Construct a control circuit so that power supply for the I/O circuits does not

come ON before power supply for the Unit. If power supply for the I/O circuits

comes ON before power supply for the Unit, normal operation may be temporarily interrupted.

• If the operating mode is changed from RUN or MONITOR mode to PROGRAM

mode, with the IOM Hold Bit ON, the output will hold the most recent status. In

such a case, ensure that the external load does not exceed specifications. (If

operation is stopped because of an operation error (including FALS instructions), the values in the internal memory of the CPU Unit will be saved, but the

outputs will all turn OFF.)

• Always use the power supply voltage specified in the operation manuals. An

incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

xviii

Application Precautions

5

• Do not apply voltages to the input terminals in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the output terminals in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Install the Unit properly as specified in the operation manual. Improper installation of the Unit may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

• Be sure to leave the labels attached at the time of shipment on the CPM1 or

CPM2A when wiring in order to prevent wiring cuttings from entering the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Be sure to perform wiring in accordance with the relevant operation manual.

Incorrect wiring may result in burning.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• Double-check all the wiring before turning ON the power supply. Incorrect wiring may result in burning.

• Be sure that the terminal blocks, expansion cables, and other items with locking devices are properly locked into place. Improper locking may result in malfunction.

• Be sure that terminal blocks and connectors are connected in the specified direction with the correct polarity. Not doing so may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM and HR Areas required for resuming operation. Not doing so may result

in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• Do not short the battery terminals or charge, disassemble, heat, or incinerate

the battery. Do not subject the battery to strong shocks. Doing any of these

may result in leakage, rupture, heat generation, or ignition of the battery. Dispose of any battery that has been dropped on the floor or otherwise subjected

to excessive shock. Batteries that have been subjected to shock may leak if

they are used.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching the Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or

damage.

• Do not touch the expansion I/O connecting cable while the power is being supplied in order to prevent any malfunction due to static electricity.

xix

• When using a thermocouple-input type Temperature Sensor Unit, observe the

following precautions:

• Do not remove the cold junction compensator attached at the time of deliv-

ery. If the cold junction compensator is removed the Unit will not be able to

measure temperatures correctly.

• Each of the input circuits is calibrated with the cold junction compensator

attached to the Unit. If the Unit is used with the cold junction compensator

from other Units, the Unit will not be able to measure temperatures correctly.

• Do not touch the cold junction compensator. Doing so may result in incor-