- Manuals

- Brands

- Kyocera Mita Manuals

- All in One Printer

- KM-1500

- Operation manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

1500

KM-

Please read the Operation Guide before using the copier

Keep it close to the copier for easy reference

Related Manuals for Kyocera Mita KM-1500

Summary of Contents for Kyocera Mita KM-1500

-

Page 1

1500 Please read the Operation Guide before using the copier Keep it close to the copier for easy reference… -

Page 2

All rights reserved. No part of this material may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage and retrieval system, without permission in writing from the Publisher. Legal Restriction On Copying •… -

Page 3

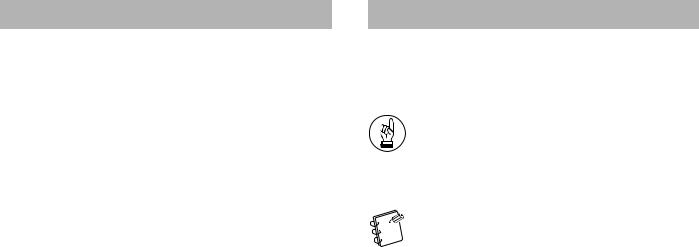

Introduction to this Operation Guide Symbols in this guide The explanations contained in this operation guide have been This Operation Guide contains certain symbols to indicate points of separated into different sections in order to allow even those using caution and additional information that is important for you to a copier for the first time to use this machine efficiently, properly know. -

Page 4: Table Of Contents

CONTENTS Section 7 TROUBLESHOOTING ……7-1 Energy Star Program …………..iii Please read this Operation Guide before using the copier. Keep it If one of the following indications is displayed ……7-1 close to the copier for easy reference……….iv If paper jams ………………7-3 Misfeed location indicators ………….

-

Page 5: Energy Star Program

Energy Star Program We have determined as a participating company in the International Energy Star Program that this product is compliant with the standards laid out in the International Energy Star Program. About the International Energy Star Program International Energy Star Program has as its basic goals the promotion of efficient energy use and the reduction of the environmental pollution that accompanies energy consumption by promoting the manufacture and sale of products that fulfill…

-

Page 6: Please Read This Operation Guide Before Using The Copier. Keep It Close To The Copier For Easy Reference

Please read this Operation Guide before using the copier. Keep it close to the copier for easy reference. Please read this Operation Guide before using the copier. Keep it close to the copier for easy reference. The sections of this guide and parts of the copier marked with symbols are safety warnings meant to protect the user, other individuals and surrounding objects, and ensure correct and safe usage of the copier.

-

Page 7: Important! Please Read First

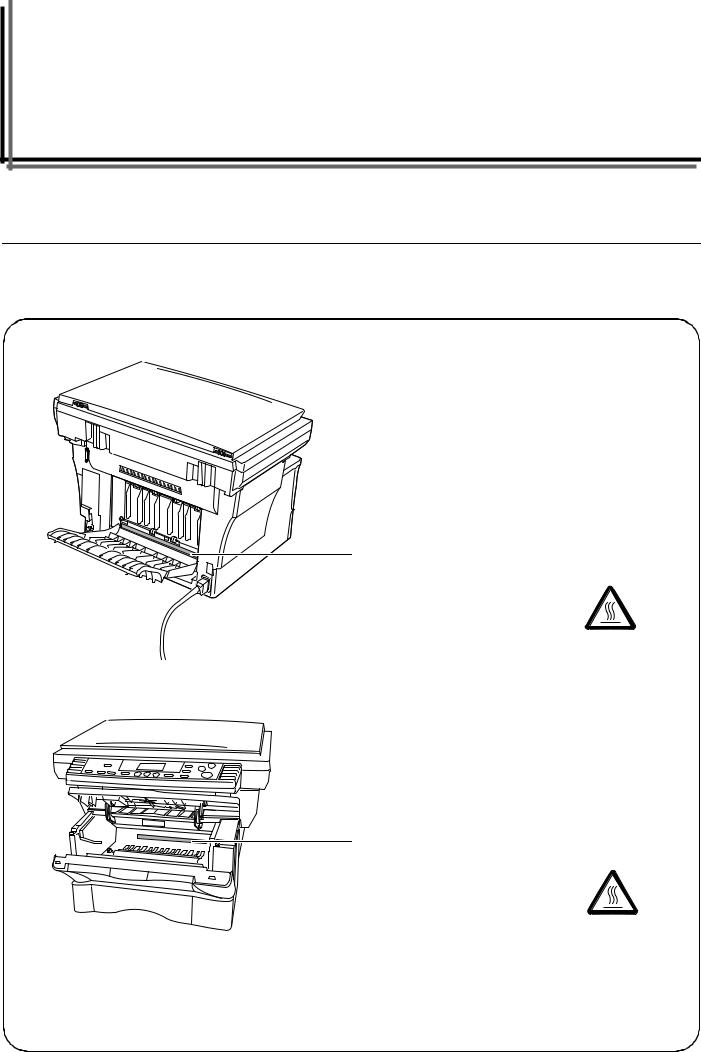

Section 1 IMPORTANT! PLEASE READ FIRST. CAUTION LABELS Caution labels have been attached to the copier at the following locations for safety purposes. BE SUFFICIENTLY CAREFUL to avoid fire or electric shock when removing a paper jam or when replacing toner.

-

Page 8: Installation Precautions

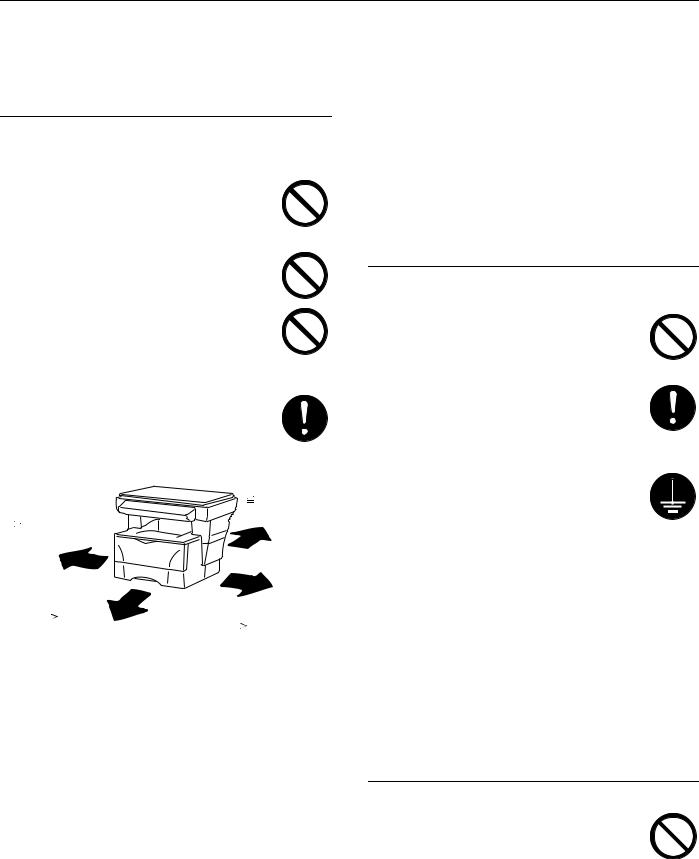

INSTALLATION PRECAUTIONS Environment During copying, some ozone is released, but the amount does not cause any ill effect to one’s health. If, CAUTION however, the copier is used over a long period of time in a poorly ventilated room or when making an extremely large number of copies, the smell may become unpleasant.

-

Page 9: Precautions For Use

PRECAUTIONS FOR USE CAUTION Cautions when using the copier WARNING DO NOT pull the power cord when removing it from the outlet. If the power cord is pulled, the wires may become broken and there is a DO NOT place metallic objects or containers danger of fire or electrical shock.

-

Page 10: Cautions When Handling Consumables

Cautions when handling Other precautions consumables DO NOT place heavy objects on the copier or cause CAUTION other damage to the copier. DO NOT open the upper front cover, turn off the power switch, or pull out the power plug during copying.

-

Page 11: Laser Safety

Laser Safety Laser radiation could be hazardous to the human body. For this reason, laser radiation emitted inside this machine is hermetically sealed within the protective housing and external cover. In the normal operation of the product by user, no radiation can leak from the machine. This machine is classified as Class 1 laser product under IEC 60825.

-

Page 12

CAUTION! The power plug is the main isolation device! Other switches on the equipment are only functional switches and are not suitable for isolating the equipment from the power source. VORSICHT! Der Netzstecker ist die Hauptisoliervorrichtung! Die anderen Schalter auf dem Gerät sind nur Funktionsschalter und können nicht verwendet werden, um den Stromfluß… -

Page 13

DECLARATION OF CONFORMITY 89/336/EEC, 73/23/EEC and 93/68/EEC We declare under our sole responsibility that the product to which this declaration relates is in conformity with the following specifications. Limits and methods of measurement for immunity characteristics of information technology equipment EN55024 Limits and methods of measurement for radio interference characteristics of information technology equipment… -

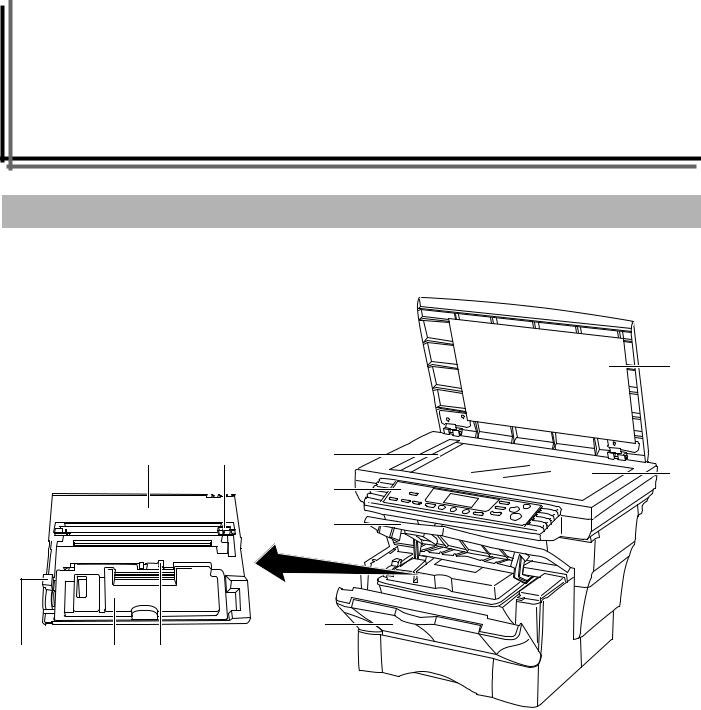

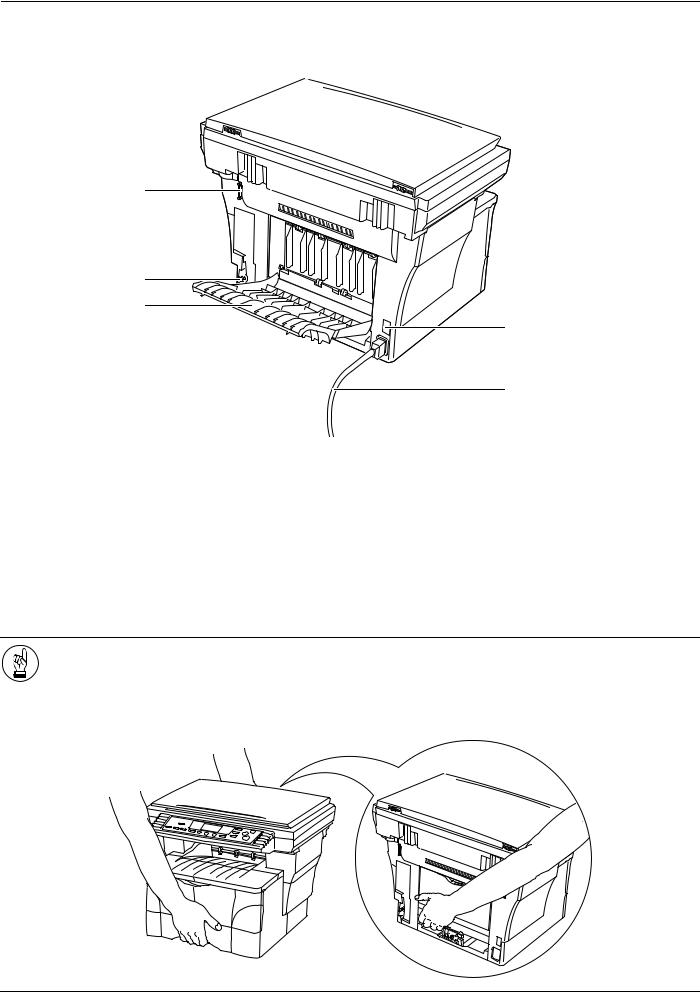

Page 15: Names Of Parts

Section 2 NAMES OF PARTS Main Body (11) (10) (1) Original cover (8) Toner container (Open/close this cover when you are setting the original on the (9) Lock lever platen.) (Operate this lever when you need to replace the toner (2) Platen container.) (Set originals here for copying.

-

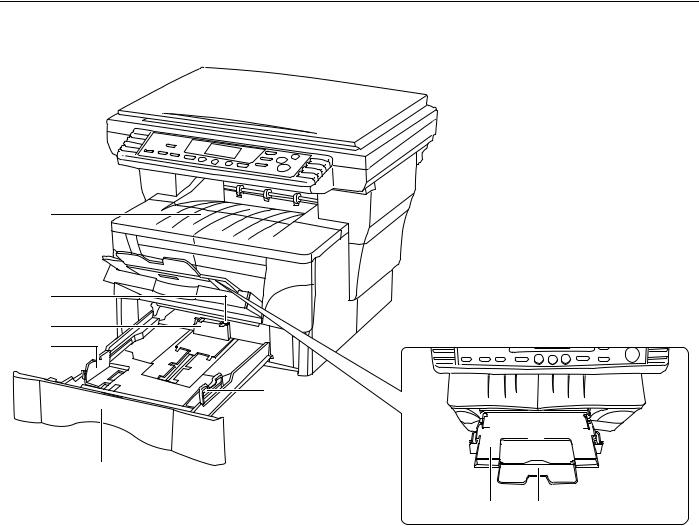

Page 16

Section 2 NAMES OF PARTS (16) (15) (14) (13) (13) (19) (19) (12) (17) (18) (12) Drawer (This drawer has a storage capacity of 250 sheets of standard copy paper (80 g/m²).) (13) Paper width guides (Adjust these guides to fit the width of the paper that is to be loaded in the drawer.) (14) Paper stopper (Adjust this stopper to fit the length of the paper that is to be… -

Page 17

Section 2 NAMES OF PARTS (23) (24) (21) (20) (22) (20) Power switch (23) Document Processor connector (Turn this switch ON ( | ) before copying.) (Attach the connection cable here when installing the optional (21) Face-up tray Document Processor.) (Finished copies can be ejected and stored face-up on this tray. -

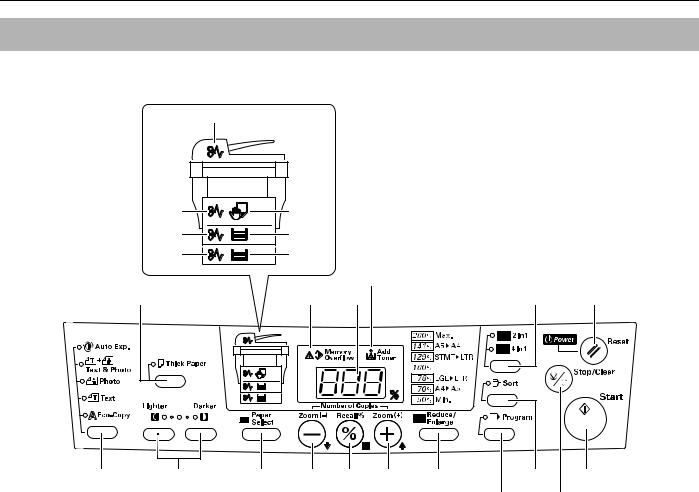

Page 18: Operation Panel

Section 2 NAMES OF PARTS Operation panel (24) (23) (22) (19) (18) (21) (20) (16) (12) (17) (13) (11) (10) (14) (15) (1) Start key & indicator (8) Number of Copies / Zoom(-) key (Press this key when you want to start copying. Copying will (Press this key when you want to lower the number of copies begin immediately if you press this key when the indicator is to be made, as well as to decrease the currently selected copy…

-

Page 19: Auto Clear Function

Section 2 NAMES OF PARTS Initial mode (15) Program key & indicator (the state that the copier enters at the end of (Press this key when you want to copy with the Program warm-up or when the Reset/Power key is pressed) function.

-

Page 20

Section 2 NAMES OF PARTS… -

Page 21: Section 3 Preparations

Section 3 PREPARATIONS Loading paper Loading paper into a drawer Copy paper can either be loaded into the drawer(s) or set on the multi-bypass tray. Standard copy paper (60 g/m² – 90 g/m²), thick paper (90 g/m² – 105 g/m²), recycled paper, or color paper can be loaded into each Note when adding paper drawer.

-

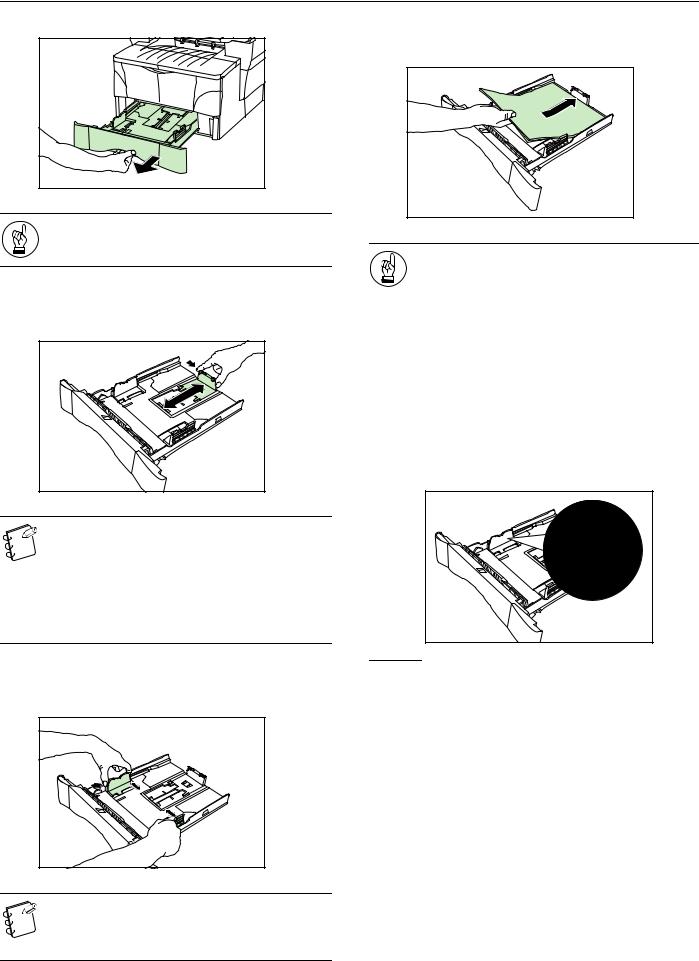

Page 22

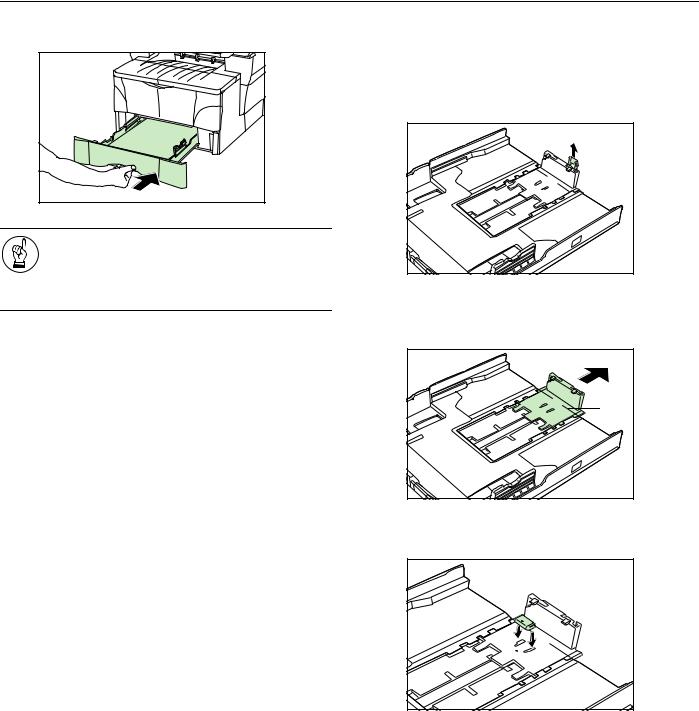

Section 3 PREPARATIONS Pull the drawer all the way out of the copier. Set the paper in the drawer so that the leading edge is aligned against the paper stopper, but making sure that none of the paper gets caught on the overhanging tabs. IMPORTANT! When pulling the drawer out of the copier, be sure to IMPORTANT! -

Page 23

Section 3 PREPARATIONS Adjusting the paper stopper for Folio or Push the drawer securely all the way back into the copier until it stops. Oficio II size paper Perform the following procedure to adjust the paper stopper when you want to load Folio or Oficio II size paper into the drawer. Remove the stopper extension lock from the paper stopper. -

Page 24: Selecting The Paper Size

Section 3 PREPARATIONS Selecting the paper size Press down on the stopper extension lock and slide the paper stopper towards the rear of the drawer to set the lock Perform the following procedure to use the operation panel and into place. The paper stopper is now in position for Folio select the size of paper that is loaded in the drawer.

-

Page 25: Setting Paper On The Multi-Bypass Tray

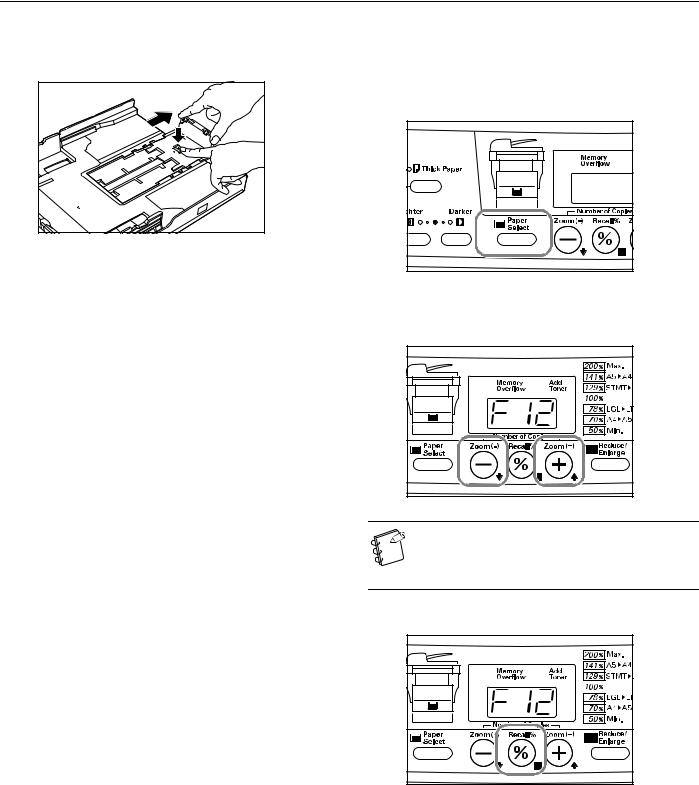

Section 3 PREPARATIONS Setting paper on the multi-bypass tray Press the Number of Copies / Zoom(+) or Number of Copies / Zoom(-) key to select the appropriate paper size. The displayed code numbers refer to the available paper Standard copy paper (60 g/m² – 90 g/m²), thick paper (90 g/m² – sizes as explained in the following table.

-

Page 26

Section 3 PREPARATIONS Open the multi-bypass tray towards you until you hear it Slide the paper all the way in, along the insert guides, as click into place. far as it will go. Pull out the multi-bypass extension and then flip it open. IMPORTANT! •… -

Page 27

Section 3 PREPARATIONS Selecting the paper size Press the Number of Copies / Zoom(+) or Number of Copies / Zoom(-) key to select the appropriate paper size. Perform the following procedure to use the operation panel and The displayed code numbers refer to the available paper select the size of paper that is set on the multi-bypass tray. -

Page 28

Section 3 PREPARATIONS Selecting the paper size (temporary setting) Press the Recall%/Enter key. The copier will return to a copy-ready state. Press the Paper Select key until the multi-bypass tray indicator is lit. Press the Number of Copies / Zoom(+) or Number of Copies / Zoom(-) key to select the appropriate paper size. -

Page 29: Thick Paper Mode

Section 3 PREPARATIONS Thick Paper mode Perform the following procedure to select the Thick Paper mode when copying onto thick copy paper (90 g/m² – 163 g/m²). When this mode is selected, copying will be carried out at a higher fixing temperature and the copy speed will be lowered in order to ensure efficient fixing of the toner to the copy paper.

-

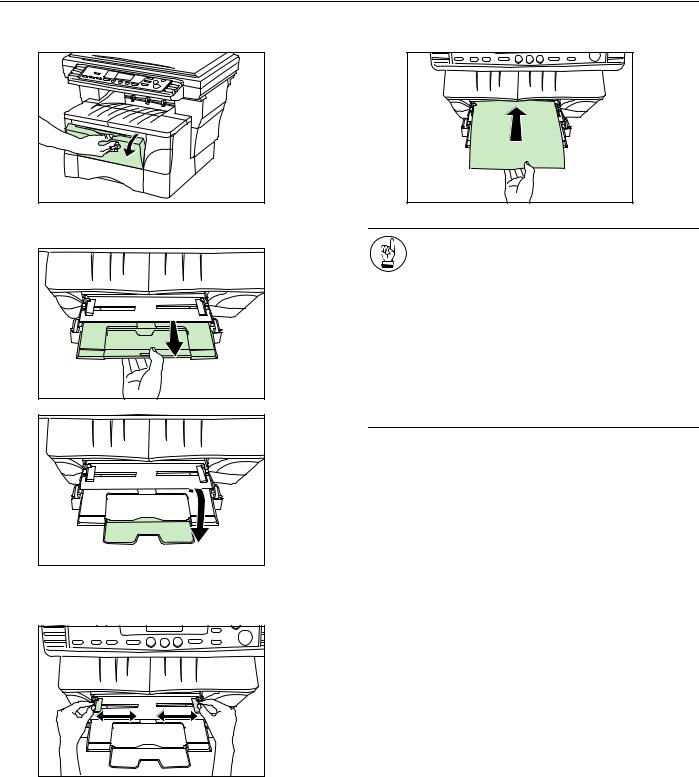

Page 30: Attaching The Face-Up Tray

Section 3 PREPARATIONS Attaching the face-up tray When copying onto special paper, such as thick paper (90 g/m² – Perform the standard copying procedure. Finished copies 163 g/m²) and OHP transparencies, ALWAYS use the face-up tray. will be ejected onto the face-up tray. The face-up tray has a storage capacity of 30 sheets of standard copy paper (80 g/m²) but only 1 sheet of special paper should be stored there at one time.

-

Page 31: Basic Operation

Section 4 BASIC OPERATION Basic copying procedure Warm-up Selecting the image quality Turn the power switch ON ( | ). At the end of warm-up, the The image quality mode can be selected according to the Start indicator will light. type of original.

-

Page 32

Section 4 BASIC OPERATION Adjusting the copy exposure Setting an original The copy exposure can be manually adjusted in all of the Open the original cover and set the original that you want image quality modes, except for the Auto Exposure to copy face-down onto the platen. -

Page 33

Section 4 BASIC OPERATION At the end of copying Finished copies will be ejected onto the copy storage table. NOTE The copy storage table has a storage capacity of 150 sheets of standard copy paper (80 g/m²). CAUTION If the copier will not be used for a short period of time (overnight, etc.), turn the power switch OFF ( ). -

Page 34: Making Enlarged And Reduced Copies

Section 4 BASIC OPERATION Making enlarged and reduced copies Zoom mode Press the Recall%/Enter key. The new magnification ratio will be registered and the copy quantity/magnification display will return to showing the number of copies to be With this mode, the magnification ratio can be set to any 1% made.

-

Page 35: Preset Zoom Mode

Section 4 BASIC OPERATION Preset Zoom mode Press the Recall%/Enter key. The new magnification ratio will be registered and the copy quantity/magnification display will return to showing the number of copies to be With this mode, the magnification ratio can be set to one of the made.

-

Page 36

Section 4 BASIC OPERATION… -

Page 37: Copy Functions

Section 5 COPY FUNCTIONS Layout modes 2-in-1 With this mode, the images from either 2 or 4 originals can be reduced and then combined onto a single copy. In addition, the borderline of each original can also be marked with a solid or Use this mode when you want to copy two originals onto each sheet dotted line.

-

Page 38

Section 5 COPY FUNCTIONS Caution on setting the originals The following illustrations indicate how the orientation of the original will affect the resulting copies. <When setting the originals on the platen> NOTE Make sure the originals are set so that the first page is scanned first. -

Page 39

Section 5 COPY FUNCTIONS <When setting the originals in the Document Processor> NOTE Make sure the originals are set so that the first page is scanned first. -

Page 40

Section 5 COPY FUNCTIONS Press the 2in1/4in1 key until the 2in1 indicator lights. Once you have finished scanning all of the originals, press the Recall%/Enter key or the 2in1/4in1 key. Copying will start. NOTE It is possible for you to change the type of borderline. (See “Selecting the borderline”… -

Page 41: In-1

Section 5 COPY FUNCTIONS 4-in-1 <When setting the originals in the Document Processor> Use this mode when you want to copy four originals onto each sheet of copy paper. Original Copy Caution on setting the originals Be sure to set the originals as shown in the following illustrations. <When setting the originals on the platen>…

-

Page 42: Selecting The Borderline

Section 5 COPY FUNCTIONS Selecting the borderline Press the Start key. Scanning of the first original will start. Perform the following procedure when you want to change the type of borderline. NOTE If the optional Document Processor is installed on your copier, all of the originals set there will be scanned and the copy operation will start.

-

Page 43: Selecting The Order Of 4-In-1 Layout

Section 5 COPY FUNCTIONS Selecting the order of 4-in-1 layout Press the Number of Copies / Zoom(+) or the Number of Copies / Zoom(-) key to select the desired borderline. The displayed code numbers refer to the available Perform the following procedure if you want to select the order in borderline types as explained in the following table.

-

Page 44

Section 5 COPY FUNCTIONS Press the Number of Copies / Zoom(+) or the Number of Copies / Zoom(-) key until the number that corresponds to desired layout order (1 – 4) is shown. The displayed code numbers refer to the available layout orders as explained in the following table. -

Page 45: Sort Mode

Section 5 COPY FUNCTIONS Sort mode Multiple originals can be scanned into memory in a single Once scanning of the first original is completed, “1-” (the operation and then the desired number of copy sets created. number of originals already scanned) will be shown. Set the next original and press the Start key.

-

Page 46

Section 5 COPY FUNCTIONS 5-10… -

Page 47: Copy Default Settings

Section 6 COPY DEFAULT SETTINGS Available default items The state that the copier enters at the end of warm-up or when the Reset/Power key is pressed is called the “initial mode”. The modes, functions and other settings that are automatically pre-set for use in the initial mode are called “default settings”. These default settings can be changed as desired to suit your copying needs.

-

Page 48

Section 6 COPY DEFAULT SETTINGS Item Reference Default Description Available settings number page Multi-Bypass Tray Paper Registers the size of paper that is to be set on -A4: A4 Size the multi-bypass tray. -A5: A5 * The “XXX” shown here refers to the actual -A6: A6 width of the paper as registered under the -Fo: Folio… -

Page 49

Section 6 COPY DEFAULT SETTINGS Item Reference Default Description Available settings number page Paper Feeder Skewed Adjusts for off-center printing. -1.0 – 3.0 (mm) Feed Adjustment (option) * If the optional Paper Feeder is not installed (Adjustment is complete on your copier, this default setting will not at the time of purchase.) appear. -

Page 50: Section 6 Copy Default Settings

Section 6 COPY DEFAULT SETTINGS Accessing and changing the default settings Press the Recall%/Enter key. NOTE If you selected default items “F01” or “F32”: The If you want to access the “F30” default item (Document corresponding list/report will be printed out. Proceed to Processor Skewed Feed Adjustment), proceed directly to step 4.

-

Page 51

Section 6 COPY DEFAULT SETTINGS Sample User Copy Setting List Press the Number of Copies / Zoom(+) or the Number of Copies / Zoom(-) key to select either ON or OFF. (F21 and F25) Press the Recall%/Enter key. The operation panel will return to the display in step 2. -

Page 52

Section 6 COPY DEFAULT SETTINGS Press the Recall%/Enter key. The operation panel will If the result is as shown in example (1), increase the return to the display in step 2. Once you are finished setting. If the result is as shown in example (2), decrease accessing default items, proceed to step 17. -

Page 53

Section 6 COPY DEFAULT SETTINGS The selected setting will change each time you press the Prior to performing the adjustment procedure, it is Number of Copies / Zoom(+) or the Number of Copies / necessary to use the Document Processor to make copies in Zoom(-) key. -

Page 54

Section 6 COPY DEFAULT SETTINGS If the result is as shown in example (1), increase the Prior to performing the adjustment procedure, it is setting. If the result is as shown in example (2), decrease necessary to use the Document Processor to make copies in the setting. -

Page 55

Section 6 COPY DEFAULT SETTINGS Arrange the original and copy one on top of the other to verify the direction and amount of the shift. If the result is as shown in example (1), increase the setting. If the result is as shown in example (2), decrease the setting. -

Page 56: Checking The Total Copy Count And Printing Out A Report

Section 6 COPY DEFAULT SETTINGS Checking the total copy count and printing out a report It is possible to use the operation panel to check the total number of Sample Total Count Report copies made. It is also possible to print out that information in the form of a report.

-

Page 57: Troubleshooting

Section 7 TROUBLESHOOTING If one of the following indications is displayed When any of the following indications appears on the copy quantity/magnification display, perform the corresponding procedure. Reference Indication Procedure Page “E07” appears on the copy quantity/ The size of paper registered in the default settings is different than the magnification display size of the paper actually used.

-

Page 58: Section 7 Troubleshooting

Section 7 TROUBLESHOOTING Reference Indication Procedure Page “E72” appears on the copy quantity/ Originals for another job were set in the optional Document Processor — magnification display during copying from the platen in the 2-in-1 or 4-in-1 layout mode or in the Sort mode.

-

Page 59: If Paper Jams

Section 7 TROUBLESHOOTING If paper jams If a paper jam occurs, copying will stop. In this case, an indication about the jam will appear on the operation panel. Leave the power switch ON ( | ) and refer to “Removal procedures” on page 7-4 to remove the jammed paper. Misfeed location indicators Cautions WARNING…

-

Page 60: Removal Procedures

Section 7 TROUBLESHOOTING Removal procedures If the leading edge of the jammed paper is visible, pull it out towards you. If the paper is not visible at all, perform the “Paper jam in a drawer” procedure. Paper jam inside the copier If the paper has been fed to the rear of the copier but the leading edge is not visible, perform the “Paper jam in the paper eject section”…

-

Page 61

Section 7 TROUBLESHOOTING Paper jam in a drawer Open and then close the upper front cover. The error indications will go out. Pull out the drawer that is currently being used. Remove the jammed paper. NOTE If a paper jam occurs in the optional Paper Feeder, the procedure to remove jammed paper is the same as with the included drawer. -

Page 62

Section 7 TROUBLESHOOTING Paper jam in the paper eject section Open and then close the upper front cover. The error indications will go out. Open the face-up tray. Remove the jammed paper. CAUTION The copier’s fixing unit is extremely hot. Take sufficient care when working in this area, as there is a danger of getting burned. -

Page 63

Section 7 TROUBLESHOOTING Paper jam in the multi-bypass tray Original jam in the optional Document Processor Remove all of the paper remaining on the multi-bypass tray. Remove all of the originals remaining on the original table. Open and then close the upper front cover. The error Open the left cover to the Document Processor. -

Page 64

Section 7 TROUBLESHOOTING Remove the jammed original. Close the Document Processor. Reset the originals. -

Page 65: If Other Trouble Occurs

Section 7 TROUBLESHOOTING If other trouble occurs If trouble occurs with your copier, carry out the applicable checkpoints and procedures indicated on the following pages. If the trouble persists, contact your service representative or authorized service center. Reference Trouble Checkpoint Procedure Page Nothing lights on the…

-

Page 66

Section 7 TROUBLESHOOTING Reference Trouble Checkpoint Procedure Page Black or white vertical bands Is the charger cleaner in its home position Remove the Process Unit and return the appear on the copies. (marked “CLEANER HOME POSITION”)? charger cleaner to its home position. If you are using the optional Document Clean the slit glass. -

Page 67: Maintenance And Operation Information

Section 8 MAINTENANCE AND OPERATION INFORMATION Cleaning the copier If the optional Document Processor is installed on your copier, lift open the Document Processor and wipe the gray portion, as shown CAUTION in the illustration, with a soft cloth dampened with alcohol or mild detergent.

-

Page 68: Replacing The Toner Container

Section 8 MAINTENANCE AND OPERATION INFORMATION Replacing the toner container When toner runs low, the Add Toner indicator will light. If you Open the upper front cover. continue to make copies while the Add Toner indicator is lit, “E33” will appear on the copy quantity/magnification display and the copier will stop.

-

Page 69

Section 8 MAINTENANCE AND OPERATION INFORMATION Pull the lock lever towards you into its release position Shake the new toner container horizontally 5 or 6 times to (marked “UNLOCK”), then pull the toner container release ensure that the toner is evenly distributed inside. lever to the right as indicated by the arrow ( ) in the illustration. -

Page 70: Cleaning The Charger And The Registration Roller

Section 8 MAINTENANCE AND OPERATION INFORMATION Cleaning the charger and the registration roller Hold the Process Unit stable and push on the areas marked “PUSH HERE” on the toner container, until the container Perform the following cleaning operation whenever you replace the clicks into place.

-

Page 71

Section 8 MAINTENANCE AND OPERATION INFORMATION Close the front cover. Close the upper front cover. After use, ALWAYS dispose of the toner container in accordance with Federal, State and Local rules and regulations. -

Page 72: Specifications

Section 8 MAINTENANCE AND OPERATION INFORMATION Specifications Main Body Type……………..Desktop Original table …………..Fixed type Copying system …………..Indirect electrostatic system Acceptable originals …………Sheets of paper, books and 3-dimensional objects (Maximum size: 8 » × 14″ (Legal) / Folio) Copy sizes ……………Drawer: 8 «…

-

Page 73: Document Processor (Option)

Section 8 MAINTENANCE AND OPERATION INFORMATION Document Processor (option) Original feed system …………Automatic feeding Acceptable originals…………Sheets of paper Original sizes …………..Max.: 8 » × 14″ (Legal) and Folio Min.: 5 » × 8 » (Statement) and A5R Original paper weight…………

-

Page 74: Environmental Specifications

Section 8 MAINTENANCE AND OPERATION INFORMATION Environmental Specifications • Recovery time from the Low Power mode….10 seconds • Transition time to the Low Power mode (at time of purchase) ………..15 minutes • Transition time to the Off and Sleep modes (at time of purchase) ………..30 minutes Duplex (2-sided) copying •…

-

Page 75

For best copy results and machine performance, we recommend that you use only KYOCERA MITA original supplies for your KYOCERA MITA copier. -

Page 76

KYOCERA MITA DEUTSCHLAND GMBH KYOCERA MITA GMBH AUSTRIA KYOCERA MITA TAIWAN CORPORATION KYOCERA MITA SVENSKA AB KYOCERA MITA KYOCERA MITA NORGE CORPORATION ©2003 KYOCERA MITA CORPORATION is a trademark of Kyocera Corporation 2003. 3 is a registered trademark of KYOCERA MITA CORPORATION 2DC80030A…

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

KM-1500

SERVICE

MANUAL

Published in Mar. ’04

842DC113

Revision 3

Related Manuals for Kyocera KM-1500

Summary of Contents for Kyocera KM-1500

-

Page 1: Service Manual

KM-1500 SERVICE MANUAL Published in Mar. ’04 842DC113 Revision 3…

-

Page 2

CAUTION Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. CAUTION Double-pole/neutral fusing. -

Page 3: Safety Precautions

Safety precautions This booklet provides safety warnings and precautions for our service personnel to ensure the safety of their customers, their machines as well as themselves during maintenance activities. Service personnel are advised to read this booklet carefully to familiarize themselves with the warnings and precautions described here before engaging in maintenance activities.

-

Page 4

Safety warnings and precautions Various symbols are used to protect our service personnel and customers from physical danger and to prevent damage to their property. These symbols are described below: DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect compliance with warning messages using this symbol. -

Page 5: Installation Precautions

1. Installation Precautions WARNING • Do not use a power supply with a voltage other than that specified. Avoid multiple connections to one outlet: they may cause fire or electric shock. When using an extension cable, always check that it is adequate for the rated current………………… •…

-

Page 6

2. Precautions for Maintenance WARNING • Always remove the power plug from the wall outlet before starting machine disassembly….• Always follow the procedures for maintenance described in the service manual and other related brochures……………………….• Under no circumstances attempt to bypass or disable safety features including safety mechanisms and protective circuits. -

Page 7

• Do not pull on the AC power cord or connector wires on high-voltage components when removing them; always hold the plug itself………………….. • Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a cable cover or other appropriate item. -

Page 8: Specifications

2DC-2 CONTENTS 1-1 Specifications 1-1-1 Specifications ……………………….1-1-1 1-1-2 Name of parts ……………………….1-1-2 (1) Copier ……………………….. 1-1-2 (2) Operation panel ……………………..1-1-3 1-2 Handling Precautions 1-2-1 Drum …………………………1-2-1 1-2-2 Installation environment ……………………1-2-1 1-3 Installation 1-3-1 Unpacking and installation ……………………1-3-1 (1) Installation procedure ……………………

-

Page 9: Table Of Contents

2DC-2 (8) The eraser lamp does not turn on………………..1-5-21 (9) The exposure lamp does not turn on……………….. 1-5-21 (10) The exposure lamp does not turn off……………….. 1-5-21 (11) The heater lamp does not turn on………………..1-5-21 (12) The heater lamp does not turn off.

-

Page 10

2DC-2 (6) Adjusting magnification of the scanner in the auxiliary scanning direction ……..1-6-46 (7) Adjusting the scanner leading edge registration …………….1-6-47 (8) Adjusting the scanner center line ………………..1-6-48 (9) Adjusting the margins for scanning an original on the contact glass ……….1-6-49 (10) Adjusting the DP magnification ………………… -

Page 11

2DC-2 1-1-1 Specifications Type ……….Desktop Copying system ……Indirect electrostatic system » × 14″ [legal]) Originals ……… Sheets of paper (Maximum original size: folio/8 Platen: Sheets of paper, books, 3-dimensional objects (Maximum original size: folio/ » × 14″ [legal]) Original feed system …… -

Page 12

2DC-2 1-1-2 Name of parts (1) Copier ‹ › ⁄ ¤ & Figure 1-1-1 Name of parts 1 Original holder # Paper guide 2 Contact glass $ Paper stopper 3 Original size indicator % Stopper extension lock 4 Operation panel ^ Face-down output tray 5 Front top cover &… -

Page 13

2DC-2 (2) Operation panel ⁄ & Figure 1-1-2 1 Start key (Indicator) @ Thick Paper key (Indicator) 2 Reset/Power key # 2in1/4in1 key (Indicators) 3 Stop/Clear key $ Sort key (Indicator) 4 Copy quantity/magnification display % Program key (Indicator) 5 Copy exposure adjustment keys ^ Add toner indicator 6 Image mode selection key &… -

Page 14: Installation Environment

2DC-2 1-2-1 Drum Note the following when handling or storing the drum. • When removing the process unit, never expose the drum surface to strong direct light. • Keep the drum at an ambient temperature between 10°C/50°F and 32.5°C/90.5°F and at a relative humidity not higher than 80% RH.

-

Page 15: Unpacking And Installation

1-3-1 Unpacking and installation (1) Installation procedure Start Unpack. Remove the tapes, pads and sheets. Remove the pin holding scanner unit. Install a toner container. Connect the power cord. Inisializing the copier. Load paper. Make test copies. Completion of the machine installation. 1-3-1…

-

Page 16

Unpack & & Figure 1-3-1 Unpacking 1 Copier ! Front spacer 2 Power cord @ Front pad 3 Toner container # Bottom spacer 4 Operation guide $ Corner support 5 Installation guide % Products cover 6 Cleaning cloth ^ Plastic bag 7 Outer case &… -

Page 17

CAUTIONS • Be sure to hold both the front and rear sides of the copier when carrying it, as shown in the illustration. • Be sure not to pull the cassette out when holding the front of the copier. • Be sure that the original cover is closed whenever transporting the copier. •… -

Page 18

Remove the tapes, pads and sheets. 1. Remove the sheet and the two tapes. Tapes Sheet Figure 1-3-3 2. Open the original cover. Original cover Figure 1-3-4 1-3-4… -

Page 19

3. Remove the nine tapes, the three pads and the sheet. Tapes Tape Tapes Sheet Tapes Figure 1-3-5 4. Pull the cassette out of the copier. Cassette Figure 1-3-6 5. Remove the pad from inside the cassette. Figure 1-3-7 1-3-5… -

Page 20

Remove the pin holding scanner unit. 1. Remove the yellow pin for scanner unit and the paper tag from the left side of the copier. Paper tag Figure 1-3-8 Install a toner container. 1. Open the front top cover and front cover. Front top cover Front cover Figure 1-3-9… -

Page 21

3. Remove the process unit from the copier. CAUTIONS • Place the process unit on a clean, level surface. • Never expose the process unit to any sort of impact or shock. • The drum in the process unit is sensitive to light. Never expose the drum even to normal office lighting (500 lux) for more than five minutes. -

Page 22

6. Shake the toner container horizontally back and forth five or six times so that the toner inside of it becomes evenly distributed. Toner container Figure 1-3-14 7. Remove the orange protective seal. Seal Figure 1-3-15 8. Set the toner container into the process unit. Toner container Process unit Figure 1-3-16… -

Page 23

9. Hold the process unit stable and push in on the areas of the toner container marked “PUSH Toner container HERE” until the container clicks into place in the process unit. Figure 1-3-17 10. Push the lock lever back into its locked position. Lock lever Figure 1-3-18 11. -

Page 24

12. Close the front cover. Front cover Figure 1-3-20 13. Close the front top cover. Front top cover Figure 1-3-21 1-3-10… -

Page 25

2DC-2 Connect the power cord. 1. Connect the power cord. Power cord Figure 1-3-22 Initializing the copier. 1. Turn the power switch to the copier ON ( | ). Power switch Figure 1-3-23 First “900” will appear in the copy quantity/ magnification display on the copier’s operation panel. -

Page 26

Load paper. 1. Pull the cassette out of the copier. Cassette Figure 1-3-25 2. Adjust the paper stopper in the rear portion of the Paper stopper cassette to fit the size of the paper being loaded there by pressing in on the release buttons and sliding the paper stopper to the corresponding paper size. -

Page 27

2DC-2 4) Press down on the stopper extension lock and slide the paper stopper towards the rear of the cassette to set the lock into place. Paper stopper The paper stopper is in position for Folio and Oficio II size paper. Stopper extension lock Figure 1-3-28… -

Page 28

NOTES • DO NOT set more paper than indicated by the lines located on the paper width guides. Paper width guide • Be sure to load paper with the side to be copied onto facing down. Figure 1-3-31 5. Push the cassette securely all the way back into the copier until it stops. -

Page 29

2DC-2 1-3-2 Installing the document processor (option) Procedure 1. Remove all of the components to the document processor from the box. CAUTION Be sure to hold both sides of the document processor when carrying it, as shown in the illustration. Be particularly careful NOT to touch the guide film or the thin white surface indicated by the A in the illustration. -

Page 30

4. Attach the document processor to the copier. CAUTION Be sure that the connection cable does not get caught between the document processor and the copier when attaching the document processor to the copier. Connection cable Figure 1-3-36 5. Gently close the document processor. Document processor Figure 1-3-37… -

Page 31

2DC-2 CAUTION Be sure to tighten the pins securely when connecting the cable. Pins Figure 1-3-39 7. Turn the power switch to the copier back ON ( | ). Warm up will begin. “1” will appear on the operation panel and the Start indicator will light when the copier is in a copy-ready state. -

Page 32

1-3-3 Installing the expanding memory (option) The main board of the copier is equipped with one socket for memory expansion. Expansion memory is available in the form of DIMM (Dual In-line Memory Module). CAUTION Take precautions that no foreign substances such as metal chips or liquid get inside the copier during the installation process. -

Page 33

1-4-1 Maintenance mode The copier is equipped with a maintenance function which can be used to maintain and service the machine. (1) Executing a maintenance item Start Press the stop/clear key, start key and the left copy exposure adjustment key in the order presented and hold them down. -

Page 34

2DC-2 (2) Maintenance mode item list Item Initial Section Maintenance item contents setting* General U000 Outputting an own-status report — U001 Exiting the maintenance mode — U004 Checking the machine number — U005 Copying without paper — U019 Displaying the ROM version —… -

Page 35

2DC-2 Item Initial Section Maintenance item contents setting* Fixing and U161 Setting the fixing control temperature cleaning • Primary stabilization fixing temperature • Secondary stabilization fixing temperature • Copying operation temperature 1 • Copying operation temperature 2 • Number of sheets for fixing control U162 Stabilizing fixing forcibly —… -

Page 36

(3) Contents of maintenance mode items Maintenance Description item No. U000 Outputting an own-status report Description Outputs lists of the current settings of the maintenance items, and paper jam and service call occurrences. Purpose To check the current setting of the maintenance items, or paper jam or service call occurrences. Before initializing the backup RAM, output a list of the current settings of the maintenance items to reenter the settings after initialization or replacement. -

Page 37

2DC-2 Maintenance Description item No. U005 Copying without paper Description Simulates the copy operation without paper feed. Purpose To check the overall operation of the machine. Method 1. Press the start key. A selection item appears. 2. Select the item to be operated using the copy exposure adjustment keys. Display Operation Only the copier operates. -

Page 38

2DC-2 Maintenance Description item No. U020 Initializing all data Description Initializes all the backup RAM on the main board to return to the original settings. U004, however, is not initialized. Purpose Run as needed. Method 1. Press the start key. 2. -

Page 39

2DC-2 Maintenance Description item No. U030 Checking motor operation Description Drives each motor. Purpose To check the operation of each motor. Method 1. Press the start key. A selection item appears. 2. Select the motor to be operated using the copy exposure adjustment keys. When selecting the feed motor, pull out the optional drawer in advance. -

Page 40

Maintenance Description item No. U032 Checking clutch operation Description Turns each clutch on. Purpose To check the operation of each clutch. Method 1. Press the start key. A selection item appears. 2. Select the clutch to be operated using the copy exposure adjustment keys. 3. -

Page 41

2DC-2 Maintenance Description item No. U063 Adjusting the shading position Description Changes the shading position. Purpose Used when white lines continue to appear longitudinally on the image after the shading plate is cleaned. This is due to flaws or stains inside the shading plate. To prevent this problem, the shading position should be changed so that shading is possible without being affected by the flaws or stains. -

Page 42

Maintenance Description item No. U073 Checking scanner operation Description Simulates the scanner operation under arbitrary conditions. Purpose To check scanner operation. Method 1. Press the start key. 2. Select the item to be changed by lighting a copy exposure indicator using the copy exposure adjustment keys. -

Page 43

Maintenance Description item No. U087 Turning the DP scanning position adjust mode on/off Description Turns on or off the DP scanning position adjust mode, in which the DP original scanning position is adjusted automatically by determining the presence or absence of dust on the slit glass. Also changes the reference data for identifying dust. -

Page 44

Maintenance Description item No. U088 Setting the input filter (moiré reduction mode) Description Turns moiré reduction mode on and off by switching the input filter on and off. Purpose Used to prevent regular density unevenness (moiré) on halftone image areas of the copy image in text mode and text and photo mode. -

Page 45

Maintenance Description item No. U091 Checking shading Description Performs scanning under the same conditions as before and after shading is performed, displaying the original scanning values at nine points of the contact glass. Purpose To check the change in original scanning values before and after shading. The results may be used to decide the causes for fixing unevenness (uneven density) of the gray area of an image: either due to optical (shading or CCD) or other problems. -

Page 46

2DC-2 Maintenance Description item No. U091 When scanning is performed before shading, the scan value at the machine center should be slightly different from those at the machine front and rear. When scanning is performed after shading, there should be no difference between respective values. Any differences between the values at machine front and rear indicates that scanner problem causes the fixing unevenness. -

Page 47

2DC-2 Maintenance Description item No. U093 Setting the exposure density gradient Description Changes the exposure density gradient in manual density mode, depending on respective image modes (text, text and photo, photo). Purpose To set how the image density is altered by a change of one step in the manual density adjustment. Also used to make copy image darker or lighter. -

Page 48

2DC-2 Maintenance Description item No. U093 Test copy mode While this maintenance item is being performed, copying from an original can be made in test copy mode. Completion Press the stop/clear key while a selection item is displayed. The indication for selecting a maintenance item No. appears. -

Page 49

Maintenance Description item No. U144 Setting toner loading operation Description Sets toner loading operation. Purpose To run when drum filming (background blur in paper edge section) occurs. Change the setting value to 3 when poor-quality paper is used and filming occurs frequently. Method Press the start key. -

Page 50

2DC-2 Maintenance Description item No. U158 Checking/clearing the developing count Description Displays the developing count for checking, clearing or changing a figure. Purpose To check the developing count. Method 1. Press the start key. 2. Select the item by lighting a copy exposure indicator using the copy exposure adjustment keys. Copy exposure indicator Description Setting range Initial setting… -

Page 51

Maintenance Description item No. U162 Stabilizing fixing forcibly Description Stops the stabilization fixing drive forcibly, regardless of fixing temperature. Purpose To forcibly stabilize the machine before the fixing section reaches stabilization temperature. Method 1. Press the start key. “on” appears. 2. -

Page 52

Maintenance Description item No. U203 Operating DP separately Description Simulates the original conveying operation separately in the DP. Purpose To check the DP. Method 1. Press the start key. 2. Place an original in the DP if running this simulation with paper. 3. -

Page 53

2DC-2 Maintenance Description item No. U244 Checking the DP switches Description Displays the status of the switches in the DP. Purpose To check if switches in the DP operate correctly. Method 1. Press the start key. «-S-» appears. 2. Manually turn on and off each switch to check the status. When the on-status of a switch is detected, the image mode LED corresponding to the operated switch lights. -

Page 54

Maintenance Description item No. U254 Turning auto start function on/off Description Selects if the auto start function is turned on. Purpose Normally no change is necessary. If incorrect operation occurs, turn the function off: this may solve the problem. Method Press the start key. -

Page 55

Maintenance Description item No. U258 Switching copy operation at toner empty detection Description Selects if continuous copying is enabled after toner empty is detected. Method Press the start key. The screen for selecting an item is displayed. The current setting is displayed. Setting 1. -

Page 56

Maintenance Description item No. U265 Setting the destination specifications Description Sets whether or not to print the product name on the reports that users print. Purpose To be set according to user request. Method Press the start key. The current setting appears. Setting 1. -

Page 57

2DC-2 Maintenance Description item No. U402 Adjusting margins of image printing Adjustment See page 1-6-43. U403 Adjusting margins for scanning an original on the contact glass Adjustment See page 1-6-49. U404 Adjusting margins for scanning an original from the DP Adjustment See page 1-6-54. -

Page 58

Maintenance Description item No. U903 Checking/clearing the paper jam counts Description Displays or clears the jam counts by jam locations. Purpose To check the paper jam status. Also to clear the jam counts after replacing consumable parts. Method 1. Press the start key. 2. -

Page 59

Maintenance Description item No. U905 Checking/clearing counts by the DP Description Displays or clears the counts of the DP. Purpose To check the use of the DP. Also to clear the counts after replacing consumable parts. Method 1. Press the start key. 2. -

Page 60

2DC-2 Maintenance Description item No. U911 Checking/clearing copy counts by paper size Description Displays or clears the paper feed count value by paper size. Purpose To check the time to replace consumable parts. Also to clear the counts after replacing the consumable parts. Method 1. -

Page 61

Maintenance Description item No. U911 Clearing copy counts by paper size 1. Select the paper size to clear the count. 2. Display “CLE” using the copy exposure adjustment keys. 3. Press the start key. The count is cleared. Clearing copy counts for all paper size 1. -

Page 62

Maintenance Description item No. U991 Checking the scanner count Description Display the scanner count value. Purpose To check the scanner count value. Method 1. Press the start key. 2. Change the indication of the copy quantity display by lighting a copy exposure indicator using the copy exposure adjustment keys. -

Page 63: Copier Management

2DC-2 1-4-2 Copier management In addition to a maintenance function for service, the copier is equipped with a management function which can be operated by users (mainly by the copier administrator). In this copier management mode, default settings can be changed.

-

Page 64

2DC-2 (2) Default settings Text original exposure adjustment User status report Adjusts the exposure to be used when text original is Outputs the details of the default settings. selected for the image mode. 1. Select “F01” and press the Recall%/Enter key. 1. -

Page 65

2DC-2 Optional drawer paper size Layout (borderline) Sets the size of paper loaded in the optional drawer. Selects the type of borderline for layout copying. 1. Select “F13” and press the Recall%/Enter key. 1. Select “F18” and press the Recall%/Enter key. 2. -

Page 66

2DC-2 Off mode time Paper feed shifting adjustment (bypass tray) Sets the amount of time without any operation being Adjusts displacement of the copy image. performed until the off mode automatically engages. 1. Select “F29” and press the Recall%/Enter key. 1. -

Page 67: Paper Misfeed Detection

1-5-1 Paper misfeed detection (1) Paper misfeed indication When a paper misfeed occurs, the copier immediately stops copying and displays the jam location on the operation panel. Paper misfeed counts sorted by the detection condition can be checked in maintenance item U903. To remove paper jammed in the copier, open the face-up output tray, front top cover, front cover or pull the drawer out.

-

Page 68

(2) Paper misfeed detection conditions Registration Exit sensor sensor Figure 1-5-2 1-5-2… -

Page 69

2DC-2 Section Jam code Description Conditions System No paper feed When the power switch is turned on, the machine detects activation of the registration sensor or the exit sensor. Cover open JAM A cover open state is detected during copying. Secondary paper feed When the machine waits for secondary paper feed, 30 s or timeout… -

Page 70

2DC-2 (3) Paper misfeeds • Copier Problem Causes/check procedures Corrective measures A piece of paper torn from Check visually and remove it, if any. A paper jam in the copy paper is caught conveying, fixing or around registration sensor exit section is indi- or exit sensor. -

Page 71

Problem Causes/check procedures Corrective measures Check if the MP feed roller Check visually and replace any deformed roller. A paper jam in the is deformed. paper feed section Defective registration sen- Run maintenance item U031 and turn registration sensor on and is indicated during sor. -

Page 72

Problem Causes/check procedures Corrective measures Defective registration sen- Run maintenance item U031 and turn registration sensor on and A paper jam in the sor. off manually. Replace registration sensor if indication of the cor- exit section is indi- responding sensor is not light. cated during copy- Defective exit sensor. -

Page 73

2DC-2 • DP Problem Causes/check procedures Corrective measures A piece of paper torn from Remove any found. An original jams an original is caught when the power around the DP timing switch is turned on. switch. Defective DP timing Run maintenance item U244 and turn DP timing switch on and switch. -

Page 74

2DC-2 1-5-2 Self-diagnosis (1) Self-diagnostic function This unit is equipped with a self-diagnostic function. When a problem is detected, copying is disabled. «C» and a number between 0100 and 7990 altenates, indicating the nature of the problem. After removing the problem, the self-diagnostic function can be reset by turning interlock switch off and back on. (2) Self diagnostic codes Remarks Code… -

Page 75

Remarks Code Contents Causes Check procedures/corrective measures C0610 Bitmap (DIMM) problem Defective main Replace the main board (KP-5060) and (A0610*) • There is a problem with the data or board (KP-5060). check for correct operation. address bus of the bitmap DRAM. DIMM installed Check if the DIMM is inserted into the incorrectly. -

Page 76

Remarks Code Contents Causes Check procedures/corrective measures C3200 Exposure lamp problem Defective scanner Replace the scanner board (KP-5063) and (A3200*) • In indicator check before starting board (KP-5063). check for correct operation. copying, the average value in scan- Defective expo- Replace the exposure lamp or inverter ning of the shading plate with the sure lamp or in-… -

Page 77

Remarks Code Contents Causes Check procedures/corrective measures C6000 Broken fixing heater wire Poor contact in Check the connection of connector CN4 on • In fixing warm-up, the time to reach the thermistor the power supply board (KP-5059) and the 50°C/122 °F exceeds 13.5 s, the time connector termi- continuity across the connector terminals. -

Page 78

2DC-2 Remarks Code Contents Causes Check procedures/corrective measures C7800 Broken external temperature ther- Poor contact in Reinsert the connector. Also check for con- (A7800*) mistor the operation tinuity within the connector cable. If none, • The input voltage is 0.5 V or less. board connector remedy or replace the cable. -

Page 79: Image Formation Problems

1-5-3 Image formation problems (1) No image appears (2) No image appears (3) Image is too light. (4) Background is visible. (entirely white). (entirely black). See page 1-5-14 See page 1-5-14 See page 1-5-15 See page 1-5-15 (8) One side of the copy (5) A white line appears (7) A black line appears (6) A black line appears…

-

Page 80

(1) No image appears Causes (entirely white). 1. No transfer charging. Causes Check procedures/corrective measures 1. No transfer charging. A. The connector terminals of the high voltage Reinsert the connector. Also check for continuity within the board make poor contact. connector cable. -

Page 81

(3) Image is too Causes light. 1. Insufficient toner. 2. Deteriorated developer. 3. Dirty or deteriorated drum. Causes Check procedures/corrective measures 1. Insufficient toner. If the add toner indicator lights, replace the toner container. 2. Deteriorated developer. Replace the process unit. 3. -

Page 82

(6) A black line appears Causes longitudinally. 1. Dirty contact glass. 2. Dirty or flawed drum. 3. Deformed or worn cleaning blade. 4. Dirty scanner mirror. Causes Check procedures/corrective measures 1. Dirty contact glass. Clean the contact glass. 2. Dirty or flawed drum. Replace the process unit. -

Page 83

(9) Black dots appear Causes on the image. 1. Dirty or flawed drum. 2. Dirty contact glass. 3. Deformed or worn cleaning blade. Causes Check procedures/corrective measures 1. Dirty or flawed drum. Replace the process unit. 2. Dirty contact glass. Clean the contact glass. -

Page 84

(12) Paper creases. Causes 1. Paper curled. 2. Paper damp. Causes Check procedures/corrective measures 1. Paper curled. Check the paper storage conditions. 2. Paper damp. Check the paper storage conditions. (13) Offset occurs. Causes 1. Defective cleaning blade. Causes Check procedures/corrective measures 1. -

Page 85

(15) Fixing is poor. Causes 1. Wrong paper. 2. Flawed press roller. Causes Check procedures/corrective measures 1. Wrong paper. Check if the paper meets specifications. 2. Flawed press roller. Replace the press roller (see page 1-6-26). (16) Image center does not Causes align with the original 1. -

Page 86

2DC-2 1-5-4 Electrical problems Problem Causes Check procedures/corrective measures No electricity at the power Measure the input voltage. The machine does outlet. not operate when The power cord is not Check the contact between the power plug and the outlet. the power switch is plugged in properly. -

Page 87: The Eraser Lamp Does Not Turn On

Problem Causes Check procedures/corrective measures Broken MP feed clutch Check for continuity across the coil. If none, replace the MP feed The MP feed clutch coil. clutch. does not operate. Poor contact in the MP Reinsert the connector. Also check for continuity within the con- feed clutch connector ter- nector cable.

-

Page 88: Main Charging Is Not Performed

2DC-2 Problem Causes Check procedures/corrective measures (13) Broken main charger wire. See page 1-5-14. Main charging is not Leaking main charger performed. housing. Poor contact in the high voltage board connector terminals. Defective engine board (KP-5061). Defective high voltage board. (14) Poor contact in the high See page 1-5-14.

-

Page 89: Mechanical Problems

1-5-5 Mechanical problems Problem Causes/check procedures Corrective measures Check if the surfaces of the feed roller and Clean with isopropyl alcohol. No primary paper feed. MP feed roller are dirty with paper powder. Check if the feed roller and MP feed roller Check visually and replace any deformed are deformed.

-

Page 90: Precautions For Assembly And Disassembly

2DC-2 1-6-1 Precautions for assembly and disassembly (1) Precautions • Be sure to turn the power switch off and disconnect the power plug before starting disassembly. • When handling PCBs, do not touch connectors with bare hands or damage the board. •…

-

Page 91: Removing The Process Unit

2DC-2 1-6-2 Removing the process unit 1. Open the front top cover. 2. Open the front cover. 3. Lift the process unit together with the toner container out of the copier. Front top cover Front cover Process unit Figure 1-6-1 Removing the process unit CAUTIONS •…

-

Page 92: Removing The Principal Outer Covers

1-6-3 Removing the principal outer covers (1) Removing the front top cover/face-down output tray 1. Remove the one screw and then remove the memory cover. 2. Remove the one screw and then remove the rear cover. Screw Rear cover Memory cover Screw Figure 1-6-2 Removing the memory cover and rear cover 3.

-

Page 93: Removing The Right Cover

(2) Removing the right cover 1. Remove the front top cover/face-down output tray (See page1-6-3). 2. Remove the memory cover (See page 1-6-3). 3. Unlatch the snaps and hook, remove the right cover. Right cover :Snap/Hook (inside cover) Right cover Figure 1-6-4 Removing the right cover (3) Removing the left cover 1.

-

Page 94: Removing The Feed Roller

1-6-4 Removing the feed roller CAUTION When refit the feed roller, fit the D-cut shaft into the D-shape hole of the feed roller. 1. Remove the paper cassette and the process unit (See page 1-6-2). 2. Stand the machine the front side up. 3.

-

Page 95: Removing The Mp Feed Roller

1-6-5 Removing the MP feed roller 1. Remove the engine board (See page 1-6-9). 2. Remove one screw. 3. Remove the grounding plate. 4. Remove one stop ring . 5. Remove the MP feed clutch. MP feed clutch Stop ring Grounding plate Screw…

-

Page 96

6. Remove one screw. 7. Remove the toner sensor and spring. 8. Remove two screws. 9. While pressing the latch by using the driver and then remove the MP feed unit. Toner sensor Screw Screw Spring Screw Latch MP feed unit Figure 1-6-8 Removing the MP feed unit 10. -

Page 97: Removing The Transfer Roller

1-6-6 Removing the transfer roller CAUTION Do not touch the transfer roller (sponge) surface. Oil and dust (particles of paper, etc.) on the transfer roller can significantly deteriorate the print quality (white spots, etc.). When refitting the bushes and springs, make sure to refit the black colored bush and spring on the left side. Also, observe the correct direction to which the bush is fit in reference to the paper passing direction.

-

Page 98: Removing The Principal Circuit Boards

2DC-2 1-6-7 Removing the principal circuit boards (1) Removing the engine board 1. Remove the right cover (See page 1-6-4). 2. Remove all (twelve) connectors from the engine board. 3. Remove three screws. 4. Remove the engine board. * When replacing the board with a new board, remove the EEPROM from the old board and mount it to the new board.

-

Page 99: Removing The Main Board

(2) Removing the main board 1. Remove the right cover (See page 1-6-4). 2. Remove the three connectors. 3. Remove the one flexible flat cable. 4. Remove the seven screws and then remove the main controller shield (with main board). Main controller shield (with main board) Flexible flat cable…

-

Page 100

2DC-1 5. Remove two screws at the back of the main board. * When replacing the board with a new board, remove the EEPROM from the old board and mount it to the new board. Main board Screws EEPROM Figure 1-6-13 Removing the main board 1-6-11… -

Page 101: Removing The Power Supply Board And High Voltage Board

(3) Removing the power supply board and high voltage board 1. Remove the process unit (See page 1-6-2). 2. Remove the left cover (See page 1-6-4). 3. Remove three connectors from the power supply board. 4. Remove eight screws. 5. Remove the power supply board and high voltage board. (Note: The high voltage board is directly connected to the bias board.) 6.

-

Page 102: Removing The Bias Board

(4) Removing the bias board 1. Remove the cassette and process unit (See page 1-6-2). 2. Remove the left cover (See page 1-6-4). 3. Remove the power supply board and high voltage board (See the previous page). 4. Stand the machine with the front side up. 5.

-

Page 103: Removing The Main Motor And Drive Unit

2DC-2 1-6-8 Removing the main motor and drive unit 1. Remove the cassette and process unit (See page 1-6-2). 2. Remove the right cover (See page 1-6-4). 3. Remove three connectors from the main motor. 4. Remove four screws. 5. Remove main motor. Connectors Main motor Screws…

-

Page 104

6. Remove the engine board (See page 1-6-9). 7. Remove wires from wire saddles on the cord cover. 8. Remove one screw. 9. Remove the cord cover. Wire saddle Screw Wire saddles Cord cover Figure 1-6-17 Removing the cord cover 1-6-15… -

Page 105

10. Remove the main board (See page 1-6-10). 11. Remove one screw and then remove the grounding plate. 12. Remove one screw and then remove the feed clutch. 13. Remove three stop rings. 14. Remove MP feed clutch (gear), feed clutch (gear), and registration clutch (gear). MP feed clutch (gear) Grounding Stop ring… -

Page 106

15. Remove the four screws. 16. Remove the drive unit. Drive unit Screws Figure 1-6-19 Removing the drive unit 1-6-17… -

Page 107: Removing And Splitting The Fuser Unit

1-6-9 Removing and splitting the fuser unit WARNING • The fuser unit is hot after the copier was running. Wait until it cools down. CAUTION • When refitting the fuser unit, make sure the fuser unit gear and the copier’s drive gear are properly meshed with each other.

-

Page 108

6. Remove two screws. 7. Open and split the fuser unit. Screw Fuser unit Screw Figure 1-6-21 Splitting the fuser unit 1-6-19… -

Page 109: Removing The Separation Craws

(1) Removing the separation claws WARNING The separation claws are extremely hot immediately after the copier was running. Allow substantial period of time until it cools down. 1. Remove and split the fuser unit (See page 1-6-18). 2. Loosen the stopper screws. 3.

-

Page 110: Removing The Heater Lamp

(2) Removing the heater lamp WARNING • The heater lamp is extremely hot immediately after the copier was running. • Allow substantial period of time until it cools down. Also, the heater lamp is fragile: Handle it with great care. CAUTION •…

-

Page 111: Removing The Heat Roller

(3) Removing the heat roller WARNING • The heat roller is extremely hot immediately after the copier was running. Allow substantial period of time until it cools down. 1. Remove and split the fuser unit (See page 1-6-18). 2. Remove the heater lamp (See previous page). 3.

-

Page 112

4. Remove the heat gear Z33, heat R bush, and heat L bush from the heat roller. Heat gear Z33 Heat R bush Heat L bush Heat roller Figure 1-6-25 Removing the heat roller 1-6-23… -

Page 113: Removing The Thermistor

(4) Removing the thermistor 1. Remove and split the fuser unit (See page 1-6-18). 2. Remove the heater lamp (See page 1-6-21). 3. Remove the heat roller (See page 1-6-22). 4. Remove one screw. 5. Remove the thermistor. Screw Thermistor Figure 1-6-26 Removing the thermistor 1-6-24…

-

Page 114: Removing The Thermal Cutout

(5) Removing the thermal cutout CAUTION • Do not bend the terminals of the thermal cutout. 1. Remove and split the fuser unit (See page 1-6-18). 2. Remove the heater lamp (See page 1-6-21). 3. Remove the heat roller (See page 1-6-22). 4.

-

Page 115: Removing The Press Roller

(6) Removing the press roller WARNING • The press roller is extremely hot immediately after the copier was running. Allow substantial period of time until it cools down. 1. Remove and split the fuser unit (See page 1-6-18). 2. Remove the press roller from the fuser unit. Press roller Fuser unit Figure 1-6-28 Removing the press roller…

-

Page 116: Removing The Scanner Unit

1-6-10 Removing the scanner unit 1. Remove the right and left cover (See page 1- 6-4). 2. Remove the five connectors and two flexible flat cables from the scanner board. 3. Remove the five screws and then remove the scanner board. Screw Scanner board Screws…

-

Page 117

4. Remove the two screws. 5. Slide the scanner unit and then remove the scanner unit. Scanner unit Screws Figure 1-6-30 Removing the scanner unit 1-6-28… -

Page 118

1. Remove the scanner unit (See page 1-6-27). 2. Remove each two screws and then remove two grounding plates. 3. Remove each two screws and then remove the right and left scanner stays. Screws Screws Left scanner stay Grounding plates Right scanner stay Screws Figure 1-6-31 Removing the right and left stays… -

Page 119

6. Remove three screws. 7. Remove two connectors from the laser scanner unit. 8. Remove the laser scanner unit. * When refitting the laser scanner unit, tighten a screw in order of 3 from 1. Screws Laser scanner unit Conncetor Conncetor Figure 1-6-33 Removing the laser scanner unit 1-6-30… -

Page 120

9. Remove the eraser lamp. Eraser lamp 5-2-34 Removing the eraser lamp 1-6-31… -

Page 121: Removing The Isu Unit

1-6-12 Removing the ISU unit 1. Unhook the two hooks by using screw driver through the holes and then remove the operation unit. Hole Operation unit Hook Hook Hole Figure 1-6-35 Removing the operation unit 2. Remove two screws and then remove the original holder cover.

-

Page 122

3. Remove two screws and then remove two grounding plates. 4. Remove the one stopper ring and then detach the scanner shaft. * Detach the shaft taking care to tilt it as little as possible. Stopper ring Screw Grounding plates Scanner shaft Screw Figure 1-6-37 Detaching the scanner shaft… -

Page 123: Removing The Exposure Lamp

1-6-13 Removing the exposure lamp 1. Remove the ISU unit (See page 1-6-32). 2. Remove the two connectors from the inverter board. 3. Remove the one screw and then remove the inverter board. ISU unit Inverter board Screw Connectors Figure 1-6-39 Removing the inverter board 4.

-

Page 124

5. Remove the exposure lamp and cables from the exposure lamp mount. • Do not touch the glass surfaces of the exposure lamp with bare hands. Exposure lamp Exposure lamp mount Cables Figure 1-6-41 Removing the exposure lamp 1-6-35… -

Page 125: Removing The Scanner Mirror A

1-6-14 Removing the scanner mirror A 1. Remove the ISU unit (See page 1-6-32). 2. Remove the exposure lamp (See page 1-6- 34). 3. Unhook the two mirror A holders and then Mirror A holder remove the scanner mirror A. Scanner mirror A Hook Mirror A holder…

-

Page 126: Removing The Scanner Motor

1-6-15 Removing the scanner motor 1. Remove the original holder cover (See page 1-6-32). 2. Remove the left cover (See page 1-6-4). 3. Remove the one connector from the scanner board. Scanner board Connector Figure 1-6-43 Removing the scanner motor (1) Screw 4.

-

Page 127

7. Remove three screws and then remove the grounding plate. Screws Grounding plate Screw Figure 1-6-46 Removing the scanner motor (4) 8. Remove the one stopper ring and then detach the scanner shaft. Stopper ring * Detach the shaft taking care to tilt it as little as possible. -

Page 128

9. Remove the cable from the cable clamps. 10. Remove the four screws and then remove the scanner motor mount with scanner motor. Screws Screw Scanner motor mount Cable Cable clamps Figure 1-6-48 Removing the scanner motor (6) 11. Remove the one screw and then remove the scanner motor. -

Page 129: Removing The Main Charger Unit

1-6-16 Removing the main charger unit 1. Remove the process unit from the copier (See page 1-6-2). 2. Unlatch the three snaps, and remove the main charger cap. 3. Draw the main charger unit in the direction of arrow A, then pull it out in the direction of arrow B. Main charger unit Snap…

-

Page 130: Adjustment The Maintenance Mode

2DC-2 1-6-17 Adjustment the maintenance mode (1) Adjusting the leading edge registration of image printing Make the following adjustment if there is a regular error between the leading edges of the copy image and original. U066 U071 U034 (P. 1-6-47) (P.

-

Page 131: Adjusting The Center Line Of Image Printing

(2) Adjusting the center line of image printing Make the following adjustment if there is a regular error between the center lines of the copy image and original when paper is fed from the drawer. U067 U072 U034 (P. 1-6-48) (P.

-

Page 132: Adjusting The Margins For Printing

(3) Adjusting the margins for printing Make the following adjustment if the margins are not correct. U403 U404 U402 (P. 1-6-49) (P. 1-6-54) Caution: Check the copy image after the adjustment. If the margins are still incorrect, perform the above adjustments in maintenance mode.

-

Page 133: Adjusting The Amount Of Slack In The Paper

2DC-2 (4) Adjusting the amount of slack in the paper Make the following adjustment if the leading edge of the copy image is missing or varies randomly, or if the copy paper is Z-folded. Procedure Start Enter maintenance mode. Enter “051” using the copy exposure Correct image Output Output…

-

Page 134: Adjusting Magnification Of The Scanner In The Main Scanning Direction

(5) Adjusting magnification of the scanner in the main scanning direction Perform the following adjustment if the magnification in the main scanning direction is not correct. U065 U065 U067 (auxiliary scanning (main scanning (P. 1-6-48) direction) (P. 1-6-46) direction) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

-

Page 135: Adjusting Magnification Of The Scanner In The Auxiliary Scanning Direction

(6) Adjusting magnification of the scanner in the auxiliary scanning direction Perform the following adjustment if the magnification in the auxiliary scanning direction is not correct. U065 U065 U070 (main scanning (auxiliary scanning (P. 1-6-50) direction) (P. 1-6-45) direction) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode.

-

Page 136: Adjusting The Scanner Leading Edge Registration

(7) Adjusting the scanner leading edge registration Perform the following adjustment if there is regular error between the leading edges of the copy image and original. U034 U071 U066 (P. 1-6-41) (P. 1-6-51) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure Start Enter maintenance mode.

-

Page 137: Adjusting The Scanner Center Line

(8) Adjusting the scanner center line Perform the following adjustment if there is a regular error between the center lines of the copy image and original. U034 U072 U067 (P. 1-6-42) (P. 1-6-53) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure Scanner center line Start…

-

Page 138: Adjusting The Margins For Scanning An Original On The Contact Glass

(9) Adjusting the margins for scanning an original on the contact glass Perform the following adjustment if the margins are not correct. U402 U404 U403 (P. 1-6-43) (P. 1-6-54) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure (3 ±…

-

Page 139: Adjusting The Dp Magnification

2DC-2 (10) Adjusting the DP magnification Adjust magnification in the auxiliary scanning direction if magnification is incorrect when the DP is used. U065 U070 (P. 1-6-46) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure Main scanning direction…

-

Page 140: Adjusting The Dp Leading Edge Registration

2DC-2 (11) Adjusting the DP leading edge registration Perform the following adjustment if there is a regular error between the leading edge of the original and the copy image. U034 U066 U071 (P. 1-6-41) (P. 1-6-47) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure Start Enter maintenance mode.

-

Page 141: Adjusting The Dp Trailing Edge Registration

(12) Adjusting the DP trailing edge registration Perform the following adjustment if the original scanning end position is not correct when the DP is used. Caution: If the copy image looks like copy example 2, clean the DP original scanning section. Procedure Start Enter maintenance mode.

-

Page 142: Adjusting The Dp Center Line

2DC-2 (13) Adjusting the DP center line Perform the following adjustment if there is a regular error between the centers of the original and the copy image. U034 U067 U072 (P. 1-6-42) (P. 1-6-48) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure Reference Start…

-

Page 143: Adjusting The Margins For Scanning The Original From The Dp

(14) Adjusting the margins for scanning the original from the DP Perform the following adjustment if margins are not correct. U402 U403 U404 (P. 1-6-43) (P. 1-6-49) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure (3 ±…

-

Page 144

(14) Adjusting the margins for scanning the original from the DP Perform the following adjustment if margins are not correct. U402 U403 U404 (P. 1-6-43) (P. 1-6-49) Caution: Before making the following adjustment, ensure that the above adjustments have been made in maintenance mode. Procedure (3 ±… -

Page 145: Upgrading The Firmware On The Main Pcb

2DC-3 1-7-1 Upgrading the firmware on the main PCB Firmware upgrading requires the following tools: Flash DIMM (P/N 2DC01090) Procedure 1. Run maintenance mode U019 to check the version of the ROM. 2. Turn the power switch off and disconnect the power plug.

-

Page 146: Paper Feeding System

2-1-1 Paper feeding system The paper feeding system picks up paper from the cassette, MP tray, or if installed, the paper feeder, feeds it in the copier, and delivers in the output tray. Paper is fed at the precise timing in synchronization with data processing. The paper feeding system finally delivers the printed page to either the face-down or face-up tray as manipulated by the user.

-

Page 147: Paper Feed Control

(1) Paper feed control The following diagram shows interconnectivity of the feeding system components including the sensors and rollers. The engine board provides the signals in conjunction with the electrophotography process that is driven by the main board. Power train Toner container Process unit Registration…

-

Page 148: Paper Feeding Mechanism

(2) Paper feeding mechanism Driving power train A For process unit; drum (From main unit) B For process unit; toner container, developing roller etc. (From main unit) C From process unit; drum (To transfer roller) & fl fi 1 Main motor (gear) ›…

-

Page 149: Original Scanning System

2-1-2 Original scanning system The scanner unit consists of the image scanning unit (ISU) for main-direction scanning, and drive part for traveling the ISU unit to sub-direction. ^ & ⁄ ¤ › ) ‹ Figure 2-1-4 Scanner unit 1 Original holder # Scanner gear 39/22 2 Scanner upper frame $ Scanner shaft…

-

Page 150

Original Scanner unit ISU unit Scanner board Exposure Main board lamp image YC1-2 YC1-4 sensor YC1-3 YC1-5 CCDCLKN YC1-4 YC1-14 Inverter CCDCLK YC1-5 YC1-12 CCD board board YC1-8 YC1-10 YC1-10 YC1-8 LAMP YC2-2 YC1-12 YC1-6 CCDG(O) YC1-16 YC1-18 CCDB(E) YC1-18 YC1-20 CCDR YC1-22… -

Page 151: Isu Unit

(1) ISU unit The ISU unit consists of an exposure lamp, three mirrors, an ISU lens, a CCD board, and so on. Also an inverter board for driving the exposure lamp and a scanner home position sensor for detecting the home position of the ISU unit are incorporated.

-

Page 152: Electrophotographic System

2-1-3 Electrophotographic system Electrophotography is the technology used in laser printing which transfer data representing texts or graphics objects into a visible image which is developed on the photosensitive drum, finally fusing on paper, using light beam generated by a laser diode. This section provides technical details on the copier’s electrophotography system.

-

Page 153: Process Unit Mechanism

(1-1) Process unit mechanism Driving power train A For drum (From main unit) B For toner container, developing roller, etc. (From main unit) C For main unit (Transfer roller) D For toner container ¤ & ⁄ ‹ Figure 2-1-8 Process unit mechanism 1 Main charger unit # DLP screw B 2 Charger wire…

-

Page 154: Main Charging

(2) Main charging (2-1) Photo conductive drum The durable layer of organic photoconductor (OPC) is coated over the aluminum cylinder base. The OPC tend to reduce its own electrical conductance when exposed to light. After a cyclic process of charging, exposure, and development, the electrostatic image is constituted over the OPC layer.

-

Page 155: Charging The Drum

(2-2) Charging the drum The following shows a simplified diagram of the electrophotographic components in relation to the engine system. Charging the drum is done by the main charger unit A. High voltage board Engine board Bias board MHVDR CN2-A4 YC8-5 YC-M Main charging output…

-

Page 156: Exposure

(3) Exposure The charged surface of the drum A is then scanned by the laser beam from the laser scanner unit B. Figure 2-1-11 Exposure The laser beam (780 nm wavelength) beam is dispersed as the polygon motor (polygon mirrors) revolves to reflect the laser beam over the drum.

-

Page 157: Laser Scanner Unit

(3-1) Laser scanner unit Diversion mirror Figure 2-1-12 Laser scanner unit 1 Laser diode ……….. Emits diffused, visible laser. 2 Cylindrical lens ……….Compensates the vertical angle at which the laser beam hits a polygon mirror segment. 3 Polygon mirror (motor) ……..Has six mirror segments around its hexagonal circumference; each mirror corresponding to one scanned line width on the drum when laser beam scans on it.

-

Page 158: Drum Surface Potential

(3-2) Drum surface potential The laser beam is continually switched on and off depending on the print data. It is on for a black (exposed) dot and off for a white (blank) dot. Since the drum surface is evenly charged, whenever it is illuminated by the laser beam, the electrical resistance of the photoconductor is reduced and the potential on the photoconductor is also lowered.

-

Page 159: Development

(4) Development The latent image constituted on the drum is developed into a visible image. The developing roller A contains a 3-pole (S-N-S) magnet core B and an aluminum cylinder rotating around the magnet core B. Toner attracts to the developing roller A since it is powdery ink made of black resin bound to iron particles.

-

Page 160: Transfer

(5) Transfer The image developed by toner on the drum A is transferred onto the paper because of the electrical attraction between the toner itself and the transfer roller B. The transfer roller is negatively biased so that the positively charged toner is attracted onto the paper while it is pinched by the drum and the transfer roller.

-

Page 161: Fusing

(6) Fusing The toner on the paper is molten and pressed into the paper as it passes between the heat roller A and the press roller B in the fuser unit. Figure 2-1-16 Fusing The heat roller has a halogen lamp inside which continuously turns on and off by the thermistor to maintain the constant temperature onto the heat roller surface.

-

Page 162: Fuser Unit Mechanism