Анализ «Расширенный» содержит перечень наиболее часто встречающихся загрязнителей воды, вне зависимости от источника, и включает 31 показатель:

- органолептические: мутность, цветность, запах, привкус;

- общехимические: рН, жесткость, окисляемость перманганатная, минерализация, электропроводность, щелочность общая, щелочность свободная;

- катионы: железо, аммоний, марганец, калий, магний, кальций, алюминий, натрий;

- анионы: фториды, хлориды, нитраты, сульфаты, карбонаты, гидрокарбонаты;

- тяжелые металлы и металлоиды: медь, мышьяк, свинец, кадмий, цинк, стронций.

Данный набор рекомендуется, в первую очередь, владельцам колодцев и скважин. Помимо катионов и анионов, органолептических и общих химических параметров содержит перечень основных тяжелых металлов и метталоидов. Перед покупкой системы водоподготовки рекомендуем провести исследование воды с данным перечнем загрязнителей. Ориентируясь на полученную информацию, Вы сможете подобрать оборудование водоочистки с эффективностью до 98%, а так же корректно его настроить. Если вода из Вашего источника имеет выраженный запах сероводорода (запах тухлых яиц), рекомендуем дополнительно проверить воду на содержание сероводорода.

Если Вы самостоятельно отберете пробу и доставите её в один из пунктов приема, то получите скидку 600 руб, и стоимость исследования составит 6 600 руб.

Преимущества:

- Точность определений

- Подходит для подбора водоочистного оборудования

- Подходит для колодцев и скважин

- Содержит перечень тяжелых металлов

- Позволяет оценить эффективность фильтрующей загрузки в фильтре и всей системы в целом

- Позволяет корректно и экономично настроить водоочистное оборудование

- Срок выполнения — 5-6 рабочих дней

Важные детали:

- Не включает определение опасных органических веществ

FLECK® 9000/9100/9500

SERVICE MANUAL

www.pentairaqua.com

|

TABLE OF CONTENTS |

|

|

JOB SPECIFICATION SHEET………………………………………… |

2 |

|

EQUIPMENT CONFIGURATION…………………………………….. |

2 |

|

INSTALLATION & START-UP……………………………………….. |

3 |

|

9000/9100/9500 (3200 SERIES) ELECTRO MECHANICAL |

|

|

TIMER ASSEMBLY………………………………………………….. |

6 |

|

POWER HEAD ASSEMBLY……………………………………………. |

8 |

|

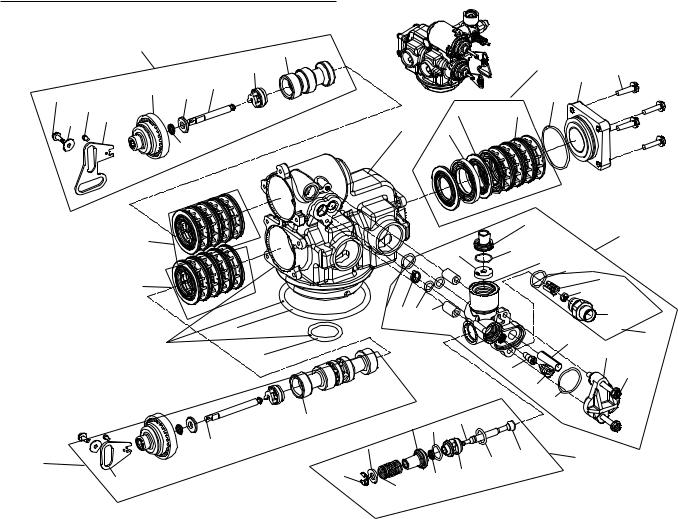

9000 CONTROL VALVE ASSEMBLY……………………………… |

10 |

|

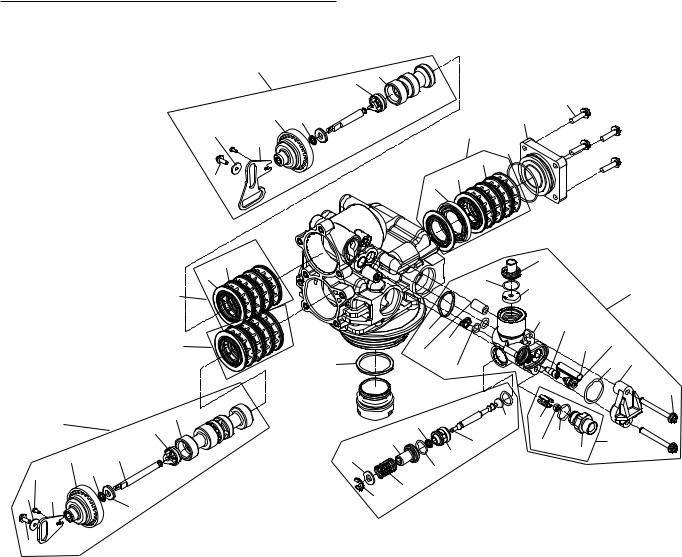

9100 CONTROL VALVE ASSEMBLY……………………………… |

13 |

|

9500 CONTROL VALVE ASSEMBLY……………………………… |

16 |

|

1600 BRINE VALVE SYSTEM (FOR 9500)……………………… |

19 |

|

1700 BRINE VALVE SYSTEM (FOR 9500)……………………… |

20 |

|

1710 BRINE VALVE SYSTEM (FOR 9500)……………………… |

21 |

|

3/4-INCH METER ASSEMBLY…………………………………….. |

22 |

|

1-INCH METER ASSEMBLY………………………………………… |

23 |

|

1-INCH METER ASSEMBLY………………………………………… |

24 |

|

1-1/2 INCH METER ASSEMBLY …………………………………. |

25 |

|

9000 SECOND TANK ASSEMBLY………………………………… |

26 |

|

9100 SECOND TANK ASSEMBLY………………………………… |

27 |

|

9500 SECOND TANK ASSEMBLY………………………………… |

28 |

|

2300 SAFETY BRINE VALVE……………………………………….. |

29 |

|

2310 SAFETY BRINE VALVE……………………………………….. |

30 |

|

2310 SAFETY BRINE VALVE……………………………………….. |

31 |

|

2350 SAFETY BRINE VALVE……………………………………….. |

32 |

|

BYPASS VALVE ASSEMBLY (METAL)…………………………… |

33 |

|

BYPASS VALVE ASSEMBLY (PLASTIC)………………………… |

34 |

|

GENERAL SERVICE HINTS FOR METER CONTROL………. |

35 |

|

TROUBLESHOOTING…………………………………………………. |

36 |

|

9000/9100/9500 METER FLOW DATA………………………….. |

37 |

|

9000/9100/9500 INJECTOR FLOW DATA (1600 SERIES |

|

|

INJECTORS)………………………………………………………… |

38 |

|

9500 INJECTOR FLOW DATA (1600 &1700 SERIES |

|

|

INJECTORS)………………………………………………………… |

39 |

|

9000 CONTROL DIMENSIONS…………………………………….. |

40 |

|

9100 CONTROL DIMENSIONS…………………………………….. |

41 |

|

9500 CONTROL DIMENSIONS…………………………………….. |

42 |

|

WATER CONDITIONER FLOW DIAGRAMS……………………. |

43 |

|

9000/9500 WIRING DIGRAM……………………………………….. |

45 |

|

SERVICE ASSEMBLIES………………………………………………. |

46 |

CALIFORNIA PROPOSITION 65 WARNING

WARNING: This product contains chemicals known to the State of California to cause cancer or birth defects or other reproductive harm.

2 • FLECK® 9000/9100/9500 Service Manual

JOB SPECIFICATION SHEET

Job Number:_________________________________________

Model Number:_______________________________________

Water Test: __________________________________________

Capacity Per Unit:_____________________________________

Mineral Tank Size:_ ________ Diameter:_______Height:_ ______

Brine Tank Size and Salt Setting per Regeneration:__________

9000/9100/9500 Control Valve Specifications:

1.Type of Timer:

A.82 minute available regeneration time, 1/15 RPM

B.164 minute available regeneration time, 1/30 RPM

2.Meter Size:

A.3/4- inch Std Range (125 — 2,100 gallon setting)

B.3/4-inch Ext Range (625 — 10,625 gallon setting)

C.1-inch Std Range (310 — 5,270 gallon setting)

D.1-inch Ext Range (1,150 — 26,350 gallon setting)

E.1-1/2 inches Std Range (625 — 10,625 gallon setting)

F.1-1/2 inches Ext Range (3,125 — 53,125 gallon setting)

3.Timer Gallon Setting:_ ______________________ Gallons

4.Regeneration Program Setting:

A.Backwash:____________________________ Minutes

B.Brine and Slow Rinse:___________________ Minutes

C.Rapid Rinse:___________________________ Minutes

D.Brine Tank Refill:_______________________ Minutes

5.Drain Line Flow Control:_______________________ gpm

6.Brine Refill Rate:_____________________________ gpm

7.Injector Size: ____________________________________

EQUIPMENT CONFIGURATION

Figure 1 9000/9100 Equipment Configuration

Figure 2 9500 Equipment Configuration

INSTALLATION & START-UP

Water Pressure

A minimum of 25 pounds (1.7 bar) of water pressure is required for regeneration valve to operate effectively.

Electrical Facilities

A continuous 115 volt, 60 Hertz current supply is required. Make certain the current supply is always hot and cannot be turned off with another switch.

Existing Plumbing

Condition of existing plumbing should be free from lime and iron buildup. Piping that is built up heavily with lime and/ or iron should be replaced. If piping is clogged with iron,

a separate iron filter unit should be installed ahead of the water softener.

Location Of Softener And Drain

The softener should be located close to a drain to prevent air breaks and back flow.

Bypass Valves

Always provide for the installation of a bypass valve.

CAUTION Water pressure is not to exceed 125 psi (8.6 bar), water temperature is not to exceed 110°F (43°C), and the unit cannot be subjected to

freezing conditions. Installation Instructions

1.Place the softener tank where you want to install the unit.

NOTE: Be sure the tank is level and on a firm base.

2.During cold weather, the installer should warm the valve to room temperature before operating.

3.Perform all plumbing according to local plumbing codes.

•Use a 1/2-inch minimum pipe size for the drain.

•Use a 3/4-inch drain line for backwash flow rates that exceed 7 gpm or length that exceeds 20 feet (6 m).

4.Both tanks must be the same height and diameter and filled with equal amounts of media.

5.The distributor tube must be flush with the top of each tank. Cut if necessary. Use only non-aerosol

silicone lubricant.

6.Lubricate the distributor o-ring seal and tank o-ring seal. Place the main control valve on one tank and the tank adapter on the second tank.

NOTE: If required, solder copper tubing for tank interconnection before assembling on the main control valve and tank adapter. Maintain a minimum of 1 inch distance between tanks on final assembly.

7.Solder joints near the drain must be done before connecting the Drain Line Flow Control fitting (DLFC). Leave at least 6 inches (152 mm) between the DLFC and solder joints when soldering pipes that are connected on the DLFC. Failure to do this could cause interior damage to DLFC.

8.Use only plumber tape on the drain fitting.

9.Be sure the floor under the salt storage tank is clean and level.

10.Place approximately 1 inch (25 mm) of water above the grid plate. If a grid is not utilized, fill to the top of the air check in the salt tank. Do not add salt to the brine tank at this time.

11.On units with a bypass, place in Bypass position.

12.Turn on the main water supply.

13.Open a cold soft water tap nearby and let water run a few minutes or until the system is free of foreign material (usually solder) resulting from the installation. Close the water tap when water runs clean.

14.Place the bypass In Service position and let water flow into the mineral tank. When water flow stops, slowly open a cold water tap nearby and let water run until air is purged from the unit. Then close tap.

15.Make all electrical connections according to codes. Plug the valve into an approved power source. Do not insert meter cable into the meter yet.

16.Tank one has control valve and tank two has adapter.

17.Look on the right side of the control valve, it has indicators showing which position the control valve is in during Regeneration and which tank is In Service.

NOTE: Make sure the meter cable is not inserted in the meter dome. Swing the timer out to expose the program wheel. To swing timer out, grab onto the lower right corner of timer face and pull outward.

Figure 3 Control Valve Position Indicators

61591 Rev A

Figure 4 Timer

FLECK® 9000/9100/9500 Service Manual • 3

INSTALLATION & STARTUP CONTINUED

19210 Rev D

Figure 5 Program Wheel

18.Cycle timer into backwash position. Turn manual knob so that the micro switch rides on the first set of pins. In this position the tanks switch (lower piston) and the control valve moves to the backwash position (upper piston). Wait until the positioning of upper and lower pistons stops before advancing the timer further. If advanced too fast the control will not home into the In Service position (it will not advance to any other position). To correct this, rotate the manual knob back to In Service and start again into backwash.

NOTE: Once valve positions itself into the backwash cycle, the homing circuit locks in.

19.With all the air backwashed, slowly cycle the timer to the brine position; rapid rinse; and brine tank refill. Wait for the control drive motor to position itself in each cycle and stop, before advancing on to the next position.

20.Once back in the In Service position, cycle the control valve again into the backwash position. The tanks switch again, and air head backwashes out of the other tank. Cycle the control back to the In Service position. Leave the timer in the open position. DO NOT insert meter cable yet.

NOTE: Two motors are available.

1/15 RPM has 82 minute regeneration time. 1/30 RPM has 164 minute regeneration time.

Valve To Tank Installation

1.Spin the valve onto the tank, ensuring the threads are not cross-threaded.

NOTE: All Fleck® valves are right-hand threads, or clockwise, to install

2.Rotate the valve freely without using force until it comes to a stop (this position is considered zero).

3.Rotate the valve clockwise from zero, between 1/4-turn and 1/2-turn (see “Figure 6”).

NOTE: If lubricant is required, a silicone compound is strongly recommended. Dow Corning® Silicone Compound (available from Pentair), is recommended for best possible results. Dow Corning® 7 Release Compound is used in the

manufacture of Pentair control valves. The use of other types of lubricants may attack the control’s plastic or rubber components. Petroleum-based lubricants can cause swelling in rubber parts, including o-rings and seals.

|

Part No. |

Description |

|

16174 |

Silicone, 2 oz Tube |

|

16586-8 |

Silicone, Dow #7 |

|

8 lb |

4 • FLECK® 9000/9100/9500 Service Manual

Figure 6

Setting the Regeneration Cycle Program

The Regeneration cycle program on the water conditioner is preset at the factory. However, portions of the cycle or program time may be lengthened or shortened for local conditions or system design.

1.Expose cycle program wheel by grasping timer in lower right hand corner and pulling. This releases snap retainer and swings timer to the left

NOTE: Meter cable must be removed from meter dome before opening timer.

2.Remove the program wheel by grasping program wheel and squeezing protruding lugs towards center. Lift program wheel off timer. Switch arms may require movement to facilitate removal.

3.Return timer to closed position by engaging snap retainer in back plate. Make certain all electrical wires locate above snap retainer post.

Changing Length of the Backwash Time

Looking at the numbered side of the program wheel, the group of pins starting at zero determines the length of time the

unit backwashes.

Example: If there are six pins in this section, the time of backwash is 12 minutes (2 minutes per pin). To change the length of backwash time, add or remove pins as required.

The number of pins multiplied by two equals minutes of backwash.

Changing Length of Brine and Rinse Time

The group of holes between the last pin in the backwash section and the second group of pins determines the length of time that a unit will brine and rinse (2 minutes per hole).

To change the length of brine and rinse time, add or remove pins in the rapid rinse group of pins to increase or decrease the number of holes in the brine and rinse section.

The number of holes multiplied by two equals minutes of brine and rinse.

Changing Length Of Rapid Rinse

The second group of pins on the program wheel determines the length of time the water conditioner rapid rinses (2 minutes per pin). To change the length of rapid rinse time, add or remove pins at the higher numbered end of this section as required.

The number of pins multiplied by two equals minutes of rapid rinse.

NOTE: Program wheels with 0–82 minute cycle times, use one minute per pin or hole to set Regeneration times. The layout of pins and holes on the program wheel follow the same procedure as on this page.

INSTALLATION & STARTUP CONTINUED

Changing Length of Brine Tank Refill Time

The second group of holes on the program wheel determines the length of time the water conditioner refills the brine tank (2 minutes per hole).

To change the length of refill time, move the two pins at the end of the second group of holes as required.

The Regeneration cycle is complete when the two pin set at end of the brine tank refill section trips the outer micro-switch. The program wheel, however, continues to rotate until the inner micro-switch drops into the notch on the program wheel.

Programming

1.The control valve is set at the factory for backwash; brine and slow rinse; rapid rinse and brine tank fill times. Change any of these times by repositioning the pins and holes or adding more pins.

NOTE: Two timer motors are available.

1/15 RPM has 82 minute Regeneration Time and each pin or hole equals one minute.

1/30 RPM has 164 minute Regeneration Time and each pin or hole equals two minutes.

2.The control valve has a separate brine tank fill cycle. Calculate the desired salt setting using the brine line flow control rate of refill (in gpm) multiplied by the timer setting. Then, using one gallon of fresh water dissolving approximately 3 lbs salt, calculate the refill time.

Example: A desired 30 lbs salt setting:

The unit has a 1.0 gpm refill rate so a 10 gallon fill is required.

10 gallons x 3 lbs/gals = 30 lbs salt Set the timer refill section at 10 minutes.

10 minutes x 1.0 gpm = 10 gallon fill

NOTE: There must always be two pins at the end of a refill time to stop the fill cycle. With the Regeneration times set, place timer back to its original position, making sure the lower right hand corner snaps back into the backplate and the meter cable slides through the backplate and does not bind.

3.Setting the gallon wheel. Knowing the amount of resin in each tank and the salt setting per Regeneration, calculate the gallons available, using the following capacities as a guide:

(capacity per ft3 x ft3 of resin per tank) = gallons available compensated hardness of H2O

NOTE: Based on tank size: More resin increases capacity, less resin decreases capacity.More salt increases capacity, less salt decreases capacity.

Example:

|

Tank Diameter |

= |

16 inches |

|

|

Compensated |

= |

35 grains per gallon |

|

|

Hardness |

(tested sample) |

||

|

ft3 Resin (based on |

= |

4 |

|

|

flow rate) |

|||

|

lbs of Salt per ft3 |

= |

8 |

|

|

Capacity per ft3 |

= |

24,000 |

|

|

(24,000 x 4 ft3 of resin |

2,740 gallons available |

||

|

per tank) |

= |

||

|

before regeneration |

|||

|

35 grains |

Complete step 4 before setting gallons on the meter wheel.

4.Because the control valve regenerates with soft water from the other tank, subtract the water used for regeneration. Take each regeneration cycle and calculate the water used.

Example: Unit is set for a 16-inch diameter tank with 4 ft3 of resin and salted at 8 lbs. per ft3, 7 gpm backwash, #3 injector, 1.0 gpm brine refill, and 60 psi and timer set for 10 min. backwash, 60 min. brine and rinse, 10 min. rapid rinse, 10 min. brine tank fill.

|

Backwash |

10 min x 7.0 gpm |

= |

70.0 gal |

|

Brine and Rinse |

60 min x 1.0 gpm |

= |

60.0 gal |

|

Rapid Rinse |

10 min x 7.0 gpm |

= |

70.0 gal |

|

Brine Tank Fill |

10 min x 1.0 gpm |

= |

10.0 gal |

|

Total Regeneration Water |

= |

210.0 gal |

With the 2740 gallons available calculated in Step 3, subtract the Regeneration water used from the total water available.

2740 gallons available — 210 gallons used = 2530 gallons (in Regeneration, Step 4)

5.Set meter wheel at approximately 2530 gallons. Lift the inner dial of the meter program wheel so that you can rotate it freely. Position the white dot opposite the

2530 gallon setting.

NOTE: There is a slight delay between the time the meter zeros out and the cycle starts. Units using the:

1/15 RPM motor, 82 minute Regeneration Time has a 9 minute delay

1/30 RPM motor, 180 minute Regeneration Time has an 18 minute delay.

NOTE: This delay period is not critical on residential equipment. However, take this factor into consideration for commercial applications by subtracting continuous flows for 9 minutes or 18 minutes from water available.

6.Insert meter cable into meter.

7.Check bypass.

8.Plug in unit.

FLECK® 9000/9100/9500 Service Manual • 5

9000/9100/9500 (3200 SERIES) ELECTRO MECHANICAL TIMER ASSEMBLY

40

10A

39

39

6 • FLECK® 9000/9100/9500 Service Manual

9000/9100/9500 (3200 SERIES) ELECTRO MECHANICAL TIMER ASSEMBLY CONTINUED

|

Item No. QTY Part No. |

Description |

1 1 13870-03 Housing, Timer, 9000

2 1 17870 Label, Indicator, 9000 Timer

3 1 15465 Label, Caution

4 1 16930 Label, Instruction

5 1 15227 Plate, Clutch, Actuator

6 1 10300 Screw, Slot Hex Washer, 18-8 x 3/8

7 1 17513 Clip, Spring

8 1 15407 Washer, Plain, #4

9 1 15228 Spring, Return

10 1 16270-10 Program Wheel Assy, 9000/9100, 3/4-inch STD, 0-2, 100

16270-30 Program Wheel Assy, 9000/9100, 1-inch STD, 0-5, 100

16270-40 Program Wheel Assy, 9000/9100, 1-inch EXT, 0-25, 500

16270-50 Program Wheel Assy, 9000/9100/9500, 3/4-inch EXT, 1.5-inch STD,

0-10, 500

16270-60 Program Wheel Assy, 9500, 1.5-inch EXT, 0-50, 000

10A 24673 Volume Label, Metric, 9000/9100, 3/4-inch STD, 0-8m3

24672 Volume Label, Metric, 9000/9100, 1-inch STD, 0-20m3

24676 Volume Label, Metric, 9000/9100, 1-inch EXT, 0-100m3

24675 Volume Label, Metric, 9000/9100/9500, 3/4-inch EXT, 1.5-inch STD 0-40m3

25027 Volume Label, Metric, 9500, 1.5-inch EXT, 1.5-inch EXT 0-200m3

11 1 13806 Retainer, Program Wheel 12 1 13748 Screw, Flt Hd St, 6-20 x 1/2 13 2 11999 Label, Button

14 1 15223 Actuator, Cycle

15 1 13886 Know, 3200

16 4 13296 Screw, Hex Washer,

6-20 x 1/2

17 1 17724 Program Wheel, Pinion Drive

18 1 17723 Clutch, Drive Pinion

19 1 14276 Spring, Meter Clutch

20 1 14253 Retainer, Clutch Spring

|

Item No. QTY Part No. |

Description |

21 3 14087 Insulator

22 1 15314 Switch, Micro, Modified

23 1 15320 Switch, Micro, Timer

24 2 11413 Screw, Pan Hd Mach, 4-40 x 1 1/8

25 1 13018 Pinion, Idler

26 1 18563 Spring, Idler Shaft

27 1 13017 Gear, Idler

28 1 13164 Gear, Drive

29 1 13887 Plate, Motor Mounting

30 1 18743-1 Motor, 120V, 60 Hz 1/30 RPM, 5600

18824-1 Motor, 230V, 50 Hz 1/30 RPM

19170 Motor, 120V 60 Hz 1/15 RPM

18825 Motor, 230V, 50 Hz 1/15 RPM Mallory

31 2 13278 Screw, Phil Hd Mach, 6-32 x 1/8 Steel Zinc

32 1 14265 Clip, Spring

33 1 15055 Timer, Main Drive Gear

34 1 19210-02 Program Wheel Assy, 9000 1/15

19210-05 Program Wheel Assy, 9000/3230

35 23 15493 Pin, Spring, 1/16 x 5/8 SS 36 1 15203 Harness, 9000/9500, Timer 37 2 40422 Nut, Wire, Tan

38 1 60320-02 Switch Kit, 3200/9000 Timer Auxiliary

39 61420-69 Program Wheel & Gear Assy, 5-30-5-10-2, 2 Min

Per Pin

61420-80 Program Wheel & Gear Assy, 5-40-5-7-2, 2 Min Per Pin

40 1 * Complete 9000 Meter Immediate Timer Assembly

*Call your distributor for Part Number

FLECK® 9000/9100/9500 Service Manual • 7

8 • FLECK® 9000/9100/9500 Service Manual

POWER HEAD ASSEMBLY CONTINUED

|

Item No. QTY Part No. |

Description |

1 2 18728 Nut, Tinnerman, U Type, 8-32

2 1 11838 Power Cord, 6′ Fleck

11839 Power Cord, 12′ Fleck

40084-12 Power Cord, 12′ U.S., Round, 120V Sys 5, 6, 7 & 2900/3150/3900 #4

19885-01 Power Cord Assy, Japanese

11545-01 Power Cord Assy, 4′ Black, Euro w/Terminals

14678 Power Cord, U.S., 220/60

19303-01 Power Cord Assy, Australian w/Terminals

40085-12 Power Cord, 12′ US, Round, 240V

19674 Transformer, 24V, 9.6VA Residential Valves

41475 Transformer, 24V, 9.6VA, European

3 1 15202 Harness, 9000/9500, Drive

14822 Harness, 2900

4 1 15134 Gear Assy, Drive, 1/2-inch Stroke 9000/9500

5 1 15135 Gear, Drive, 9000

6 1 14896 Wheel, Geneva

7 2 40422 Nut, Wire, Tan

8 2 19367 Screw, Designer Cover, Thumb 8-32 Blank UV Stable Material

9 1 15175 Label, Shaft Position

10 2 14917 Ring, Retaining

11 1 42296 Plate, Ground, 9000/9500

12 1 14430 Screw, Hex Washer St, 6 x 1/4 Type «B»

13 2 19160 Screw, Phil Pan, Thread 6-32 x 3/8 Type 23 Zinc

14 1 18737 Motor, 24V, 50/60 Hz, 1 RPM

18738 Motor, 120V, 50/60 Hz 1 RPM

18739 Motor, 220V, 50/60 Hz 1 RPM

15 1 15131 Backplate, 9000, Mechanical, SXT

17784-05 Panel, Control, 9000/9500 XT

17784-02 Panel, Control, 9000, 9500 w/Terminal Block

16 2 15172 Screw, Flt Hd Mach, 4-40 x 1 3/8 Steel Zinc Plate

|

Item No. QTY Part No. |

Description |

17 2 10340 Washer, Lock #4, Zinc 18 2 16433 Switch, Miniature

19 1 10339 Nut, Hex, 4-40 Zinc Plated

20 1 15331 Screw, Hex Washer Mach, 10-24 x 3/4 410 S.S.

21 1 15133 Gear Assy, Drive, 3/4-inch Stroke

22 1 13547 Strain Relief, Flat Cord Heyco #30-1

1 13547-01 Strain Relief, Round Cord 23 1 15810 Ring, Retaining

24 1 17331 Cam, 9000, 9100, 9500

17765 Cam Assy, Aux Switch, 9000, 9100, 9500

25 1 15368 Tube, Cable Guide, 2-Tank, 9000/9100

17337 Tube, Cable Guide, 9500 26 2 15372 Washer, Thrust, 3/8

27 1 15425 Meter Cable Assy, 13.25 inches 9000/9100 3/4-inch STD & EXT

15216 Meter Cable Assy, 15.25 inches 9000/9100 1-inch STD & EXT

17744 Meter Cable Assy, 20.75 inches 9500 1.5-inch STD & EXT

|

28 |

2 |

15692 |

Washer, Plain, 3/8-inch |

30 1 10302 Insulator, Limit Switch

31 2 15173 Screw, Slot Rd Hd Mach, 5-20 x 3/8

32 * Complete 9000/9100/9500 Powerhead Assy

Not Shown

1 60232-110 Cover, Designer, 1 Pc Black

1 60232-112 Cover, Designer, 1 Pc Black w/Left Window, Electric

1 60320-10 Switch Assy, Drive Cam, 9000, 9100, 9500

*Call your distributor for Part Number

FLECK® 9000/9100/9500 Service Manual • 9

9000 CONTROL VALVE ASSEMBLY

|

50 |

12 |

||||||

|

53 |

|||||||

|

11 |

20 |

||||||

|

5 |

|||||||

|

10 |

|||||||

|

13 |

|||||||

|

7 |

15 |

19 |

|||||

|

6 |

8 |

2 |

3 |

||||

|

9 |

1 |

||||||

|

4 |

|||||||

|

14 |

|

32 |

||||||||

|

52 |

55 |

|||||||

|

31 |

||||||||

|

33 |

22 |

|||||||

|

41 |

||||||||

|

53 |

42 |

|||||||

|

43 |

||||||||

|

24 46 23 21 |

45 |

|||||||

|

14861-01 |

48 |

25 |

56 |

|||||

|

28 |

||||||||

|

VALVE BODY,9000,MACHINED |

||||||||

|

W/O-RINGS(P/Ns 11710 & 12281) |

47 |

27 |

30 |

|||||

|

26 |

29 |

|||||||

|

18 |

37 |

24 |

34 |

|||||

|

17 |

40 |

|||||||

|

51 |

35 |

54 |

||||||

|

39 |

24 |

|||||||

|

16 |

38 |

44 |

36 |

|||||

|

BR61500-9000 Rev E |

||||||||

10 • FLECK® 9000/9100/9500 Service Manual

9000 CONTROL VALVE ASSEMBLY CONTINUED

|

Item No. |

QTY |

Part No. |

Description |

|

1 |

1 |

14861 |

Valve Body, 9000 |

|

2 |

16 |

13242-02 |

Seal, 5600,9000, 9100 |

|

3 |

12 |

14241 |

Spacer, 5600,9000, 9100 |

|

4 |

1 |

16595 |

Spacer, 9000, 9100 |

|

5 |

1 |

43458 |

End Cap, Plastic, 9000/9100 |

|

6 |

2 |

13363 |

Washer, Plain |

|

7 |

2 |

17020 |

Screw, STL. Hex Washer, |

|

6-20 x 3/8 |

|||

|

8 |

2 |

11335 |

Screw, #4-40 |

|

9 |

1 |

14921 |

Link, Piston Rod |

|

10 |

1 |

14919 |

Piston, Rod, Upper |

|

11 |

2 |

14309 |

Retainer, Piston Rod |

|

12 |

1 |

14914 |

Piston, 9000, 9100 Upper |

|

13 |

2 |

13243 |

Plug, End, 5600, 9000, 9100 |

|

14 |

2 |

10209 |

Quad Ring, -010 |

|

15 |

2 |

13008 |

Retainer, End Plug Seal |

|

16 |

1 |

15019 |

Link, Piston Rod, 9000/9500, |

|

9100 |

|||

|

17 |

1 |

14920 |

Rod, Piston, Lower, 9000, |

|

9100 |

|||

|

18 |

1 |

14905 |

Pistion, 9000, 9100 Lower |

|

19 |

1 |

40952 |

O-ring, -030 |

|

20 |

4 |

15331 |

Screw, Hex Washer Head |

|

21 |

2 |

13361 |

Spacer, 4600, 9000, 9100 |

|

22 |

1 |

15215 |

Body, Injector, 9000, 9100 |

|

23 |

2 |

13301 |

O-ring, -011 |

|

24 |

3 |

13302 |

O-ring, -014 |

|

25 |

1 |

10227 |

Screen, Injector |

|

26 |

1 |

10913-000 |

Nozzle, Injector, #000, Brown |

|

10913-00 |

Nozzle, Injector, #00, Violet |

||

|

10913-0 |

Nozzle, Injector, #0, Red |

||

|

10913-1 |

Nozzle, Injector, #1, White |

||

|

10913-2 |

Nozzle, Injector, #2, Blue |

||

|

10913-3 |

Nozzle, Injector, #3, Yellow |

||

|

10913-4 |

Nozzle, Injector, #4, Green |

||

|

27 |

1 |

10914-000 |

Throat, Injector, #000, Brown |

|

10914-00 |

Throat, Injector, #00, Violet |

||

|

10914-0 |

Throat, Injector, #0, Red |

||

|

10914-1 |

Throat, Injector, #1, White |

||

|

10914-2 |

Throat, Injector, #2, Blue |

||

|

10914-3 |

Throat, Injector, #3, Yellow |

||

|

10914-4 |

Throat, Injector, #4, Green |

||

|

28 |

1 |

13166 |

Cap, Injector, 5600, 9000, |

|

9100 |

|||

|

29 |

1 |

13303 |

O-ring, -021 |

|

30 |

2 |

13387 |

Screw, Hex Washer Head |

|

31 |

1 |

15348 |

O-ring, -563 |

|

32 |

1 |

13173 |

Retainer, DLFC Button |

|

Item No. |

QTY |

Part No. |

Description |

|

33 |

1 |

19153 |

Washer, Flow, 0.6 GPM |

|

19152 |

Washer, Flow, 0.8 GPM |

||

|

12097 |

Washer, Flow, 1.0 GPM |

||

|

12085 |

Washer, Flow, 1.2 GPM |

||

|

19150 |

Washer, Flow, 1.3 GPM |

||

|

12086 |

Washer, Flow, 1.5 GPM |

||

|

19149 |

Washer, Flow, 1.7 GPM |

||

|

12087 |

Washer, Flow, 2.0 GPM |

||

|

12088 |

Washer, Flow, 2.4 GPM |

||

|

12089 |

Washer, Flow, 3.0 GPM |

||

|

12090 |

Washer, Flow, 3.5 GPM |

||

|

12091 |

Washer, Flow, 4.0 GPM |

||

|

19147 |

Washer, Flow, 4.5 GPM |

||

|

12092 |

Washer, Flow, 5.0 GPM |

||

|

17814 |

Washer, Flow, 6.0 GPM |

||

|

12408 |

Washer, Flow, 7.0 GPM |

||

|

34 |

1 |

14925 |

Brine Valve Stem, 9000, 9100 |

|

35 |

1 |

12626 |

Seat, Brine Valve |

|

36 |

1 |

13167 |

Spacer, Brine Valve |

|

37 |

1 |

13165 |

Cap, Brine Valve |

|

38 |

1 |

11973 |

Spring, Brine Valve |

|

39 |

1 |

11981-01 |

Ring, Retaining, SS |

|

40 |

1 |

16098 |

Washer, Nylon Brine |

|

41 |

1 |

12977 |

O-ring, -015 |

|

42 |

1 |

13245 |

Retainer, BLFC |

|

43 |

1 |

17307 |

Washer, Flow, 0.125 GPM |

|

12094 |

Washer, Flow, 0.25 GPM |

||

|

12095 |

Washer, Flow, 0.50 GPM |

||

|

12097 |

Washer, Flow, 1.0 GPM |

||

|

44 |

1 |

12550 |

Quad Ring, -009 |

|

45 |

1 |

13244 |

Adapter, BLFC |

|

46 |

1 |

13497 |

Air Disperser, Injector |

|

47 |

1 |

11710 |

O-ring, -215 |

|

48 |

1 |

12281 |

O-ring, -338 |

|

50 |

60400 |

Piston Assy, 9000, 9100 |

|

|

Upper |

|||

|

60400-01 |

Piston Assy, 9000 Upper, HW |

||

|

60400-001 |

Piston Assy, 9000, 9100 |

||

|

Upper, 560CD |

|||

|

51 |

60401 |

Piston Assy, 9000, 9100 |

|

|

Lower |

|||

|

60401-01 |

Piston Assy, 9000 Lower, HW |

||

|

60401-001 |

Piston Assy, 9000, 9100 |

||

|

Lower, 560CD |

|||

|

52 |

60125 |

Seal & Spacer Kit, |

|

|

5600/9000/9100 Upper |

|||

|

60125-15 |

Seal & Spacer Kit, |

||

|

5600/9000/9100 Upper Blue |

|||

|

60125HW |

Seal & Spacer Kit, 9000 |

||

|

Upper |

|||

|

FLECK® 9000/9100/9500 Service Manual • 11 |

9000 CONTROL VALVE ASSEMBLY CONTINUED

|

Item No. QTY Part No. |

Description |

53 60421 Seal & Spacer Kit, 9000/9100 Lower

60421HW Seal & Spacer Kit, 9000 Lower

60421-50 Seal & Spacer Kit, 9000/9100 Lower, 559PE

54 60350 Brine Valve Assy, 9000, 9100

60350-01 Brine Valve Assy, 9000, 560CD, Hot Water

55 60385-0011 Injector Drain, 9000, 9100, 0.25 BLFC #0 INJ,

1.2 DLFC

60385-0111 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ,

1.2 DLFC

60385-0121 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ,

1.5 DLFC

60385-0131 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ,

2.0 DLFC

60385-0141 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ,

2.4 DLFC

60385-0012 Injector Drain, 9000, 9100, 0.50 BLFC #0 INJ,

1.2 DLFC

60385-0112 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 1.2 DLFC

60385-0122 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 1.5 DLFC

60385-0132 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 2.0 DLFC

60385-0142 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 2.4 DLFC

60385-0182 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 5.0 DLFC

60385-0222 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 1.5 DLFC

60385-0242 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 2.4 DLFC

60385-0252 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 3.0 DLFC

60385-0262 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 3.5 DLFC

60385-0272 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 4.0 DLFC

60385-0282 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 5.0 DLFC

60385-02A2 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 6.0 DLFC

60385-0202 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, Blank DLFC

60385-0372 Injector Drain, 9000, 9100, 0.50 BLFC #3 INJ, 4.0 DLFC

12 • FLECK® 9000/9100/9500 Service Manual

|

Item No. QTY Part No. |

Description |

60385-0382 Injector Drain, 9000, 9100, 0.50 BLFC #3 INJ, 5.0 DLFC

60385-0482 Injector Drain, 9000, 9100, 0.50 BLFC #4 INJ, 5.0 DLFC

60385-0133 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 2.0 DLFC

60385-0143 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 2.4 DLFC

60385-0163 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 3.5 DLFC

60385-0233 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 2.0 DLFC

60385-0243 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 2.4 DLFC

60385-0253 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 3.0 DLFC

60385-0263 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 3.5 DLFC

60385-0273 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 4.0 DLFC

60385-0353 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 3.0 DLFC

60385-0373 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 4.0 DLFC

60385-0383 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 5.0 DLFC

60385-0393 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 7.0 DLFC

60385-0120 Injector Drain, 9000, 9100, Blank BLFC #1 INJ, 1.5 DLFC

56 60022-12 BLFC, 0.125 GPM, 5000/5600/9000/9100

60022-25 BLFC, 0.25 GPM, 5000/5600/9000/9100

60022-50 BLFC, 0.50 GPM, 5000/5600/9000/9100

60022-100 BLFC, 1.0 GPM, 5000/5600/9000/9100

Not Shown

1 12128 Label, 0.25 GPM BLFC

1 13333 Label, Injector

1 10760 Label, 1 GPM, 3 lbs salt/min

10759 Label, 0.5 GPM, 1.5 lbs Salt

19654 Label, 0.125 GPM Brine Refill Flow

9100 CONTROL VALVE ASSEMBLY

15

17

16

3

2

52

53

|

51 |

18 |

|

|

9 |

||

|

11 |

19 |

|

|

15 |

13 |

|

|

17 |

20 |

12 |

|

16 |

50

9

12

11 13

14  10

10

1

48

49

39

54

8

7

5

53

6

3

2

4

31

|

30 |

32 |

55 |

||||

|

21 |

22 |

26 |

||||

|

46 |

24 |

25 |

||||

|

47 |

28 |

27 |

||||

|

23 |

||||||

|

29 |

||||||

|

43 |

34 |

41 |

40 |

56 |

||

|

36 |

35 |

33 |

42 |

|||

|

45 |

||||||

|

44 |

37

38

BR61500-9100 Rev E

|

Item No. |

QTY |

Part No. |

Description |

Item No. |

QTY |

Part No. |

Description |

|

|

1 |

1 |

40688 |

Valve Body Assy, 9100 |

17 |

2 |

13363 |

Washer, Hague Drive |

|

|

18 |

1 |

14905 |

Piston, 9000, 9100 Lower |

|||||

|

2 |

16 |

13242-02 |

Seal, 5600,9000, 9100 |

|||||

|

19 |

1 |

14920 |

Rod, Piston, Lower, 9000, |

|||||

|

3 |

12 |

14241 |

Spacer, 5600,9000, 9100 |

|||||

|

9100 |

||||||||

|

4 |

1 |

16595 |

Spacer, 9000, 9100 |

|||||

|

20 |

1 |

15019 |

Link, Piston, Rod, 9000/9500 |

|||||

|

5 |

1 |

43458 |

End Cap, Plastic, 9000/9100 |

|||||

|

21 |

1 |

41500 |

O-ring, 9100 Drain |

|||||

|

6 |

1 |

40952 |

O-ring, -030 |

|||||

|

22 |

1 |

15215 |

Body, Injector, 9000, 9100 |

|||||

|

7 |

4 |

15331 |

Screw, Hex Washer Head |

|||||

|

23 |

2 |

13301 |

O-ring, -011 |

|||||

|

8 |

1 |

14914 |

Piston, 9000, 9100 Upper |

|||||

|

24 |

1 |

10227 |

Screen, Injector |

|||||

|

9 |

2 |

14309 |

Retainer, Piston Rod |

|||||

|

25 |

1 |

10913-000 |

Nozzle, Injector, #000, Brown |

|||||

|

10 |

1 |

14919 |

Piston, Rod, Upper |

|||||

|

10913-00 |

Nozzle, Injector, #00, Violet |

|||||||

|

11 |

2 |

13243 |

Plug, End, 5600, 9000, 9100 |

|||||

|

10913-0 |

Nozzle, Injector, #0, Red |

|||||||

|

12 |

2 |

13008 |

Retainer, End Plug Seal |

|||||

|

10913-1 |

Nozzle, Injector, #1, White |

|||||||

|

13 |

2 |

10209 |

Quad Ring, -010 |

|||||

|

10913-2 |

Nozzle, Injector, #2, Blue |

|||||||

|

14 |

1 |

14921 |

Link, Piston Rod |

|||||

|

10913-3 |

Nozzle, Injector, #3, Yellow |

|||||||

|

15 |

2 |

11335 |

Screw, #4-40 |

|||||

|

10913-4 |

Nozzle, Injector, #4, Green |

|||||||

|

16 |

2 |

17020 |

Screw, STL. Hex Washer, |

|||||

|

6-20 x 3/8 |

FLECK® 9000/9100/9500 Service Manual • 13

9100 CONTROL VALVE ASSEMBLY CONTINUED

|

Item No. |

QTY |

Part No. |

Description |

|

26 |

1 |

10914-000 |

Throat, Injector, #000, |

|

Brown |

|||

|

10914-00 |

Throat, Injector, #00, Violet |

||

|

10914-0 |

Throat, Injector, #0, Red |

||

|

10914-1 |

Throat, Injector, #1, White |

||

|

10914-2 |

Throat, Injector, #2, Blue |

||

|

10914-3 |

Throat, Injector, #3, Yellow |

||

|

10914-4 |

Throat, Injector, #4, Green |

||

|

27 |

1 |

13166 |

Cap, Injector, 5600, 9000, |

|

9100 |

|||

|

28 |

1 |

13303 |

O-ring, -021 |

|

29 |

2 |

13387 |

Screw, Hex Washer Head |

|

30 |

1 |

15348 |

O-ring, -563 |

|

31 |

1 |

13173 |

Retainer, DLFC Button |

|

32 |

1 |

19153 |

Washer, Flow, 0.6 GPM |

|

19152 |

Washer, Flow, 0.8 GPM |

||

|

12097 |

Washer, Flow, 1.0 GPM |

||

|

12085 |

Washer, Flow, 1.2 GPM |

||

|

19150 |

Washer, Flow, 1.3 GPM |

||

|

12086 |

Washer, Flow, 1.5 GPM |

||

|

19149 |

Washer, Flow, 1.7 GPM |

||

|

12087 |

Washer, Flow, 2.0 GPM |

||

|

12088 |

Washer, Flow, 2.4 GPM |

||

|

12089 |

Washer, Flow, 3.0 GPM |

||

|

12090 |

Washer, Flow, 3.5 GPM |

||

|

12091 |

Washer, Flow, 4.0 GPM |

||

|

19147 |

Washer, Flow, 4.5 GPM |

||

|

12092 |

Washer, Flow, 5.0 GPM |

||

|

17814 |

Washer, Flow, 6.0 GPM |

||

|

12408 |

Washer, Flow, 7.0 GPM |

||

|

33 |

1 |

14925 |

Brine Valve Stem, 9000, |

|

9100 |

|||

|

34 |

1 |

12626 |

Seat, Brine Valve |

|

35 |

1 |

13167 |

Spacer, Brine Valve |

|

36 |

1 |

13165 |

Cap, Brine Valve |

|

37 |

1 |

11973 |

Spring, Brine Valve |

|

38 |

1 |

11981-01 |

Ring, Retaining, SS |

|

39 |

1 |

16098 |

Washer, Nylon Brine |

|

40 |

1 |

12977 |

O-ring, -015 |

|

41 |

1 |

13245 |

Retainer, BLFC |

|

42 |

1 |

17307 |

Washer, Flow, 0.125 GPM |

|

12094 |

Washer, Flow, 0.25 GPM |

||

|

12095 |

Washer, Flow, 0.50 GPM |

||

|

12097 |

Washer, Flow, 1.0 GPM |

||

|

43 |

1 |

12550 |

Quad Ring, -009 |

|

44 |

2 |

13302 |

O-ring, -014 |

|

45 |

1 |

13244 |

Adapter, BLFC |

|

46 |

1 |

13497 |

Air Disperser, Injector |

14 • FLECK® 9000/9100/9500 Service Manual

|

Item No. QTY Part No. |

Description |

47 1 13361 Spacer, 4600, 9100

48 1 40538 Retainer, 32 mm, O-ring DIST, 7000

49 1 61419 Kit, 1.05-inch Distributor Adapter

50 60400 Piston Assy, 9000, 9100 Upper

60400-001 Piston Assy, 9000, 9100 Upper, 560CD

51 60401 Piston Assy, 9000, 9100 Lower

60401-01 Piston Assy, 9000 Lower, HW

60401-001 Piston Assy, 9000, 9100 Lower, 560CD

52 60125 Seal & Spacer Kit, 5600/9000/9100 Upper

60125-15 Seal & Spacer Kit, 5600/9000/9100 Upper Blue Silicone

53 60421 Seal & Spacer Kit, 9000/9100 Lower

60421-50 Seal & Spacer Kit, 9000/9100 Lower, 559PE

54 60350 Brine Valve Assy, 9000,

9100

55 60385-0011 Injector Drain, 9000, 9100, 0.25 BLFC #0 INJ, 1.2 DLFC

60385-0111 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ, 1.2 DLFC

60385-0121 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ, 1.5 DLFC

60385-0131 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ, 2.0 DLFC

60385-0141 Injector Drain, 9000, 9100, 0.25 BLFC #1 INJ, 2.4 DLFC

60385-0012 Injector Drain, 9000, 9100, 0.50 BLFC #0 INJ, 1.2 DLFC

60385-0112 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 1.2 DLFC

60385-0122 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 1.5 DLFC

60385-0132 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 2.0 DLFC

60385-0142 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 2.4 DLFC

60385-0182 Injector Drain, 9000, 9100, 0.50 BLFC #1 INJ, 5.0 DLFC

60385-0222 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 1.5 DLFC

60385-0242 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 2.4 DLFC

60385-0252 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 3.0 DLFC

9100 CONTROL VALVE ASSEMBLY CONTINUED

|

Item No. QTY Part No. |

Description |

|

60385-0262 |

Injector Drain, 9000, 9100, |

|

0.50 BLFC #2 INJ, 3.5 |

|

|

DLFC |

60385-0272 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 4.0 DLFC

60385-0282 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 5.0 DLFC

60385-02A2 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, 6.0 DLFC

60385-0202 Injector Drain, 9000, 9100, 0.50 BLFC #2 INJ, Blank DLFC

60385-0372 Injector Drain, 9000, 9100, 0.50 BLFC #3 INJ, 4.0 DLFC

60385-0382 Injector Drain, 9000, 9100, 0.50 BLFC #3 INJ, 5.0 DLFC

60385-0482 Injector Drain, 9000, 9100, 0.50 BLFC #4 INJ, 5.0 DLFC

60385-0133 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 2.0 DLFC

60385-0143 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 2.4 DLFC

60385-0163 Injector Drain, 9000, 9100, 1.0 BLFC #1 INJ, 3.5 DLFC

60385-0233 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 2.0 DLFC

60385-0243 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 2.4 DLFC

60385-0253 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 3.0 DLFC

60385-0263 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 3.5 DLFC

60385-0273 Injector Drain, 9000, 9100, 1.0 BLFC #2 INJ, 4.0 DLFC

60385-0353 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 3.0 DLFC

60385-0373 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 4.0 DLFC

60385-0383 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 5.0 DLFC

60385-0393 Injector Drain, 9000, 9100, 1.0 BLFC #3 INJ, 7.0 DLFC

|

Item No. QTY |

Part No. |

Description |

|

60385-0120 |

Injector Drain, 9000, 9100, |

|

|

Blank BLFC #1 INJ, 1.5 |

||

|

DLFC |

||

|

56 |

60022-12 |

BLFC, 0.125 GPM, |

|

5000/5600/9000/9100 |

||

|

60022-25 |

BLFC, 0.25 GPM, |

|

|

5000/5600/9000/9100 |

||

|

60022-50 |

BLFC, 0.50 GPM, |

|

|

5000/5600/9000/9100 |

||

|

60022-100 |

BLFC, 1.0 GPM, |

|

|

5000/5600/9000/9100 |

||

|

Not Shown |

||

|

1 |

13333 |

Label, Injector |

|

1 |

10759 |

Label, 0.5 GPM, 1.5 lbs salt/ |

|

min |

||

|

18569 |

Retainer, Tank Seal |

|

|

18303 |

O-ring, -336, Top of Tank |

|

|

12128 |

Label, 0.25 GPM BLFC |

|

|

10760 |

Label 1 GPM, 3 lbs Salt |

|

|

19654 |

Label, 0.125 GPM Brine Refill |

|

|

Flow |

FLECK® 9000/9100/9500 Service Manual • 15

Loading…

Loading…

Блок управления Fleck 9500/1710 SXT Eco 1.5″ (умягчение, счётчик)

| Допустимые диаметры баллонов | 10-24″ |

| Рабочее напряжение | 24 В |

| Производительность | 8,4-11,2 куб.м/ч |

| Промывка | 3,3 куб.м/ч |

| Рабочая температура | 1-50°С |

| Рабочее давление | 1,4-8,5 бар |

| Диаметры присоединений (вх/вых/дрен) | 40/40/40 мм |

| Диаметр трубки водосчётчика | 1,5″ |

| Допустимые диаметры баллонов | 10-24″ |

| Рабочее напряжение | 24 В |

| Производительность | 8,4-11,2 куб.м/ч |

| Промывка | 3,3 куб.м/ч |

| Рабочая температура | 1-50°С |

| Рабочее давление | 1,4-8,5 бар |

| Диаметры присоединений (вх/вых/дрен) | 40/40/40 мм |

| Диаметр трубки водосчётчика | 1,5″ |

Блок управления непрерывного действия (twin alternating) Fleck 9500/1710 SXT Eco 1.5″ на умягчение с водосчётчиком. Программируемый, с памятью. Является устройством для распределения потоков воды. Снабжён жёстким латунным соединением между баллонами.

Блок управления (управляющий клапан) Fleck 9500/1710 SXT Eco 1.5″, специально создан для twin-систем, когда один клапан управляет двумя корпусами фильтров. Один корпус находится в работе, а второй — в режиме ожидания, или регенерации. Таким образом, становится возможным непрерывное потребление умягченной воды. Регенерация начинается сразу после выработки фильтроцикла баллоном фильтра. Клапан оснащен двумя поршнями (плунжерами): нижний предназначен для переключения режимов работы корпусов фильтра, а верхний для изменения потоков воды во время регенерации.

Управляющий механизм электронный

Корпус выполнен из латуни

LCD дисплей с подсветкой

Солевая система 1700 позволяет использовать клапан для работы с корпусами диаметром от 10 до 24 дюймов

Регенерация по объему очищенной воды

Посадка на бак: верхняя

В комплект управляющего клапана не входят латунные трубки (аксессуар, код 28137-24) для соединения двух частей клапана между собой

Table of Contents for Pentair GW9500:

-

11 Great White Installation and User’s Guide Section 3 Operation This section contains information describing the movement and operation of your Great White Cleaner, as well as tips for “fine-tuning” your pool’s valves and connections to optimize Great White’s cleaning ability. Cleaner Operation and Movement Clicking sound This is the sound of the oscillator moving back and forth in the oscillator chamber. The

-

6 Great White Installation and User’s Guide Standard Installation (Continued) The vacuum regulator must be installed in conjunction with the reducer cone (Figure 10). The reducer cone is required to make most skimmer connections. It will keep the hose and vacuum regulator in place once the filter system is stopped. To install the vacuum regulator, insert the vacuum regulator and reducer cone in the skimmer. Attach the end of the hose to the regulator (Figure 11). Make sure the

-

13 Great White Installation and User’s Guide Fine-tuning valves and connections (continued) Not enough vacuum? You don’t have enough vacuum if the cleaner moves sluggishly or not at all. Be sure the filter system is clean and the regulator and all valves are adjusted to give you maximum vacuum. If the cleaner is still not moving, your pump may not be strong enough to operate the cleaner. Please refer to

-

7 Great White Installation and User’s Guide Standard Installation (Continued) 5. Check Flow With the main drain closed, and one end of the hose attached to the regulator installed in the skimmer, insert the flow gauge into the other end of the hose. Keep the hose and flow gauge underwater. Turn on the pump. With the pump running, adjust the vacuum regulator (in your skimmer) until the indicator on the flow gauge is between minimum and maximum flow (Figure 12). Remove the flow gauge and proceed to step

-

5 Great White Installation and User’s Guide Section 2 Installation This section describes how to install the Great White pool cleaner. Great White is designed to work in a wide variety of swimming pools. Both the standard in-skimmer installation and optional vac port installation are covered below. If your pool configuration is unlike any of the examples, contact your Pentair Water Pool and Spa dealer for assistance, or call our toll-free Customer Helpline at 1-800-831-7133. Standard Installation For pools with one skimmer, using the

-

2 Great White Installation and User’s Guide Preparation of your pool Before you assemble and install your Great White automatic pool cleaner, you should make sure that your pool is clean and free of algae. If necessary, make the following preparations before proceeding. • Chemically balance the pool water • Brush the pool and let the debris settle • Hand vacuum the pool thoroughly • Clean the filter and pump strain

-

© 2011 Pentair Water Pool and Spa, Inc. All rights reserved This document is subject to change without notice 1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000 10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 553-5000 Trademarks and Disclaimers: Great White ® and Pentair Water Pool and Spa ® are registered trademarks of Pentair Water Pool and Spa, Inc. and/or its affiliated companies in the United States and/or othe

-

i Great White Installation and User’s Guide Contents Important Safety Precautions ……………………………………………………………………ii Section 1: Overview ……………………………………………………………………………….. 1 Preparation of your pool ……………………………………………………………………. 2 Cleaner assembly …………………………………………………………………. 2 Hose Assembly …………………………………………………………….

-

iii Great White Installation and User’s Guide General Installation Information (continued) Before installing the cleaner, fill the hose with water: Always make sure the cleaner head is submerged and the hose is full of water before connecting the hose to the filtration system (whether through a skimmer or dedicated wall fitting). Air in the system can damage the pump through dry running and overheating. Before installing the cleaner, understand cleaner coverage: The cleaner is designed

-

14 Great White Installation and User’s Guide Blank Page

-

4 Great White Installation and User’s Guide Blank Page

-

Automatic Pool Cleaner Installation and User’s Guide IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS

-

9 Great White Installation and User’s Guide Optional Installation (continued) 5. Install vacuum regulator WARNING! Hazardous suction. Can cause entrapment with severe personal injury or drowning. To install the vacuum regulator, insert the vacuum regulator and reducer cone in the skimmer (Figure 17). To prevent water from flowing through the top of the vacuum regulator, attach the regulator cap to the vacuum regulator (Figure 18). Attach the end of the hose to the vac port fitting installed in the dedicated vacuum line (Figure 17). Vacuum Regulator

Questions, Opinions and Exploitation Impressions:

You can ask a question, express your opinion or share our experience of Pentair GW9500 device using right now.