Потолочные

детекторы

14

Охранные извещатели: справочное руководство

ISN-CC1-50W

ISN-CC1-100N

Тип монтажа

Потолочный

Потолочный

Технология обнаружения

Пассивный инфракрасный детектор (PIR)

Пассивный инфракрасный детектор (PIR)

Описание

Низкопрофильный широкоугольный PIR

Низкопрофильный PIR дальнего радиуса действия

Применение

Пассивный инфракрасный

датчик (PIR)

Один сенсор с двумя элементами

Один сенсор с двумя элементами

Сверхвысокочастотная

доплеровская РЛС

—

—

Условия окружающей среды

Стандарт

Стандарт

Уровень надежности/риска

Низкий

Низкий

Защищенность от мелких

животных, дружественность

к домашним животным

—

—

Рабочая температура

†

от -20° до +50°

от -20° до +50°

Ус

тановк

а

Оптика

Регулируемое по вертикали зеркало 30 градусов

Регулируемое по вертикали зеркало 33 градуса

Зона покрытия

14 x 14 м

20 x 2,8 м

Высота установки

2,5 — 5 м

2,5 — 5 м

Нерегулируемая высота установки

—

—

Выбираемая зона нижнего обзора

—

—

Дизайн корпуса

Низкопрофильный

Низкопрофильный

Возможность установки

на монтажный кронштейн

—

—

Регулировка уровня

чувствительности

•

•

Функциональные во

змо

жнос

ти

Память тревожных сигналов

—

—

Обнаружение антимаскировки

—

—

Тампер крышки

•

•

Защищенность от сквозняков

и насекомых

—

—

Отключение светодиодного

индикатора

•

•

Удаленная самопроверка

—

—

Удаленный пошаговый тест

—

—

Температурная компенсация

•

•

Выход «неисправность»

•

•

Настенный тампер

—

—

Сертификаты

C-Tick, UL

C-Tick, UL

Эл. х

ар

-ки

Выход сигнализации

Реле НЗ/НО

Реле НЗ/НО

Рабочее напряжение

9 — 28 В пост. тока

9 — 28 В пост. тока

Потребляемый ток

(мин./макс.) – мА

25

25

Обработка сигнала

Стандарт

Стандарт

Прочие характеристики

Дополнительно

‡

‡

In this article, we will be talking about the photoelectric sensor wiring and setup. We will be talking about the 24-volt DC Through-Beam, Retroreflective, and Diffused photoelectric sensors. These are the three basic types of photoelectric sensors and they come in many different shapes and sizes.

Photoelectric sensor mounting

Some of the larger photoelectric sensors have holes in the sensor body that can be used to mount the sensor and some of the smaller photoelectric sensors require some type of bracket to hold them in place.

You can buy premade brackets to mount these sensors and these brackets can be adjustable or non-adjustable.

Photoelectric sensor application

A belt conveyor transporting an empty box will be used to explain how to set up each sensor. On the conveyor below, the sensor will trigger the Motor Starter to start or stop the motor. We will also talk about troubleshooting these photoelectric sensors.

Photoelectric sensor wiring

First, we will show you how to wire the Through-Beam photoelectric sensor emitter. Through-Beam sensors have two separate devices, one is called the emitter and the other is called the receiver.

The emitter is what sends the light out and the receiver is what catches the light.

Both of these sensor devices will need to be connected to 24-volt DC power. The receiver will also be connected to the 24-volt DC Motor Starter coil.

To be safe, make sure the power is turned off before connecting any wires.

To connect the emitter of the Through-Beam sensor to 24-volt DC power, connect the brown wire to 24-volt DC positive and the blue wire to 24-volt DC negative, just as you see in the picture below. The emitter is now hooked up and ready to use.

The wires of the Through-Beam receiver, the Retroreflective sensor, and the Diffused sensor all get connected to the belt conveyor in the same way.

So to connect 24-volt DC power to any of these three sensors, connect the brown wire to 24-volt DC positive and the blue wire to 24-volt DC negative.

Now connect the sensor output black wire to the 24-volt DC Motor Starter coil to complete the wire connections. With the sensor wire connections being complete, you can now turn the power back on.

1) Through-Beam photoelectric sensor wiring

Now we will show you how to mount these three sensors to the conveyor starting with the Through-Beam sensor. As you can see in the picture below, we are useing a premade adjustable bracket for all three sensors, to make mounting and aiming of the sensors easier.

With the Through-Beam sensor, use a straight edge to line up and mount the emitter and receiver, so they are straight across the conveyor belt from each other.

Adjust the sensor if needed and tighten everything down to lock the sensor in place.

To check alignment, block and unblock the sensor with your hand to make sure the sensor indicator light turns on and off. The Through-Beam photoelectric sensor is now ready to test.

With the Retroreflective sensor, it needs a reflector to work. Use a straight edge to line up and mount the sensor and the reflector, so they are straight across the conveyor belt from each other.

Adjust the sensor if needed and tighten everything down to lock the sensor and reflector in place.

To check alignment, block and unblock the sensor with your hand to make sure the sensor indicator light turns on and off. The Retroreflective photoelectric sensor is now ready to test.

2) Retroreflective photoelectric sensor wiring

With the Retroreflective sensor, it needs a reflector to work. Use a straight edge to line up and mount the sensor and the reflector, so they are straight across the conveyor belt from each other.

Adjust the sensor if needed and tighten everything down to lock the sensor and reflector in place.

To check alignment, block and unblock the sensor with your hand to make sure the sensor indicator light turns on and off. The Retroreflective photoelectric sensor is now ready to test.

3) Diffused photoelectric sensor wiring

To mount the Diffused photoelectric sensor put the empty box on the conveyor where you want it to stop, as per picture below. Mount the sensor at the front edge of the box, adjust and tighten everything down.

Diffused sensors have a sensitivity adjustment screw. If the sensitivity is set too high the sensor might stay on all the time. If the sensitivity is set to low it might not turn on.

To set the sensitivity for this belt conveyor, put the box in front of the sensor in the middle of the conveyor belt. Adjust the sensitivity until the sensor indicator light just turns on with the box in this position.

Block and unblock the sensor with the box in different positions to see if the sensor turns on and off and this will also double-check the sensitivity setting. The Diffused sensor is now ready to use.

Photoelectric sensor troubleshooting

To test out these sensors we will place an empty box on the conveyor belt and start the conveyor. If the photoelectric sensor is set up correctly the box will travel to the sensor, and then shut down the conveyor motor when it blocks the sensor.

If the photoelectric sensor is not working correctly, the conveyor motor might not start, it might only run when the sensor is blocked, or it might not turn off.

A) The conveyor does not start

If the conveyor does not start, the sensor might need to be adjusted or it might be dirty.

1) Clean the lens of the sensor and check the alignment by blocking the sensor and watching the sensor indicator light to see if it turns off and on. If the light turns off and on, the sensor is aligned.

2) If the light doesn’t turn off and on, adjust the sensor so the emitter and receiver are aligned.

3) If the conveyor still does not start, look at the Motor Starter and block the sensor again. If the sensor is working correctly you should be able to hear the Motor Starter contacts close when the sensor gets blocked.

4) If the Motor Starter contacts do not close, the sensor or sensor cable is bad and will need to be replaced.

B) The motor only runs when the sensor is blocked

If the motor only runs when the sensor is blocked, it is probably in dark-on mode. Flip the mode switch to light-on mode to correct this issue.

Some Photoelectric Sensors have a light-on, dark-on mode selector switch. Light-on mode means the sensor output turns on when the receiver sees the emitter light.

Dark-on mode means the sensor output turns on when the receiver does not see the emitter light.

C) The conveyor motor stays running

If the conveyor motor stays running,

1) the sensor might be misaligned and in dark-on mode,

2) the sensor or the sensor cable might be bad and will need to be replaced.

Summary

In review, by reading this article you have learned about the three basic types of photoelectric sensors Through-Beam, Retroreflective, and Diffused; How to connect the wires of these sensors and how to set them up on a belt conveyor. You also learned how to troubleshoot these photoelectric sensors.

Please let us know if you have any questions about wiring or setting up 24-volt DC photoelectric sensors in the comments below and we will get back to you in less than 24 hours.

Got a friend, client, or colleague who could use some of this information? Please share this article.

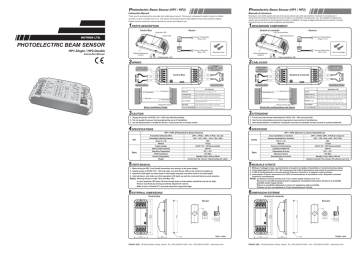

Photoelectric Beam Sensor (HP1 / HP2) Photoelectric Beam Sensor (HP1 / HP2) Instruction Manual Manuale di istruzioni Thank you for purchasing this automatic door safety beam sensor. This sensor is designed to detect intrusion to initiate an alarm, an door controller and so on. This sensor will provide long and dependable service when properly installed. Please read this instruction manual carefully for correct and effective use. Grazie per aver scelto questo sensore di sicurezza a fascio per porte automatiche. Il sensore è concepito per il rilevamento di intrusioni finalizzato all'innesco di allarmi, di centraline controllo porte, ecc. Se installato correttamente, questo sensore garantirà un funzionamento duraturo e affidabile. Si prega di leggere attentamente il presente manuale di istruzioni per un uso corretto ed efficace del dispositivo. 1PARTS DESCRIPTION 1DESCRIZIONE COMPONENTI Control Box Sensor Scatola di comando Operation LED Power LED HOTRON LTD. Sensore LED funzionamento LED alimentazione Sensor (Transmitter) (Gray / 5m) Sensore (Trasmettitore) (Grigio / 5 m) PHOTOELECTRIC BEAM SENSOR HP1-Single / HP2-Double Sensor (Receiver) (Blue / 5m) Distance adjustment Volume Instruction Manual NC NO Mounting screw Sensore (Ricevitore) (Blu / 5 m) Volume regolazione distanza NC NO < Default value : NO > 2WIRING < Valore predefinito: NO > 2CABLAGGIO POWER (AC/DC 12V ~ 30V) Non-polarity Contact output (door controller) Control Box L2 Scatola di comando L2 L1 Receiver (Blue) ALIMENTAZIONE (CA/CC 12V ~ 30V) Senza polarità Uscita contatti (centralina controllo porta) L2 L1 L2 L1 L1 Ricevitore (Blu) Transmitter (Gray) Trasmettitore (Grigio) LED Indication L2 Transmitter L1 Receiver L2 Receiver Segnalazione LED Ricevitore L2 Power On Green and Red LED cross-lights up Once Acceso I fasci di luce del LED verde e del LED rosso si illuminano una volta L1 Found only Green LED lights up 5times and then Red LED On Rilevato solo L1 Il LED verde si illumina 5 volte, poi si accende il LED rosso L2 Found only Red LED lights up 5times and then Red LED On Rilevato solo L2 Il LED rosso si illumina 5 volte, poi si accende il LED rosso L1, L2 Found Green and Red LED light up 5times at same time and then Red LED On No found Green and Red LED cross-lights up continuously Trasmettitore L2 Ricevitore L1 L1 Transmitter Height Min 500mm Trasmettitore L1 Guida alla configurazione del fascio 3CAUTION contemporaneamente, poi si accende il LED rosso Non rilevato I fasci di luce del LED verde e del LED rosso si illuminano continuamente L1 o L2 interrotto Il LED verde è acceso durante l'interruzione 3ATTENZIONE 1. Supply the power of AC/DC 12V ~ 30V only with Non-polarity 2. Do not supply the power during engineering work of installation 3. Do not disassemble or modify the device, it may cause fire or electric shock. 1. Fornire esclusivamente alimentazione CA/CC 12V ~ 30V senza polarità 2. Non fornire alimentazione durante le operazioni meccaniche di installazione 3. Non disassemblare o modificare il dispositivo perché ciò potrebbe causare incendi o scariche elettriche. 4SPECIFICATIONS 4SPECIFICHE HP1 / HP2 (Photoelectric Beam Sensor) HP1 / HP2 (Sensore a fascio fotoelettrico) Transmitter & Receiver Wire (HP1 : 2 PCS) / (HP2 : 4 PCS) 5m each Transmitter & Receiver Sensor (HP1 : 1EA / 1EA) / (HP2 : 2EA / 2EA) Screw (4 x 18) 2EA Manual Imposta Cavo trasmettitore e ricevitore (HP1 : 2 PCS) / (HP2 : 4 PCS) 5 m ciascuno Sensore trasmettitore e ricevitore (HP1 : 1EA / 1EA) / (HP2 : 2EA / 2EA) Vite (4 x 18) 2EA 1Copy Manuale 1 Copia CA/CC 12V ~ 30V (Senza polarità) Supply voltage AC/DC 12V ~ 30V (Non-polarity) Tensione di alimentazione Relay contact capacity 24V/1A Capacità contatti relè 24V/1A Operation Temperature -30℃~ 55℃ Temperatura di lavoro -30℃~ 55℃ Spec Working distance 10m Max Distanza di lavoro 10m Max Current consumption Standby 75mA / Active 100mA Assorbimento di corrente Standby 75 mA / Attivo 100 mA Weight Control box 75g / Sensor 133g (Including 5m cable) Peso Scatola di comando 75 g / Sensore 133 g (Incluso cavo 5 m) 5USER MANUAL 5MANUALE UTENTE 1. 2. 3. 4. Make wiring as REF 2 and Install transmitter and receiver at the same height. Supply power of AC/DC 12V ~ 30V and make sure that Power LED on the control box lights up Operation LED lights up when beam is interrupted and goes out when beam is not interrupted. Interrupt beam, and make sure that operation LED lights up and the connected devices work properly. Note) Working distance is Min 15cm and Max 10m In case operation LED goes off even though beam is interrupted, sensitivity may be too high. Reduce sensitivity by turning sensitivity adjustment volume. Make a hole ø 12mm(0.47”) and clean away the rough hole edge. 6EXTERNAL DIMENSIONS 1. 2. 3. 4. Effettuare il cablaggio in base a quanto illustrato nel riquadro 2 e installare il trasmettitore e il ricevitore alla stessa altezza. Fornire alimentazione CA/CC 12V ~ 30V e assicurarsi che il LED di alimentazione sulla scatola di comando sia acceso Il LED di funzionamento si accende quando il fascio è interrotto e si spegne in caso contrario. Interrompere il fascio, assicurarsi che i LED di funzionamento si accendano e che i dispositivi connessi funzionino correttamente. Nota) La distanza di lavoro minima è di 15 cm, mentre quella massima è di 10 m Nel caso in cui il LED di funzionamento si spegnesse nonostante l'interruzione del fascio, la sensibilità potrebbe essere troppo elevata. Ridurre la sensibilità utilizzando il volume di regolazione della sensibilità. Praticare un foro con diametro di 12 mm smussando poi il bordo. 6DIMENSIONI ESTERNE Scatola di comando Sensor Sensore Ø12 Ø12 Ø15 2 103,3 114,2 103,3 114,2 103,3 Control Box 103,3 Spec 14.3 Ø15 16.3 43,7 Il LED verde e il LED rosso si illuminano 5 volte Rilevati L1, L2 Altezza minima 500 mm L1 or L2 interrupted Green LED On while interrupted Beam installation Guide Set Vite di montaggio 29,0 Ø3.5 Unit : m/m Hotron Ltd. 26 Dublin Street, Carlow, Ireland Tel: +353 (0)59 914 0345 Fax: +353 (0)59 914 0543 www.hotron.com 2 14.3 16.3 43,7 29,0 Ø3.5 Unità: m/m Hotron Ltd. 26 Dublin Street, Carlow, Irlanda Tel: +353 (0)59 914 0345 Fax: +353 (0)59 914 0543 www.hotron.com Photoelectric Beam Sensor (HP1 / HP2) Photoelectric Beam Sensor (HP1 / HP2) Photoelectric Beam Sensor (HP1 / HP2) Manual de instrucciones Mode d'emploi Anleitungen Le agradecemos que haya adquirido este sensor automático de haz de seguridad para puertas. El sensor ha sido diseñado para detectar intrusiones e iniciar una alarma, un controlador de puertas, etc. Este sensor puede ofrecer un servicio prolongado y fiable si se instala correctamente. Lea atentamente este manual de instrucciones para un uso correcto y eficaz. Nous vous remercions d'avoir acheté ce capteur de sécurité à faisceau pour portes automatiques. Ce capteur est conçu pour détecter toute intrusion, déclenchant une alarme, un dispositif de commande de la porte, etc. L'installation correcte de ce capteur garantit un fonctionnement fiable sur une longue durée. Veuillez lire attentivement le présent mode d'emploi afin d'utiliser ce produit de manière correcte et efficace. Vielen Dank, dass Sie sich zum Kauf dieses automatischen Türsicherheitsstrahlsensors entschieden haben. Dieser Sensor wurde so konzipiert, dass er ein Eindringen erkennt, um einen Alarm, eine Türsperre oder ähnliche Aktionen auszulösen. Bei richtigem Einbau wird dieser Sensor lange und problemlos funktionieren. Bitte lesen Sie diese Anleitungen sorgfältig durch, um einen richtigen und effektiven Einsatz des Sensors sicherzustellen. 1DESCRIPCIÓN DE LAS PIEZAS 1DESCRIPTION DES COMPOSANTS 1TEILEBESCHREIBUNG Caja de control Sensor Boîtier de commande LED de funcionamiento Steuerkästchen DEL de fonctionnement LED de alimentación Sensor (Receptor) (Azul / 5 m) Tornillo de montaje Capteur (récepteur) (bleu/5 m) NC NO 2CABLEADO Stromversorgungs-LED Capteur (transmetteur) (gris/5 m) Volume de réglage de la distance < Valor predeterminado : NO > Vis de montage Salida de contacto (controlador de puerta) Caja de control L2 Receiver (Azul) Boîtier de commande < Standardwert : NO > Steuerkästchen L2 L1 Receiver (bleu) STROM (AC/DC 12 V ~ 30 V) Ohne Polarität Kontaktausgang (Türkontrolle) L2 L1 Transmisor (Gris) L2 L1 L1 Empfänger (Blau) Transmetteur (gris) Sender (Grau) LED-Anzeige Indicadores luminosos L2 Receptor L2 Transmisor L1 Receptor L1 Transmisor Einschalten Grüne und rote LED blinken abwechselnd ein Mal El LED verde se ilumina 5 veces y luego el LED rojo permanece iluminado Nur L1 gefunden Grüne LED blinkt 5 Mal, dann rote LED an Sólo se encuentra L2 El LED rojo se ilumina 5 veces y luego el LED rojo permanece iluminado Nur L2 gefunden Rote LED blinkt 5 Mal, dann rote LED an Transmetteur L2 Récepteur L1 Los LEDs verde y rojo se iluminan 5 veces simultáneamente L1 o L2 interrumpidos L1 Empfänger Transmetteur L1 L1, L2 gefunden Strahl-Einbauanleitung Guide d'installation du faisceau 4CARACTÉRISTIQUES Sensor de transmisor y receptor (HP1 : 1EA / 1EA) / (HP2 : 2EA / 2EA) Tornillo (4 x 18) 2EA Manual 1 copia Tensión de alimentación Capacidad del relé Temperatura de funcionamiento Kit Grüne und rote LED blinken kontinuierlich abwechselnd L1 oder L2 unterbrochen Grüne LED an während Unterbrechung 4TECHNISCHE DATEN HP1 / HP2 (Fotoelektrischer Strahl-Sensor) Câble transmetteur et récepteur (HP1 : 2 PCS) / (HP2 : 4 PCS) 5 m chacun Capteur transmetteur et récepteur (HP1 : 1EA / 1EA) / (HP2 : 2EA / 2EA) Vis (4 x 18) 2EA Manuel 1 copie CA/CC 12 V ~ 30 V (Sin polaridad) Tension d'alimentation 24V/1A Capacité du contact de relais -30℃~ 55℃ Température de fonctionnement Caractéristiques rote LED an 1. Stromversorgung AC/DC 12 V ~ 30 V nur ohne Polarität 2. Während der Einbauarbeiten darf das Gerät nicht mit Strom versorgt werden 3. Gerät nicht zerlegen oder verändern; dies könnte Brand oder Stromschlag zur Folge haben. HP1 / HP2 (capteur à faisceau photoélectrique) (HP1 : 2 UDS.) / (HP2 : 4 UDS.) 5 m cada uno Grüne und rote LED blinken 5 Mal gleichzeitig, dann 3CAUTION 1. Fournissez une alimentation de 12 V ~ 30 V CA/CC uniquement sans polarité 2. N'alimentez pas le dispositif en courant pendant les travaux d'ingénierie effectués lors de l'installation 3. Ne démontez ni ne modifiez le dispositif, cela pourrait provoquer un incendie ou un choc électrique. HP1 / HP2 (Sensor de haz fotoeléctrico) Cable de transmisor y receptor Keine gefunden Höhe Min 500 mm 3ATTENTION 4ESPECIFICACIONES Einstellen Kabel für Sender & Empfänger (HP1 : 2 Stk) / (HP2 : 4 Stk) je 5 m Sensor für Sender & Empfänger (HP1 : 1EA / 1EA) / (HP2 : 2EA / 2EA) Schraube (4 x 18) 2EA Anleitungen 1 Exemplar 12 V ~ 30 V CA/CC (non-polarité) Versorgungsspannung AC/DC 12 V ~ 30 V (Ohne Polarität) 24V/1A Relais-Kontaktkapazität 24V/1A -30℃~ 55℃ Betriebstemperatur -30℃~ 55℃ Techn. Daten Distancia operativa Máx. 10 m Distance de travail 10 m max. Arbeitsabstand 10m Max Consumo de corriente En standby 75 mA / Activo 100 mA Consommation électrique Veille 75 mA / Actif 100 mA Stromverbrauch Standby 75 mA / Aktiv 100 mA Peso Caja de control 75 g / Sensor 133 g (incluido el cable de 5 m) Poids Boîtier de commande 75 g / Capteur 133 g (câble de 5 m inclus) Gewicht Steuerkästchen 75 g / Sensor 133 g (incl. 5-m-Kabel) 5MANUAL DEL USUARIO 5GUIDE D'UTILISATION 1. 2. 3. 4. Realice el cableado conforme a REF 2 e instale el transmisor y el receptor a la misma altura. Suministre alimentación de CA/CC de 12 V ~ 30 V y compruebe que la caja de control se ilumina El LED de funcionamiento se ilumina cuando se interrumpe el haz y se apaga cuando no se interrumpe. Interrumpa el haz y compruebe que el LED de operación se ilumina y que los dispositivos conectados funcionan correctamente. Nota) La distancia operativa es de 15 cm (mín.) y 10 m (máx.) En el caso de que el LED de funcionamiento se apague incluso cuando se interrumpe el haz, es posible que la sensibilidad sea excesiva. Reduzca la sensibilidad girando el volumen de ajuste de sensibilidad. Efectúe un orificio de ø 12 mm (0,47”) y limpie la rebaba del borde del orificio. 6DIMENSIONES EXTERNAS Utilisez le câblage comme REF 2, puis installez le transmetteur et le récepteur à la même hauteur Fournissez une alimentation de 12 V ~ 30 V CA/CC, puis vérifiez que la DEL d'alimentation du boîtier de commande est allumée La DEL de fonctionnement s'allume quand le faisceau est interrompu et s'éteint quand le faisceau n'est pas interrompu Interrompez le faisceau et vérifiez que la DEL de fonctionnement s'allume et que les dispositifs connectés fonctionnent correctement. NB) La distance de travail est comprise entre 15 cm min. et 10 m max. Si la DEL de fonctionnement s'éteint bien que le faisceau soit interrompu, il se peut que la sensibilité soit trop élevée. Réduisez la sensibilité en tournant le volume de réglage de la sensibilité. Percez un trou de ø 12 mm (0,47”), puis nettoyez le bord brut du trou. 6DIMENSIONS EXTERNES Verkabelung gemäß REF 2 vornehmen, Sender und Empfänger in der gleichen Höhe einbauen. Stromversorgung AC/DC 12 V ~ 30 V anschließen und prüfen, ob die Strom-LED am Steuerkästchen leuchtet Die Betriebs-LED leuchtet, wenn der Strahl unterbrochen wird, und sie geht aus, wenn der Strahl nicht unterbrochen ist. Strahl unterbrechen und sicherstellen, dass die Betriebs-LED leuchtet und die angeschlossenen Geräte funktionieren. Hinweis) Der Arbeitsabstand muss zwischen 15 cm und 10 m betragen Wenn die Betriebs-LED ausgeht, auch wenn der Strahl unterbrochen ist, wurde die Empfindlichkeit evtl. zu hoch eingestellt. Empfindlichkeit durch Drehen der Empfindlichkeitseinstellung verringern. Ein 12-mm-Loch bohren und die Lochkanten entgraten. 6AUSSENABMESSUNGEN Steuerkästchen Sensor Ø12 Ø12 Ø12 14.3 Ø15 Ø3.5 Unidad : m/m Hotron Ltd. 26 Dublin Street, Carlow, Irlanda Tel: +353 (0)59 914 0345 Fax: +353 (0)59 914 0543 www.hotron.com 2 103,3 114,2 2 103,3 114,2 Ø15 103,3 Capteur 103,3 Sensor 16.3 29,0 1. 2. 3. 4. Boîtier de commande 103,3 103,3 114,2 5BENUTZERHANDBUCH 1. 2. 3. 4. Caja de control 43,7 L1 Sender Hauteur 500 mm min El LED verde permanece iluminado durante la interrupción 1. Suministre alimentación eléctrica de CA/CC 12 V ~ 30 V solamente sin polaridad 2. Interrumpa la alimentación eléctrica mientras se realizan los trabajos de instalación 3. No desmonte o modifique el dispositivo, ya que podría incendiarse o causar descargas eléctricas. Especificación L2 Sender y luego el LED rojo permanece iluminado 3PRECAUCIÓN Conjunto L2 Empfänger Los LEDs verde y rojo se iluminan alternadamente una vez Sólo se encuentra L1 No se encuentra ninguno Los LEDs verde y rojo se iluminan alternadamente continuamente Guía de instalación del haz Récepteur L2 Encendido Se encuentran L1, L2 Altura mínima 500 mm Montageschraube 2VERKABELUNG PUISSANCE (12 V ~ 30 V CA/CC) Non-polarité L2 L1 L1 Sensor (Empfänger) (Blau / 5 m) NC NO Sortie contact (dispositif de commande de la porte) L2 Sensor (Sender) (Grau / 5 m) Abstandseinstellung Stärke < Valeur par défaut : NO > 2CÂBLAGE ALIMENTACIÓN (CA/CC 12 V ~ 30 V) Sin polaridad Sensor Betriebs-LED DEL d'alimentation Sensor (Transmisor) (Gris / 5 m) Volumen de ajuste de distancia NC NO Capteur 14.3 Ø15 16.3 43,7 29,0 Ø3.5 Unité : m/m Hotron Ltd. 26 Dublin Street, Carlow, Irlande Tél. : +353 (0)59 914 0345 Télécopie : +353 (0)59 914 0543 www.hotron.com 2 14.3 16.3 43,7 29,0 Ø3.5 Einheit : m/m Hotron Ltd. 26 Dublin Street, Carlow, Ireland Tel: +353 (0)59 914 0345 Fax: +353 (0)59 914 0543 www.hotron.com

![]()

Компания «ВекторТехносервис» с 2004 года зарекомендовала себя как надежный поставщик продуктов и услуг в области промышленного оборудования.

Мы оказываем полный комплекс услуг по продаже, установке и обслуживанию всех типов ворот, перегрузочного, противопожарного оборудования, систем автоматики и дверей.

Контакты

- Адрес:

Россия, 127591, Москва,

ул. Дубнинская 79Б, офис 5 - Часы работы:

Пн — Пт: 9:00 — 18:00 - Телефоны:

+7 (495) 648-66-50

+7 (919) 786-88-81

Найдите нас:

ПочтаВконтакте

Новости

-

Роллетные ворота «АЛЮТЕХ» для регионов с высокими ветровыми нагрузками

-

Продление сертификата дилера Nice

-

Демонстрационный стенд по секционным воротам Hormann

-

С 1 марта 2019 года компания Херманн запустила новую акцию «Ворота и двери года»

H&T KOREA Co., Ltd.

- Country / Year Established

-

South Korea

/

- Business type

- Others

- Verified Certificate

-

9

| Product name | Photoelectric Beam Sensor | Certification |

— |

|---|---|---|---|

| Category |

Auto Sensors Sensors |

Ingredients | — |

| Keyword |

photoelectric beam sensor , , , |

Unit Size |

— |

| Brand name | H&T KOREA | Unit Weigh |

— |

| origin | Stock | — | |

| Supply type | — | HS code | 9024901000 |

Product Information

The safety sensor can open and close an automatic door depending on existence of an object between 2 beams.

Power Supply : AC/DC 12V ~ 24V (Non-polarity)

Relay Contact Capacity : 24V/1A

Operation Temperature : -20 ℃ ~ 60 ℃

Working Distance : 10m Max.

Current Consumption : Standby 37mA / Active 48mA

B2B Trade

| Price (FOB) |

Negotiable |

transportation | — |

|---|---|---|---|

| MOQ | Negotiable | Leadtime |

Negotiable |

| Payment Options | Negotiable | Shipping time |

Negotiable |

- Country / Year Established

-

South Korea

/

- Business type

- Others

-

9

- President

- Kim Jun Seok

- Address

- 709, Junganginduspia, Sangdaewon-Dong 517-13, Jungwon-Gu, Sungnam-Si, Kyonggi-Do, Korea

- Product Category

- Auto Sensors,Electrical Components & Telecoms,Sensors

- No. of Total Employees

- 1-50

- Company introduction

-

Since founded in 1997, H&T Korea has developed various products for customers who need controlling system, infrared/microwave sensor, wireless/wired input switch, and AM/FM remote control units which can be installed at the parking entrance, automatic slide/revolving/overhead door, and any kind of shutter/barrier. From the beginning until now, we have met the needs and expectations of various customers. The goal of our company is to keep the customers satisfied at all times through innovative technology development which is customized for users and strict quality control.

To achieve our goals, all the employees and executive will do the best and make every effort to help our customers get the benefits from our products and services. We are confident that your business will be successful with our products, supports, and services.Thank you very much for your interest with H&T Korea.

- Main Markets

- Main Product

Live Chat

Live Chat

No Data

- There is no data to load

- Check out the My tK > My Inquiries list.

- After agreeing to the use of the Live Chat service, the list is printed only when there is at least one history of receiving or sending a Live Chat request.

If you have not yet agreed to use the Live Chat service,

You can use the Live Chat freely after agreeing to the use of the Live Chat service.

View more

View more